Motorcycles

10-2 Measurements

Reasons for rejection

1. A fork has runout in excess of 0.4mm (unless permitted by the manufacturer).

2. One of the following measurements is not within the manufacturer’s specifications:

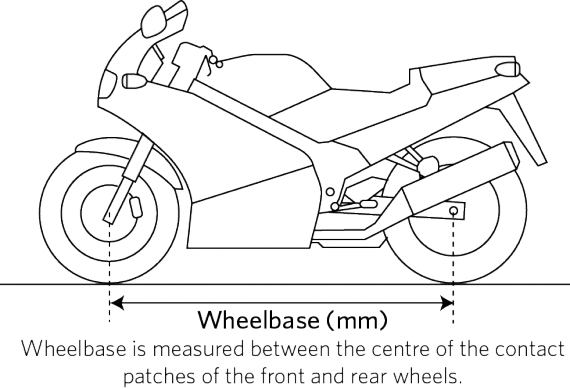

a) wheelbase (Figure 10-2-1)

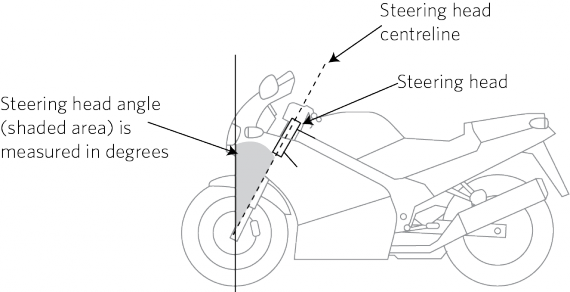

b) steering head angle (Figure 10-2-2)

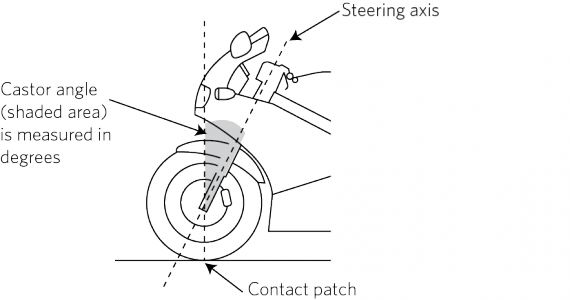

c) front wheel castor angle (Figure 10-2-3)

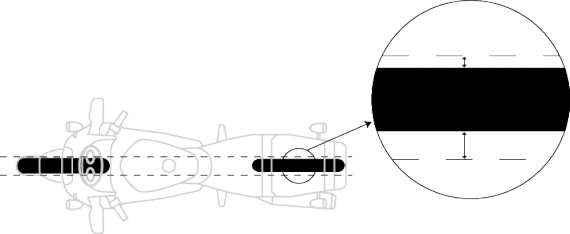

d) wheel track offset (Figure 10-2-4).

3. The wheel alignment has not been measured.

4. The wheel alignment is not within specification.

5. A reference measurement of the frame has not been completed and recorded (Note 1).

6. A reference measurement of the frame shows a difference of more than 3mm (unless permitted by the manufacturer’s instructions).

Note 1

A reference measurement of the frame is a comparative measurement of each side of the frame to verify symmetry.

Figure 10-2-1. Wheelbase measurement

Figure 10-2-2. Steering head angle measurement

Figure 10-2-3. Front wheel castor angle measurement

Figure 10-2-4. Wheel track offset measurement

Summary of legislation

Applicable legislation

Condition

1. A repair to a vehicle, its structure, systems, components or equipment must restore the damaged or worn vehicle, structure, system, component or equipment so that it is within safe tolerance of the state of the vehicle, structure, system, component or equipment when manufactured.