Correct as at 20th April 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > Entry certification > Technical bulletins

4 Technical bulletins

1 Replacement parts

Replaces Infosheet 1.81 Replacement parts

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in determining compliance of a vehicle.

Application

This document applies to any vehicle undergoing entry-level certification that has had parts, components or systems replaced during a repair or modification.

Safety concern

Vehicles entering New Zealand must have been manufactured to comply with required safety standards. Compliance with these standards ensures that a safety critical component will perform as intended. Vehicles and their systems, parts and components must remain within safe tolerance of their state when manufactured. This helps to ensure the safety of vehicles used on New Zealand roads.

Use of correct replacement parts is vital to achieving safe tolerance. A vehicle must continue to comply with safety standards and equipment requirements when it is repaired, or components are added or replaced.

Inspection

Vehicle inspectors must check whether or not the component being replaced has to meet an approved standard. Standards will vary according to the vehicle’s year of manufacture (and any modifications). The replacement part must meet the same standard as the original part, or a later version. Examples include lights, tyres, seatbelts and glazing.

If there is no specific standard for the individual component, but there is a standard for the system the component is a part of, the vehicle inspector must ensure that any replacement parts used enable the system to continue to meet the standard, and return the vehicle to safe tolerance of its state when manufactured. Examples include brake systems, frontal impact protection systems and seatbelt anchorage attachment points.

Braking systems: Brake pads and shoes are critical components in relation to returning the braking system to within safe tolerance of its state when manufactured.

Frontal impact protection systems: It is important that structural panel replacement is carried out using complying parts and in accordance with the manufacturer’s instructions (or, where these are not available, alternative repair industry standards such as I-Car). Replacement panels and welding must duplicate the original structure.

Seatbelt anchorages: Any repairs of the body or components affecting the supporting structure for seatbelt anchorages must restore these items to their original strength.

If there is no specific standard for the component or the system of which the component is a part, components must be fit for purpose. This generally applies to older vehicles, although there are components that are important to the safety of a vehicle but are not covered by a prescribed standard in new vehicles. Examples include steering and suspension components.

Recommendation

The NZ Transport Agency recommends that parts suppliers and repairers must be able to provide proof that replacement parts meet legal requirements. This could consist of de-registration papers of the donor vehicle for used body parts, standards markings, or proof that the vehicle used for parts was legally registered in New Zealand.

2 Water- or fire-damaged vehicles

Applicable legislation

- Land Transport Rule: Vehicle Standards Compliance 2002, section 11.1

- Land Transport Rule: Vehicle Repair 1998

Application

- This document applies to any vehicle undergoing entry-level (including re-entry) certification that may have suffered water or fire damage.

Note 1

Water- or fire-damaged vehicles imported from Japan may not have been de-registered in Japan. This means that vehicles imported from Japan presented with registration documents only are more ‘at risk’ vehicles.

Note 2

Do not rule out the possibility that privately imported vehicles have suffered water or fire damage.

Vehicles flagged at the border

If water or fire damage is detected on a vehicle during a border inspection, the vehicle will be flagged as damaged and the details forwarded to Waka Kotahi at frr@nzta.govt.nz.

A Waka Kotahi Case Officer will then record a water or fire damage message in the vehicle notes on LANDATA. This message reads as follows:

‘Water-damaged vehicle. Must be certified by a specialist repair certifier.’

or

'Fire damaged vehicle. Must be certified by a specialist repair certifier. Not to be certified by an IO without approval from NZTA NO.'

Any vehicle that has a water or fire damage message attached must be referred to a specialist repair certifier before processing for registration, as the vehicle may not be able to be economically repaired.

Note 3

Specialist repair certifier in this case means a light vehicle repair certifier or heavy vehicle specialist certifier as applicable to the vehicle class.

Water or fire damage detected by IOs

If an IO carrying out entry-level certification detects water or fire damage on a vehicle that has not been flagged for damage at the border, the vehicle must be referred to a specialist repair certifier. The IO must notify Waka Kotahi at frr@nzta.govt.nz, so that the vehicle can be added to the list of water and fire damaged vehicles recorded on the website. They must also record the water or fire damage message (as above) in the vehicle notes on LANDATA.

Documentation to be provided with water or fire damaged vehicles

Light vehicles

a) The following documents must be presented with a water-damaged vehicle before it can be processed for registration:

- An original Light vehicle repair record of determination (LT308) covering the repair has been carried out in accordance with the VIRM: Light vehicle repair certification.

b) The following documents must be presented with a fire-damaged vehicle before it can be processed for registration:

- An original Light vehicle repair record of determination (LT308) covering the repair has been carried out in accordance with the VIRM: Light vehicle repair certification.

Heavy vehicles

Documentation to be provided with water or fire damaged vehicles: a) The following documents must be presented with a water-damaged vehicle before it can be processed for registration:

- An LT400.

b) The following documents must be presented with a fire-damaged vehicle before it can be processed for registration:

- An LT400.

Page updated 10 December 2020 (see details).

3 Vehicles modified to change vehicle class

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in determining vehicle class as defined in the VIRM: Entry certification:

Application

This bulletin applies to vehicles undergoing entry certification in New Zealand that have been modified in such a way that the class of vehicle may have changed from when it was manufactured.

Inspection

Step one

The vehicle inspector must determine the original class of the vehicle, as it was manufactured.

Step two

The vehicle inspector must determine whether or not the vehicle complied with legal requirements for entering service in New Zealand, in its original condition (as manufactured).

If the vehicle did not comply with New Zealand legal requirements when it was manufactured, it cannot be certified for entry into New Zealand as another vehicle class.

- For example, an MA class vehicle that did not comply with a frontal impact standard could not be certified as an NA class vehicle.

Step three

If the vehicle complied with New Zealand legal requirements in its original condition, the vehicle inspector must determine whether or not the modified vehicle complies with legal requirements for vehicles operating in-service in New Zealand.

If a vehicle has modifications that exceed the low volume vehicle (LVV) or heavy vehicle thresholds, it must undergo LVV or HVS certification according to its new class, or be re-configured back to manufacturer’s specifications.

Step four

The vehicle should be recorded in LANDATA as its new class. A note must be added to the vehicle record, stating that vehicle modifications have resulted in a change of class (and identify the previous class).

Page amended 1 June 2019 (see amendment details).

4 Identifying a Honda Gyro

Application

This bulletin gives guidance to vehicle inspectors in identifying a Honda Gyro to determine applicable inspection requirements.

A Honda Gyro is a three-wheeled vehicle which requires design compliance and must be declared as a motorcycle by the NZTA in order to be registered for in-service operation in New Zealand.

Identification

The New Zealand representative of Blue Wing Honda has advised the NZTA that Honda agents identify the Honda Gyro by its frame number.

It can also be recognised by the distinctive articulating joint that allows the whole front passenger portion of the vehicle to pivot and tilt when cornering.

A Honda Gyro:

- has one wheel at the front and two wheels at the rear, and

- has a mass not exceeding one tonne, and

- has an engine output exceeding 2kW (or 50ml), and

- has a maximum speed capability exceeding 50km/h.

Therefore, a Honda Gyro can be classed as an LE1 vehicle under Table A of Land Transport Rule: Vehicle Standards Compliance 2002.

For registration purposes, the Honda Gyro is a vehicle type 11 (motorcycle).

Inspection

If a vehicle presented for entry certification is identified as a Honda Gyro, it must be declared a motorcycle by the NZTA. Applications must be made to:

Vehicle Standards

NZ Transport Agency

Private Bag 6995

Wellington 6141

Attention: Senior Engineer, Vehicles Standards team

An LT4085 Vehicle compliance certificate must be completed for the vehicle. It must meet entry-level certification requirements for class LE1 vehicles and undergo periodic in-service inspections (warrant of fitness or certificate of fitness).

To operate and inspect the vehicle, the vehicle inspector must hold a motorcycle licence.

5 Inspection requirements for temporary vehicle imports

Application

This bulletin gives guidance to vehicle inspectors carrying out entry-level inspections on vehicles imported for temporary use on New Zealand roads.

Requirements for temporarily importing a vehicle

A temporary vehicle import is a vehicle brought into New Zealand by a resident of another country, usually for a maximum of 12 months, while remaining registered in its country of origin.

The vehicle must be exported from New Zealand within the allowed temporary entry period.

Before a vehicle is released to its owner, it must be inspected by the Quarantine Service of the Ministry of Agriculture and Forestry (MAF).

The vehicle must be licensed in New Zealand as an overseas visitor’s vehicle. In addition, the vehicle’s registration in its country of origin must remain current for the duration of its stay in New Zealand, and must remain in the name of the person who imported the vehicle into New Zealand. The overseas registration plates must remain on the vehicle; it does not need New Zealand plates.

When presenting a temporary import, the vehicle importer must:

- fill out an Application for registration of an overseas visitor’s vehicle (form MR2C)

- provide proof that the vehicle is currently registered in his/her name in its country of origin (eg by providing original vehicle registration documents)

- show a carnet de passage or temporary import entry

- provide identification that shows his/her name, date of birth and signature

- pay an Accident Compensation Corporation (ACC) levy (but none of the other registration and licensing fees).

A temporarily imported vehicle does not need to meet New Zealand’s requirements for entry certification. However, an entry certifier must carry out a basic safety inspection before issuing a warrant of fitness (WoF) or certificate of fitness (CoF) label for the vehicle.

Background

In 1958, New Zealand became a contracting state of the Geneva Convention. The Convention on road traffic was signed in September 1949. This convention developed several provisions to promote the safety of international traffic, outlined below.

Generally speaking, the vehicle does not need to comply with New Zealand approved standards, or requirements for specialist certification (eg low volume vehicle certification for modifications). It must at least comply with the provisions of the Geneva Convention. It should meet the basic safety requirements for condition and performance listed in the VIRM: In-service certification.

Applicable legislation

Geneva Convention Chapter IV – Provisions applicable to motor vehicles and trailers in international traffic.

Article 22: Every motor vehicle and trailer must be in good working order and safe mechanical condition so as not to endanger the driver or vehicle occupants or other road users, or cause damage to public or private property. Inspection - Brake requirements for temporarily imported group M and N vehicles.

Mandatory equipment

1. A vehicle must be fitted with a service brake capable of slowing the vehicle and bringing it to a controlled stop under any conditions of loading, on any gradient that the vehicle may be operated on, in an efficient, safe and rapid way.

2. A vehicle must be fitted with a parking brake capable of bringing the vehicle to a controlled stop if the service brake fails.

Condition and performance

3. The brakes fitted to a vehicle must be capable of acting on at least half of the wheels, and brake performance must be balanced on each side of the longitudinal axis of the vehicle.

4. At least half of the braking devices must act on braking surfaces directly attached to the wheels (or through parts not liable to fail).

5. Braking surfaces must be in good condition, and must always be connected with the wheels of the vehicle in such a way that it is not possible to disconnect them, other than momentarily by means of clutch, gearbox or free wheel.

6. The parking brake must be readily applicable and capable of remaining applied for an indefinite period even in the absence of the driver.

Braking requirements for temporarily imported group L vehicles

Mandatory equipment

1. A group L vehicle must be fitted with two braking devices operated by hand or foot, capable of slowing the vehicle and bringing it to a controlled stop in an efficient, safe and rapid way.

Brake requirements for temporarily imported trailers

Mandatory equipment

1. A combination of a motor vehicle and one or more trailers must be fitted with a braking device capable of slowing the vehicle and bringing it to a controlled stop under any conditions of loading, on any gradient that the vehicle may be operated on, in an efficient, safe and rapid way. A trailer must have a braking device that acts on at least half of the wheels, balanced on each side of the longitudinal axis of the vehicle, as follows:

a) The braking device for a class TA or TB trailer may operate as an overrun braking device (ie the trailer is stopped by moving upon the stopped towing vehicle).

b) The braking device for a class TC or TD trailer must be capable of being operated when the service brake of the towing vehicle is applied.

2. The braking device must be capable of preventing the rotation of the wheels when the trailer is uncoupled.

3. A trailer fitted with a braking device must be equipped with a breakaway brake (Note 1).

Note 1

Two-wheeled camping trailers or light luggage trailers do not require a breakaway brake if they are fitted with a secondary attachment, such as a safety chain.

Lighting requirements for temporarily imported group M and N vehicles

Mandatory equipment

1. A vehicle must be fitted with main-beam headlamps bright enough to illuminate the road ahead for 100m in normal darkness (Note 2).

2. A vehicle must be fitted with two white or yellow dipped-beam headlamps bright enough to illuminate the road ahead for 30m in normal darkness without causing significant dazzle to other road users (Note 2).

3. A vehicle must be fitted with two white forward-facing position lamps visible from 150m in normal darkness without causing significant dazzle to other road users. These lamps must be mounted as far towards each side of the vehicle as practicable, no further than 400mm from the extreme outer edges of the vehicle.

4. A vehicle must be fitted with at least one red rearward-facing position lamp, visible from 150m from the rear of the vehicle in normal darkness.

5. A vehicle must be fitted with a rear registration plate illumination lamp that illuminates the figures and letters of the plate so that they are visible from 20m from the rear of the vehicle in normal darkness.

6. A vehicle must be fitted with two red rear reflectors symmetrically mounted as far towards each side of the vehicle as practicable, no further than 400mm from the extreme outer edges of the vehicle. Rear reflectors must be visible from 100m in normal darkness when illuminated by means of two main-beam headlamps.

7. A vehicle must be fitted with a least one red or amber stop light mounted at the rear of the vehicle. A stop light must operate when the service brake is applied. If the stop light is red, the light intensity must be greater than that of the rearward-facing position lamps.

Permitted equipment

8. A vehicle may be fitted with direction indicators as follows:

a) a moveable arm protruding beyond each side of the vehicle and illuminated by a steady amber light when the arm is in the horizontal position, or

b) a constantly blinking or flashing amber light mounted on each side of the vehicle, or

c) a constantly blinking or flashing light at each side of the front and rear of the vehicle. These lights must be white or orange towards the front of the vehicle, and red or orange towards the rear of the vehicle.

Note 2

On vehicles from left-hand drive countries the headlamps dip to the right. To avoid blinding oncoming traffic, the headlamps must be adjusted so they do not dip to the right. Generally, asymmetric beam headlamps will also need to be modified to remove the right-hand flick-up, for example by applying some form of masking, such as plastic overlay, or fitting different bulbs.

Lighting requirements for temporarily imported motorcycles

Mandatory equipment

1. A motorcycle of class LC, LD, LE1 or LE2 must be fitted with at least one main-beam headlamp bright enough to illuminate the road ahead for 100m in normal darkness.

2. A motorcycle of class LC, LD, LE1 or LE2 must be fitted with a least one dipped-beam headlamp bright enough to illuminate the road ahead for 30m in normal darkness without causing significant dazzle to other road users.

3. A motorcycle of class LD must be fitted with two white forward-facing position lamps visible from 150m in normal darkness without causing significant dazzle to other road users. These lamps must be mounted as far towards each side of the vehicle as practicable, no further than 400mm from the extreme outer edges of the vehicle.

4. A motorcycle must be fitted with at least one red rearward-facing position lamp, visible from 150m from the rear of the vehicle in normal darkness.

5. A motorcycle must be fitted with a rear registration plate illumination lamp that illuminates the figures and letters of the plate so that they are visible from 20m to the rear of the vehicle in normal darkness.

6. Rear reflectors must be fitted to the following vehicles:

a) Class LD vehicles must be fitted with two red rear reflectors symmetrically mounted as far towards each side of the vehicle as practicable, no further than 400mm from the extreme outer edges of the vehicle.

b) Class LC, LE1 and LE2 vehicles must be fitted with one red rear reflector symmetrically mounted as far towards each side of the vehicle as practicable, no further than 400mm from the extreme outer edges of the vehicle.

- Rear reflectors must be visible from 100m in normal darkness when illuminated by means of two main-beam headlamps.

Permitted equipment

7. A motorcycle may be fitted with direction indicators as follows:

a) a moveable arm protruding beyond each side of the vehicle and illuminated by a steady amber light when the arm is in the horizontal position, or

b) a constantly blinking or flashing amber light mounted on each side of the vehicle, or

c) a constantly blinking or flashing light at each side of the front and rear of the vehicle. These lights must be white or orange towards the front of the vehicle, and red or orange towards the rear of the vehicle.

Lighting requirements for trailers

Mandatory equipment

1. A trailer at the end of a combination of vehicles must be fitted with at least one red rearward-facing position lamp, visible from 150m from the rear of the vehicle in normal darkness.

2. A trailer must be fitted with a rear registration plate illumination lamp that illuminates the figures and letters of the plate so that they are visible from 20m to the rear of the vehicle in normal darkness.

3. A trailer must be fitted with two red rear reflectors visible from 100m in normal darkness when illuminated by means of two main-beam headlamps.

4. A trailer at the end of a combination of vehicles must be fitted with a least one red or amber stop light mounted at the rear of the vehicle, unless the stop light of the towing vehicle is visible from the rear. A stop light must operate when the service brake is applied. If the stop light is red, the intensity of the light output must be greater than that of the rearward-facing position lamps.

Permitted equipment

5. A trailer may be fitted with direction indicators as follows:

a) a moveable arm protruding beyond each side of the vehicle and illuminated by a steady amber light when the arm is in the horizontal position, or

b) a constantly blinking or flashing amber light mounted on each side of the vehicle, or

c) a constantly blinking or flashing light at each side of the front and rear of the vehicle. These lights must be white or amber towards the front of the vehicle, and red or amber towards the rear of the vehicle.

Other technical requirements for temporarily imported group M and N vehicles

Mandatory equipment

1. A vehicle must be equipped with a strong steering system that allows the vehicle to be turned easily, quickly and with certainty.

2. A vehicle must be equipped with at least one driving mirror of adequate size and location to provide the driver with a clear view to the rear of the vehicle.

3. A vehicle must be fitted with at least one audible warning device (horn) that is not:

a) a bell, or

b) a gong, or

c) a siren, or

d) any other loud-toned device.

4. Windscreens, where fitted, must be made of a stable, transparent material that is not likely to produce sharp splinters if broken. Objects must not appear distorted when viewed through this material.

5. Where a vehicle is fitted with a windscreen, it must have at least one efficient windscreen wiper that operates without constant control of the driver.

6. A vehicle must be fitted with an exhaust silencer system that operates constantly and cannot be interrupted by the driver while on the road.

7. A vehicle must be fitted with pneumatic tyres.

General safety provisions

1. The construction of a vehicle must not obstruct the driver’s vision to the front, right or left of the vehicle.

2. As far as possible, the machinery or equipment of a vehicle must not:

a) be at risk of fire or explosion, or

b) cause the emission of noxious gases or offensive fumes, or

c) produce excessive or disturbing noise, or

d) increase the risk of a collision and/or damage caused in a collision.

Note 3

Temporarily imported vehicles do not have to meet requirements for modification, therefore, low volume vehicle (LVV) or heavy vehicle specialist certification is not required. However, if a vehicle inspector feels that a vehicle is unsafe to operate, he/she may seek advice from a low volume vehicle or heavy vehicle specialist certifier.

6 Auxiliary bars

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

Application

This bulletin applies to class MA, MB or MC vehicles fitted with auxiliary bars (eg bullbars) undergoing entry certification in New Zealand. Auxiliary bars fitted to any class of vehicle may affect compliance with requirements for external projections and/or frontal impact systems.

Safety concern

Fitting auxiliary bars to vehicles with frontal impact protection systems may have a negative effect on the performance of frontal impact protection features, such as airbags or crush-zones.

Inspection

If auxiliary bars are fitted to any vehicle, the risk of injury to others must be minimised. This means that the vehicle must comply with the requirements for condition, performance and modification set out in the VIRM: In-service certification, section 2-1.

A vehicle inspector may refuse to certify a vehicle that is fitted with an auxiliary bar if he/she believes that it is likely to cause injury or affect the driver’s control of the vehicle.

Auxiliary bars fitted to Mitsubishi RVRs

NZ Transport Agency has been advised by Mitsubishi Motors New Zealand that the following Mitsubishi RVR models were factory-fitted with auxiliary bullbars:

|

|

|

|

|

|

If a vehicle inspector is presented with a vehicle from one of these model ranges fitted with an original equipment (OE) bullbar, the vehicle may be passed.

The following Mitsubishi RVR models were not factory-fitted with bullbars:

|

|

|

|

|

If a vehicle inspector is presented with a vehicle from one of these model ranges fitted with a bullbar, confirmation that the bullbar will not affect the vehicle’s frontal impact compliance is required. If it cannot be supplied, the vehicle cannot pass the inspection until the bullbar has been removed.

Page updated 12 October 2018 (see details)

7 Frontal impact standard exemptions

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

- Vehicle structure – 3-1 Structure, Reason for rejection 1

- Vehicle structure – 3-2 Determining frontal impact compliance.

Application

This bulletin applies to specific model ranges of class MA, MB or MC vehicles manufactured by Toyota Japan, Nissan Japan and Mazda/Ford Japan that are exempt from the requirement to meet a specified frontal impact vehicle standard under the New Zealand Gazette notice au3660.

Inspection

Vehicles manufactured by:

- Toyota Japan, in the Estima, Lucida or Emina families, and

- Nissan Japan, in the Serena or Largo families, and

- Mazda/Ford Japan, in the Bongo, Friendee or Freda families

are exempt from the requirement to meet an approved frontal impact standard (as specified in Table 3-2-1 of the VIRM: Entry certification) if the vehicle’s chassis number is included in the ranges identified below.

|

Vehicle make/model |

Industry model code |

Chassis number |

|

|---|---|---|---|

|

Range from |

Range to |

||

|

Toyota Japan

|

CXR10G |

CXR10-0001177 |

CXR10-0146676 |

|

Nissan Japan

|

KBC23 |

KBC23-007242 |

KBC23-517067 |

|

Nissan Japan

|

W30 |

W30-000106 |

W30-774375 |

|

Mazda/Ford Japan

|

SG5W |

SG5W-100012 |

SG5W-302529 |

|

IMPORTANT: Individual exemptions from frontal impact standards requirements do not need to be made for vehicles that fall within these ranges. |

8 Frontal impact compliance for Mitsubishi models

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

- Vehicle structure – 3-1 Structure, Reason for rejection 1

- Vehicle structure – 3-2 Determining frontal impact compliance.

Application

This bulletin applies to the frontal impact compliance requirements of Mitsubishi model vehicles undergoing entry certification in New Zealand.

Inspection

It has been determined that the following Mitsubishi models are class MC vehicles, therefore, if a vehicle inspector is presented with a vehicle in the following model ranges, the vehicle is only required to comply with an approved frontal impact standard if it was manufactured on or after 1 October 2003.

|

Mistubishi RVR Sportsgear vehicles (Note 1) |

||

|---|---|---|

|

E-N23WG SRXF |

E-N23WG SRHM |

Y-N28WG SNXF |

|

E-N23WG SNXF |

E-N23WG SNHM |

Y-N28WG SRXT |

|

E-N23WG SRXM |

E-N23WG SRHF |

Y-N28WG SNXT |

|

E-N23WG SNXM |

Y-N23WG SNHF |

KD-N28WG SRXF |

|

E-N23WG SNUM |

Y-N28WG SRXF |

KD-N28WG SNXF |

|

Mitsubishi Delica Spacegear (four-wheel drive) vehicles |

||

|---|---|---|

|

E-PD4W HSEHE2 |

KD-PE8W HSEXF2 |

KD-PE8W NSNGF1 |

|

E-PD4W HSEHE |

KD-PE8W HSEHF2 |

KD-PE8W NSEGF |

|

E-PD4W NSEGE1 |

KD-PE8W HSNHF2 |

KD-PE8W NSEUF |

|

E-PD4W HSEGE |

KD-PE8W HSEHF |

KD-PE8W NSNUF |

|

E-PD4W NSEGE |

KD-PE8W HSNHF |

KD-PD8W NSNJF |

|

E-PD4W NSEUE |

KD-PE8W HSEGF |

KD-PF8W HSEPF2 |

|

E-PD6W HSEXE2 |

KD-PE8W HSNGF |

KD-PF8W HSEXF2 |

|

E-PD6W HSEHE2 |

KD-PE8W HSEUF |

KD-PF8W HSEHF |

|

E-PD6W NSEHE1 |

KD-PE8W HSNUF |

KD-PF8W HSNHF |

|

E-PF6W HSEXE2 |

KD-PE8W NSEHF1 |

KD-PF8W HSEGF |

|

E-PF6W HSEHE |

KD-PD8W NSEGF1 |

|

Note 1

Not all four-wheel drive Mitsubishi RVR models are class MC vehicles. If a Mitsubishi RVR model is presented that has a full model code not listed above, it is a class MA vehicle; therefore it must comply with an approved frontal impact standard.

9 Frontal impact compliance for Toyota Cavaliers

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

- Vehicle structure – 3-1 Structure, Reason for rejection 1

- Vehicle structure – 3-2 Determining frontal impact compliance.

Application

This bulletin applies to the frontal impact compliance requirements for Toyota Cavalier vehicles undergoing entry certification in New Zealand.

Inspection

Any vehicle that is a Toyota Cavalier of model code TJG00 with a model year of 1996, 1997 or 1998 is exempt from the requirement to prove compliance with one of the approved frontal impact standards specified in section 2.3(4) of Land Transport Rule: Frontal Impact 2001.

The model year of Toyota Cavaliers can be determined by decoding the tenth character of the vehicle identification number (VIN).

The frontal impact compliance status of Toyota Cavalier vehicles, as understood by the NZTA, is described below.

|

Model year |

10th character of VIN |

Frontal impact status |

|---|---|---|

|

1995 or earlier |

NA |

There is no evidence that these vehicles comply with an approved frontal impact standard. Toyota Cavaliers with a model year of 1995 or earlier will not be eligible for an exemption from frontal impact standard requirements. |

|

1996 |

T |

Toyota Cavaliers with a model year of 1996 can be assumed to comply with an approved frontal impact standard |

|

1997 |

V |

Toyota Cavaliers with a model year of 1997 or 1998 are exempt from the requirement to comply with an approved frontal impact standard |

|

1998 |

W |

|

|

1999 or later |

X, Y, 1, 2… |

Toyota Cavaliers with a model year of 1999 or later comply with an approved frontal impact standard. |

10 Inspection for corrosion in Nissan Terrano & Mistral rear floorpan assemblies

| References below are to the VIRM: In-service certification. |

Reference

General vehicles:

Safety concern

There is concern about corrosion that can occur in Nissan Terrano or Nissan Mistral vehicles of the type whose rear floorpan assembly consists of a two-layer (double-skin) panel. If moisture gets trapped between the two layers of the floorpan, corrosion can occur around the seat or seatbelt anchorages, affecting their integrity. Corrosion can also occur where the under-floor reinforcing panel overlaps the top floor skin.

Clarification

The rear floorpan assembly consists of a two-layer (double-skin) panel. The lower layer is a reinforcing panel spot-welded to the upper layer floor section.

The Terrano has a rear seat with three seating positions. Situated in the rear floor, beneath the seat, are four seatbelt anchorages and two seat anchorages.

The Mistral has a stressed bench seat in the rear (the seatbelts are attached to the seat) with two seat anchorages in the floor and two seatbelt anchorages in the wheel well at the sides of the seat.

Inspection

The inspector must lift the rear seat to examine this area effectively. Any carpet and sound insulating material covering the panel that the seats are mounted on must be pulled back far enough to expose the rear seam of the panel (the area most commonly affected by corrosion). It is important to note that damage may be more extensive than can be detected during this inspection.

The vehicle must fail if any signs of corrosion are detected during the inspection, such as:

- bubbling of the paint or surface irregularities in the top floor skin or paint

- a patch repair that has rust around it

- separation of the reinforcement panel and the top skin

- discolouration or rust stains at the edges of the reinforcement panel

- rust holes, or

- the floorpan on a Nissan Terrano has been ‘patch’ repaired after 8 January 1997, or

- the floorpan on a Nissan Mistral has been ‘patch’ repaired after 10 November 2003.

A vehicle that has been ‘patch’ repaired before 8 January 1997 (Nissan Terrano) or 10 November 2003 (Nissan Mistral) may pass the inspection provided that:

- no signs of corrosion are apparent, and

- there is evidence that the repairs were carried out before the above dates, and

- the vehicle inspector considers, or there is evidence provided by a qualified panel beater, that the repair is effective and in sound condition.

Repair options

If any corrosion is detected and the vehicle failed, the floorpan must be replaced.

However, for the following models the Low Volume Vehicle Technical Association (LVVTA) has provided an alternative option to floorpan replacement.

Nissan Terrano Model D21

- installation of the LVVTA rear floor load-bar seatbelt anchorage reinforcement system together with a Low Volume Vehicle certification plate containing the following words in the Body/chassis field: LVVTA ‘Rear floor load-bar seatbelt anchorage reinforcement system’.

Nissan Mistral Model R20 5-door

- installation of the LVVTA rear floor load-bar seatbelt anchorage reinforcement system together with a Low Volume Vehicle certification plate containing the following words in the Body/chassis field: ‘LVVTA Rear floor load-bar seatbelt anchorage reinforcement system’.

For information about these seatbelt anchorage modifications, and for a list of the LVV certifiers who can certify them, see www.lvvta.org.nz.

11 Inspection of motorhomes

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

Application

This bulletin applies to the structural inspection of motorhomes undergoing entry certification in New Zealand. It covers the specialist certification requirements for motorhomes undergoing entry certification.

For motorhomes with overseas compliance covering the motorhome conversion, refer to Technical bulletin 41:Entry certification procedures for certain modified vehicles. Exhaust emission standard compliance can be verified by one of the methods specified in Technical Bulletin 28.

Inspection location

A light new or used motor home can be inspected at an approved heavy (used) entry site, provided that:

- It is inspected by an approved ULE Vehicle Inspector

- There is a VIN embosser on site

- There is an exhaust emission tester on site (Used Vehicle).

Structural inspection

Parallel-imported new (campervan/motorhome)

New parallel-imported (campervan/motorhome) as defined in the entry VIRM (see 2-2 Vehicle attributes definitions).

- Trim does not need to be removed as part of the structural inspection if a vehicle is a new parallel-imported (campervan/motorhome). However, a full general inspection must be carried out. The vehicle inspector may require an invasive structural inspection if any areas of concern are identified during the general inspection.

- Any vehicle identified as damaged during a border inspection will require a full invasive structural inspection.

Used light vehicles (campervan/motorhome) Category 1

A previously registered vehicle under 12 months old and having travelled less than 2000 kms.

- Interior trim does not need to be removed as part of the structural inspection if the vehicle:

- is a previously registered vehicle under 12 months old, and

- has travelled less than 2000 kms, and

- has not been identified as damaged during a border inspection.

However, an under body invasive inspection (front inner guard covers fitted to monocoque construction vehicles and front sub-frame splash guards) and full general inspection must be carried out. The vehicle inspector may require an invasive interior structural inspection if any areas of concern are identified during the general inspection.

If a motorhome is of a cab/chassis body type with the body mounted on the chassis, the vehicle inspector is only required to visually inspect the vehicle (without disassembly) to ensure general safety requirements are met. However, the vehicle inspector may require an invasive interior structural inspection if any areas of concern are identified during the general inspection.

- A Used light vehicles (campervan/motorhome) Category 1 vehicle identified as damaged during a border inspection will require a full invasive structural inspection.

Used (previously registered)

If a motorhome is of a van body type (monocoque construction), it will need the trim removed to enable a full structural inspection. If this is impracticable, the entry certifier/vehicle owner may apply to the Transport Agency for an exemption from trim removal requirements (see Reference material 18).

If a motorhome is of a cab/chassis body type with the body mounted on the chassis, the vehicle inspector is only required to visually inspect the vehicle (without disassembly) to ensure general safety requirements are met. However, if the motorhome body contains designated seating positions with certified seatbelt mountings (as is required for most motorhomes built after October 2003), it will need to have the trim removed to enable a full structural inspection. If this is impracticable, the entry certifier/vehicle owner may apply to the Transport Agency for an exemption from trim removal requirements (see Reference material 18).

Brakes

For new vehicles and scratch-built low volume vehicles, it is not necessary to disassemble any brake components.

For vehicles with rear drum brakes that are less than two years old and that have travelled less than 40,000km, only the front brakes must be disassembled initially. If the front brakes are up to standard, and there are no signs of problems with the rear brakes, disassembly of the rear brakes is not required.

Running gear

Due to the design and size of some campervans/motorhomes, the vehicle's steering and suspension can be inspected on:

- two-post vehicle hoist (with sufficient capacity)

- four-post vehicle hoist with built-in jacking mechanism (with sufficient capacity)

- inspection pit with built-in jacking mechanism (with sufficient capacity).

Specialist certification

Generally, any modifications or repairs to a motorhome that may affect the structural integrity of the vehicle will require specialist certification.

Where vehicles are converted to motorhomes, specialist certification is required unless the vehicle owner can provide documented evidence proving that the modification was a ‘manufacturer’s conversion’.

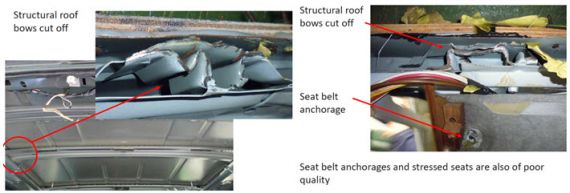

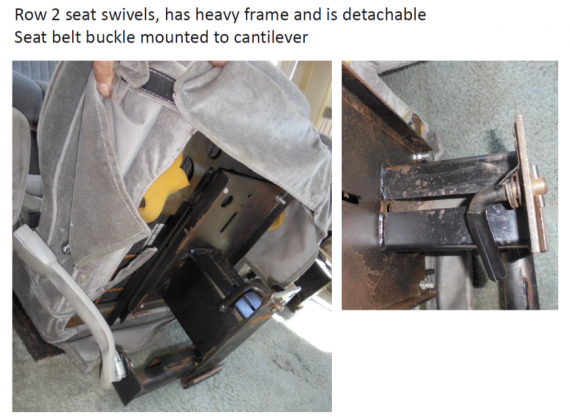

Examples of modifications or repairs to a motorhome that will normally require specialist certification are:

|

|

|

|

Page amended 10 December 2023 (see amendment details)

Page updated 14 August 2023 (see details)

12 Inspection of daytime running lamps

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

Application

This bulletin applies to the lighting equipment (daytime running lamps in particular) fitted to vehicles undergoing entry certification in New Zealand.

Identifying daytime running lamps

When trying to identify daytime running lamps, it may help to check out the beam pattern, the light intensity, the wiring and any markings on the lens.

Beam pattern

For comparison, a fog lamp has a spread beam with a sharp horizontal cutoff and must be fitted in a dipped position.

Light intensity

Under UN/ECE and Australian Design Rules (ADR), a daytime running lamp is generally of low intensity (up to 800 cd max, compared with a headlamp high beam around 80,000–100,000 cd max). There is no hotspot but a blur of light that passes as a beam. The lamps are not required to be dipped, but must turn off when the headlamps are switched on.

Under FMVSS, existing forward-facing lamps (except side lamps and fog lamps) may operate as daytime running lamps. This means that daytime running lamps automatically turn on when the vehicle is started, but turn off when the headlamps are activated. Daytime running lamps fitted as separate lamps must have a light intensity between 500 and 3000 cd.

Wiring

Fog lamps are usually wired so they can operate independently of the headlamps, while daytime running lamps are usually wired so they turn off when the headlamps are switched on.

Markings

Some daytime running lamps may be marked in accordance with a standard (eg an ‘RL’ mark on UN/ECE- and some ADR-compliant lamps, and ‘DRL’ on FMVSS-compliant lamps).

13 Glazing on house-trucks

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

Application

This document applies to house-trucks for the purpose of determining compliance with Land Transport Rule: Glazing, Windscreen Wipe and Wash, and Mirrors 1999 (the Glazing Rule).

Requirements

For this purpose, house-trucks should be considered goods vehicles of class NB or NC, depending on their gross vehicle mass (GVM).

Policy

Compliance with approved standards

House-trucks are usually modified vehicles. For example, they may consist of a cab and chassis that was manufactured in 1967, with a housing structure added to the rear in 1980. It is often difficult to determine when the modification took place. This makes it difficult to decide which date should be used to determine the applicable requirements – the year of manufacture of the original vehicle, or the year the modification was carried out.

The Glazing Rule defines year of manufacture as ‘the calendar year in which the construction of the vehicle was completed’.

The NZTA has determined that if any glazing is added or changed as part of the modification, this glazing must comply with requirements for vehicles manufactured at the time of the modification.

The vehicle owner must demonstrate when the modification was carried out.

Condition and performance

Leadlight windows fitted to a house truck are unlikely to comply with general safety requirements, which require glazing to be mechanically sound and strong.

In order to comply with general safety requirements, leadlight windows may be sandwiched between two panes of standard compliant glazing.

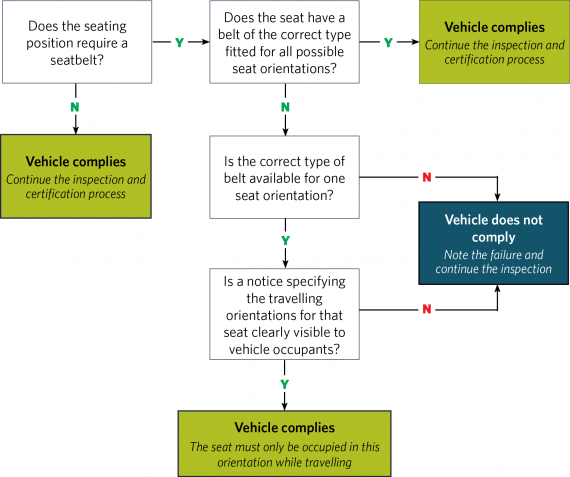

14 Seatbelt requirements for rotating seats

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

- Vehicle interior – 7-1 Seats and seat anchorages: Reasons for rejection 1

- Vehicle interior – 7-5 Seatbelts and seatbelt anchorages: Reasons for rejection 1.

Applicable legislation

Application

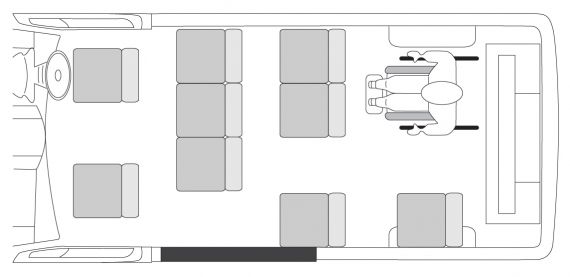

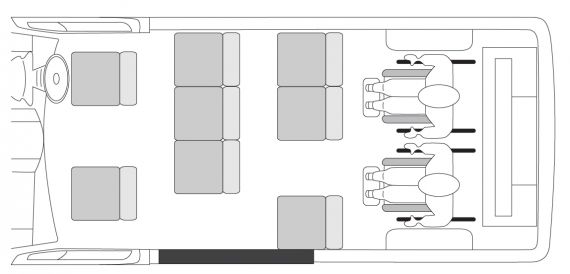

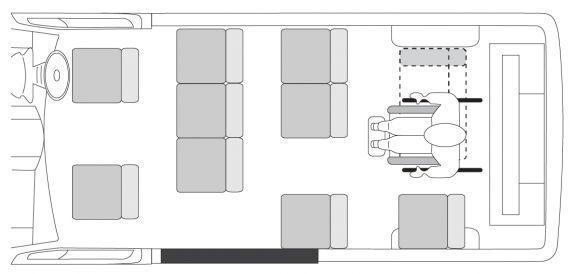

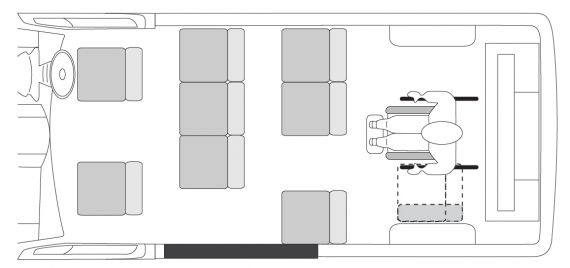

This document applies to vehicles fitted with seats that can be rotated or placed to face other directions. Usually, this is to allow front occupants to face rear occupants while the vehicle is stationary.

Safety concern

Although it may be possible to have rotating seats (other than the driver’s seat) face rearward or sideways while traveling on a road, it is only permitted for such seats to be occupied if appropriate seatbelts are fitted.

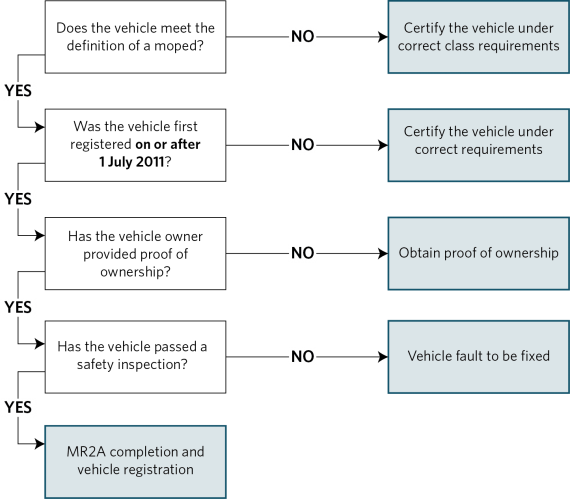

Seatbelt requirements

Seatbelt requirements depend on the vehicle type, age, number of seats and the location of the seat in the vehicle.

Seats capable of being rotated or placed in other orientations are required to have seatbelts fitted appropriate to the orientation for normal use when the vehicle is travelling on the road (usually forward facing). If the seatbelt cannot be used due to the seat orientation, the seat must not be occupied while the vehicle is moving.

Advisory decals, easily visible to vehicle occupants, must be fitted inside the vehicle to indicate which seating orientations may (or may not) be used while the vehicle is moving.

- See Figure 1-1-1. Flowchart for determining seatbelt compliance for rotating seats

Figure 1-1-1. Flowchart for determining seatbelt compliance for rotating seats

15 Toyota Hiace seat and seatbelt requirements

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

- Vehicle interior – 7-1 Seats and seat anchorages: Reasons for rejection 1 and 2

- Vehicle interior – 7-5 Seatbelts and seatbelt anchorages: Reasons for rejection 1, 2 and 3.

Application

This bulletin applies to Toyota Hiace minivan models assembled in New Zealand with type-approved seating for eight passengers installed in the rear seating compartment, to bring the total seating capacity to 11 (10 if the vehicle is approved for passenger service vehicle use).

Toyota Hiace models with factory-installed seating

Table 15-1-1 shows a list provided by Toyota New Zealand of Hiace minibus model codes with factory-installed seating. The ‘local code’ denotes factory-installed seat and seatbelt assemblies.

The seats and seatbelts fitted in vehicles listed in Table 15-1-1 have all been tested and approved to comply with international standards. The seat and seatbelt assemblies for both CKD and CBU models were installed before the vehicles were delivered to dealers.

Table 15-1-1. Toyota Hiace models with factory-installed seating

|

HIACE TMC model code |

Local code |

Assembly |

New Zealand grade |

Production date |

Engine code |

Transmission |

|---|---|---|---|---|---|---|

|

RZH113R-RRMRS |

RHMLB |

CKD |

2.4 ZL |

08/89–07/98 |

2RZ |

5M/T |

|

RZH113R-RRPRS |

RHMLB |

CKD |

2.4 ZL |

08/89–07/93 |

2RZ |

4H A/T |

|

RZH102R-SRMRS |

RHMSW |

CKD |

SR5 WAGON |

08/89–07/91 |

1RZ |

5M/T |

|

RZH103R-SRMRS |

RHMKW |

CKD |

SR5 WAGON |

08/91–04/95 |

2RZ |

5M/T |

|

RZH113R-RRMRS |

RHMLB |

CKD |

2.4 MINIBUS |

08/89–07/98 |

2RZ |

5M/T |

|

RZH113R-RRMRS |

RHPLB |

CKD |

2.4 MINIBUS |

08/89–07/98 |

2RZ |

4A/T |

|

RZH113R-RRPRS |

REPLB |

CKD |

2.4 MINIBUS |

08/89–07/93 |

2RZ |

4A/T |

|

LH113R-RRMRS |

LHMLB |

CKD |

2.8 DSL BUS |

08/94–0/798 |

3L |

5M/T |

|

LH113R-RRMRS |

LHLMV |

CBU |

2.8 ZL Diesel |

05/00–07/00 |

3L |

5M/T |

|

RZH113R-RRMRE |

RHLMV |

CBU |

2.4 ZL Petrol |

05/00– |

2RZ-E |

5M/T |

|

LH113R-RRMRS |

LHLMV |

CBU |

2.8 ZL Diesel |

05/00–07/00 |

3L |

5M/T |

|

LH172R-RRMRS |

LHMSV |

CBU |

3.0 ZL Diesel |

08/00– |

5L |

5M/T |

Standards

The Toyota Hiace minivan models listed in Table 15-1-1 are fitted with seats and seatbelts complying with the following standards:

- Seats comply with the requirements of Australian Design Rule (ADR) 3/02.

- Seatbelts, depending on the date of manufacture, comply with either:

i. New Zealand Standard (NZS) 5401; or

ii. Australian Standard/New Zealand Standard (AS/NZS) 2596.

- Seatbelt anchorages comply with ADR 5/02.

Certification requirements

The seat and seatbelt installations were not considered to be low volume vehicle (LVV) modifications due to the number of units involved and the fact that the system had been ‘type tested’.

These vehicles were all produced before the NZTA requirement for vans fitted with additional seating to be certified under the LVV code was introduced. Therefore, the vehicles are not fitted with LVV certification plates.

However, Toyota Hiace models fitted with seats and seatbelts on or after January 2002 have been LVV certified, and will have been fitted with LVV certification plates.

16 Replacement seatbelts

Vehicle inspection requirements manual references

This bulletin only applies to vehicles that are required to comply with a frontal impact standard. It gives guidance to vehicle inspectors in applying the following requirements:

Application

This document applies to all frontal impact compliant vehicles that are required to have replacement seatbelts fitted as part of entry-level certification in New Zealand.

Inspection

General safety requirements state that seatbelts fitted to a vehicle must comply with requirements relating to condition, performance or modification as set out in the VIRM: In-service certification, section 7-5. If a seatbelt does not meet these conditions, it must be replaced. The replacement part must contain at least all of the features present in the original seatbelt, unless confirmation that fitment of a seatbelt without a certain feature would not affect the safety performance of the vehicle is available from the vehicle manufacturer.

If a vehicle is presented for entry certification, it can have an original equipment (OE) (or equivalent) seatbelt fitted as a replacement. This means that the only time a webbing clamp seatbelt would need to be fitted is if the failed OE seatbelt was a webbing clamp seatbelt.

Replacement seatbelts do not necessarily have to come from the vehicle manufacturer. If a seatbelt manufacturer can confirm that a particular seatbelt is suitable as replacement for a particular vehicle model (and the seatbelt complies with an approved standard), this seatbelt would also be acceptable.

Page amended 28 April 2014 (see amendment details).

17 Seatbelt and seatbelt anchorage standards for heavy motor vehicles

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

Application

This bulletin applies to heavy motor vehicles undergoing entry certification in New Zealand.

Inspection

Land Transport Rule: Seatbelts and Seatbelt Anchorages requires class NB and NC vehicles manufactured on or after 1 October 2003 to be fitted with seatbelts and seatbelt anchorages as follows:

Seating position | Type of seatbelt required | Type of anchorage required |

|---|---|---|

Driver | A-ELR (Note 2) | 3 or 4 point anchorage |

Front outer | A-ELR (Note 2) | 3 or 4 point anchorage |

Front middle | Lap seatbelt | 2 point anchorage |

Rear outer | Not applicable | Not applicable |

Rear middle | Not applicable | Not applicable |

Seatbelts must meet one of the standards contained in Table 7-5-1 of the VIRM: Entry certification. Seatbelt anchorages must comply with one of the standards contained in Table 7-5-3 of the VIRM: Entry certification.

Note 1

For the purposes of 2.1(5)(d) of the Rule, manufactured means original manufacture by the source plant. It has nothing to do with any subsequent remanufacture/rebuild/modification/retrofit/vehicle class change. A vehicle originally manufactured before 1 October 2003 will never be required to comply with the requirements in Table 2.4 of the Rule.

Note 2

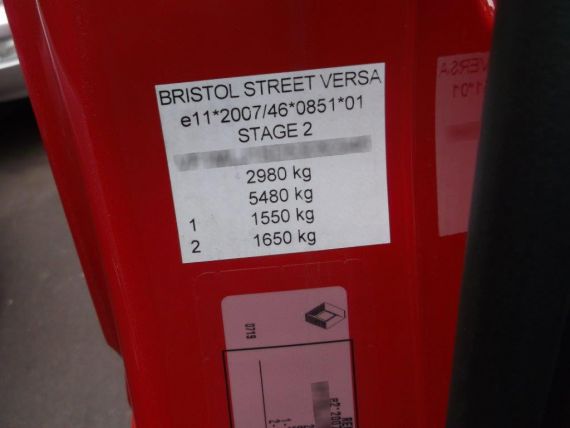

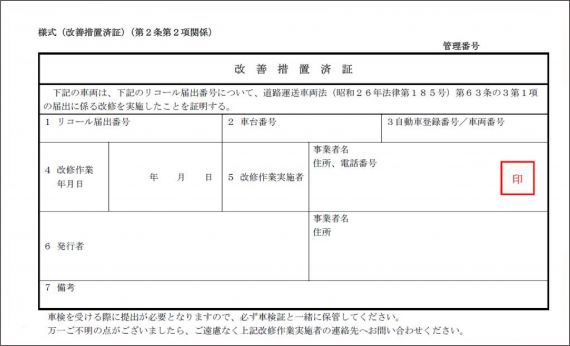

If a vehicle is fitted with an OE single-sensitive emergency locking retractor lap and diagonal seatbelt, it may remain fitted if it has a plate affixed to the vehicle (see Figure 17-1-1).

Figure 17-1-1. Example of a plate fitted to a vehicle that may retain a single-sensitive seatbelt

Standards compliance

The Motor Industry Association (MIA) has obtained the relevant information from its members so that entry certifiers will not need to request a statement of compliance for individual vehicles. Information regarding compliance with approved seatbelt and seatbelt anchorage standards for heavy motor vehicles distributed by the MIA and sold through its franchise dealer network has been supplied for the makes and models listed on the following page.

Make | Model | Seatbelt | Seatbelt Anchorage |

|---|---|---|---|

Caterpillar | CT610, CT630 | ADR 4 | ADR 5 |

DAF | ECE R16 | ECE R14 | |

Ford | EEC77/541 | ECE R14 | |

Foton | ADR 4 | ADR 5 | |

Freightliner | Argosy, Columbia, Century Class, Coronado | FMVSS 209 or ADR 4 | FMVSS 210 or ADR 5 |

Fuso | Canter/Fighter , Shogun Euro 6 Rosa/ HD Enduro, MP | ADR 4 Japan Technical Standards ECE R16 | ADR 5 Japan Technical Standards ECE R14 |

Hino | ECE R16 | ADR 5 | |

Hyundai | HD Series | ECE R16 | ECE R14 |

International | FMVSS 209 | FMVSS 210 | |

Isuzu | N series F series FX series C & E Series | ADR 4 ECE R16 ECE R16 Japan Technical Standards Or ECE R16 | ADR 5 ECE R14 ECE R14 Japan Technical Standards Or ECE R14 |

Iveco | Stralis,Powerstar & ACCO Daily & Eurocargo Trakker | ADR 4 ECE R16 ECE R16 | ADR 5 ECE R14 ECE R14 |

Kenworth | ADR 4 | ADR 5 | |

Mack | Information contained on compliance plate fitted to the vehicle | ||

MAN | ECE R16 | ECE R14 | |

Mercedes-Benz | ECE R16 | ECE R14 | |

Mitsubishi Fuso | Canter/Fighter Rosa/Shogun | ADR 4 Japan Technical Standards | ADR 5 Japan Technical Standards |

Nissan Diesel | ADR 4 | ADR 5 | |

Renault | Information contained on compliance plate fitted to the vehicle | ||

RAM | 2500 Laramie, 3500 Laramie | ADR 04/05 | ADR 05/05 |

Scania | EEC e4*77/541 | EEC e4*76/115 | |

Sterling | LT9500, LT7500 | FMVSS 209 | FMVSS 210 |

UD Trucks | ADR 4/04 | ADR 5/05 | |

Volkswagen | ECE R16 | ECE R14 | |

Volvo | Information contained on compliance plate fitted to the vehicle | ||

Western Star | FMVSS 209 | ADR 5 | |

- If an entry certifier is presented with a vehicle not covered above, and proof of compliance cannot be established by approved methods, they should contact the vehicle manufacturer directly.

- A heavy vehicle previously registered in the European Union or United Kingdom complies with the seatbelt anchorage standards for heavy vehicles if the vehicle is registered on or after 1 January 2009.

Page amended 28 April 2014 (see amendment details).

Page updated 2 November 2021 (see details)

18 Seatbelt markings

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

Application

This bulletin applies to standards markings on seatbelts fitted to vehicles undergoing entry certification in New Zealand.

Clarification

Seatbelts must be labelled with an appropriate standards marking. This helps to determine compliance with an approved standard. Seatbelts may be marked with a code that indicates the type of retractor operation, such as ELR. Table 18-1-1 lists possible seatbelt markings and describes the type of retractor operation indicated by each marking.

Table 18-1-1. Seatbelt retractor operations markings

|

Seatbelt marking |

Seatbelt retractor operation |

|---|---|

|

ELR |

Emergency locking retractor |

|

ALR |

Automatic locking retractor |

|

ELR/ALR |

A combination of emergency and automatic locking retractors, usually used in cars with child restraint seats, but can be used for other purposes. |

|

ELR-V |

Single-sensitive (for vehicle sensitivity only) emergency locking retractor |

|

ELR-VW |

Dual-sensitive (for both vehicle and web sensitivity) emergency locking retractor |

|

ELR-VW-4N or ELR-VN |

Dual-sensitive emergency locking retractor, but with less sensitivity in the webbing sensitivity function. This makes it ideal for use where an air seat or hydraulic cushion seat is fitted, as the retractor will not constantly lock-up as the operator moves up and down. |

Compliant seatbelts that are not required to have standard markings

- Seatbelts that comply with the Japanese Technical Standard for Seatbelt Assemblies are not required to have standards markings, provided the seatbelts are OE and the vehicle has Japanese type approval.

- Seatbelts in a fully Australian Design Rule (ADR)-compliant vehicle are not required to have standards markings.

Mislabelling

If the retractor operation of a seatbelt fitted to a vehicle does not match the operation indicated by the seatbelt marking (eg the seatbelt is marked ELR-V but appears to be web sensitive), the vehicle inspector must ignore the possibility of mislabelling, and inspect the performance of the seatbelts in accordance with the manufacturer’s marking.

19 Seatbelt exemptions

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements:

- VIRM: Entry certification, Vehicle interior – 7-5 Seatbelts and seatbelt anchorages: Reason for rejection 1 and 2

- VIRM: In-service certification, Tables 7-5-1 to 7-5-3.

Application

This document applies to all vehicles undergoing entry-level certification in New Zealand that are required to have seatbelts fitted.

Seatbelt exemptions

Under Land Transport Rule: Seatbelts and Seatbelt Anchorages 2002 and the New Zealand Gazette notice au2141 (dated 29 March 2001, page 781), vehicles fitted with certain occupant safety protection systems may be exempt from the requirement to have approved seatbelts of a specified type fitted, as defined in Land Transport Rule: Seatbelts and Seatbelt Anchorages 2002.

This exemption may apply to a vehicle that:

- complies with an approved frontal impact standard, or

- is fitted with airbags that are the manufacturer’s OE specifications, or

- has seatbelt features such as pretensioners or load limiters specifically designed to operate in conjunction with other parts of an integrated occupant protection system.

The exemption only applies to seatbelts fitted as part of the vehicle manufacturer’s OE specifications.

A list of specific seatbelt exemptions is available in the VIRM: In-service certification in Table 7-5-5. The VIRM: In-service certification also lists vehicles that may be exempt from specified seatbelt requirements, provided the vehicle was first registered in New Zealand before 1 January 1991.

Documentation

The inspecting organisation must retain a paper record of the exemption. This may be a note on the vehicle checksheet, or a paper exemption declaration.

A note must be recorded against the vehicle record in LANDATA stating that a single-sensitive seatbelt exemption has been issued.

Evidence of exemption

An entry certifier is required to provide the vehicle owner with evidence that the identified vehicle has been inspected and meets the criteria for a single-sensitive seatbelt exemption. This evidence may be a paper exemption (declaration) or a single-sensitive seatbelt exemption plate.

Paper exemptions

The declaration must be printed on the reverse of a copy of the New Zealand Gazette exemption notice au986. It must also contain the following information:

a) vehicle make, model, year of manufacture and VIN or chassis number, and

b) part numbers or identification numbers of the seatbelts in each sitting position, and

c) a statement declaring that the vehicle qualifies for and meets the conditions of the exemption, and

d) the date of issue, and

e) the vehicle inspector’s name, signature and contact details.

Sample seatbelt exemption declarations are shown in Reference materials 39 and 40.

Single-sensitive seatbelt exemption plate

A vehicle identification number (VIN) plate embossed with the text ‘SSBELTSOK’ followed by the last five digits of the VIN (see Figure 19-1-1) may be affixed to the front face of the right-hand B-pillar.

Figure 19-1-1 . Example of a single-sensitive seatbelt exemption plate

Both a plate and a paper exemption may be supplied if requested by the vehicle owner.

Note 1

1997 and 1998 Toyota Cavalier vehicles exempt from frontal impact system requirements are also eligible for a seatbelt exemption, provided an SSBELTSOK plate is fitted on the right-hand B-pillar.

20 OE rear upper seatbelt anchorages (with retrofitted seatbelts)

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

Application

This bulletin applies to the standards compliance of rear upper original equipment (OE) seatbelt anchorages not fitted with seatbelts at the time of manufacture.

Safety concern

It is important that the strength of OE seatbelt anchorages meets the required anchorage strength of retrofitted seatbelts. To ensure that the OE seatbelt anchorages can securely anchor the type of seatbelts fitted, the vehicle inspector must determine that the OE seatbelt anchorage complies with an approved standard.

Inspection

When inspecting a vehicle fitted with an OE-installed rear upper seatbelt anchorage not fitted with a seatbelt at the time of manufacture, one of the following methods must be used to determine compliance with an approved standard:

a) a statement of compliance supplied by the vehicle manufacturer, which lists an approved seatbelt anchorage standard, or

b) if the vehicle is class MA, if it is listed in Table 4 of MoT St. 31391 (see Reference material 41), or

c) type-testing.

If evidence of compliance with an approved standard cannot be provided, the vehicle inspector must fail the vehicle.

In such cases, the vehicle owner may choose to:

- undergo low volume vehicle (LVV) certification of the seatbelt anchorages, or

- remove the seatbelts and seating.

21 Rear seatbelts as aisle obstructions in passenger service vehicles

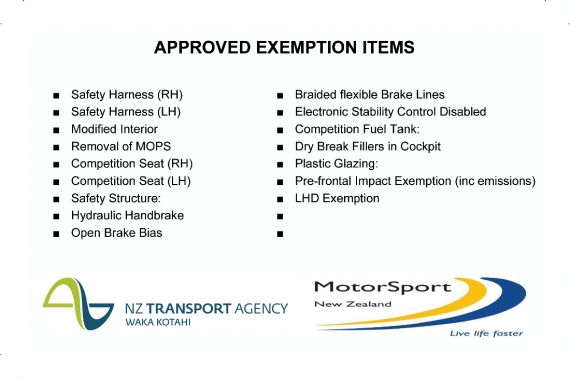

23 Used imported motorsport vehicles

Situation

Under Land Transport Rule: Frontal Impact Amendment 2008 and Land Transport Rule: Exhaust Emissions 2007, a vehicle that is of class MA or MC is not required to comply with an approved frontal impact standard or exhaust emissions standard if it is recognised as a dedicated motorsport vehicle.

Waka Kotahi and MotorSport New Zealand (MSNZ) have agreed on a process to allow a limited number of genuine dedicated motorsport vehicles to be imported and certified for use on New Zealand roads. These vehicles may participate in MSNZ-sanctioned events that have road stages requiring the vehicle to have a current WoF and registration. Such vehicles may be driven on the road to get to and from MSNZ events, and for servicing and certification. They are not for ‘daily driver’ use.

Application

This document applies to any used or parallel-imported vehicle dedicated to motorsport use that is undergoing entry certification in New Zealand, which:

- is a class MA or MC vehicle that does not meet an approved frontal impact and/or exhaust emissions standard, or

- is a left-hand drive vehicle that does not meet the requirements for importing a Category A left-hand drive vehicle, or

- was used for motorsport purposes in the country of origin, but was never registered there for use on the road, or

- is a new, purpose-built vehicle that has not been registered in the country of origin

- is an FIA Homologated Rally Car imported and used in the NZRC or international rally events providing the following requirements are met:

The car maintains complete compliance with its homologation papers and technical regulations at all times

The car must be used primarily for New Zealand Rally Championship events or International permitted events

The car must be inspected each year prior to Authority Card renewal

If the car fails to meet the above requirements, certification through LVVTA will be required.

Waka Kotahi acknowledges that the types of vehicle specified above will not meet some of the current vehicle standards and entry requirements.

People importing vehicles that fall into the above categories must be referred in the first instance to:

Technical Manager – MotorSport NZ

Phone 04 815 8015

Fax 04 472 9011

PO Box 3793

Wellington 6140

Email technical@motorsport.org.nz

Inspection

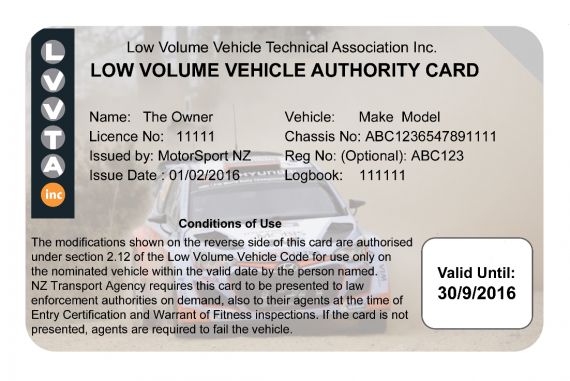

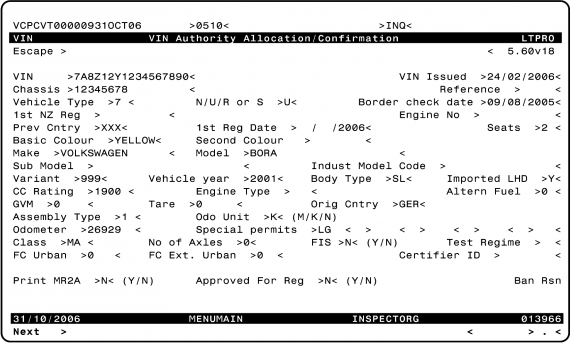

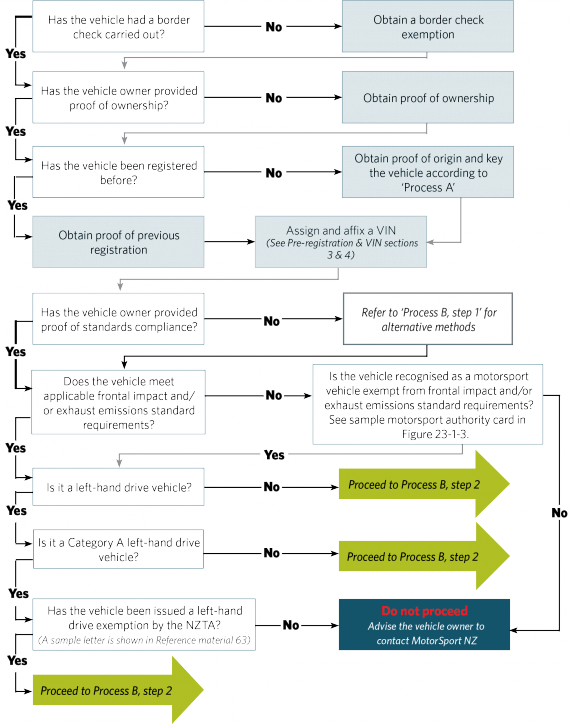

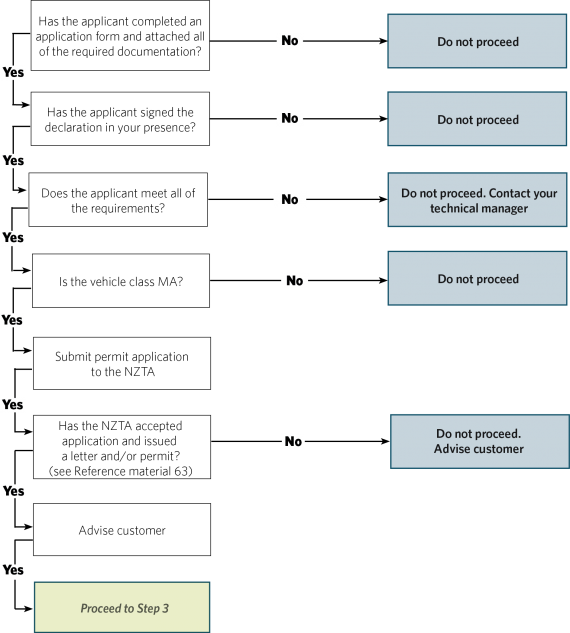

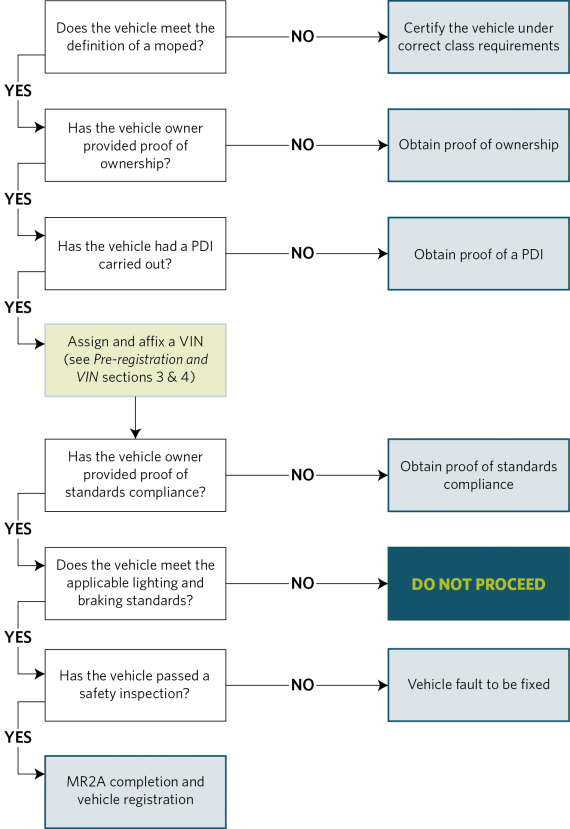

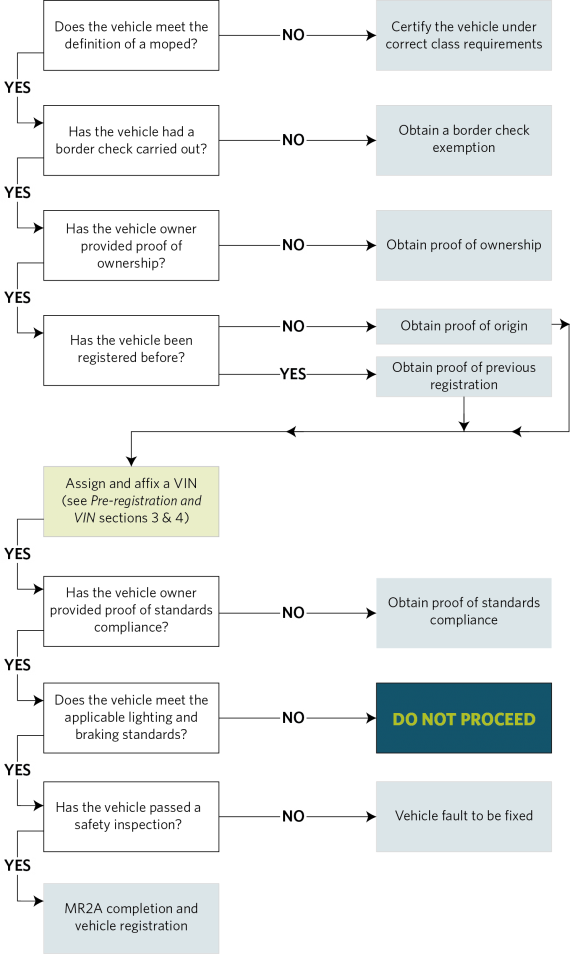

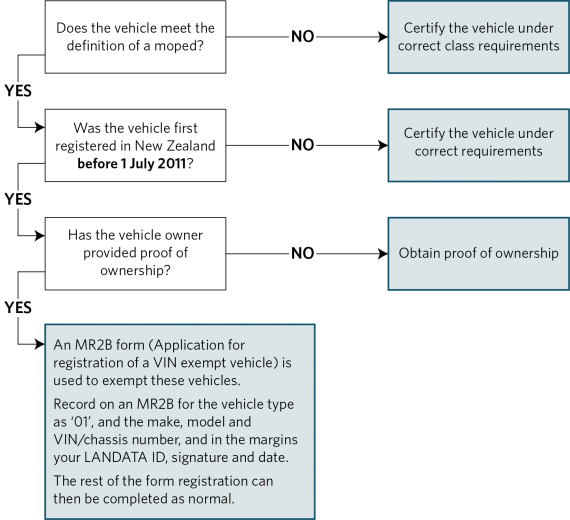

Flow diagram Figure 23-1-1 explains the procedure for processing an imported motorsport vehicle for entry certification.

Process A

Some imported motorsport vehicles may have been used but not previously registered. These vehicles will not meet the definition of a used import, but must be entered in LANDATA as used (>U<). The vehicle attributes for such vehicles should be recorded in LANDATA as follows:

In the field … | Type … |

|---|---|

Vehicle type | 07 |

1st Reg date | The year the vehicle will be first registered in New Zealand |

Prev cntry | XXX |

Orig cntry | The code for the country where the vehicle was built |

Figure 23-1-2. Sample VIN screen

Notes must be entered against the vehicle record in LANDATA explaining the motorsport vehicle exemption category. For example, ‘MotorSport vehicle manufactured in 1999 used but never registered’.

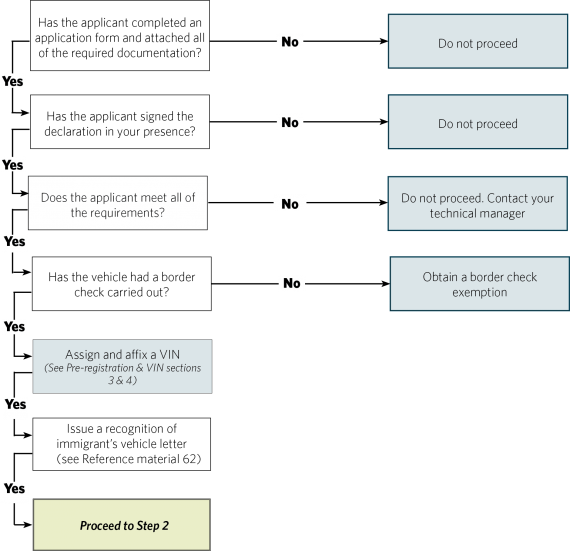

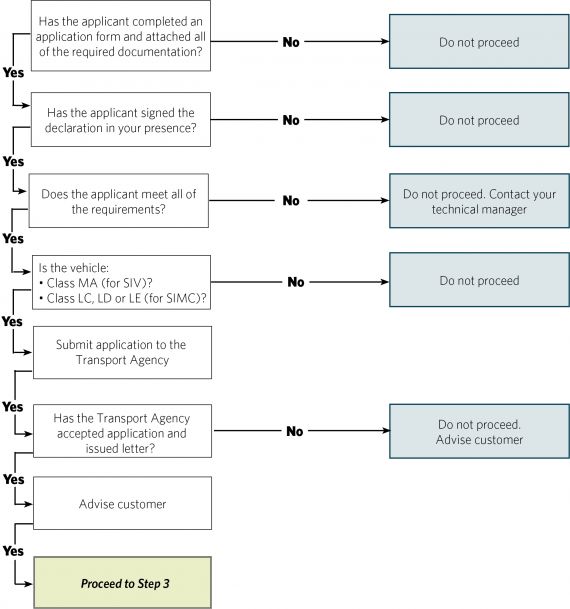

Process B

Step 1 – Documentation

Dedicated motorsport vehicles must still meet all the relevant standards applicable to the vehicle (according to age, etc).

The VIRM: Entry certification manual details the standards a vehicle and its components are required to meet. See Inspection and certification Table 1-1-2 for methods to demonstrate compliance with required standards.

Where compliance with an approved standard can not be proven by these methods, the following methods are acceptable alternatives:

a) visual confirmation and recording of standards for items such as lighting, glazing, tyres and so on

b) low volume vehicle (LVV) certification for modified components, such as brakes, steering and suspension, not covered on the MotorSport NZ authority card

c) a MotorSport NZ authority card that includes at least frontal impact assessment

Left-hand drive vehicles

Left-hand drive motorsport vehicles must meet all the requirements described in Pre-registration and VIN 6, Left-hand drive vehicles. If an exemption has been issued, the code ‘C5 (Left hand drive motorsport)’ must be entered in the ‘Special permit’ field on the VIN screen.

MotorSport authority card

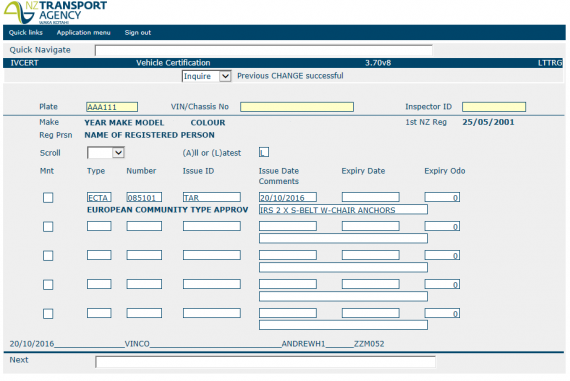

If a MotorSport NZ authority card is issued for a vehicle, the code LVAC (low volume authority card) must be entered in the IVCERT screen. The Certifier ID to be recorded for a motorsport authority card is >TMWM1<.

Record the modifications listed on the authority card in the comments field.

Step 2 – Compliance inspection

Motorsport vehicles must be inspected according to the requirements outlined in the VIRM: Entry certification.

If a vehicle has been modified, it must have LVV certification and/or a motorsport authority card (Figure 23-1-3).

If there is evidence of previous structural repairs or structural damage to a motorsport vehicle, it must be referred to a repair certifier for inspection and certification.

Step 3 – MR2A completion and vehicle registration

1. Any original exemption letters must be sighted, copied and returned to the vehicle owner.

2. Notes must be recorded against the vehicle record in LANDATA.

a) If the vehicle is recognised as a dedicated motorpsort vehicle that does not meet a frontal impact and/or exhaust emissions standard, the following note must be recorded in the LANDATA notes screen:

‘Vehicle must remain registered in the name of >vehicle owner< or motorsport vehicle recognition is void’.

The importer’s name must match the name shown on the exemption letter.

If the vehicle does not meet a frontal impact standard, the FIS (frontal impact standard) field must be set to >N<.

b) Update LANDATA with Special Permit Code MS.

c) If the vehicle has been issued a left-hand drive exemption letter, the following note must be recorded in the LANDATA notes screen:

‘Vehicle must remain registered in the name of the>vehicle owner< or left-hand drive exemption is void’.

3. The MR2A must be completed and printed in the name of the vehicle importer. This must be the same as the name shown on any exemption letter.

Note 1

If a vehicle is recognised as a motorsport vehicle exempt from frontal impact or exhaust emissions standard requirements, the MR2A must not leave the control of the entry certifier until after the vehicle is registered to ensure it is registered in the importer’s name.

Note 2

All exemptions will be issued to individuals. If a company or organisation has applied for a motorsport exemption, it will be issued to a nominated individual.

If an entry certifier wishes to deviate from these instructions, written approval from the Transport Agency must be obtained.

Assistance

Contact your technical manager if you have any questions.

Figure 23-1-3. Sample motorsport authority card (front and rear)

Figure 23-1-1. Procedure for processing an imported motorsport vehicle for entry certification

Page updated 17 May 2023 (see details)

24 Recording the number of seats for self-propelled motorhomes

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: Entry certification:

Application

This bulletin applies to self-propelled motorhome vehicles undergoing entry certification in New Zealand.

Requirements

When recording the number of seats in a self-propelled motorhome, the vehicle inspector must take the following factors into account:

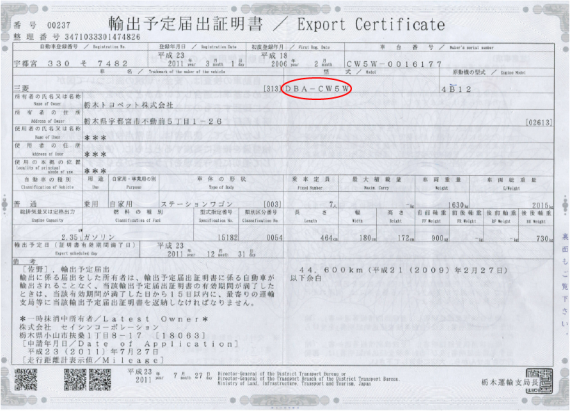

- the number of seats recorded on the importation documents (eg the de-registration or export certificate), and

- the number of seats fitted by the vehicle manufacturer, and

- the date of manufacture or conversion to a motorhome.

Vehicles manufactured or converted to a motorhome before 1 October 2003

The inspector should only count the fixed seats originally fitted by the vehicle manufacturer, not additional seats constructed by folding up or repositioning squabs, tables or beds.

The number of seats recorded in LANDATA should not exceed the number of seats recorded on the importation documents.

The vehicle must be fitted with seatbelts appropriate for the class of vehicle it was recorded as when first registered as a motorhome.

Examples

1. A motorhome manufactured in 2001 is imported. Two seats are indicated on the de-registration certificate. There are six seating positions in the vehicle but four of these seating positions fold down into beds. The vehicle should be recorded in LANDATA as a two-seater.

2. A vehicle is imported with eight seats indicated on the de-registration certificate. There are three factory seats in the front, with two seats in the rear that fold down into beds. The vehicle should be recorded in LANDATA as a three-seater.

Vehicles manufactured or converted to a motorhome after 1 October 2003

The number of seating positions recorded in LANDATA should match the number of sleeping berths.

The vehicle must be fitted with:

a) seatbelts in front seating positions as specified for class MB vehicles in the VIRM: In-service certification Table 7-5-3 (column three).

b) seatbelts in rear seating positions as specified for class MB vehicles in the VIRM: In-service certification Table 7-5-3 (column three) for at least as many rear seating positions as the number of sleeping berths minus the number of front seating positions.

c) a notice displayed in a prominent location, which recommends on safety grounds that passengers use the seats that are fitted with seatbelts when the vehicle is travelling, and stating that it is compulsory to wear fitted seatbelts.

Example

1. A motorhome manufactured in 2004 is imported. The vehicle has five sleeping berths. There are two front seating positions. There must be at least three rear seating positions fitted with lap or lap-and-diagonal seatbelts. The vehicle should be recorded in LANDATA as a five-seater.

2. A motorhome manufactured in 2004 is imported. The vehicle has two sleeping berths. There are two front seating positions and there is a two-seat sofa in the rear. There is no requirement to have any of the rear seating positions fitted with belts. The vehicle should be recorded in LANDATA as a two-seater.

Page amended 1 March and 11 March 2016 (see amendment details).

25 Immigrants' vehicles

Situation

- Under Land Transport Rule: Frontal Impact Amendment 2008 and Land Transport Rule: Vehicle Exhaust Emissions Amendment 2007, a vehicle is not required to comply with an approved frontal impact standard or exhaust emissions standard if it is recognised as an immigrant’s vehicle.

- Under Land Transport Rule: Light Vehicle Brakes 2002, class LC, LD and LE vehicles are not required to meet advanced brake systems requirements if it is recognised as an immigrant’s vehicle.

The following standards marking will be sufficient to determine that an immigrants’ vehicle may not comply with the necessary standards and can therefore be processed under immigrant’s vehicle criteria.

Emissions

- A whole vehicle approval plate with the framework approval number 98/14 or earlier for both petrol and diesel powered vehicles

- An ADR plate with the approval date of 12/2005 or earlier for petrol, LPG or CNG powered vehicles

- An ADR plate with the approval date of 12/2006 or earlier for diesel powered vehicles

- An EPA label with the model year of 2000 or earlier for petrol, LPG or CNG powered vehicles

- An EPA label with the model year of 2003 or earlier for diesel powered vehicles.

Frontal impact

- A whole vehicle approval plate with the approval number 98/14 or earlier

- An ADR plate with the approval date of 12/1995 or earlier.

Electronic stability control (ESC)

ESC provisions do not apply to immigrants' vehicles.

Advanced brake system (ABS) requirements

ABS requirements do not apply to immigrants’ vehicles of class LC, LD or LE.

Application

This document applies to any used vehicle that is undergoing entry certification in New Zealand, which:

- has been identified in writing by a Transport Agency entry certification agent as an immigrant’s vehicle appropriate for certification to enter service in New Zealand, and

- is imported to New Zealand by an immigrant entitled to take up permanent residence in New Zealand, or

- is imported by a New Zealand citizen or resident returning to New Zealand after at least 21 months overseas.

Obtaining recognition of an immigrant’s vehicle

To be eligible to register an immigrant’s vehicle, an applicant must:

1. apply to an organisation appointed by the Transport Agency (such as a Transport Agency entry certification agent), before the vehicle is certified for entry into service in New Zealand (an application form is available in Reference material 50), and

2. pay the appropriate fees (if any) specified in accordance with regulations made under the Act.

Recognition of an immigrant’s vehicle may be granted if: