In-service certification (WoF and CoF) - Motorcycles

Correct as at 25th April 2024. It may be superseded at any time.

1-1 VIN and chassis number

Important Ensure that the VIN or chassis number is recorded in full on the checksheet. This number must be:

Also refer to Table 1-1-1. Location of New Zealand VIN numbers, Figure 1-1-1. Structure of a VIN issued by the NZ Transport Agency and Figure 1-1-2. Structure of a VIN issued by the vehicle manufacturer. |

Reasons for rejection

Mandatory requirements

1. A vehicle first registered or re-registered in New Zealand before 1 April 1994 does not have a VIN or chassis number (Note 1) (Note 4).

2. A vehicle first registered or re-registered in New Zealand from 1 April 1994 does not have a VIN number (Note 1) (Note 4).

3. A VIN number is not valid (Note 2).

Condition

4. A VIN or chassis number has been (Note 1) (Note 3) (Note 4):

a) removed, or

b) erased, or

c) altered, or

d) defaced, or

e) obscured, or

f) destroyed, or

g) obliterated, or

h) affixed unlawfully or by unauthorised persons (Note 3).

Note 1

The vehicle inspector must notify Waka Kotahi using the vehicle report form if there is reason to believe that the VIN or chassis number has been tampered with in any way.

The vehicle inspector must not issue a WoF/CoF/permit until approved by Waka Kotahi. Approval will usually include the issue or re-issue of a new VIN plate.

The vehicle inspector must not issue a WoF/CoF/permit if there is reason to believe that the VIN or chassis number has been tampered with in any way.

Refer the vehicle to a VIN issuing agent (VTNZ, VINZ, NZAA, Drivesure, CVC, i4Checkpoint). They will inspect the vehicle and seek approval from Waka Kotahi to issue or re-issue a VIN plate. Once the vehicle has been approved the vehicle may continue through the inspection process.

Note 2

A valid VIN is a unique number that has been assigned to the vehicle in the vehicle’s country of origin or by a person appointed by the NZTA. It consists of 17 characters that never contain the letters I, O or Q, and that is capable of being decoded to provide identifying information about the vehicle.

Note 3

The vehicle inspector must advise the local police if there is reason to believe that the VIN or chassis number has been tampered with in any way.

Note 4

If the vehicle is failed because the VIN/chassis is missing or unreadable, then 'not found' must be recorded in place of the VIN number on the checksheet.

Note 5

An LVV certification plate will always have a VIN or chassis number engraved onto it. The vehicle's Waka Kotahi- or OEM-issued 17 digit VIN (or chassis number for vehicles first registered before 1989) is always considered to be the primary identifier, and vehicle inspectors should verify that the details recorded on the LVV certification plate match.

A vehicle's registration number plate that does not match the registration plate number engraved on the LVV certification plate is not considered a reason for rejection, provided the vehicle's primary identifiers (17 digit Waka Kotahi- or OEM-issued VIN or chassis numbers) match.

Table 1-1-1. Location of VIN numbers

Vehicle | Permitted VIN Locations |

|---|---|

Motorcycles |

|

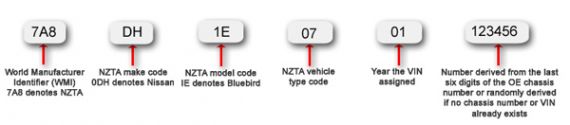

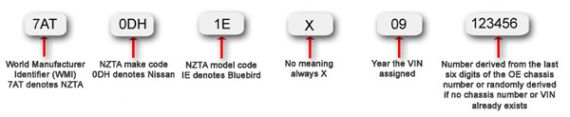

Figure 1-1-1. Structure of a VIN issued by the NZ Transport Agency

Pre-29 November 2009

Post-29 November 2009

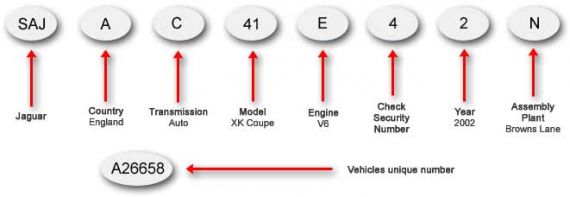

Figure 1-1-2. Structure of a VIN issued by the vehicle manufacturer

Car

Truck

Summary of legislation

Applicable legislation

Mandatory requirements

1. A vehicle first registered or re-registered in New Zealand before 1 April 1994 must have a chassis number or VIN.

2. A vehicle first registered or re-registered in New Zealand from 1 April 1994 must have a VIN.

Condition

3. A VIN or chassis number must not have been removed, erased, altered, defaced, obscured, destroyed, obliterated or affixed unlawfully, or be unauthorised.

Page amended 1 October 2022 (see amendment details).

1-2 Vehicle details

Reasons for rejection

1. The number on the registration plate(s) is not the same as stated on the licence label.

2. The licence label does not correctly describe the vehicle

- do not reject the vehicle if the label type is incorrect, eg 'B' or 'A'.

3. The WoF online or LATIS system does not correctly describe the vehicle.

Page added 1 October 2020 (see amendment details)

2 Vehicle Exterior

2-1 External projections

Reasons for rejection

Condition and performance (Note 1)

1. The risk of a component (Note 5) hooking a vehicle, or hooking or grazing a person, has not been minimised.

2. An ornamental object or fitting (Note 2) protrudes in such a way that it is likely to injure a person.

3. A protruding object or fitting that has a functional purpose (Note 3) is not installed so that the risk of causing injury to a person is minimised, eg the object or fitting:

a) is of excessively heavy construction for the purpose for which it has been fitted, or

b) has sharp corners, or

c) slopes forward, unless this is necessary to fit the contours of the vehicle, or

d) has an unnecessarily wide gap between the object or fitting and the front of the vehicle, or

e) exceeds the vehicle’s width by more than 100mm on either side.

4. A protruding component, object or fitting is not securely fitted.

5. a protruding object or fitting adversley affects the rider’s vision or control.

Modification (Note 4)

6. A modification affects an external projection – including a protruding object or fitting that has a functional purpose and affects the driver’s vision or control of the vehicle, and:

a) is not excluded from the requirements for LVV specialist certification (Table 2-1-1), and

b) is missing proof of LVV specialist or accepted overseas certification, ie:

i. the vehicle is not fitted with a valid LVV certification plate, or

ii. the operator is not able to produce a valid modification declaration or authority card, or

iii. the vehicle has not been certified to an accepted overseas system as described in Technical bulletin 13.

Note 1

The external projections requirements relate to the design and maintenance of objects and fittings that protrude from the exterior of the motor vehicle with regard to the safety of other motor vehicles, pedestrians and cyclists. The attachment of such objects and fittings to the vehicle is addressed in the Vehicle structure section of this manual.

Note 2

Ornamental object or fitting means an object or fitting that does not have a practical purpose, eg bonnet emblems.

Note 3

Functional object or fitting means an object or fitting that has a practical purpose, eg panniers, pack racks, spare wheel carriers, and so on.

Note 4

Modify means to change a vehicle from its original state by altering, substituting, adding or removing any structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with equivalent undamaged or new structures, systems, components or equipment.

Note 5

Components include damaged, corroded and exposed body panels.

Table 2-1-1. Modifications that do not require LVV certification

Fitting of or modification to: | LVV certification is never required: |

|---|---|

Any modification for the purposes of law enforcement or the provision of emergency services |

|

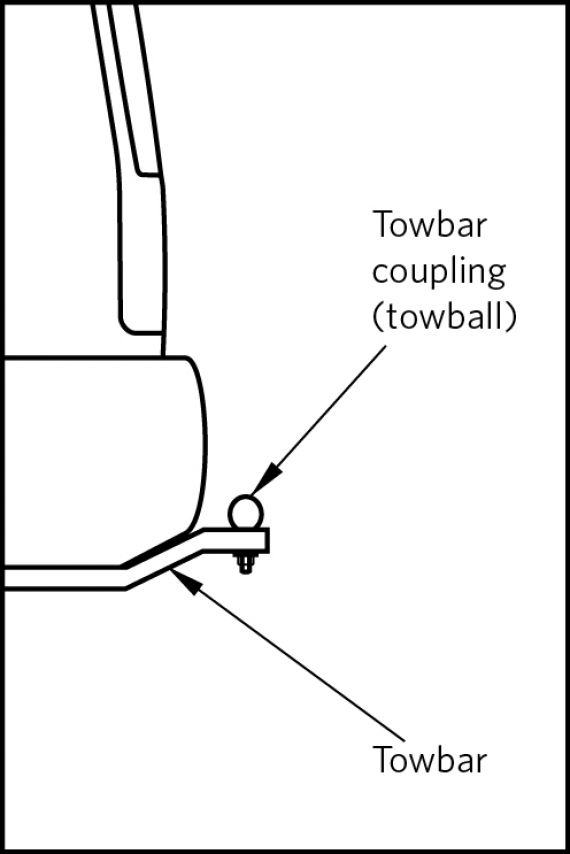

Towbars |

Summary of legislation

Applicable legislation

Permitted equipment

1. A motor vehicle may be fitted with a protruding ornamental or functional object or fitting.

Condition and performance

2. A protruding ornamental object or fitting must not be likely to injure a person.

3. A protruding object or fitting that has a functional purpose must be installed so that the risk of the object or fitting causing injury to a person is minimised.

4. Components of a motor vehicle, including damaged or corroded body panels, must be such that the risk of their hooking a vehicle, or hooking or grazing a person, is minimised.

5. A protruding object or fitting must not adversely affect driver vision or driver control.

Modification

6. A modification that affects an external projection must be inspected and certified by an LVV specialist certifier, unless the vehicle:

a) is excluded from the requirement for LVV specialist certification (Table 2-1-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 December 2016 (see amendment details).

2-2 Footrests

Reasons for rejection

Mandatory equipment

1. A motorcycle is not fitted with adequate footrests for:

a) the rider, or

b) the pillion passenger where there is a pillion passenger seating position.

Condition

2. A footrest or footrest mounting is:

a) insecure, or

b) weakened by corrosion or other damage.

Modification

3. A modification affects the footrest, and is:

a) not excluded from the requirements for LVV specialist certification (Table 2-2-1), or

b) is missing proof of LVV specialist or accepted overseas certification, ie:

i. the vehicle is not fitted with a valid LVV certification plate, or

ii. the operator is not able to produce a valid modification declaration or authority card, or

iii. the vehicle has not been certified to an accepted overseas system as described in Technical bulletin 13.

Table 2-2-1. Modifications that do not require LVV certification

Fitting of or modification to: | LVV certification is never required: |

|---|---|

Any modification for the purposes of law enforcement or the provision of emergency services |

|

Summary of legislation

Applicable legislation

Mandatory equipment

1. A motorcycle must have:

a) footrests for the rider, and

b) footrests for the pillion passenger if provision is made for pillion riding.

Condition

2. Footrests must be adequate.

Modification

3. A modification that affects a footrest must be inspected and certified by an LVV specialist certifier, unless the vehicle:

a) is excluded from the requirement for LVV certification (Table 2-2-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 December 2016 (see amendment details).

2-3 Dimensions

Note: The vehicle inspector need only inspect dimensions in detail if there is doubt about the vehicle’s compliance.

Reasons for rejection

Mandatory requirement

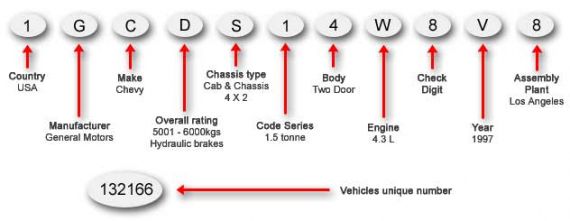

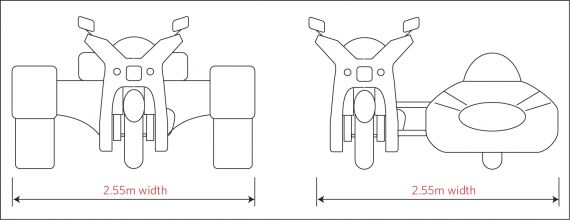

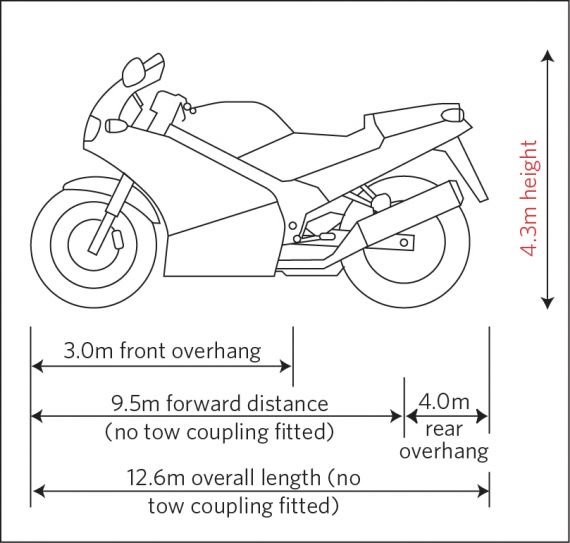

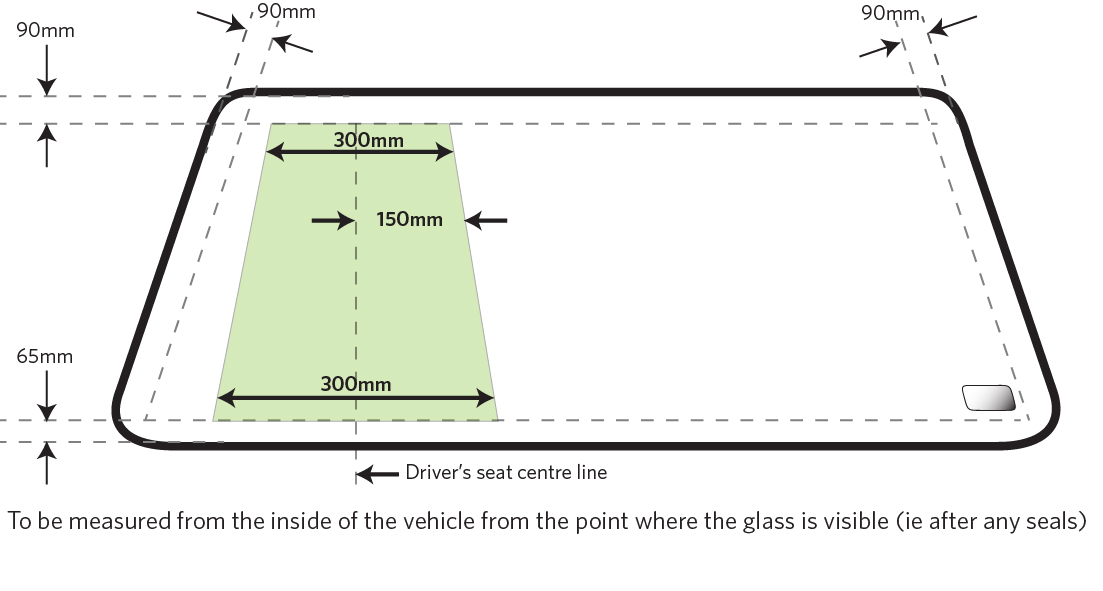

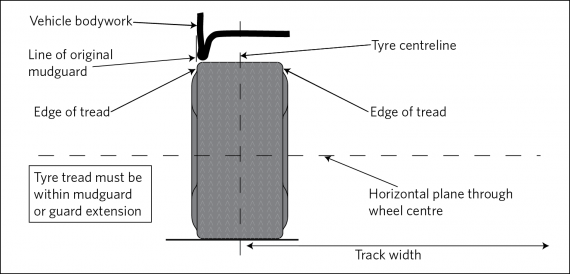

1. A vehicle does not meet the dimension requirements set out in Table 2-3-1 (see also Figure 2-3-1, Figure 2-3-2, and Figure 2-3-3).

Table 2-3-1. Dimension requirements

(see also Figure 2-3-1, Figure 2-3-2, and Figure 2-3-3)

Dimension | Maximum distance | Comments |

|---|---|---|

Width | 1.1m (motorcycle without sidecar) 2.55m (motorcycle with sidecar or motor tricycle) | Measurement does not include:

|

| Overall length | 12.6m (no tow coupling fitted) 11.5m (tow coupling fitted) | Measurement does not include collapsible mirrors. |

Height | 4.3m | |

Forward distance | 9.5m (no tow coupling fitted) 8.5m (tow coupling fitted) | Forward distance is measured from the centre of the rear axle to the front of the vehicle. Measurement does not include collapsible mirrors. |

Rear overhang | 4m | Rear overhang is measured from the centre of the rear axle to the rear of the vehicle. |

Front overhang | 3m | Front overhang is measured from the front edge of the driver’s seat to the front of the vehicle. |

Table 2-3-2. Modifications that do not require LVV certification

Fitting of or modification to: | LVV certification is never required: |

|---|---|

Any modification for the purposes of law enforcement or the provision of emergency services |

|

Figure 2-3-1. Maximum width for a motorcycle

(Note: Dimensions in red updated in VDAM 2016)

Figure 2-3-2. Maximum width for a motorcycle with sidecar or a motor tricycle

(Note: Dimensions in red updated in VDAM 2016)

Figure 2-3-3. Other dimensions for a motorcycle, motorcycle with sidecar, or motor tricycle

(Note: Dimensions in red updated in VDAM 2016)

Summary of legislation

Applicable legislation

Mandatory requirement

1. A vehicle must meet the dimensions in Table 2-3-1.

Page amended 1 February 2017 (see amendment details).

3 Vehicle Structure

3-1 Structure

Reasons for rejection

Condition

1. The structure of the motorcycle has visible:

a) deformation from the original shape that has affected the vehicle’s structural integrity (Note 2), or

b) cracking, or

c) fracture, or

d) corrosion damage (Note 1) that affects its strength, or

e) poor repairs that have not returned the structure to within a safe tolerance of when it was manufactured (Note 2), such as:

i. filler has been used in an attempt to conceal corrosion damage or deformation of a component.

ii. a high strength steel component has been heated.

iii. a component has been strengthened.

Modification (Note 4)

2. A modification affects the vehicle structure, and:

a) is not excluded from the requirements for LVV specialist certification (Table 3-1-1), and

b) is missing proof of LVV specialist or accepted overseas certification, ie:

i. the vehicle is not fitted with a valid LVV certification plate, or

ii. the operator is not able to produce a valid modification declaration or authority card , or

iii. the vehicle has not been certified to an accepted overseas system as described in Technical bulletin 13 .

Note 1

Corrosion damage is where the metal has been eaten away, which is evident by pitting. The outward signs of such corrosion damage is typically displayed by the lifting or bubbling of paint. In extreme cases the area affected by the corrosion damage will fall out and leave a hole.

Note 2

The vehicle inspector may request additional relevant information from a repairer or other relevant person.

Note 3

Modify means to change a vehicle from its original state by altering, substituting, adding or removing any structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with equivalent undamaged or new structures, systems, components or equipment.

Note 4

The addition of a side-car requires LVV certification unless the side-car is OE.

Table 3-1-1. Modifications that do not require LVV certification

Fitting of or modification to: | LVV certification is never required: |

|---|---|

Any modification for the purposes of law enforcement or the provision of emergency services |

|

Towbars |

Summary of legislation

Applicable legislation

Condition

1. A vehicle must not be affected by corrosion or weakening of its structure, that is apparent by visual examination, so that the vehicle is unsafe to operate.

2. The performance of a frontal impact occupant protection system must not be affected by any factor, including corrosion, structural damage, material degradation, inadequate repair, the fitting of additional equipment, or the removal of equipment.

Modification

3. A modification that affects the integrity of the vehicle structure must be inspected and certified by an LVV specialist certifier, unless the vehicle:

a) is excluded from the requirement for LVV specialist certification (Table 3-1-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 December 2016 (see amendment details).

4 Lighting

4-1 Headlamps

Reasons for rejection

Mandatory and permitted equipment

1. A motorcycle is not fitted with one dipped-beam headlamp.

2. A motorcycle is fitted with more than:

a) two dipped-beam headlamps, or

b) two main-beam headlamps.

3. A motorcycle (eg a vintage or veteran motorcycle) does not meet standard headlamp requirements, and:

a) does not have a valid vehicle identity card with a lighting equipment endorsement, or

b) does not meet the conditions of the lighting equipment endorsement in its vehicle identity card.

4. A device that allows the headlamps to flash alternately is fitted to a motorcycle that is not an emergency vehicle or a pilot vehicle.

5. A motorcycle is fitted with a dipped-beam headlamp that projects the maximum intensity of the beam to the right.

Condition (Note 4)

6. A lamp is insecure, obscured, or contains moisture in the form of large droplets, runs or puddles .

7. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A reflector is damaged or has deteriorated so that light output is reduced.

9. A main-beam headlamp warning device is obscured from the driver’s vision.

Performance

10. When switched on, a headlamp emits light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity from the other lamp in a pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead, eg due to modification, deterioration or an incorrect light source, or

e) too bright, eg due to the fitment of an HID or LED conversion kit (Note 7) or other incorrect light source (see also reason for rejection 16 below), or

f) altered, eg due to damage or modification.

11. When the dipped-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than the two lamps operate on dipped beam, or

c) more than four lamps operate on dipped beam on a motorcycle first registered anywhere between 1 January 1977 and 31 March 1980, or

d) the light beam produces an incorrect beam pattern, is not focused, or is reduced or altered, or

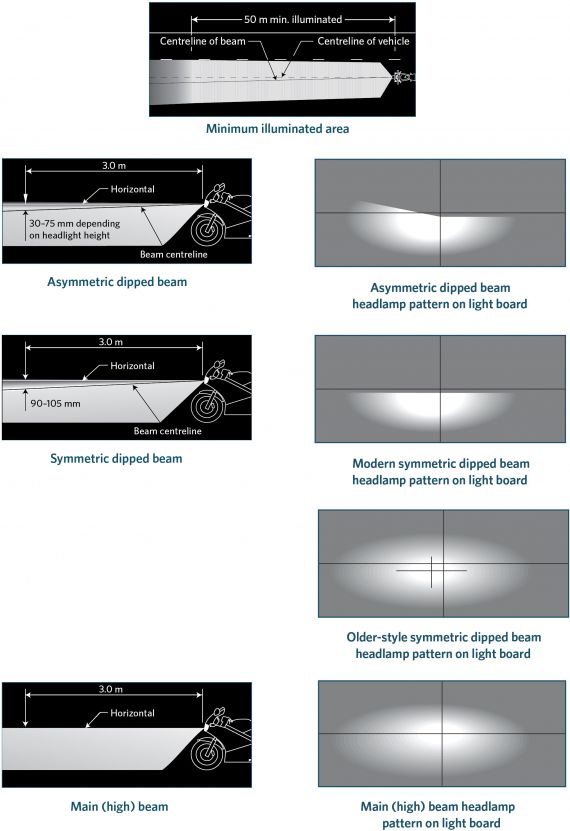

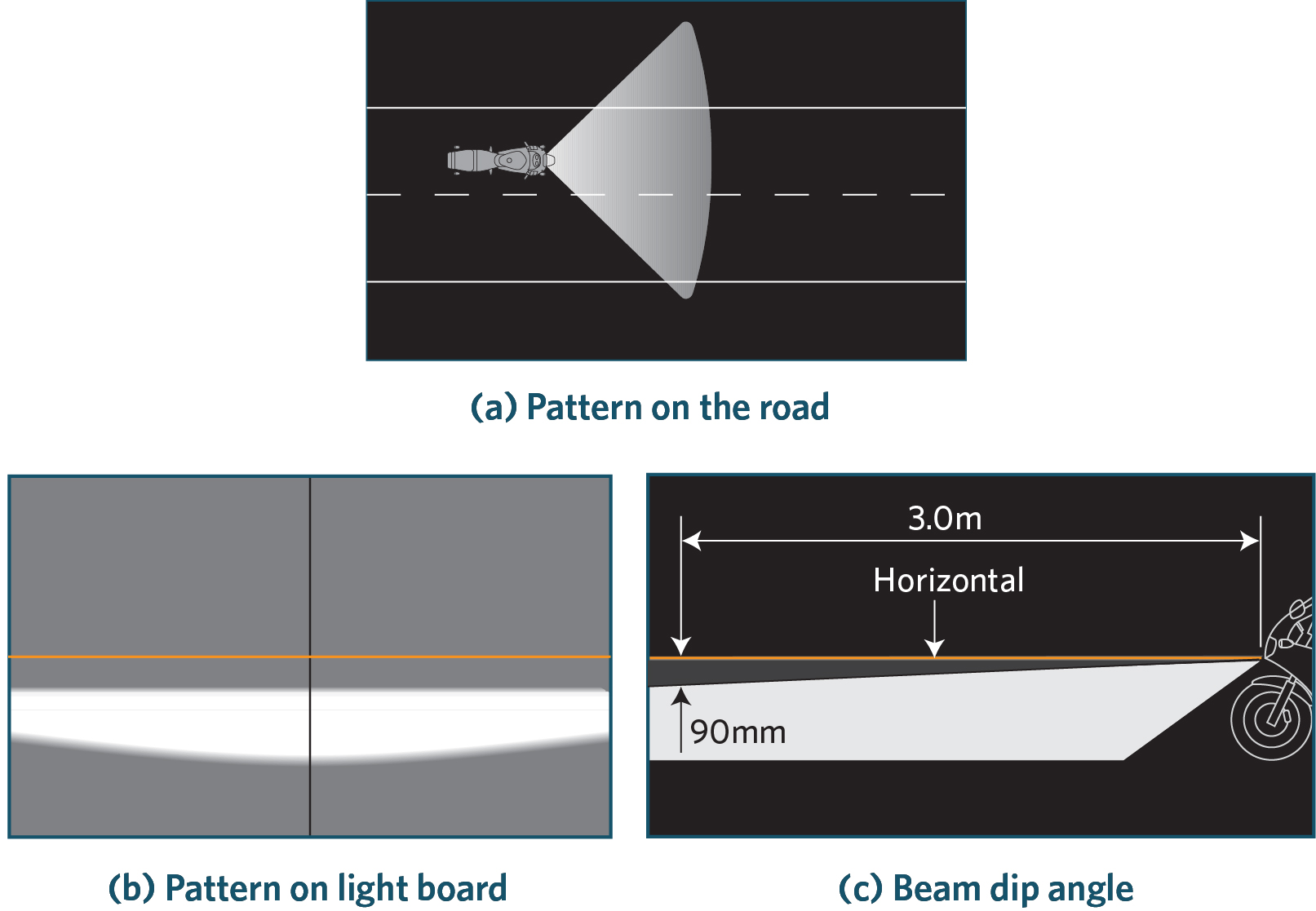

e) the centreline of the light beam is too far to the left or slopes down too far so that the headlamp is no longer capable of illuminating the road at least 50m ahead (Figure 4-1-1), or

f) the centreline of a lamp’s beam projects to the right of the motorcycle’s centreline, or projects down from the lamp at an angle other than:

i. as specified by the motorcycle or lamp manufacturer, or

ii. as specified in Table 4-1-1.

12. When the main-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than two lamps operate on main beam, or

c) the centreline of a lamp’s beam projects to the right of the motorcycle’s centreline or up from the horizontal, or

d) the lightbeam produces an incorrect beam pattern, is not focused, or is reduced or altered, or

e) the lamps are not capable of being switched to dipped beam or switched off from the driver’s seating position, or

f) a main-beam headlamp warning device does not indicate to the driver that the main-beam headlamps are switched on.

13. A device fitted to a motorcycle that allows the headlamps to flash alternately:

a) does not indicate to the driver that the device is activated, or

b) flashes:

i. faster than two flashes per second, or

ii. slower than one flash per second, or

iii. at a varying frequency.

14. Where a headlamp comprises an array of light sources (eg LEDs) fewer than 75% of these operate.

Modifications

15. An overlay has been applied that reduces or distorts the light emitted from the lamp (eg a tinted cover).

16. A headlamp is retrofitted with a type of light source other than that specified by the vehicle manufacturer or the headlamp manufacturer (eg a headlamp designed for a halogen bulb is fitted with any other type of light source such as an HID or LED bulb, or any other light source such as LED strips or non-OEM angel eyes).

17. A retrofitted pair of headlamps is not fitted:

a) symmetrically, or

b) as far towards each side of the motorcycle as practicable.

18. A retrofitted dipped-beam headlamp is positioned at a height exceeding 1.2m from the ground.

Note 1

If the dipped-beam headlamps are able to be adjusted from the driver’s seating position, the alignment must be checked with the adjustment at its highest position.

Note 2

If the motorcycle is fitted with self-levelling suspension, the alignment must be checked with the suspension at its normal level.

Note 3 Definitions

Headlamp means a lamp designed to illuminate the road ahead of a vehicle, and that is a:

a) dipped-beam headlamp (single lamp), or

b) main-beam (high-beam) headlamp (single lamp), and includes a driving lamp, or

c) combination of a dipped-beam headlamp and a main-beam headlamp (dual lamp unit).

Dipped-beam headlamp means a headlamp that is designed to emit a dipped beam, which is a beam of light that is angled downwards in such a way that it prevents undue dazzle or discomfort to oncoming drivers and other road users.

Main-beam headlamp means a headlamp that is designed to illuminate the road over a long distance ahead of the vehicle.

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component, or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp.

All other lamps are considered retrofitted (non-OE).

Note 4

If a headlamp is fitted with a readily removable cover, other than a clear plastic cover, this must be removed for inspection of the headlamp.

Note 5

A vehicle originally manufactured with a headlamp arrangement that differs from what is required or permitted in this section may retain the original headlamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 6

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle.

Note 7

A high-intensity discharge (HID or Xenon HID) or LED conversion kit consists of an HID or LED bulb which fits into the original headlamp unit in place of the original bulb with no change to the headlamp lens, reflector or housing.

It is illegal to fit an HID or LED conversion kit to a vehicle as it brings the headlamp out of standards compliance by producing poor beam patterns and light that is often far too bright to be safe. The bulbs can also produce light that is noticeably blue and not the required substantially white or amber colour. Vehicle and headlamp manufacturers do not permit this modification, and these kits cannot be LVV certified.

It is permitted to replace a complete halogen headlamp unit with a complete HID or LED headlamp unit. If the vehicle is required to meet an approved safety standard for headlamps, only approved headlamps can be retrofitted.

Table 4-1-1. Allowable dipped-beam headlamp alignment

Headlamp type | Distance from ground to centre of light source | Dip rate of beam centre: lower and upper limits | |||

|---|---|---|---|---|---|

Percent (%) | mm/3 m | Degrees (°) | |||

EITHER | Any headlamp dipped beam | N/A | That specified by the motorcycle or headlamp manufacturer | ||

OR | Headlamp with and older-style symmetric dipped-beam pattern (see Figure 4-1-2) | N/A | 3.0–3.5 | 90–105 | 1.7–2.0 |

OR | Headlamp with a modern symmetric or asymmetric dipped-beam pattern and distance from ground to centre of light source (see Figure 4-1-2) | less than 0.8m | 1.0–1.5 | 30–45 | 0.57–0.85 |

0.8–1.2m | 1.0–2.0 | 30–60 | 0.57–1.15 | ||

more than 1.2m | 2.0–2.5 | 60–75 | 1.15–1.43 | ||

Table 4-1-2. Dipped-beam angle conversions

Percent (%) | mm/3 m | Degrees (°) | Percent (%) | mm/3 m | Degrees (°) | |

|---|---|---|---|---|---|---|

1.0 | 30 | 0.6 | 2.3 | 69 | 1.3 | |

1.1 | 33 | 0.6 | 2.4 | 72 | 1.4 | |

1.2 | 36 | 0.7 | 2.5 | 75 | 1.4 | |

1.3 | 39 | 0.7 | 2.6 | 78 | 1.5 | |

1.4 | 42 | 0.8 | 2.7 | 81 | 1.5 | |

1.5 | 45 | 0.9 | 2.8 | 84 | 1.6 | |

1.6 | 48 | 0.9 | 2.9 | 87 | 1.7 | |

1.7 | 51 | 1.0 | 3.0 | 90 | 1.7 | |

1.8 | 54 | 1.0 | 3.1 | 93 | 1.8 | |

1.9 | 57 | 1.1 | 3.2 | 96 | 1.8 | |

2.0 | 60 | 1.1 | 3.3 | 99 | 1.9 | |

2.1 | 63 | 1.2 | 3.4 | 102 | 1.9 | |

2.2 | 66 | 1.3 | 3.5 | 105 | 2.0 |

Figure 4-1-1. Dipped beams

Summary of legislation

Applicable legislation

- Land Transport Rule: Vehicle Lighting 2004

- New Zealand Gazette, 28 August 1980, issue 108, page 2569.

Mandatory and permitted equipment

1. A motorcycle:

a) must be fitted with one or two dipped-beam headlamps, and

b) may be fitted with one or two main-beam headlamps.

2. A motorcycle (eg a vintage or veteran motorcycle) manufactured without lamps, or with lamps that cannot meet specified requirements, may obtain a WoF if:

a) the motorcycle has a valid vehicle identity card with a lighting equipment endorsement, and

b) the motorcycle meets the conditions of that endorsement.

3. A vehicle required to meet an approved safety standard for lighting must continue to meet an approved safety standard for lighting.

4. A warning device may be fitted that indicates that the main-beam headlamps are switched on.

5. An emergency vehicle or a pilot vehicle may be fitted with a device that allows the headlamps to flash alternately, provided it is also fitted with equipment that indicates to the driver that the device is activated.

6. A retrofitted pair of headlamps must be symmetrically mounted as far towards each side of the motorcycle as ispracticable.

7. A retrofitted dipped-beam headlamp must be positioned at a height not exceeding 1.2 m from the ground.

Prohibited equipment

8. A dipped-beam headlamp designed solely for a left-hand drive vehicle, where the maximum intensity of the beam is dispersed to the right, must not be fitted.

Condition

9. A headlamp must:

a) be in sound condition, and

b) not be obscured.

Performance

10. A headlamp must operate in a way that is appropriate for the lamp and the vehicle.

11. A headlamp must emit a steady light.

12. A headlamp must provide sufficient illumination and light output to illuminate the road ahead.

13. If fitted with a device that allows headlamps to flash alternately, the lamps must flash at a fixed frequency.

14. A pair of headlamps must emit light that is approximately of equal colour and intensity when switched on.

15. A headlamp must emit a beam that is substantially white or amber.

16. A main-beam headlamp must be capable of being dipped or turned off from the driver’s position.

17. A warning device that indicates that the main-beam lamps are in operation must be in good working order.

18. When the headlamps are switched on and the motorcycle’s front wheel is pointing in the straight ahead position:

a) the headlamp beam must be either parallel to or to the left of the longitudinal centreline of the motorcycle, and

b) the centre of a main-beam headlamp beam must be either parallel to or dipping down from the horizontal, and

c) the centre of a dipped-beam headlamp beam must dip at an angle specified by the motorcycle or lamp manufacturer, or

i. 3–3.5% for a symmetric beam pattern, or

ii. 1–1.5% for an asymmetric beam pattern where the centre of the light source is less than 0.8m from the ground, or

iii. 1–2% for an asymmetric beam pattern where the centre of the light source is 0.8–1.2m from the ground, or

iv. 2–2.5% for an asymmetric beam pattern where the centre of the light source is above 1.2m from the ground.

19. The dipped beam headlamps must illuminate the road ahead for 50m in normal darkness.

20. A device fitted to a motorcycle that allows the headlamps to flash must:

a) make the headlamps flash alternately at a frequency of 1–2 Hertz, and

b) incorporate equipment that indicates to the driver that the device is activated.

21. A headlamp must be fitted with a light source that is specified by the motorcycle manufacturer or the headlamp manufacturer.

22. Where a headlamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

23. A headlamp that is affected by a modification must meet equipment, condition and performance requirements.

Page amended 1 April 2021 (see amendment details).

4-2 Front and rear fog lamps

Reasons for rejection

Permitted equipment

1. A motorcycle is fitted with more than:

a) two front fog lamps, or

b) two rear fog lamps.

2. A retrofitted pair of fog lamps is not:

a) fitted symmetrically, or

b) fitted as far towards each side of the motorcycle as is practicable, or

c) positioned higher than the dipped-beam headlamps.

Condition (Note 1)

3. A lamp is insecure or contains moisture in the form of large droplets, runs or puddles .

4. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

5. A reflector is damaged or has deteriorated so that light output is reduced.

6. A fog lamp warning device, if fitted, is obscured from the driver’s vision.

Performance

7. When switched on, a front fog lamp does not operate.

8. When switched on, a front fog lamp emits light that:

a) is not projected to the front, or

b) produces an incorrect beam pattern (Figure 4-2-1), or

c) is not substantially white or amber to the front, or

d) is not approximately equal in colour or intensity from the other lamp in the pair, or

e) is not steady, or

f) is not bright enough to illuminate the road ahead in conditions of severely reduced visibility, eg due to modification, deterioration, dirt or an incorrect light source, or

g) is too bright, and could dazzle other road users, eg due to an incorrect light source, or

h) is altered, eg due to damage or modification, or

i) has a beam centre to the right of the motorcycle’s centreline, or

j) has a beam that is not permanently dipped, or

k) has a beam centre that dips at an angle of less than 3% (Figure 4-2-1).

9. When switched on, a rear fog lamp emits light that is:

a) not projected to the rear, or

b) not diffuse, or

c) not substantially red, or

d) not approximately equal in colour or intensity from the other lamp when fitted in a pair, or

e) not steady, or

f) not bright enough to indicate the presence of the motorcycle from the rear in conditions of severely reduced visibility, eg due to modification, deterioration, dirt or an incorrect light source, or

g) is altered, eg due to damage or modification.

10. A fog lamp cannot be switched off from the driver’s seating position.

11. Where a fog lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

12. A fog lamp warning device, if fitted, does not operate.

Note 1

If a front fog lamp is fitted with a readily removable cover, other than a clear protective cover, this must be removed for inspection of the fog lamp.

Note 2 Definition

Fog lamp means a front or rear lamp designed to aid the driver or other road users in conditions of severely reduced visibility, including fog or snow, but not including clear atmospheric conditions under the hours of darkness.

Note 3

A rear fog lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 4

A vehicle originally manufactured with a fron-t or rear-fog-lamp arrangement that differs from what is required or permitted in this section may retain the original fog lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 5

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply, be removed from the vehicle, or be disabled so that it does not emit a light.

Figure 4-2-1. Front fog lamp light characteristics

Summary of legislation

Applicable legislation

Permitted equipment

1. One or two front fog lamps.

2. One or two rear fog lamps.

3. A retrofitted pair of fog lamps must be symmetrically mounted as far as practicable towards each side of the motorcycle.

4. A retrofitted front fog lamp must not be positioned higher than the dipped-beam headlamps.

5. A motorcycle may be fitted with a warning device that indicates that a front or rear fog lamp is in operation.

Condition

6. A front fog lamp must be in sound condition.

7. A rear fog lamp must be in sound condition if it emits a light.

Performance

8. A fog lamp must operate in a way that is appropriate for the lamp and the vehicle.

9. A fog lamp must emit a steady light.

10. A front fog lamp must provide sufficient light output to illuminate the road ahead in conditions of severely reduced visibility.

11. A rear fog lamp must provide sufficient light output to indicate the presence of the vehicle on the road in conditions of severely reduced visibility.

12. The light emitted from a front fog lamp must be substantially white or amber.

13. The light emitted from a rear fog lamp must be diffuse and substantially red in colour.

14. A pair of fog lamps must emit light that is approximately equal in colour and intensity.

15. The centre of a front fog lamp beam must be parallel to or to the left of the longitudinal centreline of the motorcycle.

16. The centre of a front fog lamp beam must be permanently dipped at an angle of at least 3%.

17. A fog lamp must be able to be turned off from the driver’s seating position.

18. A front or rear fog lamp warning device must be in good working order.

19. Where a fog lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

20. A fog lamp that is affected by a modification:

a) must meet equipment, condition and performance requirements, and

b) does not require LVV specialist certification.

Page amended 1 April 2021 (see amendment details).

4-3 Cornering lamps

Reasons for rejection

Permitted equipment

1. A motorcycle is fitted with:

a) only one lamp, or

b) more than one pair of lamps, or

c) a lamp that:

i. was not originally fitted by the motorcycle manufacturer, or

ii. is not fitted in the original position.

Condition

2. A lamp is insecure.

3. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

4. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

Performance

5. When activated by switching on the direction indicator lamp or by turning the handle bars, a cornering lamp:

a) does not operate, or

b) does not operate in the direction of the turn.

6. A cornering lamp emits light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity from the other lamp in the pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead in the direction of the turn, eg due to modification, deterioration, dirt or an incorrect light source, or

e) too bright, causing dazzle to other road users, eg due to an incorrect light source or misalignment, or

f) altered, eg due to damage or modification.

7. Where a cornering lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1 Definitions

Cornering lamp means a lamp designed to emit light at the front of a vehicle to supplement the vehicle’s headlamps by illuminating the road ahead in the direction of the turn.

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps are considered retrofitted (non-OE).

Note 2

A vehicle originally manufactured with a cornering lamp arrangement that differs from what is required or permitted in this section may retain the original cornering lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 3

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply, be removed from the vehicle, or be disabled so that it does not emit a light.

Summary of legislation

Applicable legislation

Permitted equipment

1. One pair of cornering lamps fitted as OE.

Condition

2. A cornering lamp must be in sound condition.

Performance

3. A cornering lamp must operate in a way that is appropriate for the lamp and the vehicle.

4. A cornering lamp must emit light that is substantially white or amber.

5. A pair of cornering lamps must emit light that is approximately equal in colour and intensity.

6. A cornering lamp must emit a steady light.

7. A cornering lamp must provide sufficient light output to illuminate the road ahead in the direction of the turn.

8. A cornering lamp must be correctly aligned.

9. Where a cornering lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

10. A cornering lamp that is affected by a modification:

a) must meet equipment, condition and performance requirements, and

b) does not require LVV specialist certification.

Page amended 1 December 2016 (see amendment details).

4-4 Daytime running lamps

Reasons for rejection

Permitted equipment

1. A motorcycle is fitted with more than two lamps .

2. A lamp is fitted in a position other than at the front of the motorcycle.

3. A retrofitted lamp is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as practicable.

Condition

4. A lamp is insecure.

5. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

6. A lamp’s reflector is damaged or hasdeteriorated so that light output is reduced.

Performance

7. When switched on, a daytime running lamp does not operate.

8. When switched on, a daytime running lamp emits light that is:

a) projected in a direction other than to the front, or

b) not substantially white or amber, or

c) not approximately equal in colour or intensity from the other lamp in the pair, or

d) not steady, or

e) not bright enough to make the motorcycle more easily seen during the daytime, eg due to modification, deterioration, dirt or an incorrect light source, or

f) too bright causing significant dazzle to other road users, eg due to an incorrect light source, or

g) altered, eg due to damage or modification.

9. Where a daytime running lamp comprises an array of light sources, fewer than 75% of these operate.

10. A daytime running lamp continues to operate when the headlamps or fog lamps are switched on.

Note 1 Definition

Daytime running lamp means a lamp designed to emit a low-intensity light forward of a vehicle to make it more easily seen in daytime.

Note 2

A vehicle originally manufactured with a daytime running lamp arrangement that differs from what is required or permitted in this section may retain the original daytime running lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 3

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply, be removed from the vehicle, or be disabled so that it does not emit a light.

Summary of legislation

Applicable legislation

Permitted equipment

1 . A vehicle may have one or two daytime running lamps fitted to the front of the motorcycle.

Condition

2. A daytime running lamp must be in sound condition.

3. Where a daytime running lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Performance

4. A daytime running lamp must operate in a way that is appropriate for the lamp and the vehicle.

5. A daytime running lamp must emit light that is substantially white or amber.

6. A pair of daytime running lamps must emit light that is of approximately equal colour and intensity.

7. A daytime running lamp must emit a steady light.

8. A daytime running lamp must provide sufficient light output to make the motorcycle more easily seen during the daytime.

9. A daytime running lamp must be correctly aligned.

10. A daytime running lamp must not operate when a front fog lamp or a headlamp is in use.

Modifications

11. A daytime running lamp that is affected by a modification:

a) must meet equipment, condition and performance requirements, and

b) does not require LVV specialist certification.

Page amended 1 December 2016 (see amendment details).

4-5 Direction indicator lamps

Reasons for rejection

Mandatory and permitted equipment

1. A motorcycle first registered in New Zealand on or after 1 January 1978, other than one that is exempted (Table 4-5-1) is not fitted with:

a) one pair of lamps to the front, and

b) one pair of lamps to the rear.

2. A motorcycle first registered in New Zealand before 1 January 1978 is fitted with more than:

a) one pair of lamps to the front, or

b) one pair of lamps to the rear, or

c) two side-facing lamps on each side of the motorcycle.

3. A motorcycle first registered in New Zealand on or after 1 January 1978 is fitted with more than:

a) two pairs of lamps to the front, or

b) two pairs of lamps to the rear, or

c) two side-facing lamps on each side of the motorcycle.

4. A motorcycle is fitted with a lamp that is not in a pair.

5. A motorcycle is not fitted with a suitable device that indicates to the driver that a lamp has failed.

6. A retrofitted lamp:

a) is not symmetrically mounted, or

b) is not mounted as far towards each side of the motorcycle as is practicable, or

c) is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5 m is not practicable due to the shape of the bodywork of the motorcycle).

7. A motorcycle (eg a vintage or veteran motorcycle) does not meet standard direction indicator lamp requirements, and:

a) does not have a valid vehicle identity card with a lighting equipment endorsement, or

b) does not meet the conditions of the lighting equipment endorsement in its vehicle identity card.

Condition

8. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

9. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

10. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

11. A visual lamp failure warning device is obscured from the driver’s vision.

Performance

12. When switched on, a direction indicator lamp:

a) does not operate, or

b) does not begin flashing within one second of switching on, or

c) flashes:

i. faster than two flashes per second, or

ii. slower than one flash per second, or

iii at a different rate from other lamps on the same side.

13. When switched on, a direction indicator lamp emits a light that is:

a) not substantially white or amber to the front, or

b) not substantially amber or red to the rear, or

c) not substantially amber to the side, or

d) not approximately equal in colour or intensity from the other lamp in a pair, or

e) not bright enough to be visible from 100m in normal daylight and from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source, or

f) too bright, causing significant dazzle to other road users, eg due to an incorrect light source, or

g) altered, eg due to damage or modification.

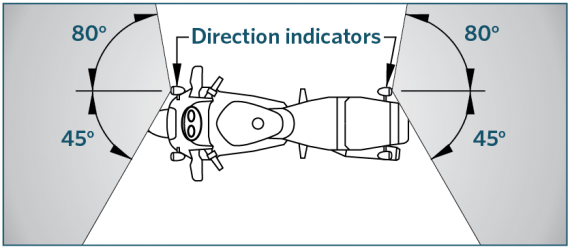

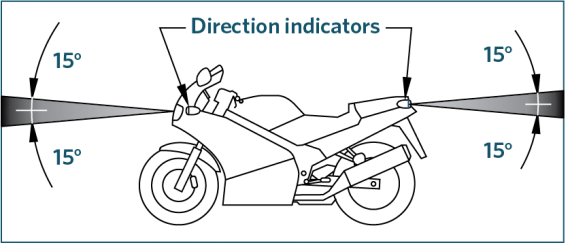

14. A mandatory lamp that is not OE and not mounted in the original position emits a light that is not visible within:

a) 15˚ above and below the horizontal, or

b) 45˚ inboard and 80˚ outboard.

15. A mandatory lamp’s visibility angles are reduced due to modification of the motorcycle so that emitted light is not visible within:

a) 15˚ above and below the horizontal (Figure 4-5-1), or

b) 45˚ inboard and 80˚ outboard (Figure 4-5-2).

16. An overlay has been applied that reduces or distorts the light emitted from the lamp (eg a tinted cover).

17. On a motorcycle manufactured for the American market and fitted with an OE combined stop/indicator lamp, the stop lamp function is not overridden by the indicator function.

18. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

19. A lamp-failure warning device does not operate.

Note 1 Definitions

Direction indicator lamp means a lamp designed to emit a flashing light to signal the intention of the driver to change the direction of the vehicle to the right or to the left.

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component, or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps are considered retrofitted (non-OE).

Note 2

A permitted (ie non-mandatory) rear or a non-OE side-facing direction indicator lamp that does not comply with equipment, condition and performance requirements must be made to comply or disabled so that it does not emit a light.

Note 3

A vehicle originally manufactured with a direction indicator lamp arrangement that differs from what is required or permitted in this section may retain the original direction indicator lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 4

Motorcycles first registered in New Zealand before 27 February 2005 may have rear direction indicator lamps that also function as reversing lamps.

Note 5

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle.

Table 4-5-1. Motorcycles exempted from direction indicator lamp requirements

Bajaj Super 150 Bultaco Sherpa T250 Bultaco Sherpa T350 Bultaco Frontera 250 Bultaco Frontera 370 DKW 125 Enduro Gemini MA 50 Honda NC50 Express Honda XR185 Enduro Honda XR200 Enduro | Honda XR250 Enduro Honda XR500 Enduro Kawasaki KLX 250 Enduro Kawasaki KV75 Kawasaki KT250 Mini Buffalo Montesa 250H6 Montesa 360H6 Montesa 247T Montesa 247 | Montesa 348 Suzuki DS80 Suzuki DR 370 Suzuki DR400 Suzuki PE 175 Suzuki PE 250 Suzuki RL 250 Suzuki TF 100 Suzuki TF 125 Suzuki TF 185 | Yamaha IT175 Yamaha IT400 Yamaha Trials TY175 Yamaha Trials TY250 Yamaha TT250 Yamaha TT500 Enduro Zundapp K 550 |

Figure 4-5-1. Direction indicator vertical beam angles

Figure 4-5-2. Direction indicator horizontal beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A motorcycle first registered in New Zealand before 1 January 1978 may be fitted with one pair to the front and one pair to the rear of the vehicle.

2. A motorcycle first registered in New Zealand on or after 1 January 1978 must be fitted with one or two pairs of lamps to the front and one or two pairs of lamps to the rear of the vehicle.

3. A retrofitted pair of lamps must be:

a) symmetrically mounted as far towards each side of the motorcycle as is practicable, and

b) at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork, not exceeding 2.1m.

4. A suitable device must be fitted that indicates to the driver the failure of a mandatory lamp.

5. A motorcycle (eg a vintage or veteran motorcycle) manufactured without lamps, or with lamps that cannot meet specified requirements, may obtain a WoF if:

a) the motorcycle has a valid vehicle identity card with a lighting equipment endorsement, and

b) the motorcycle meets the conditions of that endorsement.

6. On motorcycles of American origin, the stop lamp and direction indicator lamp functions may be combined in one lamp.

Condition

7. A direction indicator lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

8. A direction indicator lamp must operate in a way that is appropriate for the lamp and the vehicle.

9. A direction indicator lamp must emit a light that is substantially:

a) white or amber to the front, and

b) red or amber to the rear, and

c) amber to the side.

10. A lamp must flash at a fixed frequency in the range of 1–2 Hertz.

11. Each lamp in a pair must, when operated, emit a light of approximately equal intensity, colour and frequency.

12. The lamp-failure indicating device must function.

13. A lamp must emit a light that is visible from 100 m during normal daylight and 200 m in normal darkness.

14. A retrofitted mandatory lamp must emit a light that is visible within angles of:

a) 15˚ above and below the horizontal, and

b) 45˚ inboard, and

c) 80˚ outboard.

15. If a motorcycle of American origin is fitted with combined stop and indicator lamps, the indicator lamps must override the stop lamps so that the stop lamps operate as direction indicators.

16. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

17. A direction indicator lamp that is affected by a modification must meet equipment, condition and performance requirements.

Page amended 2 December 2019 (see amendment details).

Page updated 18 July 2023 (see details).

4-6 Forward-facing position lamps

Reasons for rejection

Mandatory and permitted equipment

1. One pair of lamps is not fitted to:

a) a motorcycle first registered in new Zealand on or after 1 January 1978 that exceeds 1.5m in width, or

b) a motorcycle that exceeds 2m in width.

2. A motorcycle is fitted with more than:

a) one pair of lamps, or

b) two single lamps.

3. A motorcycle (eg a vintage or veteran motorcycle) does not meet standard forward-facing position lamp requirements, and:

a) does not have a valid vehicle identity card with a lighting equipment endorsement, or

b) does not meet the conditions of the lighting equipment endorsement in its vehicle identity card.

4. A retrofitted lamp is mounted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the motorcycle).

5. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the motorcycle as is practicable.

Condition

6. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

7. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

Performance

9. When switched on, a forward-facing position lamp does not operate.

10. When switched on, a forward-facing position lamp emits a light that is:

a) not substantially white or amber, or

b) not diffuse, or

c) not projected to the front, or

d) not approximately equal in colour or intensity from the other lamp in a pair, or

e) not steady, or

f) not bright enough to be visible from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source

g) is altered, eg due to damage or modification.

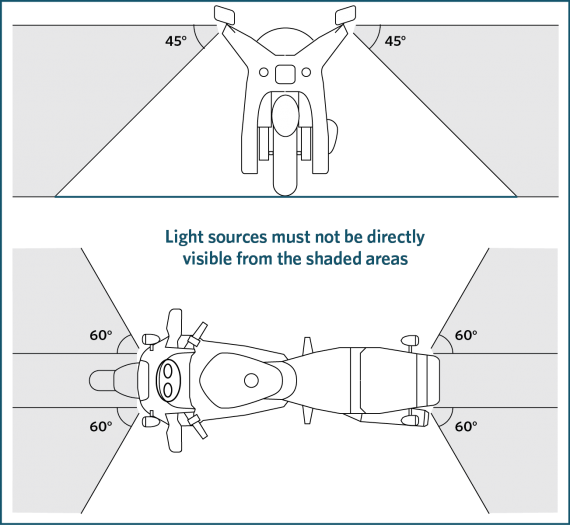

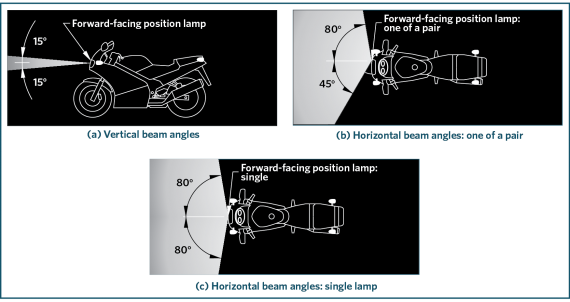

11. A mandatory lamp that is not OE and not mounted in the original position emits a light that is not visible within (Figure 4-6-1):

a) 15˚ above and below the horizontal, or

b) 45˚ inboard and 80˚ outboard.

12. A mandatory lamp’s visibility angles are reduced due to modification of the motorcycle so that emitted light is not visible within:

a) 15˚ above and below the horizontal, or

b) 45˚ inboard and 80˚ outboard.

13. An overlay has been applied that reduces or distorts the light emitted from the lamp (eg a tinted cover).

14. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp.

All other lamps are considered retrofitted (ie non-OE).

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A vehicle originally manufactured with a forward-facing position lamp arrangement that differs from what is required or permitted in this section may retain the original forward-facing position lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 3

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle.

Figure 4-6-1. Forward-facing position lamp beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. One pair of lamps must be fitted to:

a) a motorcycle first registered in New Zealand on or after 1 January 1978 that exceeds 1.5m in width

b) a motorcycle that exceeds 2m in width.

2. One or two lamps may be fitted to:

a) a motorcycle that does not exceed 1.5m in width

b) a motorcycle first registered in New Zealand before 1 January 1978 that does not exceed 2m in width.

3. A motorcycle (eg a vintage or veteran motorcycle) manufactured without lamps, or with lamps that cannot meet specified requirements, may obtain a WoF if:

a) the motorcycle has a valid vehicle identity card with a lighting equipment endorsement, and

b) the motorcycle meets the conditions of that endorsement.

4. A retrofitted pair of lamps must be symmetrically mounted as far towards each side of the motorcycle as practicable.

5. A retrofitted lamp must be mounted at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the motorcycle, not exceeding 2.1m.

Condition

6. A forward-facing position lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

7. A forward-facing position lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. A lamp must emit a light that is:

a) diffuse, and

b) substantially white or amber, and

c) steady, and

d) sufficient to indicate to other road users the presence and dimensions of the motorcycle, and

e) visible from 200 m in normal darkness, and

f) of approximately equal intensity and colour to the other lamp of a pair.

9. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

10. A forward-facing position lamp that is affected by a modification must meet the equipment, condition and performance requirements.

Page amended 2 December 2019 (see amendment details).

4-7 Rearward-facing position lamps

Reasons for rejection

Mandatory and permitted equipment

1. A motorcycle first registered in New Zealand on or after 1 January 1978 that is more than 1.5m wide:

a) is not fitted with one pair of lamps, or

b) is fitted with more than two pairs of lamps, or

c) is fitted with a lamp that is not in a pair.

2. A motorcycle first registered in New Zealand before 1 January 1978 or that is less than 1.5m wide is not fitted with at least one lamp.

3. A motorcycle (eg avintage or veteran motorcycle) does not meet standard rearward-facing position lamp requirements, and:

a) does not have a valid vehicle identity card with a lighting equipment endorsement, or

b) does not meet the conditions of the lighting equipment endorsement in its vehicle identity card.

4. A retrofitted lamp is mounted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the motorcycle).

5. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the motorcycle as is practicable.

Condition

6. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

7. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

Performance

9. When switched on, a mandatory lamp does not operate.

10. When switched on, a lamp emits a light that is:

a) not substantially red, or

b) not diffuse, or

c) not projected to the rear, or

d) not approximately equal in colour or intensity from that of the other lamp in a pair, or

e) not steady, or

f) not bright enough to be visible from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source

g) is altered, eg due to damage or modification.

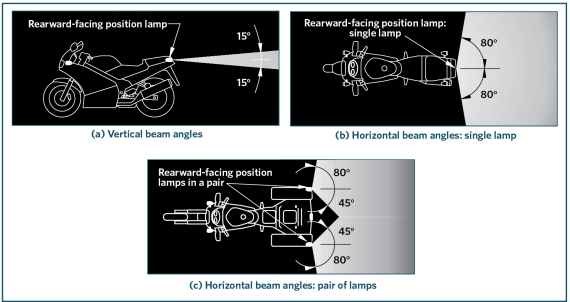

11. A non-OE mandatory lamp not mounted in the original position, emits a light that is not visible within (Figure 4-7-1):

a) 15˚ above and below the horizontal, or

b) 45˚ inboard and 80˚ outboard.

12. A modification to the motorcycle has reduced the mandatory lamp’s angles to less than (Figure 4-7-1):

a) 15˚ above and below the horizontal, or

b) 45˚ inboard and 80˚ outboard.

13. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp.

All other lamps are considered retrofitted (non-OE).

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A permitted rearward-facing position lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

A vehicle originally manufactured with a rearward-facing position lamp arrangement that differs from what is required or permitted in this section may retain the original rearward-facing position lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Figure 4-7-1. Rearward-facing position lamp beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A motorcycle first registered in New Zealand on or after 1 January 1978 and that is more than 1.5m wide must be fitted with one or two pairs of rearward-facing position lamps.

2. A motorcycle that was first registered in New Zealand before 1 January 1978 or that does not exceed 1.5m in width must be fitted with at least one rearward-facing position lamp.

3. A motorcycle (eg a vintage or veteran motorcycle) manufactured without lamps, or with lamps that cannot meet specified requirements, may obtain a WoF if:

a) the motorcycle has a valid vehicle identity card with a lighting equipment endorsement, and

b) the motorcycle meets the conditions of that endorsement.

4. A retrofitted pair of lamps must be:

a) symmetrically mounted as far towards each side of the motorcycle as is practicable, and

b) mounted at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the motorcycle, not exceeding 2.1m.

Condition

5. A rearward-facing position lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

6. A rearward-facing position lamp must operate in a way that is appropriate for the lamp and the vehicle.

7. A lamp must emit a diffuse light that is substantially red.

8. A lamp must emit a steady light.

9. A lamp must provide sufficient light output to indicate to other road users the presence and dimensions of the motorcycle.

10. A lamp must emit light that is visible from a distance of 200m in normal darkness.

11. A retrofitted mandatory lamp must be visible within angles of 15˚ above and below the horizontal, and within 45˚ inboard and 80˚ outboard.

12. Each lamp in a pair must, when operated, emit a light of approximately equal intensity and colour.

13. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

14. A rearward-facing position lamp that is affected by a modification must meet equipment, condition and performance requirements.

Page amended 2 December 2019 (see amendment details).

4-8 Side-marker lamps

Reasons for rejection

Prohibited equipment

1. A motorcycle is fitted with a side-marker lamp (Note 1).

Note 1

Only certain heavy trailers and vehicles with a length of 6 m or more may be fitted with side-marker lamps.

Note 2 Definitions

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Side-marker lamp means a position lamp designed to be fitted to the side of a vehicle or its load.

Summary of legislation

Applicable legislation

Prohibited equipment

1. A motorcycle must not be fitted with side-marker lamps (Note 1).

4-9 End-outline marker lamps

Reasons for rejection

Prohibited equipment

1. A motorcycle is fitted with an end-outline marker lamp (Note 1).

Note 2 Definitions

End-outline marker lamp means a position lamp designed to be fitted near the outer extremity of a vehicle in addition to forward-facing and rearward-facing position lamps; and includes a cab roof lamp.

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 1

End-outline marker lamps may be fitted only to certain heavy motor vehicles, and to light vehicles with an overall width exceeding 1.8 m.

Summary of legislation

Applicable legislation

Prohibited equipment

1. A motorcycle must not be fitted with end-outline marker lamps (Note 1).

4-10 Stop lamps

Reasons for rejection

Mandatory and permitted equipment

1. A motorcycle first registered in New Zealand on or after 1 January 1978 is not fitted with one stop lamp.

2. A motorcycle is fitted with more than two stop lamps.

3. A motorcycle (eg a vintage or veteran motorcycle) does not meet standard stop lamp requirements, and does not:

a) have a valid vehicle identity card with a lighting equipment endorsement, or

b) meet the conditions of the lighting equipment endorsement in its vehicle identity card.

4. A retrofitted stop lamp is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the motorcycle).

5. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the motorcycle as is practicable.

Condition

6. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

7. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

9. When the service brake is activated:

a) a mandatory lamp does not operate, or

b) a lamp does not remain steadily illuminated.

10. A lamp operates when the service brake is not activated.

11. A lamp emits a light that is:

a) not substantially red, or

b) not diffuse, or

c) not projected to the rear, or

d) not approximately equal in intensity from the other lamp in a pair, or

e) not bright enough to produce a light that is visible from 100m in normal daylight, eg due to modification, deterioration, dirt or an incorrect light source, or

f) is altered, eg due to damage or modification.

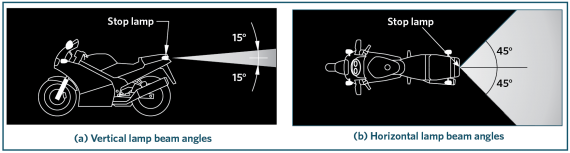

12. A non-OE mandatory lamp not mounted in the original position, emits a light that is not visible within

(Figure 4-10-1):

a) 15˚ above and below the horizontal, and

b) 45˚ either side of the vertical.

13. A modification to the motorcycle has reduced the mandatory lamp’s angles to less than (Figure 4-10-1):

a) 15˚ above and below the horizontal, or

b) 45˚ either side of the vertical.

14. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

15. On a motorcycle manufactured for the American market and fitted with an OE combined stop/indicator lamp, the stop lamp function is not overridden by the indicator function.

Note 1 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component, or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps are considered retrofitted (non-OE).

Stop lamp means a lamp that is designed to operate when the service brake is activated, that is when either the front service brake, the rear service brake, or both the front and rear service brakes are activated.

Note 2

A permitted stop lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

A vehicle originally manufactured with a stop-lamp arrangement that differs from what is required or permitted in this section may retain the original stop lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Figure 4-10-1. Stop-lamp beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A motorcycle first registered in New Zealand before 1 January 1978 may be fitted with one or two stop lamps.

2. A motorcycle first registered in New Zealand on or after 1 January 1978 must be fitted with one or two stop lamps.

3. A motorcycle (eg a vintage or veteran motorcycle) manufactured without lamps, or with lamps that cannot meet specified requirements, may obtain a WoF if:

a) the motorcycle has a valid vehicle identity card with a lighting equipment endorsement, and

b) the motorcycle meets the conditions of that endorsement.

4. A retrofitted pair of stop lamps must be symmetrically mounted as far towards each side of the motorcycle as is practicable.

5. A retrofitted stop lamp must be fitted at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the motorcycle, not exceeding 2.1m.

Condition

6. A stop lamp must:

a) be in sound condition.

b) not be obscured (if a mandatory lamp).

Performance

7. A stop lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. The light emitted from a stop lamp must be diffuse light that is substantially red.

9. A mandatory stop lamp must operate when a service brake is activated.

10. A mandatory stop lamp must provide sufficient light output to fulfill its intended purpose.

11. A stop lamp must emit a steady light.

12. A retrofitted mandatory stop lamp must emit a light that is visible within the angles of 15˚ above and below the horizontal, and 45˚ inboard and outboard.

13. If a motorcycle of American origin is fitted with combined stop and direction indicator lamps, the indicator lamps must override the stop lamps so that the stop lamps will operate as direction indicators.

14. Where a stop lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

15. A stop lamp that is affected by a modification must meet equipment, condition and performance requirements.

Page amended 2 December 2019 (see amendment details).

Page updated 18 July 2023 (see details).

4-11 High-mounted stop lamps

Reasons for rejection

Permitted equipment

1. A motorcycle is fitted with more than two high-mounted stop lamps.

2. A lamp is not fitted in a central high-mounted position.

Condition

3. A lamp is insecure.

4. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

5. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

6. When the service brake is activated, a lamp does not remain steadily illuminated.

7. A lamp operates when the service brake is not activated.

8. A lamp emits a light that:

a) is not substantially red, or

b) is not diffuse, or

c) is not projected to the rear, or

d) has insufficient light output to produce a light that is visible from 100 m in normal daylight, eg due to modification, deterioration or an incorrect light source.

9. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

10. An overlay has been applied that reduces or distorts the light emitted from the lamp (eg a tinted cover).

Note 1 Definitions

High-mounted stop lamp means a stop lamp that is designed to be fitted in a central, high-mounted position at the rear of the vehicle.

Stop lamp means a lamp that is designed to operate when the service brake is activated.

Note 2

A high-mounted stop lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

A vehicle originally manufactured with a high-mounted stop lamp arrangement that differs from what is required or permitted in this section may retain the original high-mounted stop lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Permitted equipment

1. A motorcycle may be fitted with one or two high-mounted stop lamps.

2. A lamp must be fitted in a central high-mounted position at the rear of the motorcycle.

Condition

3. A high-mounted stop lamp must be in good condition.

Performance

4. A high-mounted stop lamp must operate in a way that is appropriate for the lamp and the vehicle.

5. The light emitted from a high-mounted stop lamp must be diffuse light that is substantially red.

6. A high-mounted stop lamp must emit a steady light.

7. At least one unobscured lamp must operate when the motorcycle’s service brakes are activated.

8. Where a high-mounted stop lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

9. A high-mounted stop lamp that is affected by a modification:

a) must meet equipment, condition and performance requirements, and

b) does not require LVV specialist certification.

Page amended 2 December 2019 (see amendment details).

4-12 Rear-reg.-plate illumination lamps

Reasons for rejection

Mandatory equipment

1. A motorcycle is not fitted with at least one rear-registration-plate illumination lamp.

Condition

2. A lamp is insecure.

3. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

4. A reflector, or lens, is damaged or has deteriorated so that light output is reduced.

Performance

5. The lamp emits a light that is not:

a) substantially white, or

b) steady, or

c) diffuse.

6. The lamp does not illuminate the registration plate (eg either the lamp or plate have been moved, or the lamps orientation has been changed).

7. The light source of a lamp is visible from the rear of the motorcycle.

8. A motorcycle (eg a vintage or veteran motorcycle) does not meet standard rear-registration-plate illumination lamp requirements, and does not:

a) have a valid vehicle identity card with a lighting equipment endorsement, or

b) meet the conditions of the lighting equipment endorsement in its vehicle identity card.

9. An overlay has been applied that reduces or distorts the light emitted from the lamp (eg a tinted cover).

Note 1 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component, or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Rear registration-plate illumination lamp means a lamp designed to illuminate the rear registration plate of a vehicle.

Note 2

A vehicle originally manufactured with a rear registration-plate illumination lamp arrangement that differs from what is required or permitted in this section may retain the original rear registration-plate illumination lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Mandatory equipment