Correct as at 18th April 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > Introduction

Introduction

1 Purpose and scope

The NZ Transport Agency Waka Kotahi (NZTA) has prepared this manual to assist vehicle inspectors and inspecting organisations achieve correct and consistent standards of in-service vehicle inspection and certification (WoF and CoF).

The purpose of this manual is to enhance the safety of in-service vehicles in New Zealand by conveying to vehicle inspectors and inspecting organisations the conditions of their appointment and the requirements for the inspection and certification of vehicles for operation in service.

The scope of this manual is to set out the statutory requirements for all in-service vehicle inspections. No attempt has been made to give details on how to inspect a vehicle, a matter best addressed by training programmes.

Amendments to this manual will be issued from time to time as inspection requirements change and improvements are made. Details of amendments are available from the Amendments tab on the horizontal menu. Suggestions for improvement should be made using the feedback button found on every page.

2 Overview of the manual

How is the manual structured?

The manual is divided into ten vehicle-type sections plus technical bulletins and this introduction.

What information is in each part of the manual?

1. Introduction

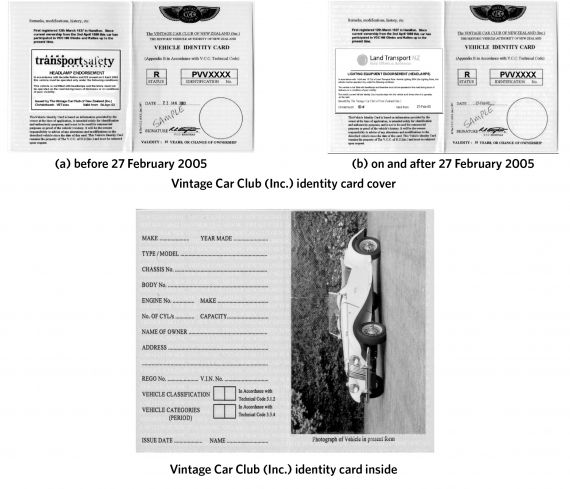

The introduction is relevant to all vehicles requiring in-service inspection and certification (WoF and CoF). It explains the duties and responsibilities of the inspecting organisation and vehicle inspector, the inspection and certification process, complaints procedures, inspection premises and equipment, and the appointment of vehicle inspectors and inspecting organisations. It also includes definitions and abbreviations, and sample certification documents. Improvement suggestions can be made by clicking the 'Send us your feedback' button found on every page.

2. General vehicles (WoF)

This section contains the WoF inspection requirements for light vehicles of classes LE that do not have motorcycle controls, MA, MB, MC, MD1 and NA.

Many of these requirements are general requirements applicable to other types and classes of vehicles. They have been copied into other relevant sections as outlined below.

3. Heavy vehicles (CoF)

This section contains the CoF inspection requirements for heavy vehicles of classes NB and NC. They consist of general requirements applicable to all vehicles and additional or replacement requirements that apply specifically to heavy vehicles.

4. Light PSVs (CoF)

This section contains the CoF inspection requirements for light passenger service vehicles (PSVs) of classes LE that do not have motorcycle controls, MA, MB, MC, MD1 and MD2. They consist of general requirements applicable to all vehicles and additional or replacement requirements that apply specifically to light PSVs.

This section also contains the transport service licence (TSL) requirements for light vehicles of the above classes used in a rental service or vehicle recovery service.

5. Heavy PSVs (CoF)

This section contains the CoF inspection requirements for heavy passenger service vehicles (PSVs) of classes MD3, MD4 and ME, and any NB and NC class vehicles used as PSVs. They consist of general requirements applicable to all vehicles, requirements applicable to all heavy vehicles and additional or replacement requirements that apply specifically to heavy PSVs.

6. Motorcycles (WoF and CoF)

This section covers the WoF and CoF inspection requirements for vehicles of classes LC, LD and LE that have motorcycle controls. For CoF, this section also contains additional requirements for these vehicles used in a passenger service or rental service.

7 General trailers (WoF)

This section covers the WoF inspection requirements for light trailers of classes TA and TB. They consist of general requirements applicable to all trailers.

8. Heavy trailers (CoF)

This section covers the CoF inspection requirements for heavy trailers of classes TC and TD. They consist of general requirements applicable to all trailers and additional or replacement requirements that apply specifically to heavy trailers.

9. Forklifts (WoF)

This section contains the WoF inspection requirements for light and heavy forklifts which must meet WoF requirements as far as practicable for their design and type.

10. Tractors (WoF)

This section contains the WoF inspection requirements for light and heavy tractors and self-propelled machines used in agricultural, land management and roading operations.

11. Unclassified vehicles (WoF)

This section contains the WoF inspection requirements for light and heavy unclassified vehicles which must meet WoF requirements as far as practicable for their design and type. It includes heavy vehicles exempt from CoF, all-terrain vehicles (ATVs) and some trailers. It does not include vehicles already covered in the Forklifts and Tractors sections.

12. Technical bulletins (general)

These contain detailed requirements or helpful information which is not appropriate to put into the vehicle sections of the manual. Examples are processes/requirements for seatbelt replacements and jacking points for correctly checking suspension ball joints. These bulletins cover WoF vehicles and vehicles in general.

13. Technical bulletins (CoF)

These bulletins are similar to the Technical bulletins (general), but cover information specific to vehicles operated on a CoF.

'WoF only’ inspecting organisations

An inspecting organisation appointed to carry out WoF inspections only will only need to view the general vehicle pages, motorcycle pages, general trailer pages, forklift pages, tractor pages, unclassified vehicle pages and technical bulletin (general) pages.

'CoF only' inspecting organisations

An inspecting organisation appointed to carry out CoF inspections only will need to view the pages for motorcycles, heavy vehicles, light PSVs, heavy PSVs, heavy trailers, technical bulletins (general) and technical bulletins (CoF).

Note that some pages will refer to general vehicles or general trailers pages where appropriate.

‘WoF and CoF’ inspecting organisations

An inspecting organisation appointed to carry out WoF and CoF inspections will need to view all the WoF and CoF pages. These are the same pages as for 'WoF only', but with additional pages for heavy vehicles, light PSVs, heavy PSVs, heavy trailers and technical bulletins (CoF).

How to use the manual

WoF inspections

- For a WoF inspection on a car, for example, refer only to the general vehicle pages.

CoF inspections

Many CoF requirements are the same as the WoF requirements and have been copied into the relevant CoF sections. Where requirements differ:

- For a light PSV, refer to the light PSV pages and link to the general vehicle pages if so indicated on the light PSV page

- For a heavy truck, refer to the heavy vehicle pages and link to the general vehicle pages if so indicated on the heavy vehicle page

- For a heavy PSV, refer to the heavy PSV pages and link to the heavy vehicle pages and/or the general vehicle pages if so indicated on the heavy PSV page.

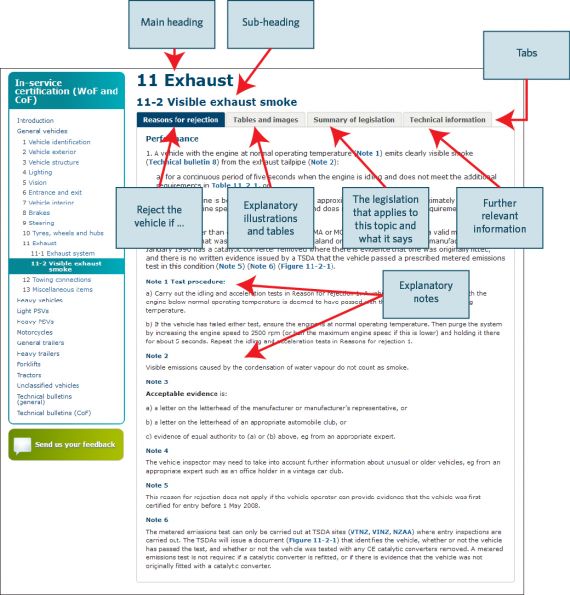

Layout of manual pages

For each vehicle component, the inspection requirement pages are generally divided into two tabs, one for reasons for rejection, the other for summary of legislation. These tabs list the requirements under ‘mandatory equipment’, ‘permitted equipment’, ‘condition’, ‘performance’ and ‘modifications’ (and ‘repairs’ for heavy vehicles on a CoF).

The Reasons for rejection column specifies the vehicle defects that must result in the vehicle being rejected for a WoF or CoF. The condition and performance reasons for rejection apply to mandatory, permitted, and modified equipment, unless otherwise stated. NZTA has imposed these requirements in accordance with Land Transport Rule: Vehicle Standards Compliance 2002, section 2.3(1). This column also contains notes for additional guidance, as referred to in the two columns.

The Summary of legislation column summarises the legislation that is relevant to in-service inspection and certification.

Many vehicle components have an additional one or two tabs:

- Tables and images contain tables and illustrations referred to in the Reasons for rejection and Summary of legislation tabs.

- Technical information contains additional relevant information that is not part of the manual, but which may be useful information, such as NZTA pamphlets.

The figure below illustrates the typical layout of pages in the manual. Greater detail is given in the Vehicle inspection portal user guide.

Page amended 1 November 2014 (see amendment details).

3 Inspection and certification process

Overview – steps in the inspection and certification process

In order to inspect and certify a vehicle for a WoF or CoF the vehicle inspector and inspecting organisation must take the following steps:

1. Know the vehicle inspector’s and inspecting organisation’s responsibilities.

The legal responsibilities are listed in section 3.1. The vehicle inspector and inspecting organisation must read these and understand them.

2. Identify the vehicle class.

A table of vehicle classes is given in section section 3.2.

3. Identify whether the vehicle requires a WoF or CoF inspection.

Section 3.3 shows a list of vehicles that require a WoF, a list of vehicles that require a CoF and a list of vehicles that do not require a WoF or CoF.

4. Establish whether the vehicle may be inspected for the purposes of issuing a WoF or a CoF.

The vehicle must meet a number of criteria before inspection. These are listed in section 3.4.

5. Establish whether the vehicle complies.

Section 3.5 explains how to use this manual in order to determine the vehicle’s compliance with the requirements.

6. Complete the inspection documentation (checksheet).

Section 3.6 explains the requirements for handling and completing checksheets.

7. Record the inspection outcome (‘determination’).

Section 3.7 explains how to record WoF and CoF inspection results into the NZTA computer system (WoF Online and LATIS).

8. Issue the WoF label, CoF label, or temporary permit.

Section 3.8 explains the requirements when issuing the WoF label, CoF label, or temporary permit and attaching it to the vehicle.

9. Collect fees.

Section 3.9 lists the requirements for the inspecting organisation when charging and collecting fees.

3.10 Operating a vehicle without a current WoF or CoF.

Section 3.10 explains the vehicle operator’s responsibilities when operating a vehicle without a current WoF or CoF.

3-1 Duties and responsibilities

3.1.1 General duties and responsibilities

Applicable legislation: Vehicle Standards Compliance Rule 2002 (the Rule).

1. Vehicle inspectors and inspecting organisations [Definitions in the Rule]

Vehicle inspector means an individual appointed by Waka Kotahi under 2.2(1) of the Rule to carry out inspection and certification activities in accordance with requirements and conditions imposed by Waka Kotahi.

Inspecting organisation means a person or organisation appointed by Waka Kotahi under 2.2(1) who is responsible for inspection and certification outcomes.

2. Inspection and certification activities [section 2.1(1) of the Rule]

Only vehicle inspectors and inspecting organisations appointed by Waka Kotahi may carry out inspection and certification activities as specified in the Land Transport Rule: Vehicle Standards Compliance 2002.

3. Primary duty [section 2.1(2) of the Rule]

Vehicle inspectors and inspecting organisations must carry out inspection and certification activities competently and diligently and in accordance with the Land Transport Rule: Vehicle Standards Compliance 2002, this manual, the Notice of appointment and the Code of conduct.

4. Inspection and certification activities that can be carried out [section 2.2(2) of the Rule]

Vehicle inspectors and inspecting organisations may carry out only those inspection and certification activities for which Waka Kotahi has appointed them.

5. Requirements, conditions, and period of appointment [section 2.3(1) of the Rule]

Waka Kotahi may specify the period of appointment for a vehicle inspector and inspecting organisation and may impose requirements and conditions as to the performance of the inspection and certification activities, including the performance of those activities at individual sites. This manual contains the requirements and conditions imposed by Waka Kotahi.

6. Driver licence

Vehicle inspectors must hold a current driver licence for the vehicles that they are inspecting.

7. Fit and proper person [section 2.3(3) of the Rule]

It is a condition of an appointment that a vehicle inspector or inspecting organisation continues to be fit and proper.

For further information about what it means to be a fit and proper person, refer to the Transport Agency's Fit and proper person guidelines.

8. Presentation and acceptance of emailed Inspection and certification documents

LT400s, chassis ratings and professional opinions from heavy vehicle specialist certifiers and chassis ratings from Waka Kotahi can be presented and accepted using email provided:

(i) emails are sent directly to the vehicle inspector or inspecting organisation from the heavy vehicle specialist certifier or Waka Kotahi, and

(ii) the electronic copy contains all of the information from the original copy and is clear and legible.

These may be:

|

9. Document retention, Advise incorrect certification, Advise vehicle defects [section 2.3(4) of the Rule]

It is a condition of an appointment that a vehicle inspector or inspecting organisation:

a) keeps all records and associated documents relating to vehicle inspections and certifications (including failed inspections) for a minimum period of 12 months (LT400s and other HVS/engineer certificates indefinitely), and

These may be:

|

b) advises Waka Kotahi as soon as practicable if there is a reason to believe that the inspection and certification of a vehicle has been carried out incorrectly, and

c) advises Waka Kotahi as soon as practicable of a defect in a manufacturer’s production run or quality control process of which the inspector or organisation has become aware that may affect the safety performance of a vehicle that has been inspected and certified.

10. Delegation [section 2.4(1) of the Rule]

A vehicle inspector or inspecting organisation may not delegate any function or power to carry out inspection and certification activities for which they were appointed, except under conditions specified by Waka Kotahi in writing.

11. Additional duties and responsibilities of inspecting organisations under the quality management system (QMS) and the Notice of appointment

In addition to requirements specified elsewhere in this manual, an inspecting organisation must comply with the requirements of their QMS and Notice of appointment, including the following:

a) advise Waka Kotahi as soon as possible when a vehicle inspector leaves or joins an inspecting organisation or moves to another site (Notification of vehicle inspector transfer)

b) manage actual, potential and perceived conflicts of interest (refer to Information for inspecting organisations)

c) report the loss or theft of controlled documents to the NZ Police and Waka Kotahi as soon as possible (Notification of lost or stolen controlled documents)

d) comply with any NZTA requirements relating to IT systems, including protecting access to the Waka Kotahi computer system from unauthorised persons

e) carry out regular internal performance assessments (at least once a year)

f) inspect and certify vehicles only at authorised sites unless otherwise permitted

g) responsible for maintaining technical and administrative competence of vehicle inspectors and other persons carrying out vehicle inspection and certification work

h) responsible for ensuring vehicle inspectors continue to abide by the Code of Conduct.

3.1.2 Inspection and certification

1. Inspection and certification of vehicles for operation in service [section 7.3(3) of the Rule]

The inspection and certification of a vehicle for operation in service must be carried out in accordance with requirements and conditions imposed by Waka Kotahi.

2. Determining compliance of a vehicle [section 7.4(1) of the Rule]

A vehicle is certified for in-service based on the condition of the vehicle at the time of the inspection.

A vehicle may be certified for operation in-service only if a vehicle inspector or inspecting organisation has identified the vehicle and has determined, on reasonable grounds, that the vehicle meets all of the following:

a) it is safe to be operated under normal conditions of use, and

b) it has been designed and constructed using components and materials that are fit for their purpose, and is within safe tolerance of its state when manufactured or modified, and

c) it complies with the applicable requirements (all of which are contained within this manual), and

d) it has undergone specialist inspection and certification as required by paragraphs 4, 5, and 6 below and the specific aspects of the vehicle have been certified.

3. Information to take into account when determining compliance of a vehicle [section 7.4(3) of the Rule]

A vehicle inspector or inspecting organisation, in making a determination, must take into account:

a) information obtained from inspecting the vehicle and associated documents, and

b) additional relevant information, if any, about the vehicle issued by a manufacturer, modifier, repairer, or other relevant person of which the inspector or organisation is aware.

4. Low volume vehicle specialist certification [section 7.5(1)(a) of the Rule]

Low volume vehicle (LVV) specialist inspection and certification is required prior to inspection and certification for in-service, if the vehicle is a light vehicle that, since it was last certified for operation in-service or last certified as a low volume vehicle, has been modified so as to affect its compliance with an applicable requirement (Note 1).

5. Heavy vehicle specialist certification [section 7.5(1)(b) of the Rule]

Heavy vehicle specialist (HVS) inspection and certification is required prior to inspection and certification for in service, if the vehicle is a heavy vehicle that, since it was last certified for operation in service or last certified for modification, has been modified so as to affect its compliance with an applicable requirement, including modifications to its chassis, brakes, log bolster attachments, towing connections or load anchorages.

6. Other specialist certification [section 7.5(1)(c) of the Rule]

Other specialist inspection and certification is required in accordance with an applicable requirement or as required by Waka Kotahi, all of which are contained within this manual.

7. Modified vehicles not requiring specialist certification [section 7.5(3) of the Rule]

Low volume vehicle (LVV) specialist inspection and certification or heavy vehicle specialist (HVS) inspection and certification is not required if a modified vehicle is:

a) excluded in this manual from the requirement for LVV or HVS certification and meets the inspection requirements in this manual, including those for equipment, condition, and performance, or

b) modified for the purposes of law enforcement or the provision of emergency services.

Note that this only covers the modifications for the specialised functions of the vehicle. Other modifications that affect compliance are subject to certification.

Note 1

Modifications not requiring LVV certification

All modifications must meet WoF or CoF requirements. However, not every modification requires LVV certification.

A modified light vehicle may or may not be required to undergo LVV certification, depending on the level of modification. Typical modifications that are made to vehicle components and systems are listed in tables, and identify:

a) those modifications that do not require LVV certification unless they exceed a certain level. Where modifications exceed those listed in the table, a WoF or CoF provider must not issue a WoF or CoF for the vehicle until LVV certification has been issued

b) those modifications that have been certified to an accepted overseas system as shown in Technical bulletin 13

c) those lower levels of modification that are never required to be LVV certified.

For most modifications, the introduction date for the requirement for LVV certification is 1 March 1999, which was the date that the Compliance Rule came into force. In addition, LVV certification was required for some items under the Transport (Vehicle Standards) Regulations 1990. In particular LVV certification is required for:

a) a modification after 1 January 1992 that affected compliance with a brake standard on a class MA vehicle, or after 1 January 1993 on a vehicle of class MB, MC or NA.

b) a modification after 1 January 1992 that affected a seatbelt anchorage standard on a passenger vehicle with up to nine seats, that is class MA, MB or MC.

c) a modification after 1 January 1992 that affected compliance with a standard for door locks and hinges, steering column impact or interior impact on a class MA vehicle.

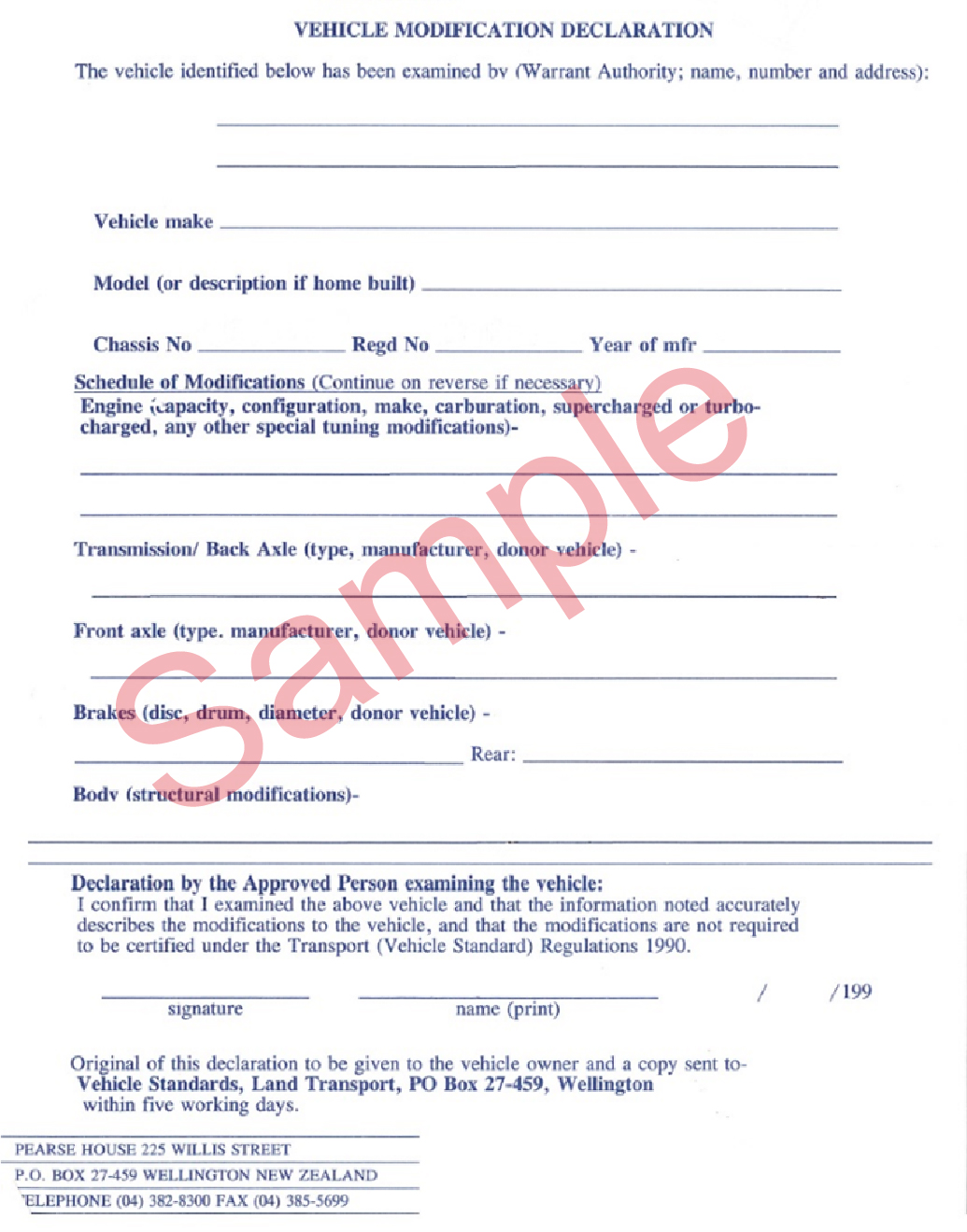

If a modification was carried out prior to LVV certification coming into force, a valid modification declaration must be produced. The vehicle inspector may also accept other authentic evidence to verify that the modifications were carried out prior to LVV certification coming into force. Examples are an invoice from the company that carried out the modification, insurance policy cover notes and motoring magazine features provided they record the vehicle’s registration number or VIN, the modification details and a date or other information verifying when the modifications were carried out. Documents such as statements from previous owners are not acceptable.

Where the information on the modification declaration (other than the plate number) differs from the vehicle, the vehicle must be failed and sent to an appropriate LVV certifier. For example, if the vehicle has been further modified or the declaration date is incorrect for the vehicle or the modifications. See sample modification declaration for information on modification declarations).

Note 2

Confirming LVV certification

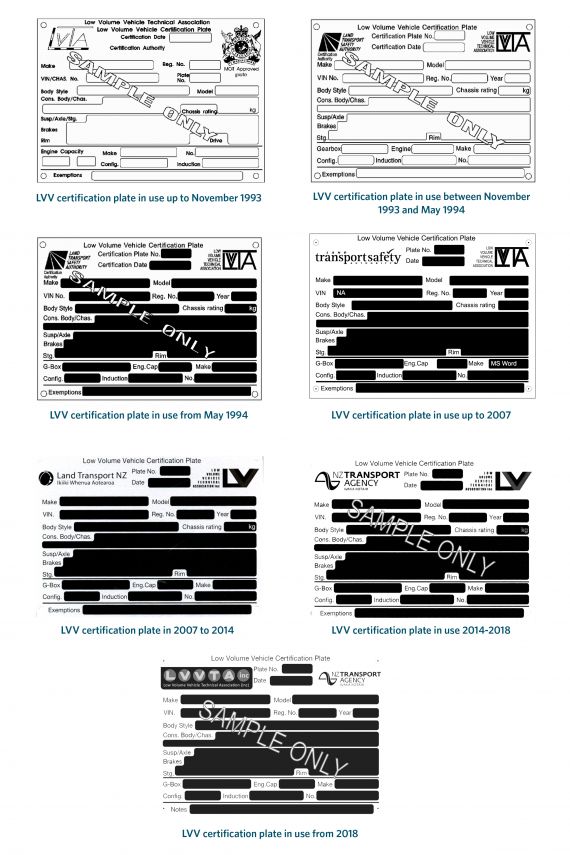

Modifications can be confirmed as certified under the LVV Code by the following means:

a) LVV certification plate riveted and glued to the vehicle in any one of the following positions:

i. within the engine compartment in a clearly visible position, or

ii. where there is insufficient available space within the engine compartment to enable the LVV certification plate to be fitted and remain clearly visible, in any one of the following locations:

(1) within the passenger compartment on the vehicle’s A-pillar or B-pillar, or

(2) in the case of a sedan, on the rear bulkhead or other prominent position within the boot area, or

(3) in the case of a van with an engine cover in the passenger compartment, on a non-removable panel steel part of the engine cover or seat frame, or

(4) in the case of a vehicle with a raised floor, on the vertical area of a step behind a door, or

(5) in the case of a hatchback or station wagon, in the spare wheel well which is accessible without the use of tools.

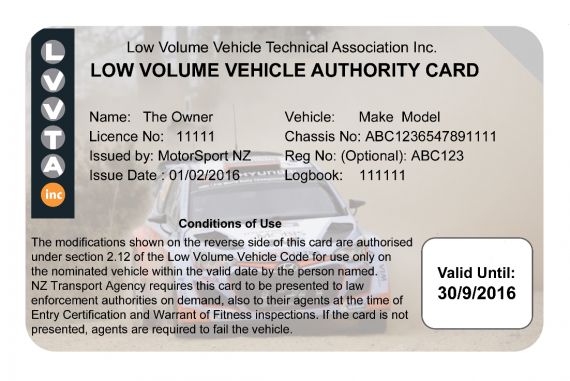

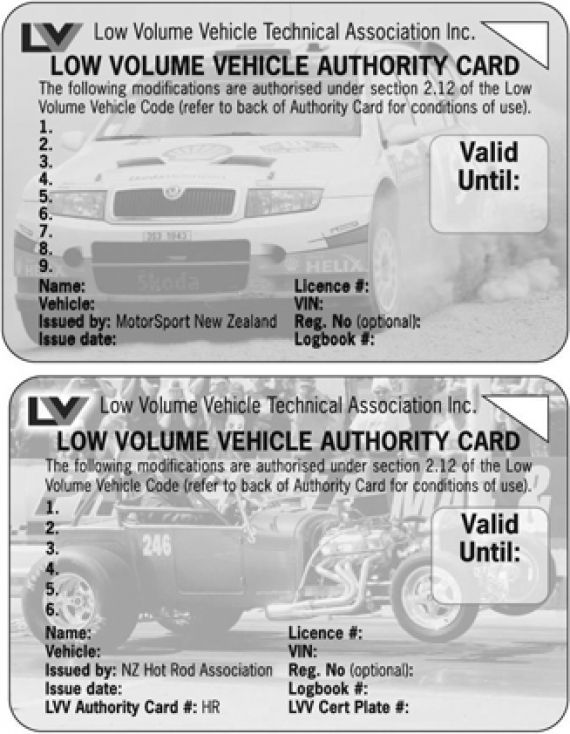

b) LVV authority card, linking listed vehicle modifications to the special requirements of one person.

All enquiries about the LVV process, LVV certifier locations and the issuing of LVV certification plates should be directed to Waka Kotahi (0800 587 287) or LVVTA (04 238 4343) .

Note 3

Information on LVV plate differs from the vehicle

Where the information on the LVV plate (other than the vehicle’s registration plate or due to the temporary removal of seats) differs from the vehicle, for example where a vehicle has been further modified or returned to original, the vehicle must be failed and sent to an appropriate LVV certifier:

a) where the vehicle has been further modified or partially returned to the original condition, the LVV certifier will inspect and certify the vehicle to ensure the correct details are on the new LVV plate, or

b) where the vehicle has been fully returned to original, the LVV certifier will confirm that this has been done and remove the LVV plate from the vehicle (only an LVV certifier or delegated Waka Kotahi staff can remove an LVV plate).

3.1.3 Revocation of a WoF, CoF, temporary permit, CoL, or record of determination

1. Revocation of evidence of vehicle inspection and conditional permit [section 11.3(1) of the Rule]

Waka Kotahi may revoke, by giving written notice to a vehicle’s operator, a WoF, CoF, conditional permit or a record of determination issued under the Land Transport Rule: Vehicle Standards Compliance 2002 if Waka Kotahi believes, on reasonable grounds, that:

a) the vehicle does not comply with applicable requirements, or

b) the WoF, CoF, permit or record of determination was issued on the basis of an incorrect determination.

2. Revocation of certificate of loading [section 11.3(2) of the Rule]

The NZTA may revoke, by giving written notice to a vehicle’s operator, a certificate of loading issued for that vehicle under the Land Transport Rule: Vehicle Standards Compliance 2002 if Waka Kotahi believes, on reasonable grounds, that the certificate is not valid.

3. Re-inspection and re-certification of a vehicle [section 11.4 of the Rule]

If a WoF, CoF, conditional permit, record of determination or certificate of loading has been revoked, Waka Kotahi may require in writing that a vehicle inspector or inspecting organisation:

a) repeat the inspection and certification of the vehicle, and

b) issue, if appropriate, a WoF, CoF, permit, record of determination or other evidence, and

c) meet the costs of the activities undertaken under (a) and (b).

3.1.4 Vehicles ordered off the road (green and pink stickers) [Land Transport Act 1998: section 115 and section 96]

A green sticker, which directs that the vehicle is not to be driven on a road, may be issued to the driver or owner of a vehicle by an enforcement officer who believes on reasonable grounds that a vehicle does not comply with the provisions of the regulations or rules, or that a vehicle was operated with unnecessary exhibition of speed or acceleration or sustained loss of traction. At the discretion of the enforcement officer, the green sticker notice will remain in force until:

a) the vehicle has been inspected and a new WoF or CoF has been issued, or

b) the enforcement officer has been notified in writing that the vehicle is now compliant (this type of green sticker is often referred to as ‘discretionary green sticker’ or ‘G2 sticker’). A new WoF or CoF is not required, however, instead of notifying the enforcement officer in writing, the vehicle driver/owner may choose to obtain a new WoF or CoF, which will automatically remove the flag from the NZ Police system.

A pink sticker, which directs that the vehicle is not to be driven on a road, may be issued to the driver or owner of a vehicle by an enforcement officer who believes on reasonable grounds that a vehicle is not in a safe condition to be driven on a road. A pink sticker will remain in force until the vehicle has been inspected and a new WoF or CoF has been issued.

Where a light vehicle has been ordered off the road by an enforcement officer for non-compliant exhaust noise, the vehicle must pass an LVVTA objective noise test before the vehicle may be issued with a new WoF or CoF – even if the vehicle is presented with a quieter or original exhaust system or with a previous LVV noise certification. Due to this requirement, for each green- or pink-stickered light vehicle presented for WoF or CoF and before issuing a new WoF or CoF, the vehicle inspector must check (usually by sighting the ordering-off-the-road notice or Landata):

a) whether the vehicle was ordered off the road for non-compliant exhaust noise, and

b) if (a) applies, that a valid LVVTA objective exhaust noise emissions test certificate was issued for the vehicle after the date the ordering off the road notice was issued.

A vehicle that has been green or pink stickered can only be inspected by a vehicle inspector who is employed with an inspecting organisation that does not engage in the repair of vehicles in the course of their business (other than replacing bulbs or wiper blades). This generally includes VTNZ, VINZ, NZAA and some independent testing stations. A new WoF or CoF must be issued by the inspecting organisation before the vehicle is permitted to be used on the road. Once the new WoF or CoF has been issued, the vehicle inspector removes the green or pink sticker. The flag is automatically removed from the NZ Police system.

3.1.5 Performance review

1. The NZTA may monitor and review performance [section 3.1(1) of the Rule]

The NZTA may monitor and review the performance of a vehicle inspector or inspecting organisation in complying with the requirements and conditions imposed by Waka Kotahi, including the performance of inspection and certification activities at individual sites.

The requirements and conditions are contained in this manual, the Notice of appointment and the Transport Agency’s Quality Management System (QMS) requirements.

2. Providing information to the Waka Kotahi [section 3.1(2) & (3) of the Rule]

In monitoring and reviewing performance, Waka Kotahi may require a vehicle inspector or inspecting organisation to undergo such monitoring and review and provide such information as Waka Kotahi reasonably considers relevant. A vehicle inspector or inspecting organisation must comply with a requirement from Waka Kotahi.

3. Costs of monitoring and review [section 3.1(4) of the Rule]

A vehicle inspector or inspecting organisation must bear the costs of the monitoring and reviewing of their performance in accordance with any prescribed fee.

Any non-payment of the required fees may result in suspension of the appointment until full payment is received.

3.1.6 Investigations

1. Investigations [section 3.2(1) of the Rule]

If Waka Kotahi has reason to believe that a vehicle inspector or inspecting organisation has failed to comply with any of the conditions of their appointment (including the Notice of appointment and Code of conduct), or has failed to comply with the Land Transport Rule: Vehicle Standards Compliance 2002 (the Rule) or with this manual, Waka Kotahi may require the inspector or organisation to undergo such an investigation and to provide such information as Waka Kotahi reasonably considers appropriate.

2. Notification of action (suspension or revocation, but not immediate suspension or imposition of conditions) [section 3.2(3) of the Rule]

Following an investigation and before carrying out action, Waka Kotahi must notify the vehicle inspector or inspecting organisation in writing of:

a) the action that is being considered, and

b) the reasons for the action that is being considered, and

c) the date by which submissions may be made to Waka Kotahi in respect of the action that is being considered, which must be at least 21 days after the notice is given, and

d) where appropriate, the date on which the action that is being considered will take effect, which, unless Waka Kotahi determines otherwise, must be at least 28 days after the notice is given.

3. Responding to a notification of action [section 3.2(5) of the Rule]

If a vehicle inspector or inspecting organisation is notified as above, they must ensure that all information that they wish Waka Kotahi to consider in relation to the action that is being considered is received by Waka Kotahi within the period specified in the notice or within any further period that Waka Kotahi may allow.

4. Waka Kotahi must consider submissions [section 3.2(6) of the Rule]

Waka Kotahi must consider the submissions made and information supplied, and must:

a) decide whether or not to take the action that is being considered, and

b) as soon as is practicable, provide written notification to the vehicle inspector or inspecting organisation of:

i. the Waka Kotahi decision, and

ii. if appropriate, the date on which the action is to take effect, and

iii. if appropriate, the right of appeal under section 106 of the Land Transport Act 1998.

5. Remedial action, suspension, revocation [section 3.2(2) of the Rule]

If, following an investigation, Waka Kotahi is satisfied that the vehicle inspector or inspecting organisation has failed to comply with any of the conditions of their appointment (including the Notice of appointment and Code of conduct), or failed to comply with the Rule or this manual, Waka Kotahi may do one or more of the following:

a) require that remedial action, such as training, be undertaken by the inspector or organisation

b) suspend the whole or any part of the appointment of the inspector or organisation for a specified period or until specified conditions are met

c) revoke the whole or any part of the appointment of the inspector or organisation.

6. Immediate suspension or imposing of conditions [section 3.3(1) of the Rule]

If Waka Kotahi has reason to believe that a vehicle inspector or inspecting organisation has failed to comply with a condition of their appointment (including the Notice of appointment and Code of conduct) or with the Rule or this manual, and that this presents a significant risk to land transport safety, Waka Kotahi may suspend, with immediate effect, the whole or any part of the appointment, or impose any conditions on the appointment.

7. Notification of immediate suspension or imposing of conditions [section 3.3(2) of the Rule]

Where Waka Kotahi suspends the whole or any part of an appointment, or imposes conditions on the appointment, Waka Kotahi must notify the vehicle inspector or inspecting organisation in writing of:

a) the grounds for the suspension or imposing of conditions

b) the fact that the inspector or organisation may make submissions to Waka Kotahi

c) the right of appeal under section 106 of the Land Transport Act 1998.

8. Waka Kotahi must consider submissions following immediate suspension or imposition of conditions [section 3.3(3) of the Rule]

Waka Kotahi must, as soon as is practicable, consider any submission made and notify the inspector or inspecting organisation in writing of the result of any such consideration.

9. Duration of immediate suspension or imposing of conditions [section 3.3(5) of the Rule]

A suspension or condition imposed remains in force until Waka Kotahi has determined the action to be taken and that action has been taken.

10. Withdrawal of immediate suspension or imposing of conditions [section 3.3(4) of the Rule]

Waka Kotahi may at any time withdraw a suspension or condition imposed.

11. Right of appeal [section 3.3(6) of the Rule]

A vehicle inspector or inspecting organisation may appeal under section 106 of the Land Transport Act 1998 against a decision by Waka Kotahi to immediately suspend or impose conditions.

12. Costs of investigations [section 3.2(7) of the Rule]

Waka Kotahi may require a vehicle inspector or inspecting organisation to bear the costs associated with an investigation or remedial action in accordance with any prescribed fee.

13. Obligation to comply [section 3.2(8) of the Rule]

A vehicle inspector or inspecting organisation must comply with a requirement of Waka Kotahi in relation to paragraphs 1, 5, and 12.

Page amended 1 April 2023 (see amendment details).

3-2 Identifying the vehicle class

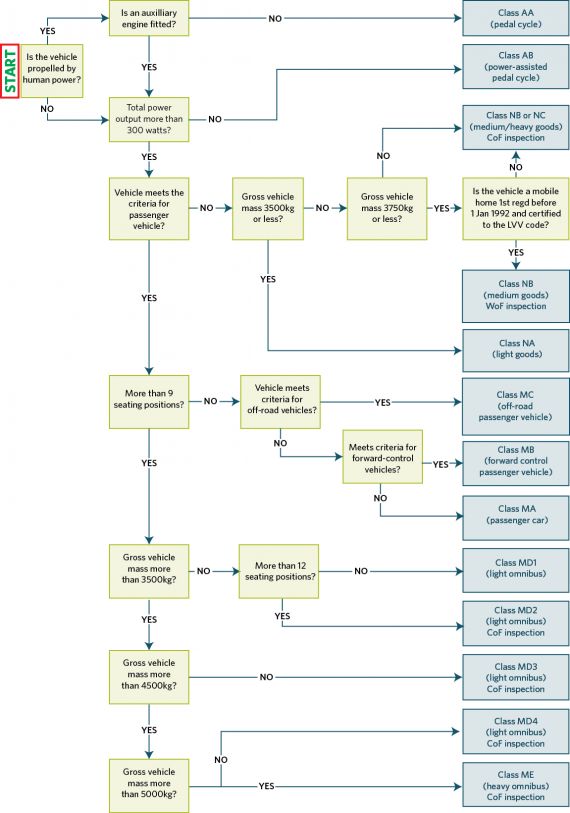

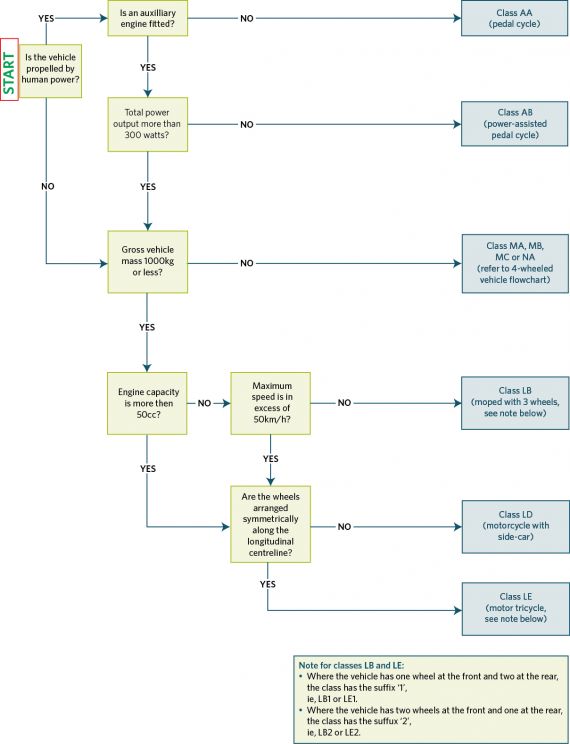

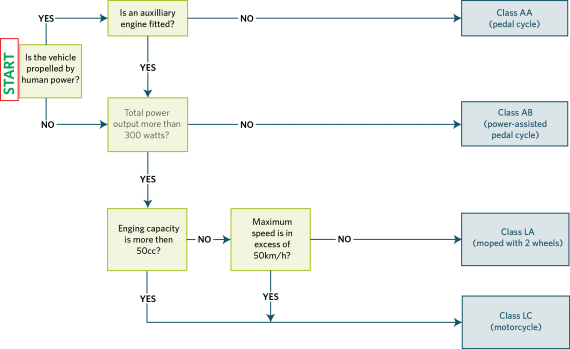

The table of vehicle classes - Table 3-2-1, and the charts in Figure 3-2-1 (four-wheeled vehicles), Figure 3-2-2 (three-wheeled vehicles), Figure 3-2-3 (two-wheeled vehicles) and Figure 3-2-4 (trailers) identify the class of the vehicle that is to be inspected.

Confirm that the vehicle inspector and inspecting organisation have been appointed by the NZTA for the purpose of inspecting and certifying vehicles for a WoF or CoF specific to the class of vehicle that has been presented.

Table 3-2-1. Vehicle equipment standards classifications

| Class | Description |

|---|---|

| AA (Pedal cycle) | A vehicle designed to be propelled through a mechanism solely by human power. |

| AB (Power-assisted pedal cycle) | A pedal cycle to which is attached one or more auxiliary propulsion motors having a combined maximum power output not exceeding 300 watts. For further information visit the Transport Agency website's Low powered vehicles page. |

| LA (Moped with two wheels)* | A motor vehicle (other than a power-assisted pedal cycle) that:

|

| LB (Moped with three wheels) | A motor vehicle (other than a power-assisted pedal cycle) that:

An LB 1 motor vehicle has one wheel at the front and two wheels at the rear. An LB 2 motor vehicle has two wheels at the front and one wheel at the rear. |

| LC (Motorcycle) | A motor vehicle that:

|

| LD (Motorcycle and side-car) | A motor vehicle that:

|

| Side-car | A car, box or other receptacle attached to the side of a motorcycle and supported by a wheel. |

| LE (Motor tri-cycle) | A motor vehicle that:

An LE 1 motor vehicle has one wheel at the front and two wheels at the rear. An LE 2 motor vehicle has two wheels at the front and one wheel at the rear. |

| Passenger vehicle | A motor vehicle that:

|

| MA (Passenger car) | A passenger vehicle (other than a class MB or class MC vehicle) that has not more than nine seating positions (including the driver's seating position). |

| MB (Forward control passenger vehicle) | A passenger vehicle (other than a class MC vehicle):

|

| MC (Off-road passenger vehicle) | A passenger vehicle, designed with special features for off-road operation, that has not more than nine seating positions (including the driver's seating position), and that:

|

| Omnibus | A passenger vehicle that has more than nine seating positions (including the driver's seating position). An omnibus comprising two or more non-separable but articulated units shall be considered as a single vehicle. |

| MD (Light omnibus) | An omnibus that has a gross vehicle mass not exceeding 5 tonnes. |

| MD 1 | An omnibus that has a gross vehicle mass not exceeding 3.5 tonnes and not more than 12 seats. |

| MD 2 | An omnibus that has a gross vehicle mass not exceeding 3.5 tonnes and more than 12 seats. |

| MD 3 | An omnibus that has a gross vehicle mass exceeding 3.5 tonnes but not exceeding 4.5 tonnes. |

| MD 4 | An omnibus that has a gross vehicle mass exceeding 4.5 tonnes but not exceeding 5 tonnes. |

| ME (Heavy omnibus) | An omnibus that has a gross vehicle mass exceeding 5 tonnes. |

| Goods vehicle | A motor vehicle that:

|

For the purpose of this description:

| |

| NA (Light goods vehicle) | A goods vehicle that has a gross vehicle mass not exceeding 3.5 tonnes. |

| NB (Medium goods vehicle) | A goods vehicle that has a gross vehicle mass exceeding 3.5 tonnes but not exceeding 12 tonnes. |

| NC (Heavy goods vehicle) | A goods vehicle that has a gross vehicle mass exceeding 12 tonnes. |

| Trailer | A vehicle without motive power that is constructed for the purpose of being drawn behind a motor vehicle. |

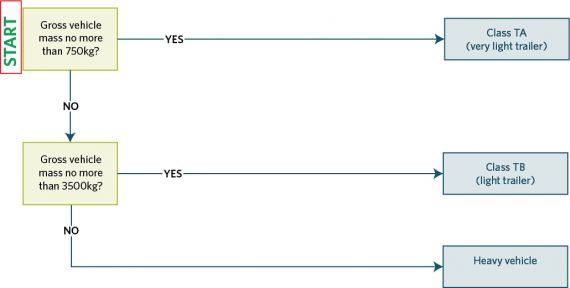

| TA (Very light trailer) | A single-axled trailer that has a gross vehicle mass not exceeding 0.75 tonnes. |

| TB (Light trailer) | A trailer (other than a class TA trailer) that has a gross vehicle mass not exceeding 3.5 tonnes. |

| TC (Medium trailer) | A trailer that has a gross vehicle mass exceeding 3.5 tonnes but not exceeding 10 tonnes. |

| TD (Heavy trailer) | A trailer that has a gross vehicle mass exceeding 10 tonnes. |

Figure 3-2-1. Vehicle class logic chart – four-wheeled vehicles

Figure 3-2-2. Vehicle class logic chart – three-wheeled vehicles

Figure 3-2-3. Vehicle class logic chart – two-wheeled vehicles

3-2-4. Vehicle class logic chart – trailers

- Download 3-2-4. Vehicle class logic chart – trailers (PDF | 309KB)

3-3 Establishing whether the vehicle requires a WoF or CoF

The lists below show the type of inspection and certification (WoF or CoF) that is required for the different types of vehicles.

3.3.1 Certificate of Fitness (CoF) (Note 1)

A CoF is required for the following vehicles:

- Heavy vehicles, other than those listed under WoF below.

- Passenger service vehicles (including MD2 vehicles), other than those listed under WoF below.

- Rental service vehicles (except light rental trailers – these only require a WoF).

- Vehicle recovery service vehicles.

3.3.2 Warrant of Fitness (WoF)

A WoF is required for the following vehicles:

1. Vehicles that are not listed under certificate of fitness (section 3.3.1) or that are not listed as a vehicle not requiring a WoF or CoF (section 3.3.3).

2. Tractors (other than agricultural tractors), or machines used solely in non-agricultural, land management or roading operations, whether for traction or otherwise, that are operated at a speed exceeding 30km/h.

3. Class MA, MB or MC vehicles that, in the carriage of passengers for hire or reward:

a) are used solely for transporting not more than seven schoolchildren, and

b) do not exceed the designed adult passenger capacity of the vehicle by more than two schoolchildren.

4. Vehicles that are lawfully affixed with and operated under the authority of trade plates.

5. Vehicles used by the New Zealand Defence Force that are being used to convey persons who would otherwise use public transport during a period in which any public transport in New Zealand is suspended.

6. Motor caravans that:

a) have an original manufacturer’s rating of 3750kg or less, and

b) were registered in New Zealand as motor caravans before 1 January 1992.

7. Vehicles that are used on a public highway only in connection with the inspection, servicing or repair of the vehicle or for the purpose of allowing any person to sit a practical driving test in that vehicle.

8. Vehicles used on roads only in road construction zones in accordance with notices declaring those zones.

9. Vehicles that are used on a road only when crossing or proceeding along a section of the road where the vehicles have been authorised to operate by an authorisation of a road-controlling authority that requires:

a) a written agreement by the vehicle’s operator or the person for whom the vehicle is being operated, to construct, reconstruct, maintain or restore to the satisfaction of the road-controlling authority all or part of the road used by the vehicle, and

b) the erection and maintenance of warning devices, signs or control devices as required by the road-controlling authority and the NZTA, and

c) where the use of the road does not consist solely of the direct crossing of the road, the prior approval of the NZTA.

10. Light rental trailers.

11. Motor vehicles designed exclusively or principally as part of the armament of the New Zealand Defence Force.

12. The vehicles listed in the table below - these vehicles require a WoF only as far as is practicable for their design or type:

|

a) vehicles propelled and supported solely by self-laying tracks |

|

b) motor vehicles exclusively designed and used on a road for driving, carrying or propelling any of the following, which must be permanently attached to the vehicle: i. aerodrome runway sweepers ii. electrical substations iii. filters for transformer oil iv. log haulers that are stationary when hauling logs v. aeroengine test benches |

|

c) tractors owned by a local authority and used exclusively for the construction, maintenance or mowing of stopbanks and the banks of rivers, streams, drains, canals or other watercourses |

|

d) mobile or movable huts, galleys or similar vehicles that are used on a road solely in connection with the construction or maintenance of roads |

|

e) tractors used exclusively for shunting railway rolling stock |

|

f) forklifts |

|

g) aerodrome crash fire tenders that are used on a road only in emergencies |

|

h) trailers while being drawn by a vehicle as stated in (b) to (g) above |

|

i) motor vehicles used exclusively in connection with the embarking and disembarking of ships’ passengers or for loading and unloading ships’ mails, cargo and passengers’ baggage, and used on a public highway only when proceeding unladen from one wharf to another wharf or from their usual place of storage to a wharf and returning to that place of storage |

|

j) cable jinkers |

|

k) front-end loaders |

|

l) log skidders |

|

m) tractor cranes |

|

n) rough-terrain cranes |

|

o) mobile crushing and screening plant machines which are mounted on trailers |

|

p) motor graders |

|

q) motor scrapers |

|

r) trailer scrapers |

|

s) plant for servicing oil-filled cables |

|

t) post debarkers |

|

u) saw bench apparatus |

|

v) forestry chippers (designed and used exclusively in the operation or management of a forest) |

|

w) tree feller bunchers |

|

x) trench diggers and excavators |

|

y) vehicles that are always used unladen on the road and that are designed exclusively for carrying earth or other bulk materials |

|

z) mobile concrete mixers that are mounted on tractors |

|

aa) a vehicle that is similar in design, construction or purpose to a vehicle listed above that cannot be categorised by vehicle class. |

| bb) an agricultural motor vehicle that is operated at a speed exceeding 40km/h. |

| cc) all-terrain vehicles (other than those listed in 3.3.3 Vehicles that do not require a WoF or CoF). |

3.3.3 Vehicles that do not require a WoF or CoF

The vehicles listed in the table below do not require a WoF or CoF:

|

a) a vehicle of class AB, LA or LB |

|

b) an armoured vehicle used exclusively as equipment of the New Zealand Defence Force |

|

c) a traction engine |

|

d) a mechanically propelled roller |

|

e) a crane fitted with self-laying tracks |

|

f) an excavator fitted with self-laying tracks |

|

g) a tractor (other than an agricultural tractor), or a machine used solely in non-agricultural, land management or roading operations, whether for traction or otherwise, that is not operated at a speed exceeding 30km/h, together with any trailer operated only while being towed by that tractor or machine |

|

h) a trailer designed exclusively for agricultural purposes and not operated except when being: i. delivered from a manufacturer to the manufacturer’s agent, or ii. taken to or from an agricultural show for display or demonstration purposes, or iii. delivered from a manufacturer or a manufacturer’s agent to a farm or an agricultural contractor iv. proceeding to or from a farm, or v. when being inspected, serviced or repaired. |

|

i) a vehicle normally propelled by mechanical power while it is being temporarily towed without the use of its own power |

|

j) an all-terrain vehicle used: i. in moving from the operator’s place of residence to a road that is not a public highway, when the distance travelled is less than 3km, or ii. in connection with its inspection, servicing or repair, or iii. as an agricultural vehicle. |

| k) an agricultural motor vehicle that is operated at a speed not exceeding 40km/h. |

Note 1

A vehicle that does not require inspection for regular use still does not need inspection if operated in a transport service (eg rental mopeds).

Page amended 1 November 2015 (see amendment details).

3-4 Establishing whether the vehicle may be inspected for a WoF or CoF

Before a vehicle can be inspected for the purpose of issuing a WoF or CoF, it must meet one of the following requirements:

The vehicle is currently registered

The WoF online or LATIS system will validate this when the inspection is entered.

The vehicle is unregistered but has been certified for entry or re-entry into service within the last two years

The WoF online or LATIS system will validate this when the inspection is entered. The inspection must be entered using the VIN.

The vehicle is unregistered and listed in the table below

These do not require certification for entry or re-entry into service. These will need to be treated as an online transaction.

a) class TA or TB trailers |

b) tractors (other than agricultural tractors) or machines, including trailers, for use solely in non-agricultural, land management or roading operations, whether for traction or otherwise that are operated at a speed exceeding 30km/h |

c) pedestrian-controlled goods service vehicles |

d) vehicles used on roads only in road construction zones in accordance with notices declaring those zones |

e) vehicles that are used on a road only when crossing or proceeding along a section of the road where the vehicles have been authorised to operate by an authorisation of a road-controlling authority that requires: i. a written agreement by the vehicle’s operator or the person for whom the vehicle is being operated, to construct, reconstruct, maintain or restore to the satisfaction of the road-controlling authority all or part of the road used by the vehicle, and ii. the erection and maintenance of warning devices, signs or control devices as required by the road-controlling authority and the NZTA, and iii. where the use of the road does not consist solely of the direct crossing of the road, the prior approval of the NZTA |

f) all-terrain vehicles |

g) motor vehicles exclusively designed and used on a road for driving, carrying or propelling any of the following, which must be permanently attached to the vehicle: i. aerodrome runway sweepers ii. electrical substations iii. filters for transformer oil iv. log haulers that are stationary when hauling logs v. aeroengine test benches |

h) tractors owned by a local authority and used exclusively for the construction, maintenance or mowing of stopbanks and the banks of rivers, streams, drains, canals or other watercourses |

i) mobile or movable huts, galleys or similar vehicles that are used on a road solely in connection with the construction or maintenance of roads |

j) tractors used exclusively for shunting railway rolling stock |

k) forklifts |

l) aerodrome crash fire tenders that are used on a road only in emergencies |

m) trailers while being drawn by a vehicle as stated in (b) to (l) above |

n) motor vehicles used exclusively in connection with the embarking and disembarking of ships’ passengers or for loading and unloading ships’ mails, cargo and passengers’ baggage, and used on a public highway only when proceeding unladen from one wharf to another wharf or from their usual place of storage to a wharf and returning to that place of storage |

o) cable jinkers |

p) front-end loaders |

q) log skidders |

r) tractor cranes |

s) rough-terrain cranes |

t) mobile crushing and screening plant machines which are mounted on trailers |

u) motor graders |

v) motor scrapers |

w) trailer scrapers |

x) plant for servicing oil-filled cables |

y) post debarkers |

z) saw bench apparatus |

aa) forestry chippers |

bb) tree feller bunchers |

cc) trench diggers and excavators |

dd) vehicles that are always used unladen on the road and that are designed exclusively for carrying earth or other bulk materials |

ee) mobile concrete mixers that are mounted on tractors |

ff) a vehicle that is similar in design, construction or purpose to a vehicle listed above that cannot be categorised by vehicle class |

gg) a vehicle that is registered for use on a road in a country other than New Zealand and that is not going to be in New Zealand for a continuous period of more than 18 months. |

| hh) an agricultural motor vehicle. |

Page amended 1 October 2020 (see amendment details).

3-5 Establishing whether the vehicle complies

2. Visually inspect the vehicle to determine whether the vehicle complies with the requirements set out in this manual (see clause 3.1.2.2 of the Introduction). Vehicle inspectors are not required to remove vehicle components during the inspection of the vehicle.

3. The vehicle inspector or inspecting organisation may refuse to inspect a vehicle which:

a) is presented in such a condition that inspection is unreasonably difficult or cannot be completed (components missing, covered in dirt, etc) or

b) has an insecure load.

4. Where the vehicle inspector determines that a Reason for rejection or clause 3.1.2.2 of the Introduction to this manual applies to a vehicle, the vehicle inspector must reject the vehicle for certification.

5. Where the vehicle inspector requires further information in order to determine compliance with the requirements, the inspector must reject the vehicle until the information has been obtained.

6. Where a vehicle has changed use to a passenger service vehicle since it was last certified for entry or in-service (ie the vehicle enters service as a passenger service vehicle), the vehicle inspector must have written confirmation (in the form of a PSV entry checksheet) that the vehicle complies with the PSV requirements in the VIRM: Entry certification before it can pass certificate of fitness inspection.

3-6 Checksheets

Applicable legislation: Land Transport Rule: Vehicle Standards Compliance 2002, section 2.3.

1. A checksheet that has been approved by the NZTA must be used. To get a checksheet approved, see:

- WoF checksheet specifications (PDF | 59KB)

- CoF checksheet specifications (PDF | 69KB).

2. The checksheet must be completed fully and accurately and the writing must be clearly legible on the original and the duplicate page. The vehicle inspector must sign the checksheet once he/she has completed the inspection and determined that the vehicle has either passed or failed the inspection.

3. Where parts of a vehicle are inspected by different people, all those inspecting the vehicle must be vehicle inspectors. The checksheet must record which inspector inspected which part of the vehicle. One vehicle inspector must take overall responsibility for the inspection of the vehicle and that vehicle inspector must sign the checksheet.

4. A vehicle inspector can determine one of two outcomes:

a) Passed inspection: record the ‘determination’ as stated in section 3-7 and issue a WoF label or CoF label or temporary permit

b) Failed inspection: record the ‘determination’ as stated in section 3-7 . The reasons for the failed inspection must be clearly stated on the checksheet.

5. The customer copy (usually the original) of the completed checksheet must be supplied to the vehicle owner or operator. The agent copy (usually the duplicate) is retained by the inspecting organisation.

For information on rechecks and reinspections see 3-11 Rechecks.

Page amended 1 June 2018 (see amendment details).

3-7 Recording the inspection outcome (‘determination’)

Applicable legislation:

Land Transport Rule: Vehicle Standards Compliance 2002, section 7.6

1. The inspection outcome is recorded in either the WoF Online system or the LATIS system.

2. The inspection details must be entered into the system before the vehicle leaves the inspecting organisation’s premises. This ensures that:

a) the vehicle can be relicensed by the vehicle owner

b) the correct inspection frequency can be ascertained

c) any restrictions placed on the vehicle are identified before issuing a WoF or CoF, such as a ban flag or a pink or green sticker

d) any vehicle issued with a 28 day conditional permit must have the fail determination entered into LATIS first, then the 28 day permit must be entered with the fault codes and any conditions imposed. Refer to sections 7.9 and 7.10a.

3. Inspection details entered into the system must be accurate at the time the vehicle was inspected. This includes updating the odometer and hubodometer readings when a vehicle is re-presented for inspection.

4. For vehicles required to operate under a TSL, vehicle inspectors must also collect and record in the system the TSL number for both passed and failed inspections, and when issuing temporary permits.

3.7.1 WoF Online

1. The inspection details must be entered into the WoF Online system on the day of inspection in either:

a) express mode,

b) pass re-check mode (use this where a vehicle is failed, repaired then passes a WoF inspection without leaving the inspecting organisation site. This mode will record a fail and a pass in one transaction), or

c) normal mode.

- Note Inspecting organisations must have the NZTA flow charts that show how to use the WoF Online system (express mode and recheck mode are mandatory; normal mode is optional).

2. Where the inspecting organisation wishes to issue WoFs but is unable to obtain the necessary authorisation numbers from the WoF Online system, several options are available:

a) The NZTA computer system is not working: the vehicle inspector or inspecting organisation must use the checksheet number as the system authorisation number. The OFF-LINE box on the reverse side of the WoF label must be ticked.

b) The inspecting organisation’s computer terminal is not working: the inspecting organisation must contact TRC Agent Help Desk (0800 804 580) who may grant permission for the inspecting organisation to continue to issue off-line WoFs.

c) The WoF Online system goes down during WoF entry: the vehicle inspector needs to ask the customer if they intend to relicense the vehicle in the next 24 hours. If NO, the WoF details should be keyed in as soon as possible. If YES, the vehicle inspector must fax or email a copy of the checksheet directly to the Transport Agency (fax 06 953 6406, email inspections@nzta.govt.nz) with a covering note of explanation. When the system is working again they must check to see if the WoF information is in the system. If not, the vehicle inspector must key the WoF in themselves to minimise any inconvenience to the customer. If it is, they must make a record of the system authorisation number, to cross reference on their copy of the checksheet.

3. To check whether or not a vehicle has a current WoF, select ‘View WoF result’ and enter the vehicle’s registration number. One of three screen displays are possible:

Case 1: |

Screen message: Problem This plate is not attached to a vehicle. If the plate number is incorrect, overtype with the correct plate number and click on the Continue button. If the plate number is correct, advise owner that a plate must be attached before a WoF can be issued. This can be done at an NZTA Plate Agent. The error message means that: The vehicle is not currently registered (never registered, registration cancelled, or registration lapsed because the licence label has been expired for more than 12 months). Action: A WoF must not be issued. The vehicle should be referred to an entry inspecting organisation for entry or re-entry inspection and certification. |

Case 2: |

Screen message: Plate Number: PX8961 Blue 1991 Holden Commodore Exec Saloon Passenger CarVan System Authorisation Number: 81-487 Inspection Date: 08/02/2006 Expires: 6 months AVIC ID: MS62621 The screen message means that: The vehicle is currently registered, licenced and has a current WoF. Action: A new WoF may be issued, or, if necessary, a duplicate WoF may be issued. |

Case 3: |

Screen message: Problem This vehicle does not have a current WoF. The error message means that: The vehicle has a registration plate attached, but the licence label has been expired for less than 12 months, and the WoF has expired. Action: A WoF may be issued. |

Case 4: |

The vehicle is unregistered and presented for inspection operating on trade plates. The vehicle must match the description on either:

|

4. Calculate the WoF expiry date as specified in clause 3.8.1.

3.7.2 LATIS

The procedures for keying inspections into LATIS are given in the LATIS users’ manual.

Page amended 1 October 2023 (see amendment details).

3-8 Issuing the WoF or CoF label - ‘evidence of vehicle inspection’ - or temporary permit

Applicable legislation: Land Transport Rule: Vehicle Standards Compliance 2002, sections 7.9 and 9

3.8.1 Expiry dates

Expiry date of the WoF

The WoF expiry date is calculated from the reference date. The reference dates are:

- For a vehicle with an expired WoF or without a previous WoF: the date the vehicle passes the inspection

- For a vehicle with a current WoF expiring in 14 days or less after the vehicle passes the inspection: the expiry date of the current WoF

- For a vehicle with a current WoF expiring in more than 14 days after the vehicle passes the inspection: the date that is 14 days after the vehicle passes the inspection

- For a vehicle that has been issued with a pink or green sticker (other than a ‘G2’ green sticker) or that has its WoF revoked: the date the vehicle passes the inspection.

The WoF expiry date must be determined as follows:

Vehicle | Date of first registration anywhere or vehicle age | WoF expiry |

|---|---|---|

Light motor vehicle | Never registered anywhere previously and not yet registered in New Zealand | 3 years from reference date |

Any WoF issued within 2 years from date of first registration anywhere | Third anniversary of date of first registration anywhere | |

| First registered anywhere on or after 1/1/2000 (other than a vehicle listed above) | 12 months from reference date | |

First registered anywhere before 1/1/2000 | 6 months from reference date | |

Heavy motor vehicle (CoF exempt) | Never registered anywhere previously | 12 months from reference date |

Less than six years old from date of first registration anywhere | 12 months from reference date | |

Six years or older from date of first registration anywhere | 6 months from reference date | |

Agricultural motor vehicle | Any age | 12 months from reference date |

| Important note: A vehicle’s date of first registration anywhere is generally not available to the WoF inspector. Where it is important to know the exact date to determine the correct expiry date, the vehicle inspector must identify the correct expiry date on Landata or WoF-online BEFORE issuing a WoF label. |

Expiry date of the CoF

The CoF expiry date is calculated from the reference date. The reference dates are:

- For a vehicle with an expired CoF or without a previous CoF: the date the vehicle passes the inspection

- For a vehicle with a current CoF expiring in 28 days or less after the vehicle passes the inspection: the expiry date of the current CoF

- For a vehicle with a current CoF expiring in more than 28 days after the vehicle passes the inspection: the date that is 28 days after the vehicle passes the inspection

- For a vehicle that has been issued with a pink or green sticker (other than a ‘G2’ green sticker) or that has its CoF or temporary permit revoked: the date the vehicle passes the inspection.

The CoF expiry date must be either:

a) six months from the reference date, or

b) between three and 12 months from the reference date (for vehicles for which NZTA have specified an alternative CoF expiry date), or

c) for a class MA rental vehicle that was new when it was first registered in New Zealand as a rental service vehicle:

i. 12 months from the date the vehicle passes its first CoF inspection, then

ii. six months from the reference date for any subsequent CoF inspections.

| Important note: As a vehicle may be on a CoF frequency other than six months, the vehicle inspector must identify the correct expiry date BEFORE issuing a CoF label. |

Expiry date of a temporary permit (CoF vehicles only)

The expiry date is 28 days after the date of issue of the permit.

When a WoF, CoF or temporary permit ceases to be current

A WoF, CoF or temporary permit ceases to be current:

a) after its expiry date , or

b) if the vehicle has been green or pink stickered and a new WoF or CoF is required (note that a new WoF or CoF is not required for a ‘G2’ green sticker so the existing expiry date remains unaffected), or

c) if the WoF, CoF or temporary permit has been revoked by a person authorised by the NZTA.

3.8.2 Completing and affixing the WoF or CoF label

Completing the WoF label

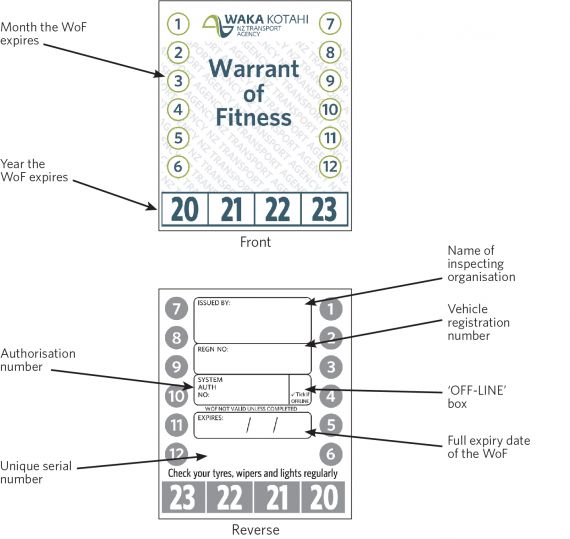

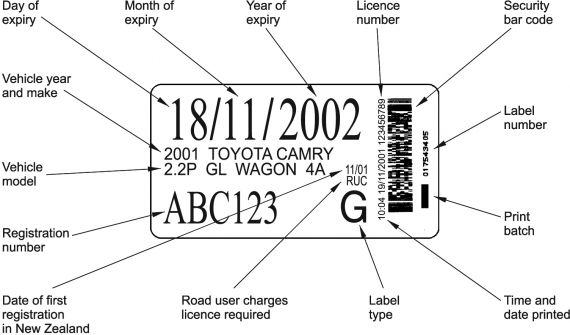

Figure 3-8-1. Warrant of fitness (WoF) label (for expiry dates from 2014 onwards)

If the vehicle passes the WoF inspection, the new WoF label must be completed in the following manner:

a) Front side:

i. select the WoF label with the correct year of expiry of the WoF, and

ii. using a hole punch of at least 6mm diameter, punch out the appropriate numbers representing the month and year of the WoF expiry date.

b) Reverse side: record the:

i. name of the inspecting organisation (a business stamp is acceptable), and

ii. vehicle registration number, and

iii. system authorisation number, and

iv. full expiry date of the WoF.

Each WoF label has a unique serial number printed on three places of the reverse side. The two small serial number stickers on the left are for cross referencing of the inspection documentation. The vehicle inspector must remove both serial number stickers and attach one to the file copy of the checksheet and the other to the customer’s copy of the checksheet.

Affixing the WoF label

The WoF label must be affixed by the vehicle inspector or a delegated employee of the inspecting organisation in one of the following positions:

a) if the vehicle is fitted with a windscreen:

i. to the inside of the windscreen facing outwards on the same side as the steering wheel, and

ii. as close as possible to the edge of the windscreen where it is clearly visible from the outside and is not obscured by an anti-glare band or sticker

b) for a trailer, on the back of the vehicle near the registration plate, or on the right-hand side of the vehicle at the rear, or if this is impracticable, in a position where it can readily be seen

c) for any other vehicle, in a position where it can readily be seen.

Not more than one WoF label may be displayed at one time. When issuing a new WoF label, the vehicle inspector or a delegated employee of the inspecting organisation must remove the existing label.

Completing the CoF label

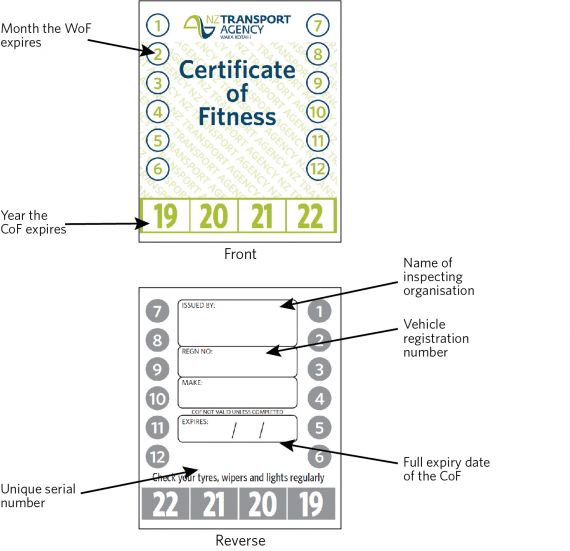

Figure 3-8-2. Certificate of Fitness (CoF) label details

If the vehicle passes the CoF inspection, the new CoF label must be completed in the following manner:

a) Front side:

i. select the CoF label with the correct year of expiry of the CoF, and

ii. using a hole punch of at least 6mm diameter:

-punch out the appropriate numbers representing the month and year of the CoF expiry date if using the CoF label in Figure 3-8-2.

b) Reverse side: record the:

i. vehicle registration number, and

ii. vehicle make, and

iii. full expiry date of the CoF, and

iv. name of the inspecting organisation.

c) Label record (butt): record the:

i. vehicle registration number, and

ii. date the CoF is issued, and

iii. full expiry date of the CoF, and

iv. signature of the vehicle inspector.

Each CoF label has a unique serial number which must be recorded on both copies of the checksheet.

Affixing the CoF label

The CoF label must be affixed by the vehicle inspector or a delegated employee of the inspecting organisation in one of the following positions:

a) if the vehicle is fitted with a windscreen:

i. to the inside of the windscreen facing outwards, on the same side as the steering wheel, and

ii. as close as possible to the edge of the windscreen where it is clearly visible from the outside and is not obscured by an anti-glare band

b) for a trailer, on the back of the vehicle near the registration plate, or on the right-hand side of the vehicle at the rear, or if this is impracticable, in a position where it can readily be seen

c) for any other vehicle, in a position where it can readily be seen.

Not more than one CoF label may be displayed at one time. When issuing a new CoF label, the vehicle inspector must remove the existing label.

3.8.3 Completing the temporary permit (’28 day permit’ for CoF vehicles only)

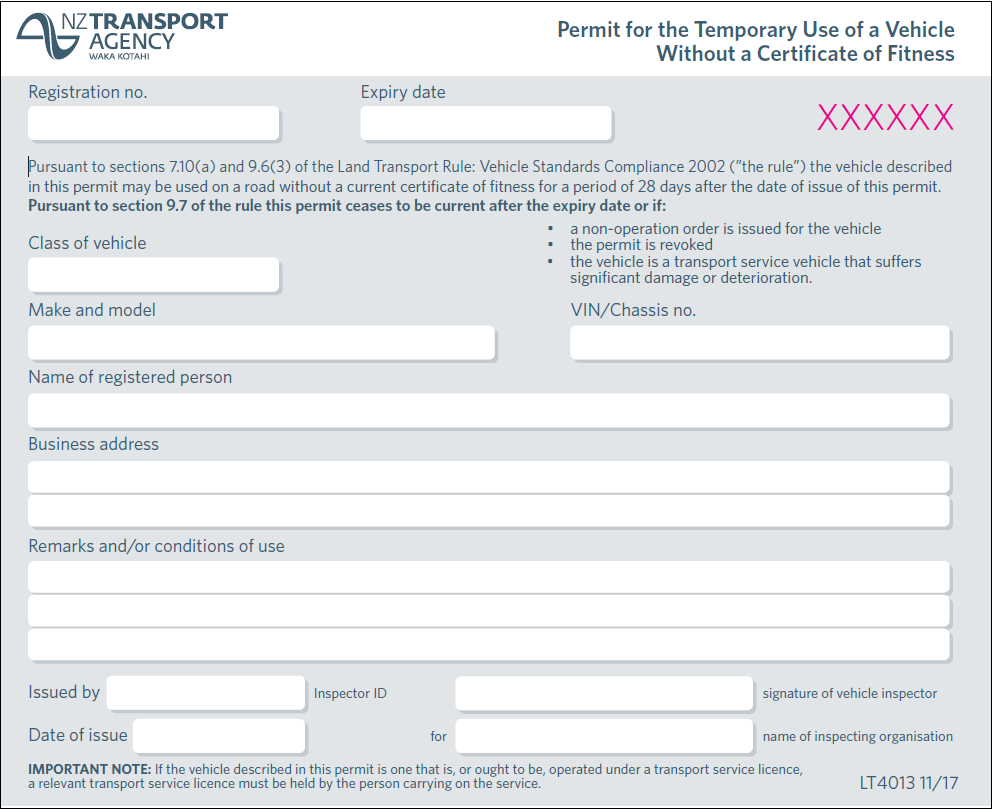

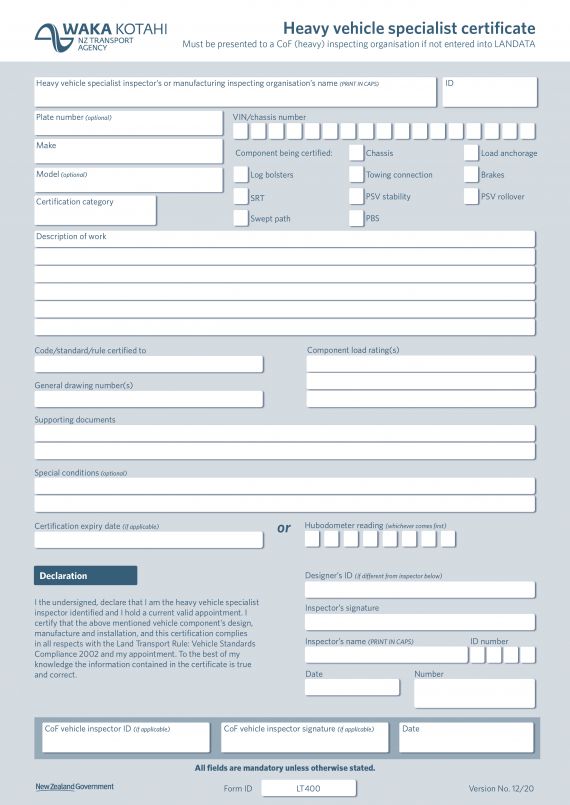

Figure 3-8-3. Temporary permit (28 day permit for CoF vehicles)

This permit may be issued by an inspecting organisation in the case of a vehicle that does not comply with all applicable requirements, but is safe to be operated subject to specified conditions. The completed permit must be carried in the vehicle.

To assist with minimising delays, temporary permits may be issued to vehicles that have had a minor fault repaired by a manufacturing certifier but that have not yet had an LT400 issued. The manufacturing certifier must issue the CoF inspector a written professional opinion stating the repair is carried out to industry best practice. The professional opinion should be on the HV manufacturing certifier company letterhead and must contain:

- vehicle details

- HV manufacturing certifier details

- details of the fault

- a statement stating that it has been repaired to industry best practice and is safe to operate on the road for up to 28 days

- the date the professional opinion was issued

- HV manufacturing certifier signature.

The permit must be completed in the following manner:

Record the:

1. vehicle registration number, and

2. expiry date of the permit, and

3. validity period of 28 days, and

4. class of the vehicle, and

5. make and model, and

6. VIN or chassis number, and

7. name of the registered owner, and

8. registered owner’s business address, and

9. specified conditions relating to the vehicle’s operation, and

10. date of issue of the permit, and

11. signature of the vehicle inspector.

- These details must be clearly legible on both copies of the permit.

- Each permit has a unique serial number which must be recorded on both copies of the checksheet.

- Any vehicle issued with a 28 day conditional permit must have the fail determination entered into LATIS first, then the 28 day permit must be entered with the fault codes and any conditions imposed. Refer to sections 7.9 and 7.10a of Land Transport Rule: Vehicle Standards Compliance 2002.

Page amended 1 October 2023 (see amendment details)

Page updated 8 April 2021 (see details)

3-9 Collecting fees

Applicable legislation: Land Transport (Certification and Other Fees) Regulations 2014.

3.9.1 Application for inspection and certification of vehicles for in-service

The fee to be paid by an applicant for inspection and certification of a vehicle for in-service (WoF, CoF or permit) is the amount fixed by the inspecting organisation that is reasonable, having regard to:

a) the time spent in inspecting the vehicle to ascertain whether it complies with the relevant requirements, and

b) any fees payable to the NZTA, and

c) any standard or usual rate at which the inspecting organisation imposes charges for other work carried out in respect of motor vehicles.

Where a vehicle fails a WoF inspection, no additional fee is payable for any subsequent inspection by the same inspecting organisation for the purpose of the same certification, if such application is made within 28 days of the first inspection for the issue of the evidence of vehicle inspection. A fee is payable for an inspection if the vehicle is presented after the 28 days have lapsed.

- For more information on rechecks and reinspections see 3-11 Rechecks.

3.9.2 Duplicate evidence of vehicle inspection

The inspecting organisation or vehicle inspector may charge a reasonable fee for providing a duplicate of an evidence of vehicle inspection.

When issuing a duplicate WoF or CoF label, the same requirements apply as for the original label as specified in section 3.8, that is, it must be attached by the vehicle inspector or delegated employee, and only one label may be attached to the vehicle at any time.

Page amended 1 June 2018 (see amendment details).

3-10 Operating a vehicle without a current WoF or CoF

A person must not operate a vehicle on the road unless it has a current WoF/CoF and complies with WoF/CoF requirements.

A person may legally operate a vehicle with an expired WoF/CoF ONLY if the vehicle is being operated SOLELY for the purpose of bringing it into compliance, and provided the vehicle is safe to be operated for that purpose.

The 28 days given after a failed WoF/CoF only relate to the payment of inspection fees and when a new inspection starts, see sections 3.6.6 and 3.9. The 28 days do NOT allow a person to continue using the vehicle for a purpose other than for bringing the vehicle into compliance.

Where a vehicle still has a current WoF/CoF when it is failed, it must be brought up to compliance before it can again be operated for other purposes up to the date the WoF/CoF expires.

3-11 Rechecks

If a vehicle fails a WoF inspection, there is no fee for any subsequent inspection as long as it is done:

- within 28 days of the first inspection where the vehicle failed, and

- at the same inspecting organisation (does not have to be the same site if the inspecting organisation operates at more than one site).

Notes

- In the case of split testing for heavy vehicle brakes at CoF, the 28 days start from the completion of the second phase of the split test.

- If a vehicle has passed a performance test but has been failed for condition and has then been repaired, the performance should be re-tested as part of the recheck (for example brakes where the pads have been replaced.

- A fee may be charged for CoF re-inspections.

A fee is payable, and a new WoF or CoF inspection is required if the vehicle is presented after the 28 days have passed.

Legislation

Land Transport (Certification and Other Fees) Regulations 2014

Page added 1 April 2022 (see amendment details).

Page updated 4 March 2024 (see update details).

4 Complaints

Customers should be encouraged to direct any complaints to the inspecting organisation in the first instance.

To ensure all written complaints received are investigated, the inspecting organisation must maintain an effective complaint management process, which must meet the following requirements:

1. a clear and concise statement that recognises the positive value of complaints

2. clear and concise instructions to all customers on how to register a complaint. This can be accomplished in several ways, for example:

a) a conspicuous notice on the workplace wall, or

b) a clear statement on any receipt or invoice issued, or

c) a clear statement on the inspecting organisation’s checksheet

3. a straightforward explanation of the expected standards for resolution and the customer’s right to appeal to the NZTA if they are dissatisfied with the proposed resolution

4. documentation of any investigation into a complaint prepared in accordance with the QMS requirements so that details of the investigation can be readily checked

5. acknowledgment of all written complaints in writing within three working days, and the investigation completed and a resolution proposed to the complainant within 20 working days of the complaint being made

6. a record of all complaints, both verbal and written, in accordance with the QMS requirements

7. directions for any customer who wishes to make a complaint or appeal a decision made by an inspecting organisation to contact the NZTA Helpdesk (0800 699 000).

Dealing with disputed failed CoF inspections for vehicles subject to the Operator Rating System (ORS)

Where the operator of a vehicle subject to ORS queries a failed inspection, please follow the Operator issue resolution process – disputed failed inspections in section 3-9-3 of the LATIS manual (password required).

Vehicle operators may be referred to the Transport Agency website for more information about querying failed CoF inspection results.

Page amended 1 November 2014 (see amendment details).

5 Inspection premises and equipment

5.1 General requirements

- The inspecting organisation must continue to comply with the applicable requirements in this section.

- The inspecting organisation must maintain their premises and equipment in a good state of repair at all times while conducting inspection and certification activities.

- The inspecting organisation must use any specified equipment when inspecting a vehicle, where appropriate.

- Inspection equipment must meet equipment manufacturer’s requirements and have current calibration.

- Brake performance testing equipment must be calibrated at least every 12 months, or more frequently if required by the equipment manufacturer, or following any maintenance that may alter the calibration.

- Inspections must take place in the inspection area, using the approved or specified equipment, unless otherwise permitted by Waka Kotahi.