Correct as at 19th April 2024. It may be superseded at any time.

Extract taken: from Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > Technical bulletins (general) > Detecting wear in spring-loaded ball joints

3 Detecting wear in spring-loaded ball joints

Reference

- General vehicles, 9-1 Steering and suspension systems

- Motorcycles, 9-1 Steering and suspension systems

- General trailers, 6-1 Steering and suspension systems

Safety concern

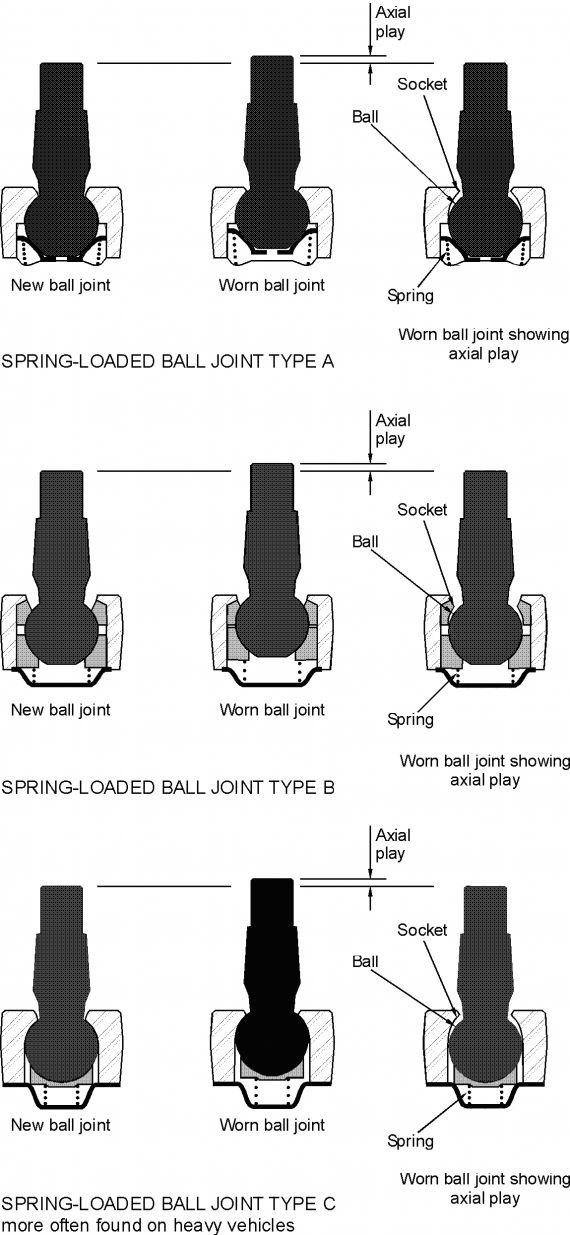

Wear in the ball joint increases axial play (along the axis of the joint). Spring-loaded ball joints are designed to be self-adjusting in order to compensate for the wear that occurs between the ball and the socket. As a result, the traditional method of rocking the steering to check for ball joint wear may not indicate how much axial play there is and therefore how worn the joint is. An excessively worn joint may be at risk of coming apart and causing steering failure.

Inspection

1. Know the correct test method for checking axial wear in ball joints. This is often specified by the vehicle manufacturer. Some manufacturers do not recommend axial testing at all and test instead for radial wear.

2. Know the manufacturer’s maximum permitted wear tolerances. These may vary from as little as 2mm up to 6mm.

Figure 3-1-1 shows three examples of common types of spring-loaded ball joints and how to check them for axial wear. If you are not sure of the correct test method or the maximum permitted wear limits, you should seek the information in the vehicle manual or from an authorised dealer for that vehicle (there may be a charge for this). This will ensure that the vehicle is correctly passed or failed during a WoF or CoF inspection.