Correct as at 26th April 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > Technical bulletins (CoF)

Technical bulletins (CoF)

1 Expiry dates recorded on ID label/plate and HVS certificate (LT400)

Application

This technical bulletin applies to components with heavy vehicle specialist certification (LT400).

Clarification

Some heavy vehicle specialist certifiers (HVS certifiers) have been stipulating an expiry date on an identification label/plate and heavy vehicle specialist certificate (LT400) for items other than the ones where the relevant standard or code specifically allows or requires an expiry date.

In other cases, some CoF inspectors have been entering an expiry date on LANDATA, most frequently 10 years after the date of the LT400, even if the certificate does not contain such data.

Both of these situations cause avoidable difficulties to the operators, which is made even more obvious if a relevant standard (eg NZ5444) has changed.

Inspection

1. CoF inspectors are not to enter any expiry date on LANDATA unless the LT400 was issued for:

a) a towing connection, first certified to NZS5446 after 1 August 1991, or

b) a bolster attachment as per the Bolster Attachment Code.

2. Where an expiry date has been entered on an identification label/plate, or LANDATA for the specialist certification of items other than those identified under 1 above, CoF inspectors must disregard it. In such cases, a lapsed expiry date is not a reason for rejection.

Page amended 1 April 2021 (see amendment details).

2 OEM wheel rim options

Vehicle inspection requirements manual reference

Safety concern

The fitting of non-approved wheel rims can cause component overloading.

Inspection

The fitting of different wheels to OEM requires heavy vehicle specialist certification unless they are approved by the vehicle manufacturer.

The following vehicle makes and models distributed by the Motor Industry Association of New Zealand and sold through its franchise dealer network have been confirmed as having optional OEM wheel rims.

Vehicles fitted with wheel rims meeting the specified requirements do no not require heavy vehicle specialist certification.

Approved distributors wishing to update this bulletin should email their information to virmupdates@nzta.govt.nz

Hino Distributors (NZ) Ltd.

Hino Distributors (NZ) Ltd. advises that the heavy motor vehicle makes listed below that have disc wheel rims have the following OEM approved rim options:

Models | Rim Type | Rim Brand Name | Rim Diameter | Rim Width |

|---|---|---|---|---|

700 Series FS1A, FS1E, SS1E, SH1E

500 Series FG8J, GH8J, FM8J GH1A, FL8J, FM1A

FS1K Model FS1K | Steel | Topy | 22.5” | 8.25” 11.75” |

Steel | Jansta | 22.5” | 8.25” 11.75” | |

Steel | Accuride | 22.5” | 8.25” 11.75” | |

Alloy | Weight Cheetah | 22.5” | 8.25” 11.75” | |

Alloy | Alcoa | 22.5” | 8.25” 11.75” |

The fitting of the above wheel rims does not alter the manufacturer's original axle ratings.

Isuzu NZ

Isuzu NZ advises that the heavy motor vehicle marques & models listed below that have 22.5-inch, disc wheel rims have the following OEM rim width options for single tired axles.

Make/Model | Rim type | Rim brand name | Rim diameter | Rim width |

|---|---|---|---|---|

Isuzu GIGA 6x4, model year 2015, (10th character of VIN = F) | Alloy | Alcoa | 22.5" | 8.25" |

11.75" | ||||

| Isuzu GIGA CYZ 6x4 from model year 2015, (10th character of VIN = F) | Steel | Maxion | 22.5" | 8.25" |

| Accuride | 11.75" | |||

Isuzu GIGA 8x4, model year 2015, (10th character of VIN = F) | Steel | Maxion | 22.5" | 8.25" |

Isuzu GIGA CYZ 6x4 from model year 2022, (10th character of VIN = N) | Alloy | Alcoa | 22.5" | 8.25" |

11.75" | ||||

Isuzu GIGA CYZ 6x4 from model year 2022, (10th character of VIN = N) | Steel | Maxion | 22.5" | 8.25" |

| Accuride | 11.75" |

The fitting of the above wheel rims does not alter the manufacturer's original axle ratings.

Penske New Zealand

Penske New Zealand advises that the heavy motor vehicle makes listed below have the following OEM-approved wheels:

| Make | Rim type | Rim brand name | Rim diameter | Rim width |

|---|---|---|---|---|

| MAN Truck and Bus | Steel | MAN | 22.5" | 7.50" |

| 8.25" | ||||

| Alloy | Alcoa | 9.00" | ||

| 11.75" | ||||

| MAN 4x4 models | Steel | MAN | 20" | 10.00" |

| 22.5" | 7.50" | |||

| 8.25" | ||||

| 9.00" | ||||

| 11.75" | ||||

| 24" | 8.50" | |||

| TRS Tyre & Wheel Ltd | 20" | 11.00" | ||

| 13.00" | ||||

| 22.5" | 11.75" | |||

| 14.00" | ||||

| Alloy | Alcoa | 22.5" | 7.50" | |

| 8.25" | ||||

| 9.00" | ||||

| 11.75" |

The fitting of the above wheel rims does not alter the manufacturer's original axle ratings.

Mercedes-Benz NZ

Mercedes-Benz NZ advises that the heavy motor vehicle makes listed below have the following OEM-approved wheels:

Make | Rim Type | Rim brand name | Rim diameter | Rim width |

|---|---|---|---|---|

Mercedes-Benz (MB) | Alloy | Alcoa | 19'5 | 6.75" |

Steel | MB | 20" | 11" | |

Steel | MB | 22.5" | 8.25" | |

9.00" | ||||

11.75" | ||||

Alloy | Alcoa | 8.25" | ||

9.00" | ||||

11.75" | ||||

| 6X4 PM model only | Alloy | Speedline | 22.5" | 8.25" |

| 9.00" | ||||

| 11.75" |

The fitting of the above wheel rims does not alter the manufacturer's original axle ratings.

Motor Truck Distributors (NZ) Ltd.

Motor Truck Distributors (NZ) Ltd advises that the heavy motor vehicle marques listed below that have 22.5 inch, disc wheel rims have the following OEM rim width options for single tired axles:

Make | Rim type | Rim brand name | Rim diameter | Rim width |

|---|---|---|---|---|

Mack Truck | Steel | Mack | 22.5” | 8.25” 9.00” 11.75” 12.25” (Mack Truck only) |

Alloy | Alcoa | |||

Renault Truck | Steel | Renault | ||

Alloy | Truck Speedline | |||

Volvo Bus and Volvo Truck | Steel | Volvo | ||

Alloy | Alcoa |

The fitting of the above wheel rims does not alter the manufacture’s original axle rating.

Scania NZ Ltd.

Must be used for Scania vehicles entry certified on or after 1 February 2023. See Cable Price (NZ) Ltd. for Scania vehicles first registered before 1 February 2023.

Scania NZ advises that the heavy motor vehicle makes listed below that have disc wheel rims have the following OEM approved rims options for single tired axles.

Make/Model | Rim type | Rim brand name | Rim diameter | Rim width |

|---|---|---|---|---|

Scania Truck | Steel | Scania | 20.0” | 8.50” |

20.0” | 10.00” | |||

22.0” | 8.00” | |||

22.5” | 7.50” | |||

22.5” | 8.25” | |||

22.5” | 9.00” | |||

22.5” | 11.75” | |||

24.0” | 8.50” | |||

Alloy | Alcoa | 22.5” | 8.25” | |

22.5” | 9.00” | |||

22.5” | 11.75” | |||

Scania Bus | Steel | Scania | 22.5” | 7.50” |

22.5” | 8.25” | |||

22.5” | 9.00” | |||

22.5” | 11.75” | |||

Alloy | Alcoa | 22.5” | 8.25” | |

22.5” | 9.00” | |||

22.5” | 11.75” |

Some rims are axle specific, contact Scania NZ for details.

The fitting of the above rims does not alter the manufacturer’s original axle ratings.

Southpac Trucks Ltd.

Southpac Trucks Ltd advises that the heavy motor vehicle makes listed below that have disc wheel rims have the following OEM approved rim options:

Make | Rim Type | Rim Brand Name | Rim Diameter | Rim Width |

|---|---|---|---|---|

DAF | Steel | DAF | 22.5" | 8.25" |

Alloy | Alcoa | 11.5" | ||

| 11.75" | ||||

Kenworth | Steel | KW | 22.5" | 8.25" |

| 9.00" | ||||

| Alloy | Alcoa | 22.5" | 8.25" | |

| 9.00" | ||||

| 12.25" | ||||

| Alloy | Armoury | 22.5" | 8.25" | |

| 9.00" | ||||

| 12.25" |

The fitting of the above wheel rims does not alter the manufacturer's original axle ratings.

UD Truck Distributors (NZ) Ltd.

UD Truck Distributors (NZ) Ltd advises that the heavy motor vehicle marques listed below that have 22.5 inch, disc wheel rims have the following OEM rim width options for single tired axles:

Make | Rim type | Rim brand name | Rim diameter | Rim width |

|---|---|---|---|---|

| UD Trucks (Heavy Duty) 2009-onwards | Steel | Topy | 22.5” | 8.25” 11.75” |

Steel | Jantsa | |||

Alloy | Alcoa | |||

Alloy | Wheels India | |||

| Steel | Wheels India |

The fitting of the above wheel rims does not alter the manufacture’s original axle rating.

Cable Price (NZ) Ltd.

Must only be used for Scania vehicles first registered up to and including 31 January 2023. See Scania NZ Ltd. for Scania vehicles first registered from 1 February 2023.

CablePrice (NZ) Ltd advises that the heavy motor vehicle makes sold under licence by Cable Price (NZ) Ltd up to and including 31/01/2023 and listed below have disc wheel rims which have the following OEM approved rim options. Any Scania vehicle entry certified after and including 01/02/2023 must conform to the approved wheel rim options covered in the Scania NZ Ltd list above:

| Make | Rim type | Rim brand name | Rim diameter | Rim width |

|---|---|---|---|---|

| Scania Truck & Scania Bus | Steel | Scania | 22.5" | 7.50" |

| 8.25" | ||||

| 9.00" | ||||

| 11.75" | ||||

| Alloy | Alcoa | 22.5" | 8.25" | |

| 9.00" | ||||

| 11.75" | ||||

| Scania 4x4 & 6x6 models | Steel | Scania | 22.5" | 7.50" |

| 8.25" | ||||

| 9.00" | ||||

| 11.75" | ||||

| TRS Tyre & Wheel Ltd | 22.5" | 14.00" | ||

| 20" | 11.00" | |||

| 13.00" | ||||

| Alloy | Alcoa | 22.5" | 8.25" | |

| 9.00" | ||||

| 11.75" |

The fitting of the above wheel rims does not alter the manufacturer's original axle ratings.

Page amended 1 April 2021 (see amendment details)

Page updated 7 November 2023 (see update details)

3 Rear seatbelts as aisle obstructions in passenger service vehicles

Vehicle inspection requirements manual references

This bulletin gives guidance to vehicle inspectors in applying the following requirements in the VIRM: In-service certification (WoF and CoF):

Application

This document applies to people-mover vehicles, such as Toyota Previas, that are used as passenger service vehicles (PSVs) and have factory-fitted seats and seatbelts that comply with approved seat and seatbelt standards.

Safety concern

Practical tests have been carried out by the Low Volume Vehicle Technical Association (LVVTA) to investigate the concern that rear seatbelts fitted to Toyota Previa vehicles may obstruct passengers in the rear row of seats from exiting the vehicle in an emergency. Results show that seatbelts fitted in these types of vehicle may cause a minor nuisance but not an obstruction; passengers in the rear row of seats can still exit in a reasonable manner in emergency situations.

Inspection

Factory-fitted seatbelts in people-mover vehicles operated as PSVs should not be considered as obstructions to the aisle provided:

a) seats and seatbelts are original equipment fitted by the manufacturer, and

b) the seatbelt that crosses the aisle is of a retractable type, and

c) the seats, seatbelts and their installation are unmodified (other than minor trimming of the seatback width to achieve the required aisle width), and standards compliant if applicable.

This concession does not apply to:

- fold-down seats encroaching on aisle space

- vehicles that are retrofitted with additional and/or modified seat and seatbelt arrangements. Disconnecting or disabling seat rotation mechanisms is not considered to be a modification.

These vehicles must comply with all PSV requirements, such as aisle width.

4 Taximeter compliance

Meters are not required in small passenger service vehicles. However, if you do use a meter you must ensure that it is accurate.

From 1 October 2017 meters are not a CoF inspection item and meter certification is not carried out by persons authorised by the Transport Agency.

Page amended 1 October 2017 (see amendment details).

5 Door test procedure: Compressed air- or vacuum-operated doors

Legal requirements

The tests are based on the following requirements (see Schedule for details):

- Land Transport Rule: Passenger Service Vehicles 1999: sections 2.2(2) and 2.2(2A)

- VIRM: In-service certification (WoF and CoF): 6-2 PSV doors and doorways (Heavy PSVs)

- VIRM: In-service certification (WoF and CoF): 6-2 PSV doors and doorways (Light PSVs)

- Test bar referred to in section 7.6.5 of EU Directive 2001/85/EC.

Equipment required

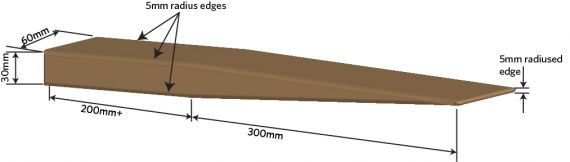

- Test bar (Figure 5-1-1)

- Scale with a midrange of approximately 12kg.

Test overview

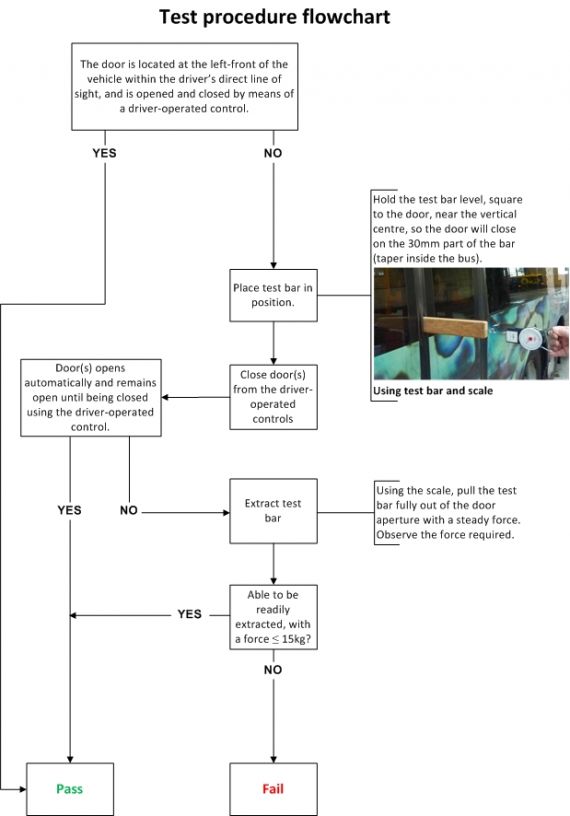

There are two test types to be carried out, as follows:

1. Testing that the door opens automatically when there is an obstruction:

Test 1: Using the non-tapered end of the test bar

2. Testing that, if the door does not open, the test bar can be easily removed, using the following test:

Test 2: Using a scale, pull to ascertain the force required to extract test bar.

Perform test(s) as outlined in the flowchart below.

-

Download the flowchart (PDF | 199KB).

Schedule

From Land Transport Rule: Passenger Service Vehicles 1999: sections 2.2 and 2.2(2A)

2.2(2) A power-operated door, its control mechanisms and associated equipment must be designed, constructed and maintained so that the opening and closing force of the door, or its method of operation, is unlikely to injure or trap any person.

2.2(2A) Without limiting the means of compliance with 2.2(2) a power-operated door complies with 2.2(2) if:

a) the door is:

1. located at the left-front of the vehicle; and

2. within the driver’s direct line of sight; and

3. opened and closed by means of a driver-operated control; or

b)in the event that the door closes onto part of a person, the person can readily extract the trapped part.

Taken from:

- VIRM: In-service certification (WoF and CoF): 6-2 PSV doors and doorways (Heavy PSVs)

- VIRM: In-service certification (WoF and CoF): 6-2 PSV doors and doorways (Light PSVs)

Power-operated doors

A power-operated door is such that it is likely to injure or trap a person, eg by excessive opening or closing force, or damage or deterioration (Note 1).

Test bar dimensions:

Section of height 60mm, width 30mm with corners radiused to 5mm and tapered at one end over a length of 300mm from a thickness of 30mm to a thickness of 5mm (Figure 5-1-1). Surface to be smooth but shall not be treated with polish or lubricated.

Figure 5-1-1. Test bar dimensions

Note 1

A power-operated door may be deemed acceptable in terms of potential injury or entrapment of a person due to excessive closing force if:

a) the door is located at the left-front of the vehicle within the driver’s clear view from his seat (without using mirrors or CCTV), and is opened and closed by means of a driver-operated control, or

b) the door automatically opens when it meets an obstruction, and remains open until being closed using the driver-operated control, or

c) in the event that the door closes onto part of a person, the person can readily extract the trapped part.

Page amended 1 November 2014 (see amendment details).

6 Michelin X Multiway tyres

Reference

Clarification

Michelin X Multiway tyres are like a cross between directional and normal highway tyres however the direction of rotation can be in either direction - meaning the tyre fits into the normal highway tread type classification.

The arrow with the larger head indicates the manufacturer’s preferred direction of rotation for the tyre, optimizing tread wear performance. The manufacturer recommends that, especially when new, tyres marked with a bi-directional arrow should be run in the direction of rotation indicated by the larger arrow head.

However, if a tyre marked with the bi-directional arrow shows an irregular wear profile, (for example, a sloped wear pattern) then it may be turned on the rim and run in the direction of the smaller arrow head with no detriment to any other performance criteria. In cases such as this, the manufacturer recommends that all tyres on the same axle should be turned on the rim such that all arrows face in the same direction.

Inspection

A vehicle presented that has these tyres is subject to the usual in-service requirements for normal highway tread type tyres.

- Despite the manufacturer’s recommendation, there is no reason for rejection if the bi-directional arrows do not face in the same direction.

- There is no reason for rejection if tyres with bi-directional arrows are mixed on the same axle with other Normal Highway tread type tyres.

- Tyres with bi-directional arrows cannot be mixed with asymmetric or directional tyres.

Page added 10 June 2016 (see details)

7 Stock crate retention certification

It is important that stock crate retention is correctly certified to the appropriate standard. This technical bulletin provides explanations of different types of stock crates (fitted to a vehicle with a GVM of 6000 kg or more) their attachments, how to identify them, and how to identify their certification.

References

- Heavy vehicles: 14-2 Stock crates and stock crate retention devices

- Heavy trailers: 10-2 Stock crates and stock crate retention devices

Stock crate attachment types

There are three common ways that stock crates are attached to heavy motor vehicles:

- J-hook

- Monocoque

- Deck-mounted.

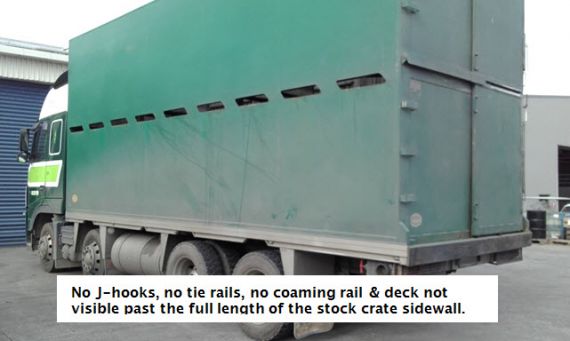

J-hook

The crate attachment is easy to see as the J-hooks sit on the outside (Figure 7-1-1).

Figure 7-1-1. J-hook stock crate

The stock crate is not a vehicle therefore the actual crate J-hook mountings and J-hooks cannot be certified with an LT400. The design can be certified with a design certificate and a plate or label attached to the stock crate.

The design certification for the stock crate anchorage is catered for with an design certificate and the certificate will be held on file by the stock crate manufacturer.

The stock crate identification plate or label needs to have all of the following information:

- Company name

- Serial number

- Date of manufacture

- J-hook capacity load

- J-hook capacity individual

- Number per side.

A certificate of fitness inspector can be satisfied in regard to the certification of the stock crate J-hook mountings if a plate or label providing all the information above is attached to the crate and there is a separate load anchorage certification plate fitted to the vehicle to cover the deck mounting points (coaming rail) used to secure the stock crate.

Monocoque

A stock crate and vehicle constructed as one integral assembly, usually without a rigid chassis, with the wheel and axle assemblies , suspension and steer dolly (in the case of a full trailer) attached directly to the crate assembly. The stock crate fits directly to the chassis and there are no coaming rails or tie rails. (Figure 7-1-2).

Figure 7-1-2. Monocoque stock transfer vehicle

This must be certified to NZS5413.

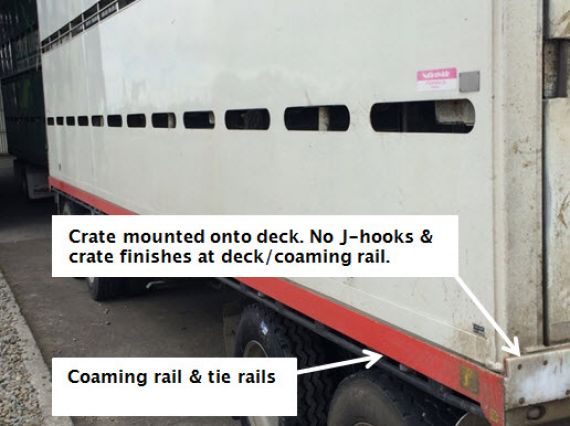

Deck-mounted

Another common attachment is the deck-mounted stock crate. There are no external attachments and the fitment looks very similar to monocoque except that the crate sits on a deck which is visible with a coaming rail and general fitment of load anchorages and tie rails (Figure 7-1-3).

Figure 7-1-3. Deck-mounted stock crate

Requirements for certification of deck mounted stock crates.

The stock crate is not a vehicle therefore the actual crate bolt mountings and bolts cannot be certified with an LT400. The design can be certified with a design certificate and a plate or label attached to the stock crate.

The design certification for the stock crate anchorage is catered for with an engineer’s design certificate and the engineers certificate will be held on file by the stock crate manufacturer.

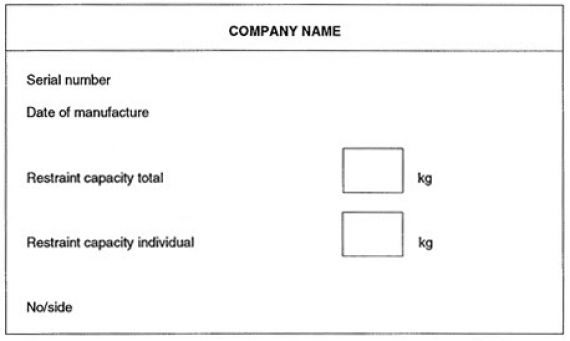

The stock crate identification plate or label needs to have all of the following information:

- Company name

- Serial number

- Date of manufacture

- Restraint capacity load

- Restraint capacity individual

- Number per side

A certificate of fitness inspector can be satisfied in regard to the certification of the stock crate bolted mountings if a plate or label providing all the information above is attached to the crate and there is a separate load anchorage certification plate fitted to the vehicle to cover the deck mounting points used to secure the stock crate.

Sample stock crate plate design

Notes

- Any vehicles inspected after 1/11/2016 that do not meet the requirements but are fit for purpose (inspector has completed a detailed visual inspection and is confident that the anchorage points are in good condition) may be passed for CoF but must have certification completed (in line with this technical bulletin) before next CoF. Notes must be recorded showing the completion of this inspection and actions needed to be taken before next CoF.

- Any vehicles presented for inspection 1 year after 1/11/2016 will not pass for CoF without correct certification.

- All vehicles presented for first time entry compliance must meet these requirements for stock crate/load anchorage immediately.

Page amended 1 November 2017 (see amendment details)

Page updated 27 February 2023 (see details)

8 Factory produced bodies fitted to new imported Heavy Motor Vehicles (first registered in New Zealand)

Vehicle inspection requirements manual reference

Manufacturers of heavy motor vehicles are building bespoke vehicles more and more in-house using the same facilities and manufacturing processes that are used for the main cab/chassis unit. Body fitments include but are not limited to:

- Tipper bins

- Tank units (fuel/water/fluids)

- Box bodies (refrigerated/curtainsided/enclosed)

- Motorhomes

- Specialty units (compactor/bin lifter/sweeper/suction)

- Dual steering conversion

This bulletin gives guidance to vehicle inspectors in applying the requirements in the VIRM.

Application

Under the Land Transport Rule: Heavy Vehicles 2004, a modification or repair that affects the vehicle structure must be inspected and certified by a heavy vehicle specialist certifier (HVSC).

The vehicles listed in the tables below have a factory produced body structure that has been manufactured by the listed manufacturer in the same facilities and using the same production standards as the main cab/chassis unit, these vehicles can be accepted for entry certification and do not need to be certified by an HVSC.

These vehicles may carry a second stage manufacturers plate or label, any details contained, such as GVM, standards compliance etc are to be considered as the manufacturer’s final configuration. Alternatively, a statement on the SoC that confirms the body unit was fitted at factory may also be accepted as proof of standards compliance for the unit.

Manufacturers with bodies that do not require an LT400

Hino

| Make | Model | Submodel |

|---|---|---|

| Hino | Model 300 | XZU605R-WKTMSQ3 |

| Hino | Model 300 | XZU605R-HKMMSQ3 |

| Hino | Model 300 | XZU710R-HKFQTQ3 |

| Hino | Model 300 | XZU710R-HKFTTQ3 |

| Hino | Model 300 | XZU710R-HKTRSQ3D |

| Hino | Model 300 | XZU710R-WKTSSQ3D |

| Hino | Model 300 | XZU730R-QKFTTQ3 |

| Hino | Model 300 | XZU730R-QKFTTQ3 |

| Hino | Model 300 | XZU655R- WKMMSQ3D |

| Hino | Model 300 | XZU710R- WKFQTQ3D |

| Hino | Model 300 | XZU710R- WKFQTQ3D-1 |

| Hino | Model 300 | XZU710R- WKFTTQ3D |

| Hino | Model 300 | XZU710R- WKFTTQ3D-1 |

| Hino | Model 300 | XZU710R- WKTRSQ3D |

| Hino | Model 300 | XZU710R- WKTRSQ3D-1 |

| Hino | Model 300 | XZU730R- ZKFQTQ3D |

| Hino | Model 300 | XZU730R- ZKFQTQ3D-1 |

| Hino | Model 300 | XZU730R- ZKFTTQ3D |

| Hino | Model 300 | XZU730R- ZKFTTQ3D-1 |

| Hino | Model 300 | XZU605R- WKMMSQ3D |

| Hino | Model 300 | XZU710R- WKTSSQ3D |

| Hino | Model 300 | XZU710R- WKTSSQ3D-1 |

| Hino | Model 300 | XZU730R- ZKTSSQ3D |

| Hino | Model 300 | XZU730R- ZKTSSQ3D-1 |

| Hino | Model 500 | FC7JEMM-ANU |

| Hino | Model 500 | FC7JGMA-ANU |

| Hino | Model 500 | FC2AE1M-DBAAE |

| Hino | Model 500 | FC2AG1A-DBAAE |

| Hino | Model 500 | FE2AJ1A-FCCAED |

Isuzu

Make | Model |

|---|---|

Isuzu | NLR |

| Isuzu | NMR |

Isuzu | NPR |

Isuzu | NQR |

Isuzu | FRR |

Foton

| Make | Model | Model code |

|---|---|---|

| Foton | Aumark | BJ1051 (2.8L) - BJ1051V9JD4-FP Tipper |

| Foton | Aumark | BJ1051 (2.8L) - BJ1051V9JD4-FP Pantech with tail lift |

| Foton | Aumark | BJ1065LT5995 - Tipper |

| Foton | Aumark | BJ1065LB5995 - Box Body with/without tail lift |

| Foton | Aumark | BJ1065LF5995 - Refrigerated pantech with/without tail lift |

| Foton | Aumark | BJ1079 (3.8L) - BJ1079VDJE6-FP Pantech with tail lift |

| Foton | Aumark | BJ1079A (3.8L) - BJ1079VDJE6-FP Pantech with tail lift |

| Foton | Aumark | BJ1099VEJEA-FP Pantech with tail lift |

| Foton | Aumark | BJ1078LT5995 - Tipper |

| Foton | Aumark | BJ1078LT8495 - Tipper |

| Foton | Aumark | BJ1078LB5995 - Pantech with/without tail lift |

| Foton | Aumark | BJ1078LB8495 - Pantech with/without tail lift |

| Foton | Aumark | BJ1078LF5995 – Refrigerated pantech with/without tail lift |

| Foton | Aumark | BJ1078LF8495 – Refrigerated pantech with/without tail lift |

| Foton | Aumark | BJ1078 - Pantech with tail lift |

| Foton | Aumark | BJ1078 - Tipper |

| Foton | Aumark | BJ1088 - Pantech with tail lift |

| Foton | Aumark | BJ1088LB5995 - Pantech with/without tail lift |

| Foton | Aumark | BJ1088LB8995- Pantech with/without tail lift |

| Foton | Aumark | BJ1088LF5995– Refrigerated pantech with/without tail lift |

| Foton | Aumark | BJ1088LF8995 – Refrigerated pantech with/without tail lift |

| Foton | Auman | BJ1126MT11995 - Tipper |

| Foton | Auman | BJ1126MT14000 - Tipper |

| Foton | Auman | BJ1088LT8995 - Tipper |

| Foton | Auman | BJ1126MF11995 - Refrigerated pantech with/without tail lift |

| Foton | Auman | BJ1126MF14000 - Refrigerated pantech with/without tail lift |

Mercedes-Benz

Make | Model | Model code |

|---|---|---|

| Mercedes-Benz | Econic | Cab/Chassis – Dual steering conversion |

| Mercedes-Benz | Econic | Dual steering and rubbish compactor |

Mitsubishi Fuso/Fuso

Make | Local Model Code | Model Name |

|---|---|---|

MITSUBISHI FUSO | FE150T | Canter 3.5t Tipper |

MITSUBISHI FUSO | FEA55T1 | Canter 2.5T Tipper |

MITSUBISHI FUSO | FEC60T1 | Canter 3.0t Tipper |

MITSUBISHI FUSO | FEC65T1 | Canter 3.5t Tipper |

MITSUBISHI FUSO | FEC75T1 | CANTER 4X2 TIPPER |

FUSO | FEA61BR | Canter 616 - City Tipper |

FUSO | FEC81CR | Canter 616/716/816 - Tipper |

FUSO | FIV2PFX2RFBAXXT | Fighter FI1217C Tipper |

FUSO | FIV2PFX2RFBA(T) | Enduro FI1217 Tipper |

FUSO | FJX3WK2RFBAXXT | Fighter FJ2528C TIPPER |

FUSO | FJX3WK2RFBA(T) | Enduro FJ2528 Tipper |

FUSO | FOX2WN | Enduro FO3128 Tipper |

FUSO | FK62FH | Fighter FK1125 Tipper |

Volkswagen

Make | Model | Model code |

|---|---|---|

| Volkswagen | Grand Californian | SCBB8Z38 – Motorhome – 2 Berth |

| Volkswagen | Grand Californian | SCCB8Z38 – Motorhome – 4 Berth |

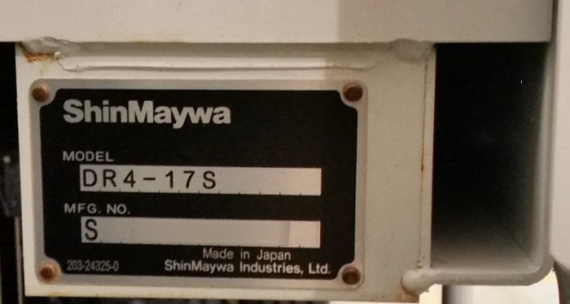

Sample plates

Trucks fitted with ShinMaywa tipper bodies will be fitted with a plate as shown in the sample below.

Trucks fitted with Fuso tipper bodies can be fitted with either the plate shown below or the ShinMaywa body builders plate (above).

Page updated 18 July 2023 (see details).

9 Park brake inspection and 4085D requirements

VIRM reference

Heavy vehicles 8-1: Service brake, parking brake and heavy vehicle emergency brake

This bulletin has been produced to supplement information provided to the repair industry and should be considered in inspecting all parts of a heavy vehicle park brake system.

Introduction

The introduction of the 4085D Operator statement of compliance with maintenance requirements for parking brake assemblies form came about due to several run-away trucks that have led to a fatal or serious injury crash where the park brake has been a contributing factor. Issues with the air-powered park brake application valve beside the driver’s seat and the Cardan shaft park brake system found on many trucks, buses and motorhomes have been the main concern, however all park brake systems are susceptible to wear and degradation that can affect the holding performance of the brake.

Investigations have found the air park brake valve wears out internally through dust and moisture ingress over time and can cause the valve detent to stick in the neck portion and not fully engage with the lock. As the driver gets out of the vehicle the valve can be knocked or on occasions get caught in the driver’s clothing releasing the lever.

There are also problems that have been traced to Cardan shaft park brakes not holding the vehicle even when the lever has been applied. This is due to several factors including a lack of maintenance that reduces the ability of the brake to hold the vehicle and its load, especially on an slope or instances where the lever feels fully applied but resistance and wear in the linkages reduces the application force at the brake unit.

The 4085D form

The 4085D Operator statement of compliance with maintenance requirements for parking brake assemblies form is designed to be used by a heavy vehicle operator where their powered heavy vehicle park brake has failed a compliance brake test at In-service certification (CoF B) inspection. The operator must have the park brake system repaired or serviced and return the completed form to the VI to show that the park brake system has been inspected and serviced by a technician and is in good working condition.

Parking brake inspection

What are the indicators that might make a vehicle inspector doubt the condition of a park brake assembly?

A park brake system is generally easily serviced (except for some sealed park brake air valves) but items that are susceptible to wear, degradation and ingress of dust and dirt need to be maintained to ensure park brake performance meets the required standard.

Not all park brake assemblies are easily accessible but visual signs that may point to no recent maintenance include:

- rusted bolts, screws, clevis pins or linkages which activate the park brake.

- dust, dirt, seat foam or general rubbish around the lever assembly.

- excessive resistance in applying the park brake.

- excessive contamination due to oil leaks or other debris.

- a lack of feel from the detent or lock position when applying the lever of an air park brake valve.

- The park brake fails to hold the vehicle in the stall test.

Are there any parts within the assembly that are more prone to cause problems than others?

The risk is more with the age of the vehicle (particularly older vehicles that have not been regularly serviced) and those working in dusty operations such as concrete mixer trucks and quarry trucks. Pay particular attention to the application valve or lever and any detents, ratchet or other mechanical locks designed to hold the lever in its applied position.

Are there specific makes/models that should be paid close attention to?

Vehicle inspectors should pay attention to all park brake systems. All makes or models should be treated equally. As mentioned above, vehicles working in dusty operations such as concrete mixer trucks and quarry trucks could be a higher risk.

Waka Kotahi has published safety alerts covering some Nissan trucks and on Cardan shaft park brakes that alert owners to maintenance and adjustments that should be carried out.

4085D requirement scenarios

If a vehicle inspector finds defects in the park brake components or the vehicle fails a stall test, they can request that the 4085D form be presented to provide proof of inspection and servicing to the manufacturer’s specifications, the vehicle inspector may issue a 28-day permit to allow the operator to have the park brake maintenance carried out and get a 4085D form completed.

When do you need to ask the operator of a powered heavy vehicle (a heavy truck, bus or motorhome above 3500kg) for a 4085D form?

- The vehicle fails the CoF inspection on park brake condition or fails a stall test for park brake performance (do not issue for RBM fails). The VI may issue a 28-day CoF permit.

- The vehicle passes the stall test for park brake performance but fails on another park brake CoF item and the VI has doubts about the park brake maintenance.

When do you NOT need to ask the operator of a powered heavy vehicle for a 4085D?

- The vehicle fails an RBM brake test for park brake performance but passes all other CoF requirements, and the VI has no doubts about park brake maintenance, the vehicle goes through the normal recheck process.

- The vehicle passes an RBM brake test for park brake performance but fails on another CoF item, and the VI has no doubts about the park brake maintenance. The VI fails the CoF for the other item(s) and the vehicle goes through the normal recheck process.

Page added 1 May 2023 (see amendment details).