Correct as at 24th April 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > Forklifts > Lighting

4 Lighting

4-1 Headlamps

Reasons for rejection

Mandatory and permitted equipment (Note 6)

1. A forklift that is likely to be operated during the hours of darkness (where the vehicle inspector can determine that) is not fitted with either:

a) one pair of dipped-beam headlamps, or

b) one pair of forward-facing work lamps (Note 1).

2. A forklift is fitted with more than:

a) one pair of dipped-beam headlamps, or

b) two pairs of main-beam headlamps.

3. A forklift is fitted with a headlamp that is not in a pair.

4. A retrofitted pair of headlamps is:

a) not fitted symmetrically, or

b) not fitted as far towards each side of the vehicle as is practicable.

5. A forklift is fitted with a dipped-beam headlamp where the maximum intensity of the beam is projected to the right.

Condition

6. A lamp is insecure.

7. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A lens or reflector is damaged or has deteriorated so that light output is reduced.

9. A mandatory lamp is obscured or contains dirt or moisture in the form of large droplets, runs or puddles.

10. A main-beam headlamp warning device is obscured from the driver’s vision.

Performance

11. When switched on, a headlamp emits a light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity to the other lamp in a pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead or be visible from 100m during the hours of darkness, eg due to modification, deterioration or an incorrect light source, or

e) too bright, eg due to the fitment of an HID or LED conversion kit (Note 7) or other incorrect light source, or

12. When the dipped-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than two lamps operate on dipped beam, or

c) the light beam produces an incorrect beam pattern, is not focused, or is reduced or altered, or

d) the centreline of the light beam (Figure 4-1-1, Table 4-1-1):

i. projects too far to the left, or

ii. projects to the right of the vehicle’s centreline, or

iii. slopes down too far so that the headlamp is no longer capable of illuminating the road ahead for safe vehicle operation, or

iv. is too high causing dazzling to other road users.

13. When the main-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than four lamps operate on main beam, or

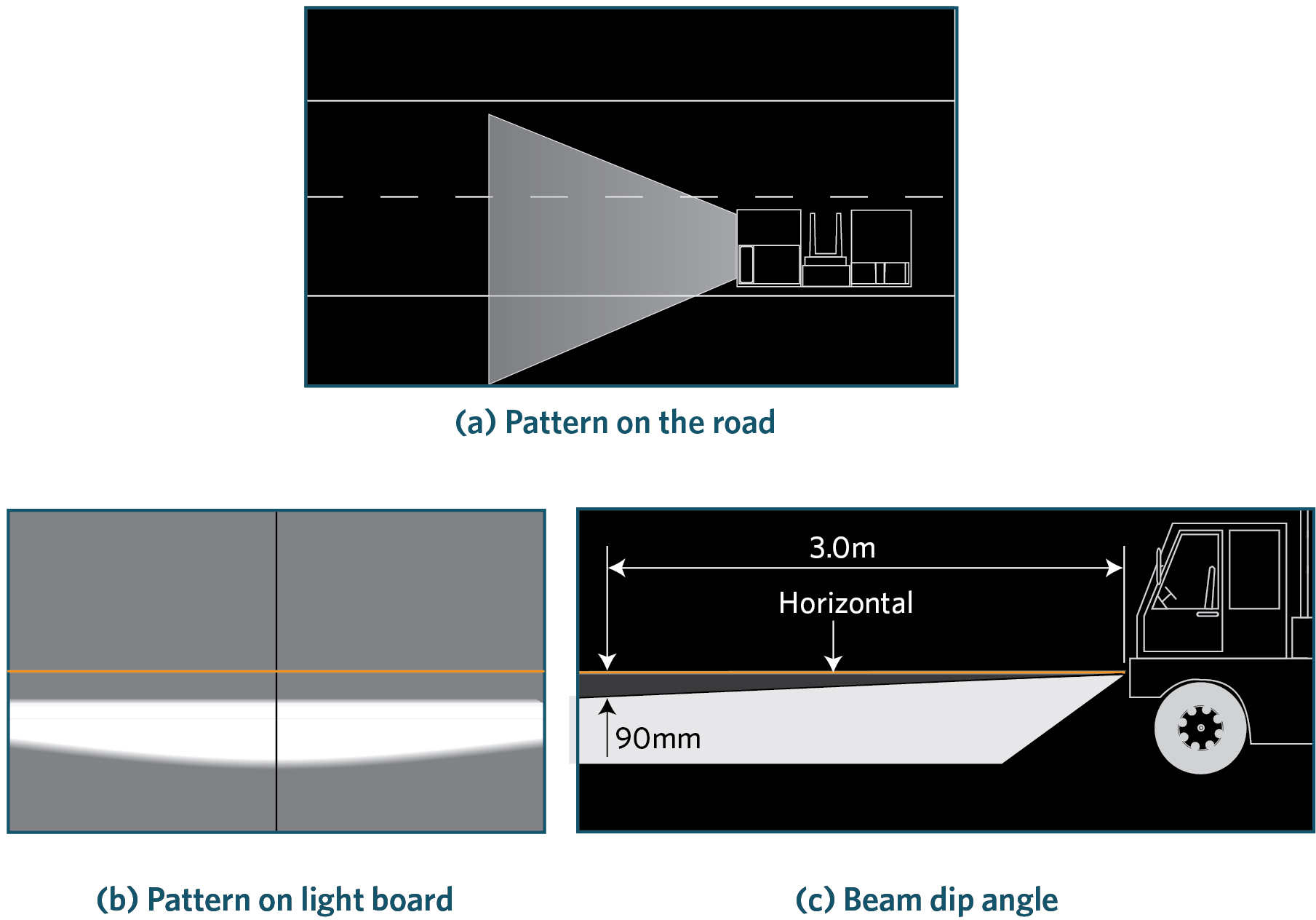

c) the centreline of the light beam projects to the right of the vehicle’s centreline or up from the horizontal (Figure 4-1-2), or

d) the lamps are not capable of being switched to dipped beam or turned off from the driver’s seating position, or

e) a main-beam headlamp warning device does not indicate to the driver that the main-beam headlamps are switched on.

14. On a forklift with no headlamps, when the forward-facing work lamps are switched on a mandatory lamp does not operate.

15. On a forklift with no headlamps, when the forward-facing work lamps are switched on a lamp emits a light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity to the other lamp in a pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead, eg due to modification, deterioration or an incorrect light source, or

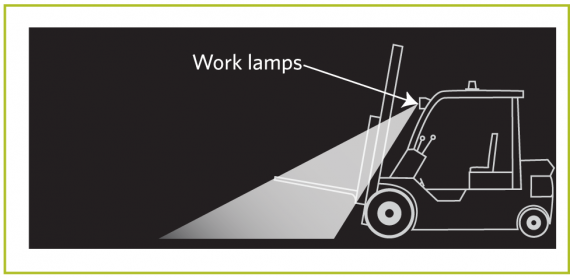

e) not aligned appropriately, causing dazzling to other road users or insufficient light illuminating the road ahead for safe vehicle operation (Figure 4-1-3).

Note 1 Definitions

Work lamp means a high-intensity lamp, which is not necessary for the operation of the vehicle but is designed to illuminate a work area or scene, and includes a scene lamp, a spot lamp and an alley lamp. In the case of a forklift without headlamps, forward-facing work lamps must be fitted to illuminate the road ahead during the hours of darkness.

Headlamp means a lamp designed to illuminate the road ahead of a vehicle, and that is a:

a) dipped-beam headlamp (single lamp), or

b) main-beam (high-beam) headlamp (single lamp), and includes a driving lamp, or

c) combination of a dipped-beam headlamp and a main-beam headlamp (dual-lamp unit).

Note 2

If the dipped-beam headlamps are able to be adjusted from the driver’s seating position, the alignment must be checked with the adjustment at its highest position.

Note 3

If the vehicle is fitted with self-levelling suspension, the alignment must be checked with the suspension at its normal level.

Note 4

If a headlamp is fitted with a readily removable cover, other than a clear protective cover, this must be removed for inspection of the headlamp.

Note 5

A vehicle originally manufactured with a headlamp arrangement that differs from what is required or permitted in this section may retain the original headlamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 6

A forklift that has no or non-compliant headlamps may be issued with a WoF provided the forklift:

a) complies with all other applicable WoF requirements, and

b) is not operated during the hours of darkness.

Note 7

A high-intensity discharge (HID or Xenon HID) or LED conversion kit consists of an HID or LED bulb which fits into the original headlamp unit in place of the original bulb with no change to the headlamp lens, reflector or housing.

It is illegal to fit an HID or LED conversion kit to a vehicle as it brings the headlamp out of standards compliance by producing poor beam patterns and light that is often far too bright to be safe. The bulbs can also produce light that is noticeably blue and not the required substantially white or amber colour. Vehicle and headlamp manufacturers do not permit this modification, and these kits cannot be LVV certified.

It is permitted to replace a complete halogen headlamp unit with a complete HID or LED headlamp unit. If the vehicle is required to meet an approved safety standard for headlamps, only approved headlamps can be retrofitted.

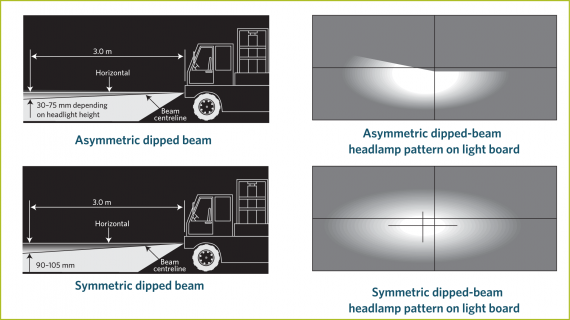

Table 4-1-1. Recommended dipped-beam headlamp alignment

Headlamp type | Distance from ground to centre of light source | Dip rate of beam centre: | |||

|---|---|---|---|---|---|

Percent (%) | mm/3m | Degrees (°) | |||

EITHER | Any headlamp dipped beam | N/A | That specified by the vehicle or headlamp manufacturer | ||

OR | Headlamp with symmetric dipped-beam pattern | N/A | 3.0–3.5 | 90–105 | 1.7–2.0 |

OR | Headlamp with asymmetric dipped-beam pattern and distance from ground to centre of light source | less than 0.8m | 1.0–1.5 | 30–45 | 0.57–0.85 |

0.8–1.2m | 1.0–2.0 | 30–60 | 0.57–1.15 | ||

more than 1.2m | 2.0–2.5 | 60–75 | 1.15–1.43 | ||

Figure 4-1-1. Headlamp dipped beam patterns and recommended dip-rates

Figure 4-1-2. Headlamp high-beam pattern

Figure 4-1-3. Work lamp beam pattern

Summary of legislation

Applicable legislation

Mandatory and permitted equipment (Note 6)

1. A forklift that is operated in the hours of darkness must be fitted with

a) one pair of dipped-beam headlamps, or

b) one pair of forward-facing work lamps (Note 1).

2. A forklift may be fitted with one or two pairs of main-beam headlamps.

3. A warning device may be fitted that indicates that the main-beam headlamps are switched on.

4. A retrofitted pair of headlamps must be symmetrically mounted as far towards each side of the vehicle as is practicable.

Prohibited equipment

5. A dipped-beam headlamp designed solely for a left-hand drive vehicle, where the maximum intensity of the beam is dispersed to the right, must not be fitted.

Condition

6. A headlamp or a mandatory forward-facing work lamp must:

a) be in sound condition, and

b) not be obscured.

Performance

7. A lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. A lamp must emit a steady light.

9. A lamp must provide sufficient illumination and light output to illuminate the road ahead.

10. A pair of lamps must emit light that is approximately of equal colour and intensity when switched on.

11. A lamp must emit a beam that is substantially white or amber.

12. A main-beam headlamp must be capable of being dipped or turned off from the driver’s position.

13. A warning device that indicates that the main-beam lamps are in operation must be in good working order.

14. When the headlamps are switched on and the vehicle’s front wheels are pointing in the straight-ahead position:

a) the centre of a headlamp beam must be either parallel to or to the left of the longitudinal centreline of the vehicle, and

b) the centre of a main-beam headlamp beam must be either parallel to or dipping down from the horizontal.

15. The dipped-beam headlamps must be visible from 100m in normal darkness.

16. A headlamp must be fitted with a light source that is specified by the vehicle manufacturer or the headlamp manufacturer.

Page amended 1 April 2021 (see amendment details).

4-2 Front and rear fog lamps

Reasons for rejection

Permitted equipment

1. A forklift is fitted with:

a) only one front fog lamp, or

b) more than one pair of front fog lamps.

2. A forklift is fitted with more than two rear fog lamps.

3. A retrofitted pair of fog lamps is:

a) not fitted symmetrically, or

b) not fitted as far towards each side of the vehicle as is practicable, or

c) positioned higher than the dipped-beam headlamps.

Condition

4. A lamp is insecure or contains moisture in the form of large droplets, runs or puddles.

5. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

6. A reflector is damaged or has deteriorated so that light output is reduced.

7. A fog lamp warning device, if fitted, is obscured from the driver’s vision.

Performance

8. When switched on, a front fog lamp does not operate.

9. When switched on, a front fog lamp emits light that:

a) is not projected to the front, or

b) produces an incorrect beam pattern (Figure 4-2-1), or

c) is not substantially white or amber to the front, or

d) is not approximately equal in colour or intensity to the other lamp in the pair, or

e) is not steady, or

f) is not bright enough to illuminate the road ahead in conditions of severely reduced visibility, eg due to modification, deterioration, dirt or an incorrect light source, or

g) is too bright, and could dazzle other road users, eg due to an incorrect light source, or

h) has a beam centre to the right of the vehicle’s centreline, or

i) has a beam that is not permanently dipped, or

j) has a beam centre that dips at an angle of less than 3% (Figure 4-2-1).

10. When switched on, a rear fog lamp emits light that is not:

a) projected to the rear, or

b) diffuse, or

c) substantially red, or

d) approximately equal in colour or intensity to the other lamp in a pair, or

e) steady, or

f) bright enough to indicate the presence of the vehicle from the rear in conditions of severely reduced visibility, eg due to modification, deterioration or an incorrect light source.

11. A fog lamp cannot be switched off from the driver’s seating position.

12. Where a fog lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

13. A fog lamp warning device, if fitted, does not operate.

Note 1

Fog lamp means a front or rear lamp designed to aid the driver or other road users in conditions of severely reduced visibility, including fog or snow, but not including clear atmospheric conditions under the hours of darkness.

Note 2

A rear fog lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

If a front fog lamp is fitted with a readily removable cover, other than a clear protective cover, this must be removed for inspection of the fog lamp.

Note 4

A vehicle originally manufactured with a front- or rear-fog lamp arrangement that differs from what is required or permitted in this section may retain the original front or rear fog lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 5

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply, be removed from the vehicle, or be disabled so that it does not emit a light.

Figure 4-2-1. Front fog lamp characteristics

Summary of legislation

Applicable legislation

Permitted equipment

1. A forklift may be fitted with:

a) one pair of front fog lamps, and

b) one or two rear fog lamps.

2. A retrofitted pair of fog lamps must be symmetrically mounted as far as is practicable towards each side of the vehicle.

3. A retrofitted front fog lamp must not be positioned higher than the dipped-beam headlamps.

4. A vehicle may be fitted with a warning device that indicates that a front or rear fog lamp is in operation.

Condition

5. A front fog lamp must be in sound condition.

6. A rear fog lamp must be in sound condition if it emits a light.

Performance

7. A fog lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. A fog lamp must emit a steady light.

9. A front fog lamp must provide sufficient light output to illuminate the road ahead in conditions of severely reduced visibility.

10. A rear fog lamp must provide sufficient light output to indicate the presence of the vehicle on the road in conditions of severely reduced visibility.

11. The light emitted from a front fog lamp must be substantially white or amber.

12. The light emitted from a rear fog lamp must be diffuse and substantially red in colour.

13. A pair of fog lamps must emit light that is approximately equal in colour and intensity.

14. The centre of a front fog lamp beam must be parallel to or to the left of the longitudinal centreline of the vehicle.

15. The centre of a front fog lamp beam must be permanently dipped at an angle of at least 3%.

16. A fog lamp must be able to be turned off from the driver’s seating position.

17. A front or rear fog lamp warning device must be in good working order.

18. Where a fog lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 1 April 2021 (see amendment details).

4-3 Cornering lamps

Reasons for rejection

Permitted equipment

1. A forklift is fitted with:

a) only one lamp, or

b) more than one pair of lamps, or

c) a lamp that either:

i. was not originally fitted by the forklift manufacturer, or

ii. is not fitted in the original position.

Condition

2. A lamp is insecure.

3. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

4. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

Performance

5. When activated by switching on the direction indicator lamp or by turning the steering wheel, a cornering lamp does not:

a) operate, or

b) project in the direction of the turn.

6. A cornering lamp emits light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity to the other lamp in a pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead in the direction of the turn, eg due to modification, deterioration, dirt or an incorrect light source, or

e) too bright, causing dazzle to other road users, eg due to an incorrect light source or misalignment.

7. Where a cornering lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Cornering lamp means a lamp that is designed to emit light at the front of a vehicle to supplement the vehicle’s headlamps by illuminating the road ahead in the direction of the turn.

Summary of legislation

Applicable legislation

Permitted equipment

1. One pair of cornering lamps fitted by the forklift manufacturer.

Condition

2. A cornering lamp must be in sound condition.

Performance

3. A cornering lamp must operate in a way that is appropriate for the lamp and the vehicle.

4. A cornering lamp must emit light that is substantially white or amber.

5. A pair of cornering lamps must emit light that is approximately equal in colour and intensity.

6. A cornering lamp must emit a steady light.

7. A cornering lamp must provide sufficient light output to illuminate the road ahead in the direction of the turn.

8. A cornering lamp must be correctly aligned.

9. Where a cornering lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-4 Daytime running lamps

Reasons for rejection

Prohibited equipment

1. A forklift is fitted with daytime running lamps.

Note 1

Daytime running lamp means a lamp designed to emit a low-intensity light forward of a vehicle to make it more easily seen in the daytime.

Summary of legislation

Applicable legislation

Prohibited equipment

1. A forklift must not be fitted with daytime running lamps.

4-5 Direction indicator lamps

Reasons for rejection

Permitted equipment

1. A forklift is fitted with more than:

a) two pairs of lamps at the rear, or

b) two pairs of lamps at the front, or

c) two side-facing lamps on each side.

2. A forklift is fitted with a lamp that is not in a pair.

3. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the forklift as is practicable.

Condition

4. A lamp is insecure.

5. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

6. A reflector is damaged or has deteriorated so that light output is reduced.

Performance (Note 2)

7. When switched on, a direction indicator lamp:

a) does not operate, or

b) does not begin flashing within one second of switching on, or

c) flashes:

i. faster than two flashes per second, or

ii. slower than one flash per second, or

iii. at a different rate from other lamps on the same side.

8. When switched on, a direction indicator lamp emits a light that is:

a) not substantially amber or red to the rear, or

b) not substantially white or amber to the front, or

c) not substantially amber to the side, or

d) not approximately equal in colour or intensity to the other lamp in a pair, or

e) not bright enough to be visible from 100m in normal daylight and from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source, or

f) too bright causing significant dazzle to other road users, eg due to an incorrect light source, or

g) altered, eg due to damage or modification.

9. On a forklift of American origin fitted with combined stop and indicator lamps, the stop lamp function is not overridden by the indicator function.

10. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Direction indicator lamp means a lamp designed to emit a flashing light to signal the intention of the driver to change the direction of the vehicle to the right or to the left.

Note 2

A rear- or side-facing direction indicator lamp that does not comply with equipment, condition and performance requirements must be made to comply or disabled so that it does not emit a light.

Note 3

A vehicle originally manufactured with a direction-indicator-lamp arrangement that differs from what is required or permitted in this section may retain the original direction indicator lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Permitted equipment

1. A forklift may be fitted with one or two pairs of lamps to the front and rear of the vehicle.

2. A forklift may be fitted with one or two side-facing lamps on each side.

3. A suitable device may be fitted that indicates to the driver the failure of a mandatory lamp.

4. A retrofitted pair of lamps must be mounted symmetrically as far towards each side of the forklift as is practicable.

5. On forklifts of American origin, the stop lamp and direction indicator lamp function may be combined in one lamp.

Condition

6. A direction indicator lamp must be in sound condition.

Performance

7. A direction indicator lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. A direction indicator lamp must emit a light that is substantially:

a) red or amber to the rear, and

b) white or amber to the front, and

c) amber to the side.

9. A lamp must flash at a fixed frequency in the range of 1 to 2 Hertz.

10. Each lamp in a pair must, when operated, emit a light of approximately equal intensity, colour and frequency.

11. The lamp-failure indicating device, if fitted, must function.

12. A lamp must emit a light that is visible from 100m during normal daylight and 200m in normal darkness.

13. If a vehicle of American origin is fitted with combined stop and indicator lamps, the indicator lamps may override the stop lamps so that the stop lamps operate as direction indicators.

14. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-6 Forward-facing position lamps

Reasons for rejection

Permitted equipment

1. A forklift is fitted with more than two pairs of lamps.

2. A retrofitted pair of lamps is:

a) not symmetrically mounted, or

b) not mounted as far towards each side of the vehicle as is practicable, or

c) mounted at a height from the ground exceeding 2.1m.

3. A pair of top-mounted lamps, if fitted, is not:

a) symmetrically mounted, or

b) mounted as far towards the top corners of the bodywork as is practicable.

4. A lamp is not positioned to the front of the vehicle.

Condition

5. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

6. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

7. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

Performance

8. When switched on, a forward-facing position lamp does not operate.

9. When switched on, a forward-facing position lamp emits a light that is not:

a) substantially white or amber, or

b) diffuse, or

c) projected to the front, or

d) approximately equal in colour or intensity to the other lamp in a pair, or

e) steady, or

f) bright enough to be visible from a reasonable distance in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source.

Note 1

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A vehicle originally manufactured with a forward-facing position lamp arrangement that differs from what is required or permitted in this section may retain the original forward-facing position lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Permitted equipment

1. A forklift may be fitted with one or two pairs of forward-facing position lamps.

2. A retrofitted pair of lamps must be symmetrically mounted as far towards each side of the vehicle as is practicable.

3. A retrofitted lamp must be mounted at a height from the ground not exceeding 2.1m.

4. A forklift may be fitted with one additional pair of forward-facing position lamps that must be symmetrically mounted as far towards the top corners of the vehicle as is practicable (top-mounted lamps).

5. A lamp must be positioned to the front of the vehicle.

Condition

6. A forward-facing position lamp must:

a) be in sound condition,

b) not be obscured (if a mandatory lamp).

Performance

7. A forward-facing position lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. A lamp must emit a light that is:

a) diffuse, and

b) substantially white or amber, and

c) steady, and

d) sufficient to indicate to other road users the presence and dimensions of the vehicle, and

e) of approximately equal intensity and colour to the other lamp of a pair.

9. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 1 November 2012 (see amendment details).

4-7 Rearward-facing position lamps

Reasons for rejection

Mandatory and permitted equipment

1. A forklift that is likely to be operated during the hours of darkness (where the vehicle inspector can determine that) is not fitted with at least one lamp.

2. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

Condition

3. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

4. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

5. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

6. A mandatory lamp is obscured.

Performance

7. When switched on, a mandatory lamp does not operate.

8. When switched on, a lamp emits a light that is not:

a) substantially red, or

b) diffuse, or

c) projected to the rear, or

d) approximately equal in colour or intensity to the other lamp in a pair, or

e) steady, or

f) bright enough to be visible from 100m in normal darkness (if a mandatory lamp), eg due to modification, deterioration, dirt or an incorrect light source.

9. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1 Definition

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A permitted rearward-facing position lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

A vehicle originally manufactured with a rearward-facing position lamp arrangement that differs from what is required or permitted in this section may retain the original rearward-facing position lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A forklift operated during the hours of darkness must be fitted with at least one rearward-facing position lamp.

2. A forklift may be fitted with one or more rearward-facing position lamps.

3. A retrofitted pair of lamps must be mounted symmetrically as far towards each side of the vehicle as is practicable.

4. A lamp must be positioned to the rear of the vehicle.

Condition

5. A rearward-facing position lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

6. A rearward-facing position lamp must operate in a way that is appropriate for the lamp and the vehicle.

7. A lamp must emit a light that is:

a) diffuse, and

b) substantially red, and

c) steady, and

d) sufficient to indicate to other road users the presence and dimensions of the vehicle, and

e) visible from a distance of 100m in normal darkness (if a mandatory lamp), and

f) of approximately equal intensity and colour to the other lamp of the pair.

8. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 1 November 2012 (see amendment details).

4-8 Side-marker lamps

Reasons for rejection

Prohibited equipment

1. A forklift that has a length of less than 6m is fitted with side-marker lamps.

Condition

2. A lamp is insecure.

3. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

4. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

5. When switched on, a lamp emits a light that is not:

a) diffuse, or

b) substantially red or amber to the rear, or

c) substantially white or amber to the front, or

d) steady.

6. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1 Definitions

Side-marker lamp means a position lamp designed to be fitted to the side of a vehicle or its load.

Position lamp means a low-intensity lamp that is designed to indicate to road users the prescence and dimensions of a vehicle being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A side-marker lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Summary of legislation

Applicable legislation

Permitted and prohibited equipment

1. A forklift with a length of 6m or more may be fitted with one or more side-marker lamps.

2. A forklift with a length of less than 6m must not be fitted with side-marker lamps.

Condition

3. A lamp must be in good condition.

Performance

4. A side-marker lamp must operated in a way that is appropriate for the lamp and the vehicle.

5. A side-marker lamp must emit light that is:

a) diffuse, and

b) substantially red or amber to the rear, and

c) substantially white or amber to the front, and

d) steady.

6. Where a side-marker lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-9 End-outline marker lamps

Reasons for rejection

Mandatory, permitted and prohibited equipment

1. A vehicle listed in Table 4-9-1:

a) is not fitted with lamps required in Table 4-9-1, or

b) is fitted with lamps that exceed the numbers permitted in Table 4-9-1.

2. A vehicle not listed in Table 4-9-1 is fitted with end-outline marker lamps.

3. An end-outline marker lamp is so positioned that it does not indicate the dimensions of the vehicle.

Condition

4. A lamp is insecure.

5. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

6. A reflector is damaged or has deteriorated so that light output is reduced.

7. A mandatory lamp is obscured.

Performance

8. When switched on, a mandatory lamp does not operate.

9. When switched on, a lamp emits a light that is not:

a) substantially red to the rear, or

b) substantially white or amber to the front, or

c) diffuse, or

d) steady, or

e) bright enough to be visible from 100m in normal daylight and 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source.

9. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1 Definitions

End-outline marker lamp means a position lamp designed to be fitted near the outer extremity of a vehicle in addition to forward-facing and rearward-facing position lamps, and includes a cab roof lamp.

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A permitted end-outline marker lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Table 4-9-1. Fitting requirements for end-outline marker lamps

|

If the vehicle was: |

Row |

Characteristics of the heavy vehicle |

Front |

Rear |

|

|---|---|---|---|---|---|

|

Mandatory lamps3 |

Maximum permitted lamps1 |

Maximum permitted lamps2 |

|||

|

Vehicle manufactured before 1/4/20113 |

A |

|

2 |

12 (No Limit if first registered before 27/2/2005) |

6 |

|

B |

A vehicle with an overall width of 1.8 m or more (other than a vehicle in row A) |

Not required |

6 |

4 |

|

|

Vehicle manufactured from 1/4/2011 |

C |

A vehicle with an overall width exceeding 2.1m and with a GVM or GCM exceeding 12,000kg |

2 |

12 |

6 |

|

D |

A vehicle with an overall width exceeding 2.1m (other than a vehicle in row C) |

2 |

6 |

4 |

|

|

E |

A vehicle with an overall width of 1.8 m or more (other than a vehicle in row C or D). |

Not required |

6 |

4 |

|

1 Maximum permitted lamps are the maximum number of lamps allowed to be fitted, including mandatory lamps.

2 A vehicle manufactured before 1/4/2011 also has the option of complying with the requirements applicable to vehicles manufactured from 1/4/2011.

3 Mandatory lamps must be positioned at a height no lower than the top edge of the windscreen

Summary of legislation

Applicable legislation

Mandatory, per5mitted and prohibited equipment

1. A vehicle in Table 4-9-1 must or may be fitted with end-outline marker lamps as specified in the table.

2. A vehicle not listed in Table 4-9-1 must not be fitted with end-outline marker lamps.

3. The position of the lamps must be such that it gives an indication of the vehicle’s dimensions.

Condition

4. A end-outline marker lamp must be:

a) in good condition, and

b) not obscured (if a mandatory lamp).

Performance

5. An end-outline marker lamp must operate in a way that is appropriate for the lamp and the vehicle.

6. Cab roof lamps must emit a light that is visible from 100m in normal daylight and from 200 in normal darkness.

7. A lamp must emit a light that is diffuse and substantially red to the rear and white or amber to the front.

8. A lamp must provide sufficient light output so that the vehicle’s dimensions are easily indicated to other road users.

9. Where an end-outline marker lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-10 Stop lamps

Reasons for rejection

Permitted equipment

1. A forklift is:

a) is fitted with more than three pairs of stop lamps (including top-mounted stop lamps), or

b) is fitted with a stop lamp that is not in a pair.

2. A retrofitted stop lamp, other than a top-mounted lamp, is fitted at a height from the ground exceeding 2.1m.

3. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

4. A pair of top-mounted lamps is not mounted as far as is practicable to the top of the bodywork of the vehicle.

Condition

5. A lamp is insecure.

6. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

7. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

8. A lamp operates when the service brake is not applied.

9. A lamp emits a light that is not:

a) substantially red, or

b) diffuse, or

c) steady, or

d) projected to the rear, or

e) approximately equal in colour or intensity to the other lamp in a pair, or

f) bright enough to produce a light that is visible from a reasonable distance in normal daylight, eg due to modification, deterioration, dirt or an incorrect light source.

10. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

12. On a vehicle of American origin fitted with combined stop and direction indicator lamps, the stop lamp function is not overridden by the indicator function.

Note 1

Stop lamp means a lamp that is designed to operate when the service brake is activated.

Note 2

A permitted stop lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

A vehicle originally manufactured with a stop-lamp arrangement that differs from what is required or permitted in this section may retain the original stop lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Permitted equipment

1. A forklift may be fitted with one or two pairs of stop lamps at the rear which emit a light that is visible from a reasonable distance.

2. A retrofitted pair of stop lamps must be symmetrically mounted as far towards each side of the vehicle as is practicable.

3. A retrofitted stop lamp must be fitted at a height from the ground not exceeding 2.1m.

4. A forklift may be fitted at the rear with an additional pair of stop lamps provided they are positioned as close as is practicable to the top of the bodywork of the vehicle (top-mounted lamps).

Condition

5. A stop lamp must be in sound condition.

Performance

6. A stop lamp must operate in a way that is appropriate for the lamp and the vehicle.

7. The light emitted from a stop lamp must be diffuse light that is substantially red.

8. A stop lamp must operate when a service brake is activated.

9. A stop lamp must emit a steady light.

10. If a vehicle of American origin is fitted with combined stop and direction indicator lamps, the indicator lamps may override the stop lamps so that the stop lamps will operate as direction indicators.

11. Where a stop lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 1 November 2012 (see amendment details).

4-11 High-mounted stop lamps

Reasons for rejection

Permitted equipment

1. A forklift is fitted with more than two high-mounted stop lamps.

2. A lamp is not fitted in a central high-mounted position.

Condition

3. A lamp is insecure.

4. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

5. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

6. When the service brake is activated a lamp does not remain steadily illuminated.

7. A lamp operates when the service brake is not activated.

8. A lamp emits a light that is not:

a) substantially red, or

b) diffuse, or

c) projected to the rear, or

d) bright enough to be visible from 100m in normal daylight, eg due to modification, deterioration, dirt or an incorrect light source.

9. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1 Definitions

High-mounted stop lamp means a stop lamp that is designed to be fitted in a central, high-mounted position at the rear of a vehicle.

Stop lamp means a lamp that is designed to operate when the service brake is activated.

Note 2

A high-mounted stop lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

A vehicle originally manufactured with a high-mounted-stop-lamp arrangement that differs from what is required or permitted in this section may retain the original high-mounted stop lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Permitted equipment

1. A forklift may be fitted with one or two high-mounted stop lamps.

2. A lamp must be fitted in a central high-mounted position at the rear of the vehicle.

Condition

3. A high-mounted stop lamp must be in good condition.

Performance

4. A high-mounted stop lamp must operate in a way that is appropriate for the lamp and the vehicle.

5. The light emitted from a high-mounted stop lamp must be diffuse light that is substantially red.

6. A high-mounted stop lamp must emit a steady light.

7. Where a high-mounted stop lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-12 Rear-reg.-plate illumination lamps

Reasons for rejection

Condition

1. A lamp is insecure.

2. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

3. A reflector, or lens, is damaged or has deteriorated so that light output is reduced.

Performance

4. The lamp emits a light that is not:

a) substantially white, or

b) steady, or

c) diffuse.

5. The lamp does not illuminate the registration plate (eg either the lamp or plate have been moved, or the lamps orientation has been changed).

6. The light source of a lamp is visible from the rear of the vehicle.

Note 1

Rear-registration-plate illumination lamp means a lamp designed to illuminate the rear registration plate of a vehicle.

Note 2

A vehicle originally manufactured with a rear-registration-plate-illumination-lamp arrangement that differs from what is required or permitted in this section may retain the original rear-registration-plate illumination lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Permitted equipment

1. A forklift may be fitted with one or more rear-registration-plate illumination lamps.

Performance

2. A rear-registration-plate illumination lamp must operate in a way that is appropriate for the lamp and the vehicle.

3. A lamp must emit a diffuse light that is substantially white.

4. A rear-registration-plate illumination lamp must emit a steady light.

5. The light source of the lamp must not be visible from the rear of the vehicle.

6. A lamp must illuminate the figures and letters of the plate so that they are visible from 20m during normal darkness.

7. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 1 October 2021 (see amendment details).

4-13 Rear reflectors

Reasons for rejection

Permitted equipment

1. A forklift is fitted with a rearward-facing reflector that is not in a pair.

2. A retrofitted reflector is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the vehicle).

3. A reflector is not positioned to the rear of the vehicle.

4. A retrofitted pair of reflectors is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

Performance

8. The reflected light from a reflector is not red.

Note 1 Definitions

Reflector means a discreet item of lighting equipment that is designed to reflect incident light back towards the light source, but does not include reflective material (such as reflective tape).

Reflective material means any material that is designed to reflect incident light back towards the light source, and includes reflective tape, but does not include a reflector.

Note 2

A vehicle originally manufactured with a rear reflector arrangement that differs from what is required or permitted in this section may retain the original rear reflectors provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Permitted equipment

1. A forklift may be fitted with one or more pairs of rearward-facing reflectors at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the vehicle, not exceeding 2.1m.

2. A rearward-facing reflector must be positioned to the rear of the vehicle.

3. A reflector must be of an area that allows it to reflect light to improve the visibility of the vehicle to other road users, but it must not cause them undue dazzle or discomfort.

4. A retrofitted pair of reflectors must be symmetrically mounted as far towards each side of the vehicle as is practicable.

Performance

7. A reflector must reflect white light as substantially red light.

Page amended 1 November 2012 (see amendment details).

4-14 Reversing lamps

Reasons for rejection

Permitted equipment

1. A forklift is fitted with more than two reversing lamps at the rear of the vehicle.

2. A retrofitted pair of reversing lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

Condition

3. A lamp is insecure or contains visible moisture or dirt.

4. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

5. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

6. A lamp controlled by gear engagement continues to display a light to the rear when the reverse gear is disengaged.

7. A lamp controlled by a manual switch continues to display a light to the rear while the headlamps are switched on.

8. When engaged, a lamp emits light that is not:

a) substantially white (Note 3), or

b) steady, or

c) diffuse or a dipped beam.

9. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Reversing lamp means a lamp designed to illuminate the area behind the vehicle while it is reversing and to warn other road users that the vehicle is reversing or about to reverse.

Note 2

A reversing lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

Vehicles first registered in New Zealand before 27 February 2005 were allowed to use rear indicator lamps as reversing lamps. Although the light emitted is amber instead of white, this arrangement is still permitted for these vehicles.

Note 4

A vehicle originally manufactured with a reversing lamp arrangement that differs from what is required or permitted in this section may retain the original reversing lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Permitted equipment

1. A forklift may be fitted with one or two reversing lamps fitted at the rear of the vehicle.

2. A retrofitted pair of reversing lamps must be symmetrically mounted as far towards each side of the vehicle as is practicable.

Condition

3. A reversing lamp must be in good condition.

Performance

4. A reversing lamp must operate in a way that is appropriate for the lamp and the vehicle.

5. A reversing lamp, when operated, must emit a diffuse light or a dipped beam of light that is substantially white (Note 3).

6. A reversing lamp must emit a steady light.

7. A reversing lamp may operate only when the reverse gear is engaged or the headlamps are turned off.

8. Where a reversing lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-15 Cosmetic lamps

Reasons for rejection

Permitted equipment

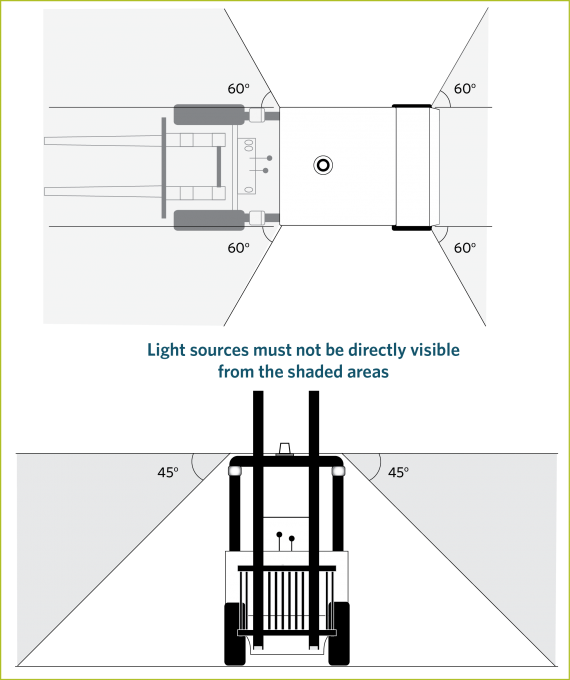

1. A cosmetic lamp (ie one not listed in Table 4-15-1) that is fitted to a vehicle:

a) has a part of its light-emitting surface positioned within 250mm of any mandatory lamps, or

b) is not mounted in a fixed position, or

c) is positioned so that its light-emitting surface is visible within the shaded areas in Figure 4-15-1.

Performance

2. When switched on, a cosmetic lamp with a light-emitting surface not visible within the shaded areas in Figure 4-15-1 emits a light that:

a) is not diffuse, or

b) flashes or otherwise varies in intensity or colour, or

c) revolves, rotates or otherwise moves, or

d) is too bright and likely to dazzle other road users, or

e) is likely to cause confusion about the orientation of the vehicle, or

f) is red when seen directly from the front, or

g) is not red or amber when seen directly from the rear.

Note 1

A rear or side cosmetic lamp that does not comply with requirements for condition or performance must be made to comply, or be disabled so that it does not emit a light.

Note 2 Definitions

Lamp means a device designed to emit light, and includes an array of separate light sources that appear as a continuous illuminated surface.

Cosmetic lamp means any lamp that is not listed in Table 4-15-1.

Note 3

A forward-facing cosmetic lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle.

Table 4-15-1. Lamps that are not cosmetic lamps

|

Lamps covered in the VIRM |

Other lighting equipment not requiring inspection |

|---|---|

|

Headlamps Stop lamps High-mounted stop lamps Direction indicator lamps Position lamps Rear-registration-plate illumination lamps Rear reflectors Fog lamps Daytime running lamps Cornering lamps Reversing lamps PSV interior lamps |

Reflective material Interior lamps Work lamps Scene lamps Alley lamps Flashing or revolving beacons (except a mandatory beacon required for some overdimension vehicles) Illuminated vehicle-mounted signs |

Figure 4-15-1. Visibility angles for cosmetic lamps

Summary of legislation

Applicable legislation

Permitted equipment

1. A vehicle may be fitted with one or more lamps not specified in Table 4-15-1, provided they are fitted so that light sources are not visible in those regions specified in Figure 4-15-1.

2. A lamp must be fitted in a fixed position on the vehicle and positioned so that no part of the light source is situated within 250mm of a mandatory lamp.

Performance

3. A lamp must:

a) only emit light that is diffuse, and

b) not emit light that flashes or otherwise varies in intensity or colour, and

c) be fitted in a way, and be of a luminance that ensures, that it does not dazzle, confuse or distract other road users, and

d) not emit a light that revolves, rotates or otherwise moves, and

e) not cause confusion as to the orientation of the vehicle, and

f) not emit a red light that is directly visible from the front of the vehicle, and

g) not emit a light other than red or amber if the light is directly visible from the rear of the vehicle.