LPG inspection

1-9 Fuel service line

Reasons for rejection

Mandatory equipment

1. A fuel service line enters an enclosed driver, passenger or luggage compartment (Note 1).

2. A fuel service line in a drive shaft tunnel is within 40mm of the drive shaft under some operating conditions.

3. The underside of a fuel service line in a drive shaft tunnel is more than 15mm from the intersection of the drive shaft tunnel and the floor pan.

4. Required fuel line protection is missing.

5. A required clip or grommet is missing.

6. A pipe, hose, component or fitting subject to container pressure that is not fully protected by a radiation shield at least 15mm away is within 150mm of a hot object at a temperature above the normal water jacket temperature.

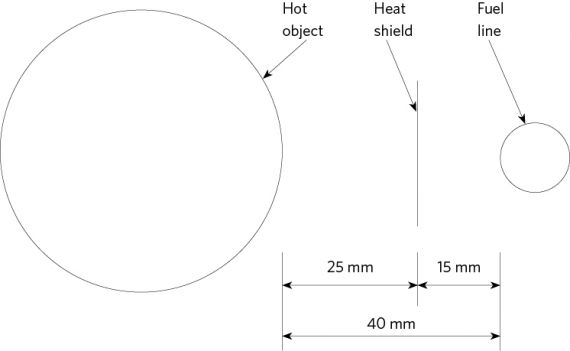

7. A pipe, hose, component or fitting subject to container pressure that is fully protected by a radiation shield at least 15mm away is within 40mm of a hot object at a temperature above the normal water jacket temperature (Figure 1-9-1).

Note 1

Fuel service line means piping, other than the fill line, used for the conveyance of LPG liquid at a pressure exceeding 450kPa.

Note 2

Corrosion damage is where the metal has been eaten away, which is evident by pitting. The outward signs of such corrosion damage are typically displayed by the lifting or bubbling of paint. In extreme cases, the area affected by the corrosion damage will fall out and leave a hole.

Figure 1-9-1. Minimum fuel line distance to hot object with heat shield

Summary of legislation

Applicable legislation

- Land Transport Rule: Vehicle Standards Compliance 2002

- Land Transport Rule: Vehicle Equipment 2004

- AS/NZS1425: 2003, section 4.

Mandatory equipment

1. A fuel service line must not enter an enclosed driver, passenger or luggage compartment.

2. A fuel service line in a drive shaft tunnel must not be closer than 40mm from the drive shaft under all operating conditions.

3. The underside of a fuel service line must be within 15mm of the intersection of the drive shaft tunnel and the floor pan.

4. A fuel service line below the body shell must be protected from impact or abrasion.

5. A fuel service line in a wheel arch must be

a) protected from thrown-up objects, and

b) positioned so the tyre cannot rub on the fuel line.

6. Rigid piping subject to corrosion must be protected throughout its exposed length.

7. Rigid piping must be secured to the chassis frame or body with cushioned clips not more than 600mm apart.

8. Hoses must be secured to the chassis frame or body with clips not more than 600mm apart.

9. A pipe or hose must be protected with a grommet where it passes through a body panel.

10. A pipe, hose, component or fitting subject to container pressure, and not fully protected by a radiation shield at least 15mm away, must not be within 150mm of a hot object at a temperature above the normal water jacket temperature.

11. A pipe, hose, component or fitting subject to container pressure, and fully protected by a radiation shield at lest 15mm away, must not be within 40mm of a hot object at a temperature above the normal water jacket temperature (Figure 1-9-1).

Condition

12. An alternative fuel system in working order must be in a safe working condition.