Correct as at 20th April 2024. It may be superseded at any time.

Extract taken: from Vehicle Inspection Portal > VIRMs > Heavy vehicle specialist certification > Introduction > Inspection and certification

3 Inspection and certification

3-1 Duties and responsibilities

In order to inspect and certify an aspect of a vehicle for a Heavy Vehicle Specialist Certificate (LT400), the HVS/M certifier must:

1. be appointed by Waka Kotahi NZ Transport Agency or the Director under section 2.2 of the Rule for the aspect of the vehicle being certified

2. know the certifier’s responsibilities

3. identify the vehicle class according to section 3.4 of this introduction

4. identify whether the vehicle requires certification. Section 3.3 of this introduction identifies the threshold for HV certification

5. establish whether the vehicle complies. Section 3.5 and section 3.6 of this introduction explain how to determine the vehicle’s compliance with the requirements

6. complete the inspection documentation, Heavy Vehicle Specialist Certificate, LT400, and any other required labels or plates. Section 3.7 of this introduction explains the requirements for handling and completing the form

7. when collecting fees take section 3.8 of this introduction into account

8. to enable Waka Kotahi to efficiently contact the certifier, the certifier must provide and maintain an email address which Waka Kotahi must use to provide any notice required or permit to be sent out by Waka Kotahi to any or all HV certifiers or IO.

3.1.1 General duties and responsibilities

The HV certifier’s prime duty is to ensure that a new, modified or repaired vehicle is safe and in compliance with the legal requirements for the aspect of the vehicle that the certifier is approved and required to certify as a Heavy Vehicle Specialist or Manufacturing Inspector or Inspecting Organisation, in Land Transport Rule: Vehicle Standards Compliance 2002 (the Rule), and in this manual.

The HV certifier shall establish, and use at all times, appropriate and reasonable inspection and certification procedures that are efficient and comply with the Rule, the Notice(s) of Appointment, the VIRM and the law.

The HV certifier shall not certify any modification or repair to a vehicle unless and until they have first satisfied themselves that the design, manufacture and installation of the modification or repair take into account the original design, manufacture and installation, and that the vehicle meets the relevant applicable requirements and is safe at the time of certification.

1. HV certifier

HV certifier means an individual appointed by Waka Kotahi under 2.2(1)(i) of the Rule to carry out inspection and certification activities in accordance with requirements and conditions imposed by Waka Kotahi, or the Director, and who is responsible for the inspection and certification outcome.

In this document, a HV certifier is one appointed for the purpose of heavy vehicle specialist or manufacturing inspection and certification. This is defined in section 6.5(1)(d) and 7.5(1)(b) of the Rule as specialist inspection and certification of modifications or repairs to the:

- load anchorages

- chassis and structure

- suspension or steering, including drive train, engine transmission and axles

- brakes

- towing connections

- log bolster attachments

- PSV structural strength, stability and roof racks, as well as

- the static rollover threshold (SRT) of a heavy vehicle

- swept path and heavy vehicle dynamics

- structural composites.

2. Inspection and certification activities (section 2.2(1)(i) of the Rule)

HV certifiers must carry out inspection and certification of modifications or repairs to a heavy vehicle that has been modified since it was manufactured or last certified so as to affect its compliance with an applicable requirement.

3. Primary duty (section 2.1(2) of the Rule)

HV certifiers must carry out inspection and certification activities competently and diligently, and in accordance with the Rule, this document, their Notice of Appointment, the PRS manual and other relevant requirements of Waka Kotahi and legislation.

4. Inspection and certification activities that can be carried out (section 2.2(2) of the Rule)

HV certifiers may carry out only those inspection and certification activities for which Waka Kotahi or the Director has appointed them.

HV certifiers are appointed as one of the following types:

- engineer

- local manufacturer (NZ)

- SRT certifier.

They may be appointed for one or more certification categories:

Table 1. Certifier Categories

Category | Specialist aspect |

|---|---|

HVEC | Chassis, suspension, steering, PSV, drive train, engine transmission and axles |

HVET | Towing connections |

HVEA | Load anchorages |

HVEL | Log bolster attachments |

HVEK | Brake modification |

HVP1 | Swept path |

HVS1 | Static rollover threshold |

5. Requirements, conditions and period of appointment (section 2.3(1) of the Rule)

Waka Kotahi may specify the period of appointment for an HV certifier and may impose requirements and conditions as to the performance of the inspection and certification activities, including the performance of those activities at individual sites. The Notice of Appointment states a period of appointment of seven years from the date the appointment starts. The period of appointment may be extended up to a maximum of ten years at the discretion of the Director. Appointments may be surrendered in writing by appointees, or be suspended or revoked by the Director in accordance with the Rule.

From the date of the end of an appointment for any reason (including surrender, suspension, or revocation) no inspection or certification activities can be carried out until the appointment is reinstated or renewed.

The HVSC Engineer Notice(s) of Appointment specify other requirements, including:

- a minimum number of inspections and certifications per annum

- self-reporting of information (such as information related to fitness and propriety)

- quality assurance and performance management systems

- making, maintaining and providing records of the activities

- management of conflicts of interest and other inappropriate influences

- insurance requirements

Please check your current notice of appointment for details.

6. Presentation and acceptance of emailed Inspection and certification documents

LT400s, chassis ratings and professional opinions from heavy vehicle specialist certifiers can be emailed to CoF vehicle inspectors and inspecting organisations provided:

(i) emails are sent directly to the vehicle inspector or inspecting organisation from the heavy vehicle specialist certifier, and

(ii) the electronic copy contains all of the information from the original copy and is clear and legible.

7. Delegation (section 2.4(1) of the Rule)

An HV certifier may be permitted by their Notice of Appointment to delegate certain functions or powers to carry out inspection and certification activities for which he was appointed.

An HV certifier may delegate certification work according to their appointment category and Table 2: Delegations:

Table 2. Delegations

Category | Duties (Note 1) | Delegation | To |

Engineer | Initial assessment | Yes | A person reasonably considered by the HVSC to be competent and trustworthy. That person should consult with the HVSC before beginning any work and may use photographs for assistance. The HVSC remains responsible for all delegated work. |

| Initial assessment (repairs) | Yes, but not for complex repairs or repairs of fatigue critical components (Note 3). | As above. Additionally, all parties involved must undertake best endeavours to determine the root cause of the issue to be repaired before starting work. | |

Design | Yes, but must personally approve the design to | A person reasonably considered to be competent. | |

Monitoring of manufacture or installation | Yes | A person reasonably considered to be competent | |

Final inspection | No | ||

Sign off (PDS/LT400 etc) | No | ||

Local manufacturer (IO) | Provide facilities to allow Local manufacturer VI to be effective | No | |

Local manufacturer (VI) | Initial assessment | Yes | A person reasonably considered to be competent. |

Monitoring of manufacture or installation | No | Unless passed to an alternative Local manufacturer certifier or Engineer certifier with a SoDC. | |

Final inspection | No | Unless passed to an alternative Local manufacturer certifier or Engineer certifier with a SoDC. | |

Sign off (PDS/LT400 etc) | No | ||

Static rollover threshold | Calculations for deriving the SRT and issuing a record of determination | Measurements | Another SRT certifier or a person who has passed the TERNZ SRT course. |

Note 1

An engineering certifier may transfer responsibility for any of the duties listed in Table 2 to another engineering certifier using a SoDC. Both engineering certifiers must hold the appropriate certification category. Where an SoDC is used in this way this is not a delegation as the issuer of the SoDC takes responsibility only for the aspects covered by the SoDC, with the issuer of the LT400 taking responsibility for all other aspects. This differs from a delegation, where the delegating engineer keeps full responsibility for the work carried out by the person they delegate to.

Note 2

No other delegations may be made without the express written consent of Waka Kotahi.

Note 3

Inspection of damage to the following components may not be delegated and must be assessed in the as-damaged state by the engineer:

- towing connections (except for replacement of bent or worn tow eyes)

- log bolster attachments

- chassis flanges

- subsequent failure of a previous repair.

A task which has been delegated to a specified employee may not be delegated further by that employee. HV certifiers are responsible for the outcomes or consequences of any delegated task.

HV certifiers must maintain a record of all persons that they have approved in accordance with any specifications in the Performance Review System manual that supports this manual.

A local manufacturer certifier (IO), who derives their authority to certify any aspect of a vehicle from the qualifications and role of a staff member agrees to inform Waka Kotahi of any change to the role or employment of that staff member.

A local manufacturer certifier (VI), who derives, in part, their authority to certify any aspect of a vehicle from their role as a staff member of a Local manufacturer certifier (IO) agrees to inform Waka Kotahi of any change to their role or employment status.

The HV certifier must ensure that, where any employee, agent or contractor to the HV certifier is authorised by the HV certifier in accordance with their appointment to carry out any part of the services on behalf of the HV certifier, that person complies in all respects with the obligations of the HV certifier under their appointment.

3.1.2 Inspection and certification

1. Heavy vehicle specialist inspection and certification (sections 6.5(1), 6.5(4), 6.5(5), 7.5(4) and 7.5(5) of the Rule)

The inspection and certification of a vehicle must be carried out in accordance with the requirements and conditions imposed by Waka Kotahi.

Waka Kotahi requirements and conditions are contained in this manual (‘the VIRM’), HVS Memos, specified standards and codes, the PRS manual, and the Notice of Appointment.

The HV certifier will provide and perform the services in accordance with any published professional or ethical standards of professional bodies to which they belong.

2. Determining compliance of a specific aspect (sections 6.5(5), 7.4 and 11.1 of the Rule)

A specific aspect of a vehicle may be certified as meeting the requirements of the Rule if an HV certifier has identified the vehicle and has determined, on reasonable grounds, that the specific aspect:

a) has not compromised the safe operation of the vehicle

b) has been designed and constructed using components and materials that are fit for their purpose and is within safe tolerance of its state when manufactured or modified

c) complies with the applicable requirements

d) is lawful and no technically competent person (recognised by Waka Kotahi) would dispute that the inspection and certification of the vehicle complies with applicable requirements.

3. Record of determination (sections 6.6 and 7.6 of the Rule)

When an HV certifier has determined whether a specific aspect of a vehicle complies, the HVS certifier must make a record of that determination on the Heavy Vehicle Specialist Certificate, LT400 – for each certification (that is, one certification for each aspect certified).

Examples:

1. A semi-trailer that is fitted with a fifth wheel, kin pin, load anchorages, and log bolsters requires five separate Heavy Vehicle Specialist Certificates as in the table below:

Component | Certification Category | Code/Standard Certified to |

|---|---|---|

Fifth wheel | HVET or HMTD | NZS 5450 |

Kin pin | HVET or HMTD | NZS 5451 |

Load anchorages | HVEA or HMAD | NZS 5444 |

Log bolsters | HVEL or HMLD | Bolster Attachment Code |

Brakes | HVEK or HMKD | Schedule 5/Section 6 HVBR |

2. A 4 x 2 truck that has the chassis lengthened, a tag axle fitted, new load anchorages, and a draw beam requires four separate Heavy Vehicle Specialist Certificates as in the table below:

Component | Certification Category | Code/Standard Certified to |

|---|---|---|

Chassis, suspension, | HVEC or HMCD | HV Rule |

Brakes | HVEK or HMKD | Schedule 5/Section 6 HVBR |

Load anchorages | HVEA or HMAD | NZS 5444 |

Draw beam | HVET or HMTD | NZS 5446 |

3. A bus or coach manufactured in NZ that already has ‘brakes’ standard compliance, requires two separate Heavy Vehicle Specialist Certificates as in the table below: (Additional Certification will be required if the vehicle is fitted with a tow bar, roof rack, a wheelchair hoist, powered ramp or wheelchair/wheelchair occupant restraints or is modified and requires brake certification.)

Component | Certification Category | Code/Standard Certified to |

|---|---|---|

Stability, | HVEC or HMCD | PSV Rule |

Rollover Strength | HVEC or HMCD | PSV Rule |

The HV certifier must immediately inform Waka Kotahi of any theft of any Waka Kotahi documents supplied to the HV certifier by Waka Kotahi or any agent of Waka Kotahi, or prepared by the HV certifier on behalf of Waka Kotahi.

The HV certifier must return to the document supplier or Waka Kotahi or destroy as required by Waka Kotahi any surplus or obsolete Waka Kotahi documents.

4. LT400

The LT400 presented must be the original or emailed directly to a CoF inspector or inspecting organisation. Where the original LT400 has been lost or destroyed the certifier may provide a duplicate (photocopy) provided it is signed and dated by the HV certifier.

5. Standards

Where an HV certifier is required to use a standard during the inspection and certification process, the latest version of the standard must be used except where otherwise specified.

The HV certifier must have available and use any and all standards which are referenced in the Rule or which the HV certifier references in certification.

The HV certifier must comply in all respects with any written instructions, interpretations or guidelines issued by Waka Kotahi to the HV certifier.

3.1.3 Re-inspection and re-certification (section 11.4 of the Rule)

If a Heavy Vehicle Specialist Certificate, LT400, has been revoked, Waka Kotahi may require the HV certifier to repeat the inspection and certification of the vehicle, issue (if appropriate) a new certification, and meet the re-inspection and re-certification costs.

3.1.4 Performance review (section 3.1(1) of the Rule)

Waka Kotahi, either directly or through an appointed agent, may monitor and review the performance of a HV certifier, including the performance of inspection and certification activities.

The requirements and conditions are contained in the Rule, this document, the Notice of Appointment and the PRS: Heavy vehicle specialist certification manual.

Waka Kotahi may require a HV certifier to provide such information as Waka Kotahi reasonably considers relevant. A HV certifier must comply with these requirements (unless expressly stated in the Notice of Appointment or this VIRM, no functions, duties or powers which may be exercised by Waka Kotahi under any statute, regulation or rule, including under section 198 of the Land Transport Act 1998, are in any way restricted).

Costs of monitoring and review (section 3.1(4) of the Rule)

HV certifiers must bear the costs of the monitoring and reviewing of their performance in accordance with any fee prescribed in the Rule or other applicable legislation.

3.1.5 Investigations

1. Investigations (sections 3.2(1) and 3.2(8) of the Rule)

If Waka Kotahi has reason to believe that an HV certifier has failed to comply with any of the conditions of his appointment, Waka Kotahi may require the HV certifier to undergo an investigation and to provide such information as Waka Kotahi reasonably considers appropriate as part of the investigation. Waka Kotahi may observe or inspect the equipment or activities of the certifier and copy relevant books and records.

Refusal to undergo monitoring, review, or investigation will be a breach of the Rule and the Notice(s) of Appointment and may result in further regulatory action.

2. Notification of action (other than immediate suspension/imposition of conditions) (section 3.2(3) of the Rule)

Following an investigation and before carrying out action, Waka Kotahi will notify the HV certifier in writing of:

a) the action that is being considered

b) the reason for the action that is being considered

c) the date by which submissions may be made to Waka Kotahi in respect of the action that is being considered, which must be at least 21 days after the notice was given

d) where appropriate, the date on which the action that is being considered will take effect, which, unless Waka Kotahi determines otherwise, must be at least 28 days after the notice was given.

3. Responding to a notification of action (section 3.2(5) of the Rule)

If a HV certifier is notified as above, he must ensure that he provides Waka Kotahi with all information within the period specified in the notice.

4. Waka Kotahi will consider submissions (section 3.2(6) of the Rule)

Waka Kotahi will consider the submissions and information supplied, and will:

a) decide whether or not to take the action that is being considered

b) as soon as is practicable, provide written notification to the HV certifier of:

i. the Waka Kotahi decision, and

ii. if appropriate, the date on which the action is take effect, and

iii. if appropriate, the right of appeal under section 106 of the Land TransportAct 1998.

5. Remedial action, suspension, revocation (sections 3.2(2) and 3.2(8) of the Rule)

If, following an investigation, Waka Kotahi is satisfied that the HV certifier has failed to comply with any of the conditions of his appointment, Waka Kotahi may do one or more of the following:

a) require that remedial action such as training or mentoring be undertaken by the HV certifier. The HV certifier cannot refuse to comply with the requirement

b) suspend the HV certifier for a specified period or until conditions are met

c) revoke the appointment of the HV certifier.

6. Immediate suspension or imposition of conditions (section 3.3(1) of the Rule)

If Waka Kotahi has reason to believe that a HV certifier has failed to comply with a condition of his appointment and that this presents a significant risk to land transport safety, Waka Kotahi may suspend the appointment with immediate effect, or impose any conditions on the appointment of the HV certifier.

7. Notification of immediate suspension or imposition of conditions (section 3.3(2) of the Rule)

When Waka Kotahi suspends the appointment, or imposes conditions on the appointment, Waka Kotahi will notify the HV certifier in writing of:

a) the grounds for the suspension or imposing of conditions

b) the fact that the certifier or organisation may make submissions to Waka Kotahi

c) the right of appeal under section 106 of the Land Transport Act 1998.

8. Waka Kotahi will consider submissions following immediate suspension or imposition of conditions (section 3.3(3) of the Rule)

Waka Kotahi will, as soon as practicable, consider any submission made and notify the certifier or inspecting organisation in writing of the result of any such consideration.

9. Duration of immediate suspension or imposition of conditions (section 3.3(5) of the Rule)

A suspension or condition imposed remains in force until Waka Kotahi has determined the action to be taken and that action has been taken.

10. Withdrawal of immediate suspension or imposition of conditions (section 3.3(4) of the Rule)

Waka Kotahi may at any time withdraw a suspension or condition imposed.

11. Right of appeal against immediate suspension or imposition of conditions (section 3.3(6) of the Rule)

A HV certifier may appeal under section 106 of the Land Transport Act 1998 against a decision by Waka Kotahi to suspend immediately or to impose conditions.

12. Costs of investigations (sections 3.2(7) and 3.2(8) of the Rule)

Waka Kotahi may require a HV certifier to bear the costs associated with an investigation or remedial action in accordance with any prescribed fee. Refusal to bear the costs will be a breach of the Rule and the Notice(s) of Appointment and may result in further regulatory action.

3.1.6 Consequences of termination or suspension

Upon revocation or termination of the appointment for any reason whatsoever, whether in whole or part, the HV certifier will:

a) cease provision of all or such part of the services under their appointment as may be required by Waka Kotahi

b) return to Waka Kotahi or authorised representative or destroy as required by Waka Kotahi any land transport documents (including unused LT400 forms), advertising and/ or display material featuring or referring to the services or the HV certifier’s provision of the services under this appointment, as the case may be.

Upon suspension of appointment (whether in whole or part) of the HV certifier for any reason whatsoever, whether by Waka Kotahi or a duly authorised representative, the HV certifier shall immediately cease providing the relevant services during the period of suspension and shall, if so required, surrender all Waka Kotahi documents to Waka Kotahi or any authorised representative.

3.1.7 Disputes and appeals

Where there is any dispute arising between parties in relation to any matter arising out of the appointment, the parties shall endeavour to resolve such disputes promptly by consultation and negotiation in good faith.

- Where the HV certifier does not agree with any decisions of Waka Kotahi, including any decision or direction of a Certification Officer, the HV certifier should, notwithstanding any other rights they may have at law, seek from Waka Kotahi a review of that decision.

- Despite the previous two points, both parties recognise that Waka Kotahi has functions in respect of land transport safety and law enforcement and that, notwithstanding any dispute or appeal, Waka Kotahi may take whatever lawful action Waka Kotahi considers necessary in the interests of road safety. The specific reasons for the action taken will be provided.

- Where there is any dispute arising between the parties in relation to technical decisions, any available dispute resolution process described in the VIRM or in an issued HVS Memo may be invoked. This will permit the disclosure of otherwise privileged information, such as designs and PRS scores, to the adjudicating body, provided that this information is pertinent to the matter being judged.

Page amended 1 November 2021 (see amendment details)

3-2 Disqualification from certification

A HV certifier must not engage in any activities that may conflict with his independence of judgement and integrity in relation to the services delivered.

A HV certifier may have a professional interest in a vehicle they certify, such as a vehicle:

a) they have modified or repaired, or

b) that has been modified or repaired by a person working for the same company as the HV certifier, and at the same premises,

However, a HV certifier may not certify a vehicle they or their immediate family have a personal ownership interest in.

A HV certifier may not certify an aspect of a vehicle for which he is not appointed.

An HVS certifier must not inspect a vehicle if:

a) they do not hold a driver licence for that class of vehicle, and

b) they are required to drive it.

3-3 Establishing whether a vehicle must be HV certified

A vehicle must be inspected for heavy vehicle specialist certification if:

a) it requires certification for entry, re-entry or an in-service CoF

b) it is a vehicle of one of the following classes:

MD3, MD4, ME, NB, NC, TC, TD (see Table 3-4-1. Vehicle equipment standards classifications)

c) it has undergone modifications or qualifying repairs to:

i. chassis, structural bodywork, brakes, bolster attachments, towing connections, drive train, engine transmission, axles, load anchorages and wheels which affect compliance with applicable requirements (includes flood/water/fire damage)

ii. any item which could affect the vehicle’s SRT

iii. corrosion in a structural part of the vehicle.

3.3.1 Repairs which do not require certification

The following types of repair do not require inspection and certification:

1. the replacement of bolted on components that do not require certification in themselves (a log bolster attachment or draw beam still requires certification but a bolted on tow-eye does not).

2. repairs to the first failures of chassis cross-members, if that cross-member is not

a) the first or last cross-member of the chassis

b) fitted within 500mm of a suspension support

c) fitted with a driveshaft centre bearing

d) supporting a:

i. ball-race turntable

ii. tow coupling

iii. bolster attachment

iv. device that may place a concentrated load on to the chassis, for example a hoist or a hydraulic cylinder of a tipping body.

3. repairs to coaming rails that do not support certified load anchorage points.

4. tow-eyes fitted to the front of a vehicle for recovery purposes.

5. repairs to non-structural components only of a vehicle’s monocoque body, for example bolt-on body panels.

6. Ferry tie down points that are attached using existing holes in the chassis and are not welded to components that require certification in themselves.

3.3.2 Repairs that require an LT400, but no statement of design compliance

The following is a list of repairs/replacements that certifying manufacturers can undertake without getting a statement of design compliance from a certifying engineer:

1. Load anchorages that are of a standard design from NZS5444, certified to this standard, and repaired using the method outlines in NZS5444.

2. Worn or damaged fifth wheels can be replaced according to the fifth wheel manufacturer’s instructions for replacing bolt-on components.

3. Worn or damaged kingpins can be replaced according to the kingpin manufacturer’s instructions on replacement.

4. Other items as defined in the manufacturing certifier section of this manual.

3.3.3 Repairs that require both an LT400 and a statement of design compliance

All other repairs to heavy vehicle chassis, towing connections, log bolsters and load anchorages require input from a certifying engineer and therefore require a statement of design compliance before an LT400 can be issued by a manufacturing certifier, except where specifically allowed for in the manufacturing certifier section of this manual

3-4 Identifying the vehicle class

Since some decisions are made according to the class of the vehicle, the HV certifier must be able to identify the class of the vehicle to be inspected. The following table describes vehicle classes.

Table 3-4-1. Vehicle equipment standards classifications

3-5 Work procedure

Any work, to which this manual applies, to be done on a vehicle, must be:

- specified correctly

- designed correctly

- manufactured correctly

- certified as within safe tolerance of the original design or specification.

The design of the work by a HV engineer certifier, where the manufacture and installation is to be the responsibility of others, is to be accompanied by a Statement of Design Compliance (SoDC) that is signed by the HV engineer certifier.

The specification of the work is set out in the Procedure Documentation Sheet (PDS) that is drawn up by an HV certifier.

- Each certification must have its own unique PDS.

Manufacturing and installation work must also be monitored or verified by an HVS certifier. Where appropriate, the certification of manufacture may be done by a form of ‘type approval’.

Final certification is based on inspection by a qualified certifier with reference to any intermediate documents, including the SoDC, the PDS, supporting documentation from any delegated tasks, any applicable standards, documented histories of used components and worksheets and calculations.

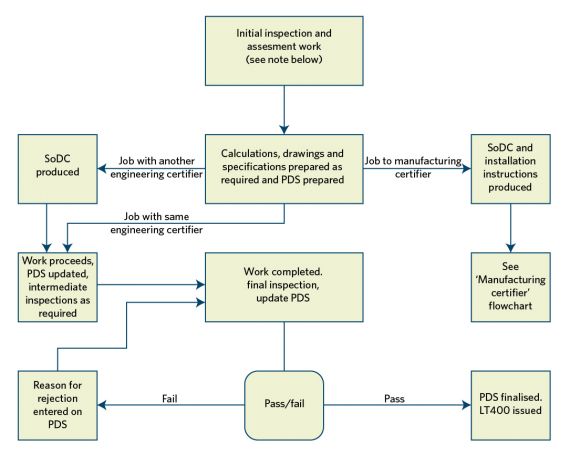

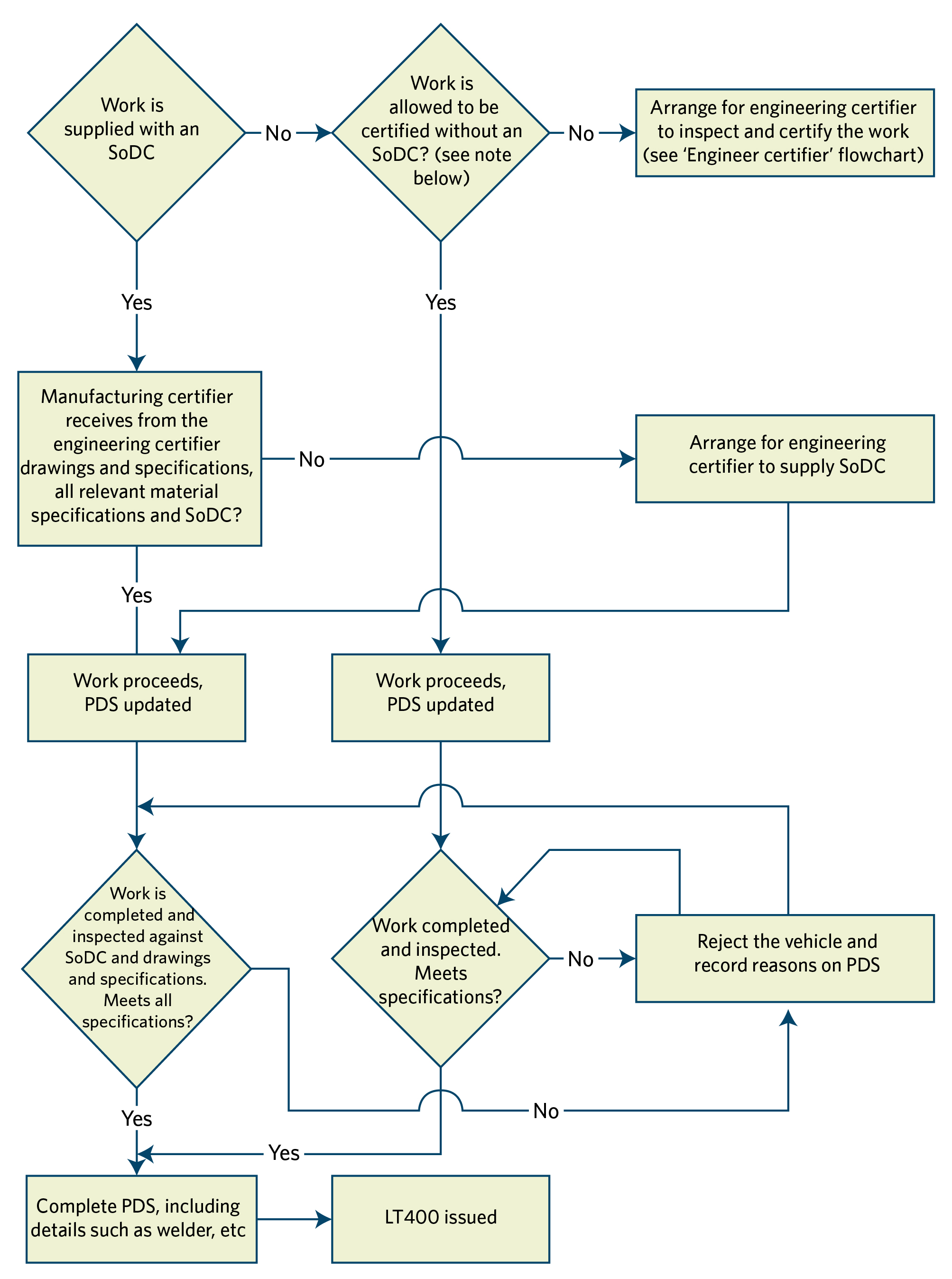

Figure 3-5-1. Certification process: Engineer certifier

Figure 3-5-2. Certification process: Manufacturing certifier

(see Note 1)

Note 1

The following work is allowed to be completed by a manufacturing certifier without a SoDC.

- Load anchorages that are of a standard design from NZS5444, certified to this standard and repaired using the method outlined in NZS5444

- Worn or damaged fifth wheels replaced according to the fifth wheel manufacturer’s instructions for replacing bolt on components

- Worn or damaged kingpins replaced according to the kingpin manufacturer’s instructions on replacement

- Work certified by the HV certifier who has designed it.

Other work that may be certified by a HV manufacturing certifier is defined in the manufacturing certifier section of this manual.

How many certificates?

Each aspect of the vehicle that requires certification is to be certified separately and issued with a separate LT400. This means that any vehicle may need multiple certificates before it can qualify for a CoF (refer to Technical bulletin 15).

3.5.1 The statement of design compliance (SoDC)

The SoDC must include the name and signature of the certifier and the date of certification. The SoDC

must also have sections with information relevant to:

- the class of motor vehicle

- the vehicle description

- vehicle identifiers

- certification.

The SoDC must include information relevant to the purpose of specialist certification, for example:

- modifications

- repair

- vehicle dimensions

- matters relevant to the structure, systems, components or equipment of a vehicle or instillation or use of a vehicle’s structure, systems, components or equipment

- alternative fuel system

- age or historic nature of a vehicle

- class of vehicle

- any other attribute of a vehicle.

The SoDC must confirm that the vehicle, or any aspect of it relevant to the purpose of specialist certification, complies with the requirements as specified in Land Transport Rule: Vehicle Standards Compliance 2002, and therefore must include the following statement:

I declare that I am a heavy vehicle specialist certifier – engineer and I hold a current valid appointment. I certify that this vehicle component design and this certification comply in all respects with the Land Transport Rule: Vehicle Standards Compliance 2002; my Notice of Appointment and applicable requirements. To the best of my knowledge the information contained in this certificate is true and correct.

The SoDC must include drawing numbers and may include other relevant details.

HV manufacturing certifiers shall not accept an SoDC that does not contain the information outlined in the Gazette notice published during the week of 21 August 2000.

HV manufacturing certifiers shall not accept an SoDC from an HV certifying engineer who has ceased to practice. An SoDC issued by that person can no longer be considered valid as the HV certifying engineer does not hold a current appointment.

Consequently, any item or component manufactured using a SoDC from a non-practicing HV certifying engineer cannot be signed off by an HV manufacturing certifier, but must be re-certified by a current HV certifying engineer of the appropriate category.

SoDCs must be specific to individual vehicles and clearly identify the VIN/chassis number. SoDCs cannot be used for ‘type’ or ‘model’ approval of generic designs.

3.5.2 Issuing a professional letter or statement

Engineering certifiers may be asked for opinion on a component where it is determined that a LT400 is not required. This may include situations where a clean and treat is required, or inspection of damage recorded where certification is not yet required.

Where an LT400 is not required, the professional opinion should be on your company letterhead and should contain:

- vehicle details

- date of inspection

- details of the area assessed

- recording of any damage and any treatment completed

- effect on the vehicle’s/components integrity and/or safety performance in relation to GVM/ratings

- your details, including category and ID

- the date and sign the document.

Page amended 1 April 2023 (see amendment details)

3-6 Establishing whether the vehicle aspect complies

Certifications by an engineer certifier

1. Start a Procedure Documentation Sheet (PDS) for the vehicle.

2. Inspect the vehicle to be certified at a location that allows adequate access and equipment to allow a full and detailed inspection.

3. Record all relevant details and dimensions for the proposed or existing aspect of the vehicle that requires certification.

4. Collect all relevant information that is required for the certification of that vehicle aspect.

5. Compare what the vehicle owner/workshop wants to do with the relevant sections of the VIRM and

ensure that no reasons for rejection will be invoked. If they are, the HV certifier should advise the owner/workshop in writing and detail the options.

6. Complete design drawings, specifications and calculations as required.

7. Complete a Statement of Design Compliance, if required (see section 3.5), and supply it as well as all drawings and specifications required to complete the proposed work to the workshop/vehicle owner. Such information should include dimensions, materials and welding specifications.

8. Supply any drawings and specifications required to complete the proposed work to the workshop/vehicle owner. Such information should include dimensions, materials and welding specifications as well as an inspection schedule from the HV certifier.

9. Carry out inspections of the work as required. If the vehicle is presented fully completed, disassembly of certain parts may be required at the discretion of the HV certifier. Compare the work against the requirements of the design drawings and specifications provided. The inspection should include the quality of materials and workmanship.

10. Compare the finished work and documentation against the VIRM for reasons for rejection and if any of the reasons for rejection apply, reject the vehicle for certification.

11. If the HV certifier requires further information in order to determine compliance with the requirements, he must reject the vehicle until the information has been obtained.

12. Complete the PDS and issue an LT400 for the aspect that has been certified if no reasons for rejection exist.

Certifications by manufacturing certifier

1. Start a PDS for the vehicle.

2. Inspect the vehicle to be certified at a premises that allows adequate access and equipment to allow a full and detailed inspection.

3. Inspect the vehicle against the Statement of Design Compliance, if required (see section 3.5), issued by a HV engineer certifier or against one of the approved pre engineered solutions. The inspection should include materials and workmanship.

4. Collect any relevant supporting documentation.

5. Compare the inspection results against the VIRM for reasons for rejection and if any exist, reject the vehicle for certification.

6. Complete the PDS and issue an LT400 for the aspect that has been certified if no reasons for rejection exist.

Prerequisite documentation

Certifications by engineer

1. Designs for the work involved in the vehicle aspect.

2. Statement of Design Compliance or LT400 signed by an HV Specialist Certifying Engineer for that aspect.

3. PDS.

Certifications by local manufacturer

1. Designs for the work involved in the vehicle aspect, where this involves the chassis, drawbar, drawbeam, heavy vehicle brakes or log bolsters.

2. Statement of Design Compliance or reference to pre engineered solutions, for the work involved in the vehicle aspect.

3. PDS.

3-7 Record of certification

1. The HV certifier must complete a Heavy Vehicle Specialist Certificate (LT400).

2.The HV certifier must include the Vehicle Identification Number (VIN) on the LT400.

3. The HV certifier must retain one copy of the LT400.

4. The HV certifier must provide one copy of the LT400 to the owner of the vehicle.

5. The HV certifier must hold all documentary evidence involved in the certification process.

One LT400 is required for each aspect of the vehicle that needs to be certified. If a single certifier who is appointed for more than one aspect of a vehicle certifies more than one aspect of the vehicle at the same time, a separate LT400 must be used for each aspect.

For some aspects of the vehicle an additional record of the determination, such as a component identification, usually in the form of a metal plate, must be issued and fixed to the vehicle. For some items, this identification may be impressed directly on to the item.

While a certifier may include an expiry date on the certification documents or certification records (eg identification plates), they are only valid if they are required by the legislation or the standard they are manufactured to, or are required by Waka Kotahi. If they are not specifically required they are not to be recorded in Landata (Where expiry dates are not specifically required by the legislation, the standard or Waka Kotahi then any certification carried out will be for the life of the vehicle).

Any vehicles or components certified after 1 December 2016 must contain the following information (on the plate or label) as a minimum:

Table 3-6-1. Data on plates and labels

Aspect | Minimum data on a plate |

|---|---|

Drawbars and drawbeams |

|

Log bolster |

|

Load anchorages and headboard |

|

Brake code |

|

PSV roof rack |

|

Replacement plates

If a plate becomes illegible, damaged or lost it may be replaced provided that:

- the information that was on the plate can be determined from the original documentation, and

- visual inspection of the plated item shows it remains in a safe condition, and

- it is the original item.

Note 1

VIN is the primary vehicle identifier required and chassis number is acceptable only if the vehicle does not have a VIN.

Page amended 9 April 2018 (see amendment details)

3-8 Collecting fees

The Land Transport (Certification and Other Fees) Regulations 1999, regulations 5 and 8 stipulate that the fee that may be charged by an HV certifier for the certification of a vehicle is an amount determined by the individual HV certifier having regard to:

a) the time spent in inspecting the vehicle to ascertain whether it complies with the relevant requirements

b) any fees payable to Waka Kotahi

c) any standard or usual rate at which the HVS certifier charges for other work carried out in respect of motor vehicles.

3-9 Documentation of heavy vehicle specialist certification

The following table defines the minimum file content that should be present in any HVSC certification file. In addition to the listed minimum requirements, all files should contain sufficient information such that another HVSC can independently verify the certification decision.

Required items | Certifier categories | ||

|---|---|---|---|

| HVEA, HVET, HVEC, HVEL, HVEK | HMAD, HMTD, HMCD, HMLD, HMKD | HVS1, HVS2, HVS3, HVP1, HVP2 |

PDS (identifying the vehicle, work carried out/certified, and the standards used) | ✔ | ✔ | ✔ |

LT400 (or SODC if applicable) | ✔ | ✔ | ✔ |

Inspection notes and sketches | ✔ | ✔ | ✔ |

Photographs showing:

| ✔ | ✔ | ✔ |

Material specifications | ✔ | ✔ | |

Calculations | ✔ | ✔ | |

Hubometer history and residual life assessment (for drawbar and drawbeam recertifications only) | ✔ | ||

Drawings / fabricator instructions | ✔ | ||

Proprietary component data | ✔ | ✔ | |

Welder qualifications (positions and techniques) | ✔ | ✔ | |

Evidence of design that was followed, ie one of:

| ✔ | ||

Vehicle information, eg data sheets, bodybuilder guide, vehicle history from LANDATA if already registered, etc | ✔ | ✔ | |

Welding/bolting procedures as appropriate | ✔ | ||

NDT records as required | ✔ | ||

Page added 9 December 2019 (see amendment details)