Correct as at 21st April 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > Heavy vehicle specialist certification > Introduction

Introduction

1 Purpose and Scope

Waka Kotahi NZ Transport Agency has prepared this document, Vehicle inspection requirements manual: Heavy vehicle specialist certification to enable heavy vehicle specialist and manufacturing inspectors to achieve correct and consistent standards of inspection and certification. In this VIRM, any reference to the NZ Transport Agency or Waka Kotahi includes reference to the Director of Land Transport (the Director).

Heavy vehicle specialist and manufacturing certifiers are required to certify specialist aspects of heavy vehicles. They are appointed by Waka Kotahi under section 2.2(1)(i) of the Land Transport Rule: Vehicle Standards Compliance 2002 (the Rule) as vehicle inspectors and/or inspecting organisations.

In order to prepare a vehicle for operational service in New Zealand, the owner may be required to fit additional equipment and to modify the vehicle design to optimise the vehicle for the role in which it is to be employed.

This modification and mounting of additional equipment must result in a vehicle that is deemed by Waka Kotahi to be safe to operate.

This means that the modifications (including any repairs or addition of equipment):

- are designed to be technically sound

- are done to a high standard of workmanship

- use parts and materials that are fit for their purpose

- comply with any standards that are applicable

- do not give the vehicle any unacceptable characteristics.

Waka Kotahi appoints heavy vehicle specialist inspectors (HVS or HVM VI) and inspecting organisations (IO) to carry out technical assessment of repairs and modifications. Since the range of knowledge, expertise and experience needed to make these assessments is very wide, HVS certifiers are appointed to certify various aspects of a vehicle. In this manual, these inspectors are generally referred to as HVS certifiers.

These aspects and Waka Kotahi requirements for them are covered in this manual. The purpose of this document is to:

- supplement the notices of appointment currently in force for HVS certifiers

- cover the requirements for the inspection and certification of specialist aspects of heavy vehicles.

This VIRM is published online only and is not supplied in hard copy.

Amendments to this manual will be issued from time to time as inspection requirements change and improvements are made. Details of amendments are available from the Amendments tab on the horizontal menu. Suggestions for improvement should be made using the feedback button found on every page.

HVS/M certifiers must ensure they have access to, are familiar with and use, the latest version of the VIRM.

Where appropriate Waka Kotahi will consult with HVS/M inspecting organisations prior to the confirmation of amendments to this manual.

An appointed certifier or inspecting organisation (IO) cannot use the Waka Kotahi brand, logo or name in connection with their business unless such use is approved in writing by Waka Kotahi.

Contacting Waka Kotahi

| Phone |

0800 587 287 then follow the instructions |

| Technical queries | vehicles@nzta.govt.nz |

| Administrative queries | vehicleinspections@nzta.govt.nz |

Safety Issues – safe work practices

Correct use of this VIRM may involve the use of hazardous materials, work practices or operations and equipment. It is the responsibility of the HVEx/HVxD certifier and IO to establish appropriate safety and health practices required by legislation. Safe work practice shall be employed at all times.

The methods and processes used for the manufacture or repair of a heavy vehicle (HV) combine the requirements of the Health and Safety at Work Act 2015 and any relevant manufacturer’s recommendations – neither of which are administered by Waka Kotahi.

This also applies to the avoidance of damage to equipment or the work or, in the case of a repair, further damage to the item being repaired. Refer to your HSE manual and work instructions before commencing any work. For repairs most vehicle manufacturers also make recommendations on safe practices.

Page amended 1 November 2021 (see amendment details)

2 Overview of the manual

The manual is in two main parts:

1. Introduction

The introduction summarises the duties and responsibilities of the HV certifier which are set out in detail in the relevant Notice(s) of Appointment, explains the inspection and certification process, complaints procedures, inspection premises and equipment, and appointment of HV certifiers.

Also included are definitions and abbreviations and sample certification documents.

The term ‘he’ in respect of an HV certifier, is intended to include ‘she’.

2. Technical

This part of the manual covers the requirements for the certification of modifications, mounting of components, design and manufacture of vehicles and components and repairs to individual aspects of heavy vehicle components, structures and systems.

To use the manual:

- the HV certifier identifies each system, structure, component, aspect or performance characteristic affected by the modification, manufacture or repair

- the HV certifier selects the corresponding chapter(s) from the technical part and inspects the vehicle to determine whether the requirements have all been met.

Not all chapters in the technical section are devoted to aspects of vehicles that are to be certified. Some of them, such as 1-1 VIN, 2-1 External projections. and 3-1 Dimensions, are to assist in the assessment of other aspects. Other chapters, such as 11-1 Welding and 11-2 Conversion to right-hand drive are also concerned with topics that are not aspects in themselves but pool all the requirements to be considered where these items are involved.

Each chapter of the technical part consists of up to six parts:

Required certifier categories | shows the certifiers who are concerned with the chapter material. |

Summary of legislation | summarises the legislation that is relevant to that section. |

Applicable references | refers to standards, codes and other documents that contain requirements. |

Requirements of the legislation | contains a synopsis of the requirements in legislation and other directives of Waka Kotahi |

Notes | are for additional guidance, where required. |

Reasons for rejection | specifies the conditions that must result in the vehicle being rejected by the specialist certifier |

Page amended 1 November 2021 (see amendment details)

3 Inspection and certification

3-1 Duties and responsibilities

In order to inspect and certify an aspect of a vehicle for a Heavy Vehicle Specialist Certificate (LT400), the HVS/M certifier must:

1. be appointed by Waka Kotahi NZ Transport Agency or the Director under section 2.2 of the Rule for the aspect of the vehicle being certified

2. know the certifier’s responsibilities

3. identify the vehicle class according to section 3.4 of this introduction

4. identify whether the vehicle requires certification. Section 3.3 of this introduction identifies the threshold for HV certification

5. establish whether the vehicle complies. Section 3.5 and section 3.6 of this introduction explain how to determine the vehicle’s compliance with the requirements

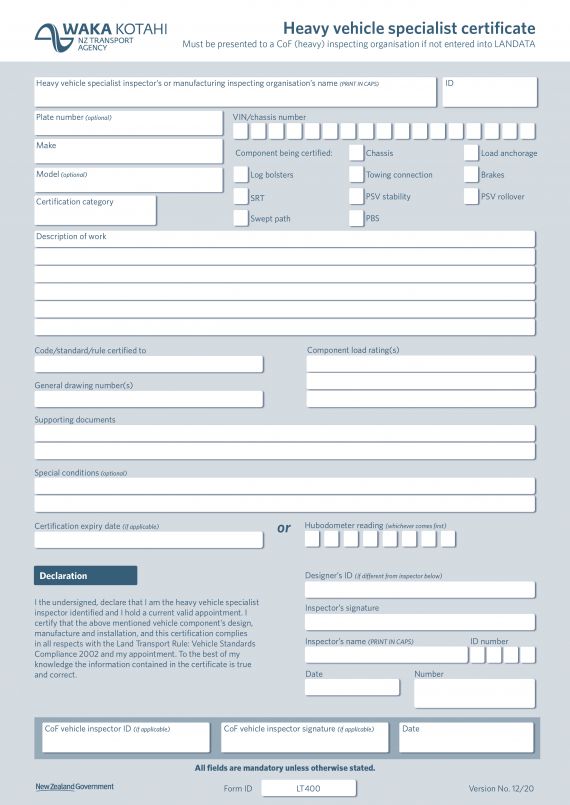

6. complete the inspection documentation, Heavy Vehicle Specialist Certificate, LT400, and any other required labels or plates. Section 3.7 of this introduction explains the requirements for handling and completing the form

7. when collecting fees take section 3.8 of this introduction into account

8. to enable Waka Kotahi to efficiently contact the certifier, the certifier must provide and maintain an email address which Waka Kotahi must use to provide any notice required or permit to be sent out by Waka Kotahi to any or all HV certifiers or IO.

3.1.1 General duties and responsibilities

The HV certifier’s prime duty is to ensure that a new, modified or repaired vehicle is safe and in compliance with the legal requirements for the aspect of the vehicle that the certifier is approved and required to certify as a Heavy Vehicle Specialist or Manufacturing Inspector or Inspecting Organisation, in Land Transport Rule: Vehicle Standards Compliance 2002 (the Rule), and in this manual.

The HV certifier shall establish, and use at all times, appropriate and reasonable inspection and certification procedures that are efficient and comply with the Rule, the Notice(s) of Appointment, the VIRM and the law.

The HV certifier shall not certify any modification or repair to a vehicle unless and until they have first satisfied themselves that the design, manufacture and installation of the modification or repair take into account the original design, manufacture and installation, and that the vehicle meets the relevant applicable requirements and is safe at the time of certification.

1. HV certifier

HV certifier means an individual appointed by Waka Kotahi under 2.2(1)(i) of the Rule to carry out inspection and certification activities in accordance with requirements and conditions imposed by Waka Kotahi, or the Director, and who is responsible for the inspection and certification outcome.

In this document, a HV certifier is one appointed for the purpose of heavy vehicle specialist or manufacturing inspection and certification. This is defined in section 6.5(1)(d) and 7.5(1)(b) of the Rule as specialist inspection and certification of modifications or repairs to the:

- load anchorages

- chassis and structure

- suspension or steering, including drive train, engine transmission and axles

- brakes

- towing connections

- log bolster attachments

- PSV structural strength, stability and roof racks, as well as

- the static rollover threshold (SRT) of a heavy vehicle

- swept path and heavy vehicle dynamics

- structural composites.

2. Inspection and certification activities (section 2.2(1)(i) of the Rule)

HV certifiers must carry out inspection and certification of modifications or repairs to a heavy vehicle that has been modified since it was manufactured or last certified so as to affect its compliance with an applicable requirement.

3. Primary duty (section 2.1(2) of the Rule)

HV certifiers must carry out inspection and certification activities competently and diligently, and in accordance with the Rule, this document, their Notice of Appointment, the PRS manual and other relevant requirements of Waka Kotahi and legislation.

4. Inspection and certification activities that can be carried out (section 2.2(2) of the Rule)

HV certifiers may carry out only those inspection and certification activities for which Waka Kotahi or the Director has appointed them.

HV certifiers are appointed as one of the following types:

- engineer

- local manufacturer (NZ)

- SRT certifier.

They may be appointed for one or more certification categories:

Table 1. Certifier Categories

Category | Specialist aspect |

|---|---|

HVEC | Chassis, suspension, steering, PSV, drive train, engine transmission and axles |

HVET | Towing connections |

HVEA | Load anchorages |

HVEL | Log bolster attachments |

HVEK | Brake modification |

HVP1 | Swept path |

HVS1 | Static rollover threshold |

5. Requirements, conditions and period of appointment (section 2.3(1) of the Rule)

Waka Kotahi may specify the period of appointment for an HV certifier and may impose requirements and conditions as to the performance of the inspection and certification activities, including the performance of those activities at individual sites. The Notice of Appointment states a period of appointment of seven years from the date the appointment starts. The period of appointment may be extended up to a maximum of ten years at the discretion of the Director. Appointments may be surrendered in writing by appointees, or be suspended or revoked by the Director in accordance with the Rule.

From the date of the end of an appointment for any reason (including surrender, suspension, or revocation) no inspection or certification activities can be carried out until the appointment is reinstated or renewed.

The HVSC Engineer Notice(s) of Appointment specify other requirements, including:

- a minimum number of inspections and certifications per annum

- self-reporting of information (such as information related to fitness and propriety)

- quality assurance and performance management systems

- making, maintaining and providing records of the activities

- management of conflicts of interest and other inappropriate influences

- insurance requirements

Please check your current notice of appointment for details.

6. Presentation and acceptance of emailed Inspection and certification documents

LT400s, chassis ratings and professional opinions from heavy vehicle specialist certifiers can be emailed to CoF vehicle inspectors and inspecting organisations provided:

(i) emails are sent directly to the vehicle inspector or inspecting organisation from the heavy vehicle specialist certifier, and

(ii) the electronic copy contains all of the information from the original copy and is clear and legible.

7. Delegation (section 2.4(1) of the Rule)

An HV certifier may be permitted by their Notice of Appointment to delegate certain functions or powers to carry out inspection and certification activities for which he was appointed.

An HV certifier may delegate certification work according to their appointment category and Table 2: Delegations:

Table 2. Delegations

Category | Duties (Note 1) | Delegation | To |

Engineer | Initial assessment | Yes | A person reasonably considered by the HVSC to be competent and trustworthy. That person should consult with the HVSC before beginning any work and may use photographs for assistance. The HVSC remains responsible for all delegated work. |

| Initial assessment (repairs) | Yes, but not for complex repairs or repairs of fatigue critical components (Note 3). | As above. Additionally, all parties involved must undertake best endeavours to determine the root cause of the issue to be repaired before starting work. | |

Design | Yes, but must personally approve the design to | A person reasonably considered to be competent. | |

Monitoring of manufacture or installation | Yes | A person reasonably considered to be competent | |

Final inspection | No | ||

Sign off (PDS/LT400 etc) | No | ||

Local manufacturer (IO) | Provide facilities to allow Local manufacturer VI to be effective | No | |

Local manufacturer (VI) | Initial assessment | Yes | A person reasonably considered to be competent. |

Monitoring of manufacture or installation | No | Unless passed to an alternative Local manufacturer certifier or Engineer certifier with a SoDC. | |

Final inspection | No | Unless passed to an alternative Local manufacturer certifier or Engineer certifier with a SoDC. | |

Sign off (PDS/LT400 etc) | No | ||

Static rollover threshold | Calculations for deriving the SRT and issuing a record of determination | Measurements | Another SRT certifier or a person who has passed the TERNZ SRT course. |

Note 1

An engineering certifier may transfer responsibility for any of the duties listed in Table 2 to another engineering certifier using a SoDC. Both engineering certifiers must hold the appropriate certification category. Where an SoDC is used in this way this is not a delegation as the issuer of the SoDC takes responsibility only for the aspects covered by the SoDC, with the issuer of the LT400 taking responsibility for all other aspects. This differs from a delegation, where the delegating engineer keeps full responsibility for the work carried out by the person they delegate to.

Note 2

No other delegations may be made without the express written consent of Waka Kotahi.

Note 3

Inspection of damage to the following components may not be delegated and must be assessed in the as-damaged state by the engineer:

- towing connections (except for replacement of bent or worn tow eyes)

- log bolster attachments

- chassis flanges

- subsequent failure of a previous repair.

A task which has been delegated to a specified employee may not be delegated further by that employee. HV certifiers are responsible for the outcomes or consequences of any delegated task.

HV certifiers must maintain a record of all persons that they have approved in accordance with any specifications in the Performance Review System manual that supports this manual.

A local manufacturer certifier (IO), who derives their authority to certify any aspect of a vehicle from the qualifications and role of a staff member agrees to inform Waka Kotahi of any change to the role or employment of that staff member.

A local manufacturer certifier (VI), who derives, in part, their authority to certify any aspect of a vehicle from their role as a staff member of a Local manufacturer certifier (IO) agrees to inform Waka Kotahi of any change to their role or employment status.

The HV certifier must ensure that, where any employee, agent or contractor to the HV certifier is authorised by the HV certifier in accordance with their appointment to carry out any part of the services on behalf of the HV certifier, that person complies in all respects with the obligations of the HV certifier under their appointment.

3.1.2 Inspection and certification

1. Heavy vehicle specialist inspection and certification (sections 6.5(1), 6.5(4), 6.5(5), 7.5(4) and 7.5(5) of the Rule)

The inspection and certification of a vehicle must be carried out in accordance with the requirements and conditions imposed by Waka Kotahi.

Waka Kotahi requirements and conditions are contained in this manual (‘the VIRM’), HVS Memos, specified standards and codes, the PRS manual, and the Notice of Appointment.

The HV certifier will provide and perform the services in accordance with any published professional or ethical standards of professional bodies to which they belong.

2. Determining compliance of a specific aspect (sections 6.5(5), 7.4 and 11.1 of the Rule)

A specific aspect of a vehicle may be certified as meeting the requirements of the Rule if an HV certifier has identified the vehicle and has determined, on reasonable grounds, that the specific aspect:

a) has not compromised the safe operation of the vehicle

b) has been designed and constructed using components and materials that are fit for their purpose and is within safe tolerance of its state when manufactured or modified

c) complies with the applicable requirements

d) is lawful and no technically competent person (recognised by Waka Kotahi) would dispute that the inspection and certification of the vehicle complies with applicable requirements.

3. Record of determination (sections 6.6 and 7.6 of the Rule)

When an HV certifier has determined whether a specific aspect of a vehicle complies, the HVS certifier must make a record of that determination on the Heavy Vehicle Specialist Certificate, LT400 – for each certification (that is, one certification for each aspect certified).

Examples:

1. A semi-trailer that is fitted with a fifth wheel, kin pin, load anchorages, and log bolsters requires five separate Heavy Vehicle Specialist Certificates as in the table below:

Component | Certification Category | Code/Standard Certified to |

|---|---|---|

Fifth wheel | HVET or HMTD | NZS 5450 |

Kin pin | HVET or HMTD | NZS 5451 |

Load anchorages | HVEA or HMAD | NZS 5444 |

Log bolsters | HVEL or HMLD | Bolster Attachment Code |

Brakes | HVEK or HMKD | Schedule 5/Section 6 HVBR |

2. A 4 x 2 truck that has the chassis lengthened, a tag axle fitted, new load anchorages, and a draw beam requires four separate Heavy Vehicle Specialist Certificates as in the table below:

Component | Certification Category | Code/Standard Certified to |

|---|---|---|

Chassis, suspension, | HVEC or HMCD | HV Rule |

Brakes | HVEK or HMKD | Schedule 5/Section 6 HVBR |

Load anchorages | HVEA or HMAD | NZS 5444 |

Draw beam | HVET or HMTD | NZS 5446 |

3. A bus or coach manufactured in NZ that already has ‘brakes’ standard compliance, requires two separate Heavy Vehicle Specialist Certificates as in the table below: (Additional Certification will be required if the vehicle is fitted with a tow bar, roof rack, a wheelchair hoist, powered ramp or wheelchair/wheelchair occupant restraints or is modified and requires brake certification.)

Component | Certification Category | Code/Standard Certified to |

|---|---|---|

Stability, | HVEC or HMCD | PSV Rule |

Rollover Strength | HVEC or HMCD | PSV Rule |

The HV certifier must immediately inform Waka Kotahi of any theft of any Waka Kotahi documents supplied to the HV certifier by Waka Kotahi or any agent of Waka Kotahi, or prepared by the HV certifier on behalf of Waka Kotahi.

The HV certifier must return to the document supplier or Waka Kotahi or destroy as required by Waka Kotahi any surplus or obsolete Waka Kotahi documents.

4. LT400

The LT400 presented must be the original or emailed directly to a CoF inspector or inspecting organisation. Where the original LT400 has been lost or destroyed the certifier may provide a duplicate (photocopy) provided it is signed and dated by the HV certifier.

5. Standards

Where an HV certifier is required to use a standard during the inspection and certification process, the latest version of the standard must be used except where otherwise specified.

The HV certifier must have available and use any and all standards which are referenced in the Rule or which the HV certifier references in certification.

The HV certifier must comply in all respects with any written instructions, interpretations or guidelines issued by Waka Kotahi to the HV certifier.

3.1.3 Re-inspection and re-certification (section 11.4 of the Rule)

If a Heavy Vehicle Specialist Certificate, LT400, has been revoked, Waka Kotahi may require the HV certifier to repeat the inspection and certification of the vehicle, issue (if appropriate) a new certification, and meet the re-inspection and re-certification costs.

3.1.4 Performance review (section 3.1(1) of the Rule)

Waka Kotahi, either directly or through an appointed agent, may monitor and review the performance of a HV certifier, including the performance of inspection and certification activities.

The requirements and conditions are contained in the Rule, this document, the Notice of Appointment and the PRS: Heavy vehicle specialist certification manual.

Waka Kotahi may require a HV certifier to provide such information as Waka Kotahi reasonably considers relevant. A HV certifier must comply with these requirements (unless expressly stated in the Notice of Appointment or this VIRM, no functions, duties or powers which may be exercised by Waka Kotahi under any statute, regulation or rule, including under section 198 of the Land Transport Act 1998, are in any way restricted).

Costs of monitoring and review (section 3.1(4) of the Rule)

HV certifiers must bear the costs of the monitoring and reviewing of their performance in accordance with any fee prescribed in the Rule or other applicable legislation.

3.1.5 Investigations

1. Investigations (sections 3.2(1) and 3.2(8) of the Rule)

If Waka Kotahi has reason to believe that an HV certifier has failed to comply with any of the conditions of his appointment, Waka Kotahi may require the HV certifier to undergo an investigation and to provide such information as Waka Kotahi reasonably considers appropriate as part of the investigation. Waka Kotahi may observe or inspect the equipment or activities of the certifier and copy relevant books and records.

Refusal to undergo monitoring, review, or investigation will be a breach of the Rule and the Notice(s) of Appointment and may result in further regulatory action.

2. Notification of action (other than immediate suspension/imposition of conditions) (section 3.2(3) of the Rule)

Following an investigation and before carrying out action, Waka Kotahi will notify the HV certifier in writing of:

a) the action that is being considered

b) the reason for the action that is being considered

c) the date by which submissions may be made to Waka Kotahi in respect of the action that is being considered, which must be at least 21 days after the notice was given

d) where appropriate, the date on which the action that is being considered will take effect, which, unless Waka Kotahi determines otherwise, must be at least 28 days after the notice was given.

3. Responding to a notification of action (section 3.2(5) of the Rule)

If a HV certifier is notified as above, he must ensure that he provides Waka Kotahi with all information within the period specified in the notice.

4. Waka Kotahi will consider submissions (section 3.2(6) of the Rule)

Waka Kotahi will consider the submissions and information supplied, and will:

a) decide whether or not to take the action that is being considered

b) as soon as is practicable, provide written notification to the HV certifier of:

i. the Waka Kotahi decision, and

ii. if appropriate, the date on which the action is take effect, and

iii. if appropriate, the right of appeal under section 106 of the Land TransportAct 1998.

5. Remedial action, suspension, revocation (sections 3.2(2) and 3.2(8) of the Rule)

If, following an investigation, Waka Kotahi is satisfied that the HV certifier has failed to comply with any of the conditions of his appointment, Waka Kotahi may do one or more of the following:

a) require that remedial action such as training or mentoring be undertaken by the HV certifier. The HV certifier cannot refuse to comply with the requirement

b) suspend the HV certifier for a specified period or until conditions are met

c) revoke the appointment of the HV certifier.

6. Immediate suspension or imposition of conditions (section 3.3(1) of the Rule)

If Waka Kotahi has reason to believe that a HV certifier has failed to comply with a condition of his appointment and that this presents a significant risk to land transport safety, Waka Kotahi may suspend the appointment with immediate effect, or impose any conditions on the appointment of the HV certifier.

7. Notification of immediate suspension or imposition of conditions (section 3.3(2) of the Rule)

When Waka Kotahi suspends the appointment, or imposes conditions on the appointment, Waka Kotahi will notify the HV certifier in writing of:

a) the grounds for the suspension or imposing of conditions

b) the fact that the certifier or organisation may make submissions to Waka Kotahi

c) the right of appeal under section 106 of the Land Transport Act 1998.

8. Waka Kotahi will consider submissions following immediate suspension or imposition of conditions (section 3.3(3) of the Rule)

Waka Kotahi will, as soon as practicable, consider any submission made and notify the certifier or inspecting organisation in writing of the result of any such consideration.

9. Duration of immediate suspension or imposition of conditions (section 3.3(5) of the Rule)

A suspension or condition imposed remains in force until Waka Kotahi has determined the action to be taken and that action has been taken.

10. Withdrawal of immediate suspension or imposition of conditions (section 3.3(4) of the Rule)

Waka Kotahi may at any time withdraw a suspension or condition imposed.

11. Right of appeal against immediate suspension or imposition of conditions (section 3.3(6) of the Rule)

A HV certifier may appeal under section 106 of the Land Transport Act 1998 against a decision by Waka Kotahi to suspend immediately or to impose conditions.

12. Costs of investigations (sections 3.2(7) and 3.2(8) of the Rule)

Waka Kotahi may require a HV certifier to bear the costs associated with an investigation or remedial action in accordance with any prescribed fee. Refusal to bear the costs will be a breach of the Rule and the Notice(s) of Appointment and may result in further regulatory action.

3.1.6 Consequences of termination or suspension

Upon revocation or termination of the appointment for any reason whatsoever, whether in whole or part, the HV certifier will:

a) cease provision of all or such part of the services under their appointment as may be required by Waka Kotahi

b) return to Waka Kotahi or authorised representative or destroy as required by Waka Kotahi any land transport documents (including unused LT400 forms), advertising and/ or display material featuring or referring to the services or the HV certifier’s provision of the services under this appointment, as the case may be.

Upon suspension of appointment (whether in whole or part) of the HV certifier for any reason whatsoever, whether by Waka Kotahi or a duly authorised representative, the HV certifier shall immediately cease providing the relevant services during the period of suspension and shall, if so required, surrender all Waka Kotahi documents to Waka Kotahi or any authorised representative.

3.1.7 Disputes and appeals

Where there is any dispute arising between parties in relation to any matter arising out of the appointment, the parties shall endeavour to resolve such disputes promptly by consultation and negotiation in good faith.

- Where the HV certifier does not agree with any decisions of Waka Kotahi, including any decision or direction of a Certification Officer, the HV certifier should, notwithstanding any other rights they may have at law, seek from Waka Kotahi a review of that decision.

- Despite the previous two points, both parties recognise that Waka Kotahi has functions in respect of land transport safety and law enforcement and that, notwithstanding any dispute or appeal, Waka Kotahi may take whatever lawful action Waka Kotahi considers necessary in the interests of road safety. The specific reasons for the action taken will be provided.

- Where there is any dispute arising between the parties in relation to technical decisions, any available dispute resolution process described in the VIRM or in an issued HVS Memo may be invoked. This will permit the disclosure of otherwise privileged information, such as designs and PRS scores, to the adjudicating body, provided that this information is pertinent to the matter being judged.

Page amended 1 November 2021 (see amendment details)

3-2 Disqualification from certification

A HV certifier must not engage in any activities that may conflict with his independence of judgement and integrity in relation to the services delivered.

A HV certifier may have a professional interest in a vehicle they certify, such as a vehicle:

a) they have modified or repaired, or

b) that has been modified or repaired by a person working for the same company as the HV certifier, and at the same premises,

However, a HV certifier may not certify a vehicle they or their immediate family have a personal ownership interest in.

A HV certifier may not certify an aspect of a vehicle for which he is not appointed.

An HVS certifier must not inspect a vehicle if:

a) they do not hold a driver licence for that class of vehicle, and

b) they are required to drive it.

3-3 Establishing whether a vehicle must be HV certified

A vehicle must be inspected for heavy vehicle specialist certification if:

a) it requires certification for entry, re-entry or an in-service CoF

b) it is a vehicle of one of the following classes:

MD3, MD4, ME, NB, NC, TC, TD (see Table 3-4-1. Vehicle equipment standards classifications)

c) it has undergone modifications or qualifying repairs to:

i. chassis, structural bodywork, brakes, bolster attachments, towing connections, drive train, engine transmission, axles, load anchorages and wheels which affect compliance with applicable requirements (includes flood/water/fire damage)

ii. any item which could affect the vehicle’s SRT

iii. corrosion in a structural part of the vehicle.

3.3.1 Repairs which do not require certification

The following types of repair do not require inspection and certification:

1. the replacement of bolted on components that do not require certification in themselves (a log bolster attachment or draw beam still requires certification but a bolted on tow-eye does not).

2. repairs to the first failures of chassis cross-members, if that cross-member is not

a) the first or last cross-member of the chassis

b) fitted within 500mm of a suspension support

c) fitted with a driveshaft centre bearing

d) supporting a:

i. ball-race turntable

ii. tow coupling

iii. bolster attachment

iv. device that may place a concentrated load on to the chassis, for example a hoist or a hydraulic cylinder of a tipping body.

3. repairs to coaming rails that do not support certified load anchorage points.

4. tow-eyes fitted to the front of a vehicle for recovery purposes.

5. repairs to non-structural components only of a vehicle’s monocoque body, for example bolt-on body panels.

6. Ferry tie down points that are attached using existing holes in the chassis and are not welded to components that require certification in themselves.

3.3.2 Repairs that require an LT400, but no statement of design compliance

The following is a list of repairs/replacements that certifying manufacturers can undertake without getting a statement of design compliance from a certifying engineer:

1. Load anchorages that are of a standard design from NZS5444, certified to this standard, and repaired using the method outlines in NZS5444.

2. Worn or damaged fifth wheels can be replaced according to the fifth wheel manufacturer’s instructions for replacing bolt-on components.

3. Worn or damaged kingpins can be replaced according to the kingpin manufacturer’s instructions on replacement.

4. Other items as defined in the manufacturing certifier section of this manual.

3.3.3 Repairs that require both an LT400 and a statement of design compliance

All other repairs to heavy vehicle chassis, towing connections, log bolsters and load anchorages require input from a certifying engineer and therefore require a statement of design compliance before an LT400 can be issued by a manufacturing certifier, except where specifically allowed for in the manufacturing certifier section of this manual

3-4 Identifying the vehicle class

Since some decisions are made according to the class of the vehicle, the HV certifier must be able to identify the class of the vehicle to be inspected. The following table describes vehicle classes.

Table 3-4-1. Vehicle equipment standards classifications

3-5 Work procedure

Any work, to which this manual applies, to be done on a vehicle, must be:

- specified correctly

- designed correctly

- manufactured correctly

- certified as within safe tolerance of the original design or specification.

The design of the work by a HV engineer certifier, where the manufacture and installation is to be the responsibility of others, is to be accompanied by a Statement of Design Compliance (SoDC) that is signed by the HV engineer certifier.

The specification of the work is set out in the Procedure Documentation Sheet (PDS) that is drawn up by an HV certifier.

- Each certification must have its own unique PDS.

Manufacturing and installation work must also be monitored or verified by an HVS certifier. Where appropriate, the certification of manufacture may be done by a form of ‘type approval’.

Final certification is based on inspection by a qualified certifier with reference to any intermediate documents, including the SoDC, the PDS, supporting documentation from any delegated tasks, any applicable standards, documented histories of used components and worksheets and calculations.

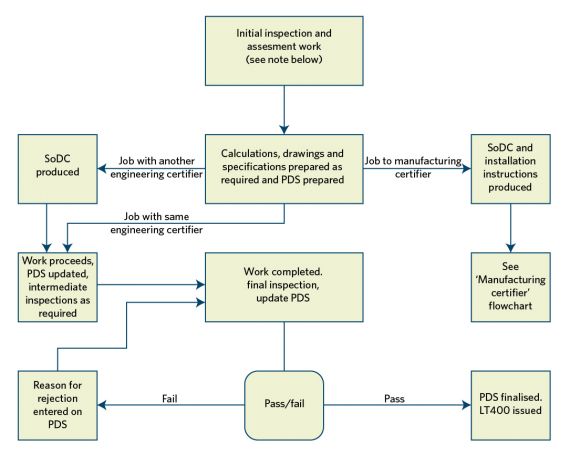

Figure 3-5-1. Certification process: Engineer certifier

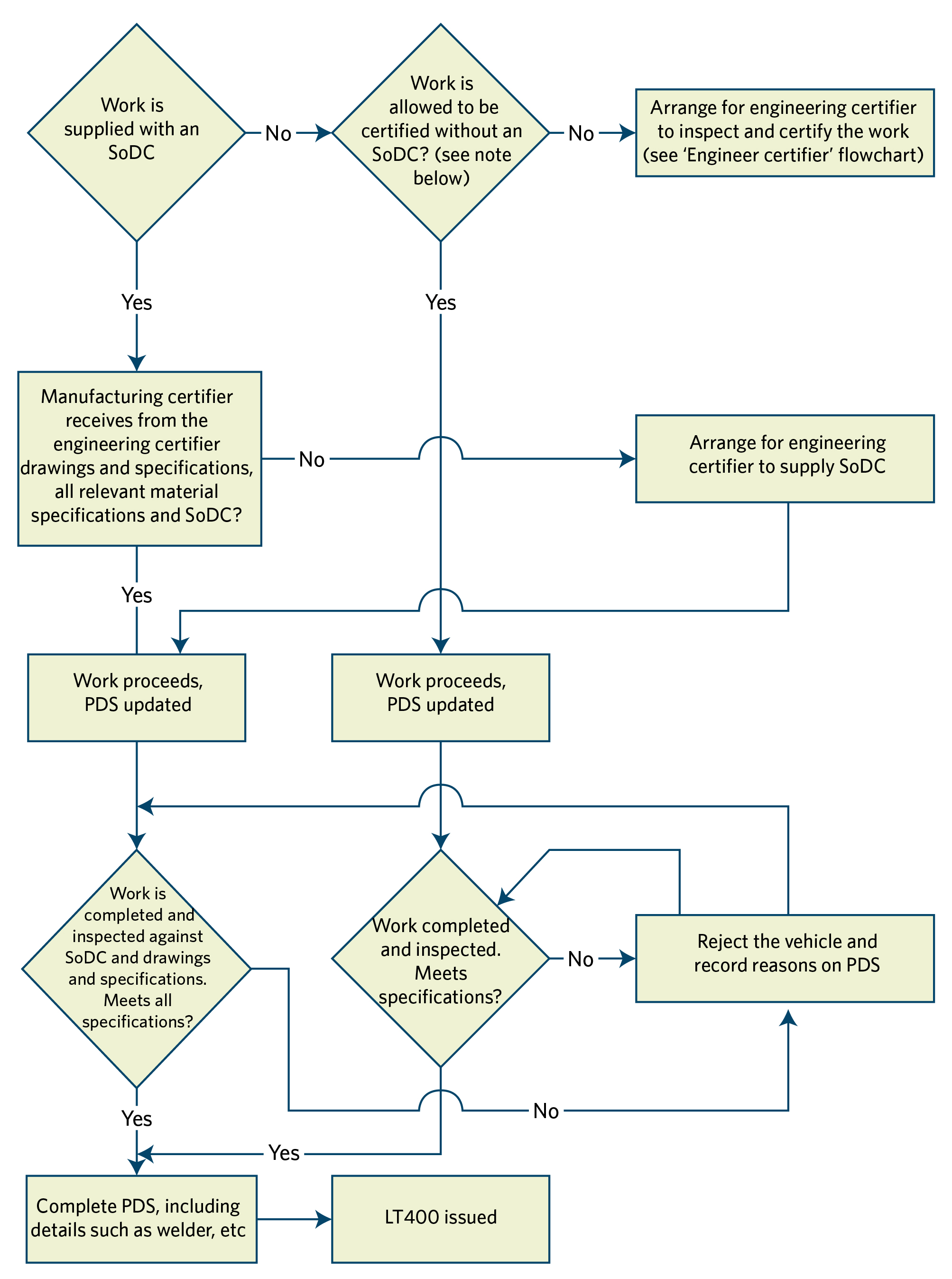

Figure 3-5-2. Certification process: Manufacturing certifier

(see Note 1)

Note 1

The following work is allowed to be completed by a manufacturing certifier without a SoDC.

- Load anchorages that are of a standard design from NZS5444, certified to this standard and repaired using the method outlined in NZS5444

- Worn or damaged fifth wheels replaced according to the fifth wheel manufacturer’s instructions for replacing bolt on components

- Worn or damaged kingpins replaced according to the kingpin manufacturer’s instructions on replacement

- Work certified by the HV certifier who has designed it.

Other work that may be certified by a HV manufacturing certifier is defined in the manufacturing certifier section of this manual.

How many certificates?

Each aspect of the vehicle that requires certification is to be certified separately and issued with a separate LT400. This means that any vehicle may need multiple certificates before it can qualify for a CoF (refer to Technical bulletin 15).

3.5.1 The statement of design compliance (SoDC)

The SoDC must include the name and signature of the certifier and the date of certification. The SoDC

must also have sections with information relevant to:

- the class of motor vehicle

- the vehicle description

- vehicle identifiers

- certification.

The SoDC must include information relevant to the purpose of specialist certification, for example:

- modifications

- repair

- vehicle dimensions

- matters relevant to the structure, systems, components or equipment of a vehicle or instillation or use of a vehicle’s structure, systems, components or equipment

- alternative fuel system

- age or historic nature of a vehicle

- class of vehicle

- any other attribute of a vehicle.

The SoDC must confirm that the vehicle, or any aspect of it relevant to the purpose of specialist certification, complies with the requirements as specified in Land Transport Rule: Vehicle Standards Compliance 2002, and therefore must include the following statement:

I declare that I am a heavy vehicle specialist certifier – engineer and I hold a current valid appointment. I certify that this vehicle component design and this certification comply in all respects with the Land Transport Rule: Vehicle Standards Compliance 2002; my Notice of Appointment and applicable requirements. To the best of my knowledge the information contained in this certificate is true and correct.

The SoDC must include drawing numbers and may include other relevant details.

HV manufacturing certifiers shall not accept an SoDC that does not contain the information outlined in the Gazette notice published during the week of 21 August 2000.

HV manufacturing certifiers shall not accept an SoDC from an HV certifying engineer who has ceased to practice. An SoDC issued by that person can no longer be considered valid as the HV certifying engineer does not hold a current appointment.

Consequently, any item or component manufactured using a SoDC from a non-practicing HV certifying engineer cannot be signed off by an HV manufacturing certifier, but must be re-certified by a current HV certifying engineer of the appropriate category.

SoDCs must be specific to individual vehicles and clearly identify the VIN/chassis number. SoDCs cannot be used for ‘type’ or ‘model’ approval of generic designs.

3.5.2 Issuing a professional letter or statement

Engineering certifiers may be asked for opinion on a component where it is determined that a LT400 is not required. This may include situations where a clean and treat is required, or inspection of damage recorded where certification is not yet required.

Where an LT400 is not required, the professional opinion should be on your company letterhead and should contain:

- vehicle details

- date of inspection

- details of the area assessed

- recording of any damage and any treatment completed

- effect on the vehicle’s/components integrity and/or safety performance in relation to GVM/ratings

- your details, including category and ID

- the date and sign the document.

Page amended 1 April 2023 (see amendment details)

3-6 Establishing whether the vehicle aspect complies

Certifications by an engineer certifier

1. Start a Procedure Documentation Sheet (PDS) for the vehicle.

2. Inspect the vehicle to be certified at a location that allows adequate access and equipment to allow a full and detailed inspection.

3. Record all relevant details and dimensions for the proposed or existing aspect of the vehicle that requires certification.

4. Collect all relevant information that is required for the certification of that vehicle aspect.

5. Compare what the vehicle owner/workshop wants to do with the relevant sections of the VIRM and

ensure that no reasons for rejection will be invoked. If they are, the HV certifier should advise the owner/workshop in writing and detail the options.

6. Complete design drawings, specifications and calculations as required.

7. Complete a Statement of Design Compliance, if required (see section 3.5), and supply it as well as all drawings and specifications required to complete the proposed work to the workshop/vehicle owner. Such information should include dimensions, materials and welding specifications.

8. Supply any drawings and specifications required to complete the proposed work to the workshop/vehicle owner. Such information should include dimensions, materials and welding specifications as well as an inspection schedule from the HV certifier.

9. Carry out inspections of the work as required. If the vehicle is presented fully completed, disassembly of certain parts may be required at the discretion of the HV certifier. Compare the work against the requirements of the design drawings and specifications provided. The inspection should include the quality of materials and workmanship.

10. Compare the finished work and documentation against the VIRM for reasons for rejection and if any of the reasons for rejection apply, reject the vehicle for certification.

11. If the HV certifier requires further information in order to determine compliance with the requirements, he must reject the vehicle until the information has been obtained.

12. Complete the PDS and issue an LT400 for the aspect that has been certified if no reasons for rejection exist.

Certifications by manufacturing certifier

1. Start a PDS for the vehicle.

2. Inspect the vehicle to be certified at a premises that allows adequate access and equipment to allow a full and detailed inspection.

3. Inspect the vehicle against the Statement of Design Compliance, if required (see section 3.5), issued by a HV engineer certifier or against one of the approved pre engineered solutions. The inspection should include materials and workmanship.

4. Collect any relevant supporting documentation.

5. Compare the inspection results against the VIRM for reasons for rejection and if any exist, reject the vehicle for certification.

6. Complete the PDS and issue an LT400 for the aspect that has been certified if no reasons for rejection exist.

Prerequisite documentation

Certifications by engineer

1. Designs for the work involved in the vehicle aspect.

2. Statement of Design Compliance or LT400 signed by an HV Specialist Certifying Engineer for that aspect.

3. PDS.

Certifications by local manufacturer

1. Designs for the work involved in the vehicle aspect, where this involves the chassis, drawbar, drawbeam, heavy vehicle brakes or log bolsters.

2. Statement of Design Compliance or reference to pre engineered solutions, for the work involved in the vehicle aspect.

3. PDS.

3-7 Record of certification

1. The HV certifier must complete a Heavy Vehicle Specialist Certificate (LT400).

2.The HV certifier must include the Vehicle Identification Number (VIN) on the LT400.

3. The HV certifier must retain one copy of the LT400.

4. The HV certifier must provide one copy of the LT400 to the owner of the vehicle.

5. The HV certifier must hold all documentary evidence involved in the certification process.

One LT400 is required for each aspect of the vehicle that needs to be certified. If a single certifier who is appointed for more than one aspect of a vehicle certifies more than one aspect of the vehicle at the same time, a separate LT400 must be used for each aspect.

For some aspects of the vehicle an additional record of the determination, such as a component identification, usually in the form of a metal plate, must be issued and fixed to the vehicle. For some items, this identification may be impressed directly on to the item.

While a certifier may include an expiry date on the certification documents or certification records (eg identification plates), they are only valid if they are required by the legislation or the standard they are manufactured to, or are required by Waka Kotahi. If they are not specifically required they are not to be recorded in Landata (Where expiry dates are not specifically required by the legislation, the standard or Waka Kotahi then any certification carried out will be for the life of the vehicle).

Any vehicles or components certified after 1 December 2016 must contain the following information (on the plate or label) as a minimum:

Table 3-6-1. Data on plates and labels

Aspect | Minimum data on a plate |

|---|---|

Drawbars and drawbeams |

|

Log bolster |

|

Load anchorages and headboard |

|

Brake code |

|

PSV roof rack |

|

Replacement plates

If a plate becomes illegible, damaged or lost it may be replaced provided that:

- the information that was on the plate can be determined from the original documentation, and

- visual inspection of the plated item shows it remains in a safe condition, and

- it is the original item.

Note 1

VIN is the primary vehicle identifier required and chassis number is acceptable only if the vehicle does not have a VIN.

Page amended 9 April 2018 (see amendment details)

3-8 Collecting fees

The Land Transport (Certification and Other Fees) Regulations 1999, regulations 5 and 8 stipulate that the fee that may be charged by an HV certifier for the certification of a vehicle is an amount determined by the individual HV certifier having regard to:

a) the time spent in inspecting the vehicle to ascertain whether it complies with the relevant requirements

b) any fees payable to Waka Kotahi

c) any standard or usual rate at which the HVS certifier charges for other work carried out in respect of motor vehicles.

3-9 Documentation of heavy vehicle specialist certification

The following table defines the minimum file content that should be present in any HVSC certification file. In addition to the listed minimum requirements, all files should contain sufficient information such that another HVSC can independently verify the certification decision.

Required items | Certifier categories | ||

|---|---|---|---|

| HVEA, HVET, HVEC, HVEL, HVEK | HMAD, HMTD, HMCD, HMLD, HMKD | HVS1, HVS2, HVS3, HVP1, HVP2 |

PDS (identifying the vehicle, work carried out/certified, and the standards used) | ✔ | ✔ | ✔ |

LT400 (or SODC if applicable) | ✔ | ✔ | ✔ |

Inspection notes and sketches | ✔ | ✔ | ✔ |

Photographs showing:

| ✔ | ✔ | ✔ |

Material specifications | ✔ | ✔ | |

Calculations | ✔ | ✔ | |

Hubometer history and residual life assessment (for drawbar and drawbeam recertifications only) | ✔ | ||

Drawings / fabricator instructions | ✔ | ||

Proprietary component data | ✔ | ✔ | |

Welder qualifications (positions and techniques) | ✔ | ✔ | |

Evidence of design that was followed, ie one of:

| ✔ | ||

Vehicle information, eg data sheets, bodybuilder guide, vehicle history from LANDATA if already registered, etc | ✔ | ✔ | |

Welding/bolting procedures as appropriate | ✔ | ||

NDT records as required | ✔ | ||

Page added 9 December 2019 (see amendment details)

4 Complaints

Customers should be encouraged to direct any complaints to the HV certifier in the first instance. |

To ensure that all written complaints are investigated, the HV certifier must maintain an effective complaints management process, which must provide:

1. a clear and concise statement that recognises the positive value of complaints.

2. clear and concise instructions to all customers on how to register a complaint. This can be accomplished in several ways, for example:

a) a conspicuous notice on the workplace wall, or

b) a clear statement on any receipt or invoice issued, or

c) a clear statement on the HVS certifier’s checksheet

3. a straightforward explanation of the expected standards for resolution and the customer’s right to appeal to Waka Kotahi if the proposed resolution is unsatisfactory

4. identification of the complainant and should address specific concerns about the service provided.

5. full documentation of each complaint processed, in accordance with the Waka Kotahi PRS manual, to enable subsequent investigation

6. acknowledgement in writing within three working days of any written complaint

7. a proposed resolution to the complainant within 20 working days of the complaint being made.

8. a record of each complaint, in accordance with the Waka Kotahi PRS manual

9. a clear direction to the Waka Kotahi helpdesk 0800 699 000 if a customer wishes to make a complaint or appeal a decision made by an HV certifier, or the complaint refers to legislation or Waka Kotahi policy.

Note: Complaints must be in writing.

5 Inspection premises and equipment

The HV certifier must ensure that the premises used for the inspection and certification of modifications and repairs comply with the applicable requirements in this section.

HV certifiers who do not have their own premises should make their inspections on premises as described below.

5.1 Premises and equipment specifications

The HV certifier must use an inspection area that:

a) enables a safe and thorough inspection

b) is provided with sufficient lighting to enable good visibility of the vehicle being certified and the equipment used in the inspection process

c) have available suitable, calibrated equipment for the inspection being carried out.

5.2 Compliance with statutory requirements

The HV certifier must not carry out inspections if the premises and equipment do not comply with:

- Occupational Safety and Health requirements

- any other relevant Acts, regulations and local bylaws, as they apply to him or his business.

6 Appointments

There are currently seven different technical certification categories of HV certifier. Waka Kotahi assesses and qualifies four and the other three are assessed by external organisations, with final approval the responsibility of Waka Kotahi.

The categories that Waka Kotahi assess are:

- chassis modification

- towing connections

- load anchorages, and

- swept path analysis.

Those assessed by external organisations are:

- log bolster attachments

- brake modifications

- static rollover threshold.

Fit and proper criteria

All persons appointed as HV certifiers are required to be and to remain ‘fit and proper persons’. The criteria considered for this include:

a) relevant criminal convictions

b) transport-related offences

c) relevant warnings, penalties and disciplinary actions imposed

d) relevant complaints

e) the interest of the public and land transport safety.

Engineering certifier requirements

All HV engineering certifiers must:

a) have a minimum qualification of NZCE (mechanical, civil or aviation) or approved equivalent >(minimum Level 6 Diploma, except where specialist knowledge and experience is deemed acceptable by Waka Kotahi. In special circumstances and upon application a Level 5 Diploma may be considered. Overseas qualifications must be referred to the New Zealand Qualifications Authority (NZQA), who will determine the New Zealand equivalent, if available.

b) have knowledge of the requirements specified in:

i. this manual, VIRM: Heavy vehicle specialist certification

ii. the relevant parts of the Land Transport Act 1998

iii. the Land Transport Rule: Vehicle Standards Compliance 2002

iv. Other relevant Land Transport Rules.

Applicants for appointment as HV engineering certifiers will be assessed on their understanding of design principles for their category and their knowledge of the general and New Zealand requirements for heavy vehicles.

Load anchorage engineering certifiers (HVEA)

Scope

All anchorages for securing loads to vehicles, excluding logging bolsters. Certifiers shall use the latest version of any standard except where permitted otherwise in the Rule.

Experience requirements

Relevant work experience in the design or fabrication of load anchorages. Working knowledge of the following documents:

1. Land Transport Rule: Heavy Vehicles 2004 and its amendments

2. Welding in the transport industry (see Technical bulletin 13)

3. NZS 5444: Load Anchorage Points for Heavy Vehicles

4. NZS 5413: Stock Crates

5. AS/NZS 1554: Structural Steel Welding (parts 1 and 4 as appropriate)

6 AS/NZS 1665: Welding of Aluminium structures

7. AS 3990: Mechanical Equipment – Steelwork (supersedes AS 1250)

8. ISO 1161: Series 1 Freight Containers – Corner Fittings – Specification

9. AS/NZS 2980: Qualification Tests for Metal Arc Welders

10. AS/NZS 4380:Cargo restraint systems – Webbing load restraint systems.

Towing connections engineering certifier (HVET)

Scope

All towing connections between vehicles. This includes fifth wheels, fifth-wheel kingpins, towbars, drawbeams and drawbars.

Experience requirements

Relevant work experience in the design or fabrication of towing connections. Working knowledge of the following documents:

1. Land Transport Rule: Heavy Vehicles 2004 and its amendments

2. Welding in the transport industry (see Technical bulletin 13)

3. NZS 5446: Heavy vehicle towing connections – Drawbeams and drawbars

4. NZS 5450: Specification for Coupling Devices for Articulated Vehicles – Fifth Wheel Assemblies

5. NZS 5451: Specification for Coupling Devices for Articulated Vehicles – Fifth Wheel Kingpins

6. AS/NZS 4968, Heavy-vehicles – Mechanical coupling between articulated vehicle combinations

7. AS 2174, Articulated vehicles – Mechanical coupling between prime movers and semitrailers

8. AS 3990: 1993, Mechanical Equipment – Steelwork

9. AS/NZS 1554: Structural Steel Welding (parts 1 and 4 as appropriate)

10 AS/NZS 1665: Welding of Aluminium structures

11. AS/NZS 2980: Qualification Tests for Metal Arc Welders

12. NZS 5467: Code of Practice for Light Trailers

13. ISO 1102: Commercial Road Vehicles – Mechanical Connections between Towing Vehicles and Trailers–50mm Drawbar Couplings

14. AS 1110: ISO Metric Hexagon Precision Bolts and Screws

15. AS/NZS 4291.1: Mechanical properties of fasteners

16. AS 2213: 50mm Pin-Type Couplings and Drawbar Eyes for Trailers

17. BS 5400: Part 10, Code of Practice for Fatigue

18. BS 7608: Code of Practice for Fatigue Design and Assessment of Steel Structures.

Chassis modification and repair engineering certifier (HVEC)

Scope

Chassis modification includes rollover strength for PSVs, steering conversions, chassis modifications and repairs, design of new chassis and ratings, mounting of cranes and other equipment, modifications and repairs to drive trains and axles, and seatbelt anchorage design.

Experience requirements

Relevant work experience in the design, modification and fabrication of vehicles and vehicle components. Working knowledge of the following documents:

1. Land Transport Rule: Vehicle Standards Compliance 2002 and its amendments

2. Land Transport Rule: Heavy Vehicles 2004 and its amendments

3. Welding in the transport industry (see Technical bulletin 13)

4. AS/NZS 1554: Structural Steel Welding (parts 1 and 4 as appropriate)

5. AS/NZS 1665: Welding of Aluminium structures

6. AS/NZS 2980: Qualification Tests for Metal Arc Welders

7. AS 3990: 1993, Mechanical Equipment – Steelwork

8. Ladder frame chassis design guide (joint MoT/IRL document)

9. BS 5400: 1980, Part 10, Code of Practice for Fatigue

10. BS 7608: 1993 Code of Practice for Fatigue, Design and Assessment of Steel Structures

11. AS 1110: ISO Metric Hexagon Precision Bolts and Screws

12. AS/NZS 4291.1: Mechanical properties of fasteners

13. Low Volume Vehicle Code.

Brake engineering certifier (HVEK)

Scope

All heavy vehicle brake system design and modification

Experience requirements

Relevant work experience in the design and modification of braking systems. Passed Heavy Vehicle Brake course and exam as approved by Waka Kotahi. Working knowledge of the following documents:

1. Land Transport Rule: Heavy Vehicles Brakes 2006 and its amendments, including Schedule 5

2. Land Transport Rule: Vehicle Standards Compliance 2002 and its amendments

3. Access to the New Zealand brake calculator or an approved proprietary device.

Bolster attachment engineering certifier (HVEL)

Scope

All logging bolster attachments, modifications and repairs.

Experience requirements

The certifier must:

1. be an appointed HVEC certifier with sufficient (three years or more) experience in the transport industry in manufacturing, supervision, quality control or drafting in a similar area:

2. have passed the log bolster attachment course and exam set by the Log Transport Safety Council

3. have a working knowledge of Land Transport Rule: Heavy Vehicles 2004 and its amendments

4. have a working knowledge of Log Transport Safety Council: Log Bolster Attachment Code.

5. have a working knowledge of Welding in the transport industry (see Technical bulletin 13)

6. have a working knowledge of AS/NZS 1554: Structural Steel Welding (parts 1 and 4 as appropriate)

7. have a working knowledge of AS/NZS 1665: Welding of Aluminium structures

8. have a working knowledge of AS/NZS 2980: Qualification Tests for Metal Arc Welders

9. have a working knowledge of AS 3990: 1993, Mechanical Equipment – Steelwork

10. have a working knowledge of BS 5400: 1980, Part 10, Code of Practice for Fatigue

11. have a working knowledge of BS 7608: 1993 Code of Practice for Fatigue, Design and Assessment of Steel Structures

12. have a working knowledge of AS 1110: ISO Metric Hexagon Precision Bolts and Screws

13. have a working knowledge of AS/NZS 4291.1: Mechanical properties of fasteners

Static rollover threshold engineering certifier (HVSx)

Scope

Measure and input vehicle data into a computer program to establish a stability angle. There are currently three different certification categories for SRT calculation

- SRT level 1

- SRT level 2

- SRT level 3.

Experience requirements

For those wishing to qualify as Waka Kotahi approved and appointed inspectors there are two tests:

- basic for level 1 inspectors and

- advanced for level 2 inspectors.

Level 1 certifiers use the SRT calculator software but are limited to simpler cases. For certification purposes a level 1 certifier may use all the features of the calculator except Load category ‘Other’, which requires the calculation of the payload centre of gravity and the ‘user defined’ suspension options, which requires the obtaining and interpretation of suspension parameters.

Level 2 certifiers also use the SRT calculator software but have all options available.

Level 3 certifiers may be approved by Waka Kotahi to use alternative methods of determining SRT. These could include tilt table testing or computer simulation.

Within the framework of the two levels of certification, there are four parties that may be involved in gathering the data for SRT certification, namely:

1. Operator: may provide tare axle weight data and may nominate load type (Uniform density/ Mixed freight/ Other) on which the certification is to be based except where this is defined by Waka Kotahi.

2. Level 1 SRT inspectors: typically these are individuals who have passed the level 1 SRT training but have not been authorised by Waka Kotahi to be certifiers.

3. HVS1 certifiers: typically these are individuals who have passed the level 1 SRT training and have been appointed by Waka Kotahi to act as certifiers under the Waka Kotahi Notice of Appointment.

4. HVS2 certifiers: typically individuals who have passed both the level 1 and level 2 SRT training and have been appointed by Waka Kotahi to act as certifiers.

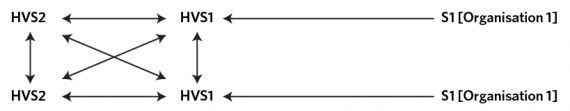

Information and measured vehicle data may be shared between the last three parties as indicated in the diagram below. In this diagram S1 refers to Level 1 SRT inspectors, while HVS1 and HVS2 refers to the certifiers. The arrows indicate allowable paths of information and data transfer. Thus a Level 1 certifier, HVS1, may receive vehicle data that has been obtained by a Level 1 SRT inspector and use these data to undertake a level 1 certification without personally inspecting the vehicle and making the measurements. However, the HVS1 certifier is ultimately responsible for the accuracy of the SRT certificate issued and must ensure that the S1 inspector is appropriately qualified and competent.

Although the allowable data transfers do permit the transfer of information from HVS1 certifiers to HVS2 certifiers, this can only be within the scope of the HVS1’s demonstrated level of competence. Thus a level 2 certification which requires an HVS2 certifier will also require that the vehicle is inspected by an HVS2 certifier.

When the certifier issues an SRT certificate he must also issue an LT400 to accompany it.

For some vehicles, the SRT certification process will lead to some vehicle or suspension modifications being undertaken in order to improve the vehicle’s stability and allow it to maintain its load carrying capacity while achieving the required SRT. These vehicle modifications will generally require certification by a Waka Kotahi approved certifying engineer and will require the issuing of an LT400 detailing the modifications made. Although the certification of the vehicle modifications and the SRT certification may be undertaken by the same engineer certifier, if he is appropriately qualified, two separate LT400s are required, one for the vehicle modifications and one for the SRT.

Dynamic Performance engineering certifier (HVPx)

Scope

To confirm swept path and dynamic vehicle performance by calculation using approved software or by physical testing. There are two different certification categories for Swept Path/Dynamic Performance

- HVP1 – Swept Path Certification

- HVP2 – Dynamic Vehicle Performance (PBS)

Experience requirements

For those wishing to qualify as Waka Kotahi approved and appointed inspectors in either of these categories there are some prerequisites. The certifier must:

1. be an appointed HVEC certifier with sufficient (one year for HVP1 or three years or more for HVP2) experience in the transport industry in manufacturing, supervision, quality control or drafting in a similar area:

2. for HVP1 & 2 have access to and be able to prove competence operating appropriate computer software (such software to be advised to Waka Kotahi who will rule on its suitability) and/or the ability to carry out appropriate physical testing.

3. have attended and passed any course and/or exam set or approved by Waka Kotahi

4. have a working knowledge of Land Transport Rule: Vehicle Dimensions and Mass 2016 and its amendments

5. have a working knowledge of Land Transport Rule: Heavy vehicles 2004 and its amendments

HVP1 certifiers use appropriate software or physical testing to provide Swept Path Certificates to either or both of Schedule 8 or Schedule 9 of Land Transport Rule: Vehicle Dimensions and Mass 2016.

HVP2 certifiers also use the appropriate software and/or physical testing to provide dynamic vehicle performance analysis for proposed high productivity vehicles, either new pro-forma or bespoke designs within the limits set by the Land Transport Rule: Vehicle Dimensions and Mass 2016 and its amendments.

HV manufacturer certifier (HMxD)

Scope

As different from the HV engineering certifier, the HV manufacturer certifier responsibility is split between an HV manufacturer inspecting organisation (IO) and an HV manufacturer vehicle inspector (VI). Each of these roles is vital and interdependent. A HV manufacturer certifier IO cannot certify a heavy vehicle while a HV manufacturer certifier VI can only certify a heavy vehicle within the requirements of the VIRM and Memos if s/he is in the employ of a manufacturing certifier IO and Waka Kotahi has a record of this employment.

There are currently five different HV manufacturer certification categories:

- chassis modification (HMCD)

- towing connections (HMTD)

- load anchorages (HMAD)

- log bolster attachments (HMLD)

- heavy vehicle brakes (HMKD)

Permitted certifications

Where permitted, all work certified by the manufacturing certifier VI at the approved manufacturing certifier IO premises is to be certified with either:

- a Statement of Design Compliance (SoDC), issued by an engineer certifier, or

- for load anchorages, to the designs in NZS 5444, or

- for worn or damaged fifth wheels, replaced to the fifth wheel manufacturer’s instructions for replacing bolt on components, or

- for worn or damaged kingpins, replaced according to the kingpin manufacturer’s instructions on replacement, or

- to Waka Kotahi approved pre-engineered solutions

- a design certificate for batch built or standard components (refer Technical bulletin 5)

HMxD manufacturer inspection organisation (IO) requirements

The manufacturing certification process is made up of two parts. The HV manufacturer certifier (VI), whose task is to ensure that any certification that they sign off is correct to the Design Certificate or SoDC, and the HV manufacturer IO responsible for ensuring that the certifications carried out in their name, meet requirements. The HV manufacturer IO must also ensure that any HV manufacturer VI in their employ has all the appropriate tools and equipment to carry out the certification that they hold the categories for.

There are separate skills and knowledge requirements for appointment by the Transport Agency as an HV manufacturer IO or HV manufacturer VI and these must be demonstrated following appropriately targeted training programmes. Once qualified and appointed as an HV manufacturer IO, a manufacturing or repair organisation must employ one or more appropriately qualified HV manufacturer VIs to carry out certifications on their behalf. Similarly, once appointed, a HV manufacturer certifier VI, must be employed by an HV manufacturer certifier IO before they can carry out certifications.

The authorised HV manufacturer IO is the company or entity responsible for the structural work carried out on a heavy vehicle (not the CEO) and the application must be signed by an appointed office holder of the company who can sign on behalf of the company (Director etc) accompanied by the company seal in the case of a registered company. Each location that is involved with manufacturing certification operations must have an individual appointment. The IO is responsible for ensuring that:

- the HV manufacturer IO takes responsibility for the certification activities carried out by any HV manufacturer VI in their employ

- the premises are well lit and meet the requirements in the VIRM of the certification categories being carried out

- the HV manufacturer IO controls and maintains all necessary equipment for the certification categories carried out

- the HV manufacturer IO controls and maintains a library of all processes and procedures required for all the certification categories carried out, including welding procedures, relevant standards and pre-Engineered Solutions.

- one or more qualified welding supervisors are appointed to oversee welding operations

- they have staff with a sound working knowledge of standards, codes of practice and general documents as well as their trade related published material. This includes:

- welding knowledge

- materials and product knowledge

- drawing interpretation

- scope of work that local manufacturing certifiers can certify

- repairs, including repairs to industry best practice for temporary endorsement

- working knowledge of documents, including the following, as they apply to the business:

- Welding in the Transport Industry (see Technical bulletin 10)

- This HVSC VIRM

- Land Transport Rule 35001: Vehicle Standards Compliance 2002 and amendments

- Land Transport Rule 34001: Vehicle Repair 1998 and amendments

- Land Transport Rule 31002: Heavy Vehicles 2004 and amendments

- Land Transport Rule 32015: Heavy-vehicle Brakes 2006 and amendments

- Other Land Transport Rules relevant to the certification categories carried out

- a PDS is completed for each certification activity carried out.

The Manufacturing HVSC IO Notice(s) of Appointment specify other requirements, including:

- self-reporting of information (such as information related to fitness and propriety)

- management, quality assurance, and performance management systems

- making, maintaining and providing records of the activities

- management of conflicts of interest and other inappropriate influences

- Insurance requirements

Please check your current notice of appointment for details.

HMxD manufacturer vehicle inspector (VI) requirements

Each appointed VI may inspect and certify the work of other operators in the employ of the same HV manufacturer IO and must:

- take full responsibility for all certifications which they sign off

- only certify work they’re permitted to certify (see Permitted certifications above).

- only certify work in categories they are authorised for

- ensure that they only carry out certification activities when there is sufficient properly controlled and maintained equipment for the certification to be carried out

- ensure that they only carry out certification activities when there is a sufficient library of all processes and procedures required for the certification being carried out, including welding procedures, relevant standards and pre-engineered solutions, DCs or SoDCs.

- ensure that, where necessary, a properly qualified and appointed welding supervisor has approved the welding on any activity being certified and all welding is carried out by an appropriately qualified and certified welder.

- ensure that they and the staff whose work they are certifying have a sound working knowledge of standards, codes of practice and general documents as well as their trade related published material. This includes:

- welding knowledge

- materials and product knowledge

- drawing interpretation

- scope of work that HV manufacturer certifiers can certify

- repairs, including repairs to industry best practice for temporary endorsement

- working knowledge of documents, including the following, as they apply to the business:

- Welding in the Transport Industry (see Technical bulletin 10)

- This HVSC VIRM

- Land Transport Rule 35001: Vehicle Standards Compliance 2002 and amendments

- Land Transport Rule 34001: Vehicle Repair 1998 and amendments

- Land Transport Rule 31002: Heavy Vehicles 2004 and amendments

- Land Transport Rule 32015: Heavy-vehicle Brakes 2006 and amendments

- Other Land Transport Rules relevant to the certification categories carried out

- Maintain a PDS for each certification carried out.

The Manufacturing HVSC Vehicle Inspector Notice(s) of Appointment specify other requirements, including:

- a minimum number of inspections and certifications per annum

- self-reporting of information (such as information related to fitness and propriety)

- use of quality assurance, and performance management systems

- making records of the activities

- management of conflicts of interest and other inappropriate influences

Please check your current notice of appointment for details.

Page amended 1 November 2021 (see amendment details)

8 Definitions

Agricultural trailer | means a trailer constructed to be operated in connection directly with the operation or management of a farm but does not include a logging trailer. |

Appointment | means the appointment by Waka Kotahi of the HV Certifier under the Notice of Appointment (NoA) and pursuant to Land Transport Rule Vehicle Standards Compliance 2002. |

Applicable requirement | means any requirement specified in an Act, Regulation or Rule that applies to a specific vehicle. |

Approved vehicle standard | means a vehicle standard with which a vehicle is required to comply by an applicable requirement. |

Articulated vehicle | means any motor vehicle with a semi-trailer attached, so that part of the semi-trailer is superimposed on the motor vehicle and a substantial part of the mass of the semi-trailer and of its load is borne by the motor vehicle. |

Aspect of a vehicle for heavy vehicle certification | means an aspect of the vehicle which belongs within certifier categories. These include chassis and frame structures, towing connections, load anchorages, bolster attachments, brakes and SRT. |

Axle | means one or more shafts, spindles or bearings in the same vertical transverse plane by means of which, in conjunction with wheels mounted on those shafts, spindles or bearings, a portion of the weight of the vehicle is transmitted to the roadway, and: a) if two or more wheels of a motor vehicle are substantially in the same line transversely and some or all of them have separate axles, the axles of all those wheels are to be treated as one axle b) if the longitudinal centreline of an axle of a motor vehicle is less than 1m distant from the longitudinal centreline of another axle, the two axles are to be treated as one axle (‘a dual axle’). |

Axle mass | means the lesser of: a) the maximum mass that can be carried by the axle, including the mass of the axle, as determined by the axle manufacturer, or b) the maximum mass that can be carried by the suspension system, including the mass of the axle, as determined by the suspension system manufacturer. |

Axle set | means a single-axle set, a tandem-axle set, a twin-steer axle set, a tri-axle set, or a quad-axle set. |

Axle-stop device | means a device to control the movement of the axle in the event of suspension failure. |

Ballrace turntable | means a device incorporating a low friction ball bearing fitted between two substantial structural components of a vehicle to enable rotational motion between those components about a vertical axis. |

Body | means the part of the vehicle that is designed for the use and accommodation of the occupants or to hold any goods. |

Bolster Attachment Code | means the Bolster Attachment Code of the Log Transport Safety Council, approved by Waka Kotahi. |

Brake control assembly | means an assembly containing the brake pedal assembly, the master cylinder or treadle valve, and associated components. |

Brake pedal assembly | means an assembly containing the brake pedal and pedal pivot, pedal bracket, pedal return spring and associated components. |

Cab-guard | means a structure attached to a vehicle that provides protection to the cab occupants from the effects of load impact, and may include a headboard. |

Certificate of loading | means a certificate of loading issued under any regulation or rule made under the Land Transport Act 1998. |

Certify | means in relation to a vehicle, or specific aspect of a vehicle, to make a record of determination under 6.6(1)(a) or 7.6(1)(a) that confirms that the vehicle inspector or inspecting organisation has determined that the vehicle or specific aspect of the vehicle complies with the applicable requirements. |

Chassis | means the structural lower part of a vehicle to which the running gear and, as applicable, engine, transmission, steering system and body may be attached. |

Chassis assembly | means a chassis with running gear attached and, as applicable, engine, transmission and steering system attached. |

Chassis rating | means: a) for a vehicle first registered before 1 February 1989 that has not been modified on or after b) for a vehicle first registered on or after 1 February 1989 or a vehicle that has been modified on or after 1 April 2005, a set of data, containing the permitted maximum axle and/or axle-set masses, gross vehicle mass, gross combination mass (if applicable) and maximum towed mass (if applicable), approved or determined by Waka Kotahi or a person appointed by Waka Kotahi. |

Class | in relation to vehicles, means a category of vehicle of one of the groups A, L, M, N and T, as specified in Table A in Land Transport Rule Heavy Vehicles 2004. |

Combination vehicle | means a towing vehicle in combination with one or more trailers or other motor vehicle that is being towed. |