Tyres, wheels and hubs

10-1 Tyres and wheels

Reasons for rejection

Mandatory equipment

Tyres

1. Tyres on the same axle are not of the same:

a) size designation, or

b) construction type (ie mixed steel ply, fabric radial ply, bias/cross ply), or

c) tread pattern type (mixed asymmetric, directional, normal highway, traction).

2. An asymmetric tyre is fitted to a vehicle with the ‘inside’ tyre wall facing outwards.

3. A unidirectional tyre is fitted contrary to its correct direction of rotation.

4. A tyre has a speed category (Table 10-1-1) that is less than the speed limit for the vehicle or less than the vehicle’s maximum speed if this is less than the speed limit (Note 3) (Note 4).

5. The forklift has one or more of the following types of tyre fitted (Note 1):

a) a space-saver tyre, or

b) a metal tyre, or

c) a tyre with studs, cleats, lugs or other gripping devices.

6. A tyre is not compatible with the vehicle to which it is fitted, eg a tyre that is marked with any of the following:

a) ‘FOR TRAILER USE ONLY’

b) ‘ADV’ (Agricultural Drawn Vehicle)

c) ‘RACING PURPOSES ONLY’.

Wheels

7. A wheel is not compatible with the tyre fitted to it for rim profile, flange height or valve fitment.

8. A wheel is:

a) not compatible with the vehicle to which it is fitted. or

b) not correctly attached to the vehicle.

Condition

Tyres (excluding spare tyres)

9. There are signs that a tyre is fouling on another part of the vehicle.

10. A pneumatic tyre shows damage that is likely to compromise its ability to operate in a safe manner or lead to premature tyre failure, such as:

a) a lump or bulge that is likely to be caused by separation of the tyre structure, or

b) a cut or crack in a side wall or tread more than 25mm long that reaches the cords (see Note 5 for visible cords in the tread area of heavy vehicle radial-ply tyres), or

c) exposed or cut cords (see Note 5 for visible cords in the tread area of heavy vehicle radial-ply tyres), or

d) the tread of a retreaded tyre shows signs of separation, or

e) nails or other sharp objects embedded in the tyre, or

f) significant perishing, eg due to age, moisture or exposure.

11. A pneumatic tyre has a string type repair visible from the outside.

12. A tyre is noticeably under- or over-inflated.

13. A non-pneumatic tyre is significantly disintegrated or shows signs that are likely to be the result of separation or partial failure of the tyre structure.

14. Tyre repairs have not been carried out in accordance with acceptable industry practice.

15. A tyre has insufficient tread to allow safe operation of the vehicle.

Spare tyres

16. A spare tyre, if carried, is not securely attached to or stored in the vehicle.

Wheels

17. There are signs that a wheel is fouling on another part of the vehicle.

18. A wheel is:

a) cracked, or

b) significantly damaged, distorted or has deteriorated, or

c) not securely attached to the hub.

19. A wheel nut is:

a) missing, or

b) loose, or

c) deteriorated, or

d) the incorrect type, or

e) has insufficient thread engagement to the wheel stud, or

f) is an aftermarket wheel nut made from aluminium.

Note 1

A forklift may be fitted with non-pneumatic tyres such as solid rubber tyres or tyres filled with polyurethane.

Note 2 Definitions:

Asymmetric tyre means a tyre which, through tread pattern or construction, is required to be fitted to a vehicle so that one particular sidewall faces outwards.

Construction, in relation to a tyre, means

a) for a pneumatic tyre, the type of carcass (including ply orientation and ply rating or load index)

b) for any other tyre, characteristics relating to size, shape and material.

Cross ply means a pneumatic tyre structure in which the ply cords in the tyre carcass extend to the beads and are laid at alternate angles, which are substantially less than 90 degrees, to the centreline of the tread. This tyre structure is also referred to as ‘bias ply’ or ‘diagonal ply’.

Directional tyre means a tyre with a tread pattern designed to operate in one direction only, and marked accordingly.

Pneumatic tyre means a tyre that, when in use, is inflated by air or gas introduced from time to time under pressure so as to enclose under normal inflation a cushion of air or gas forming altogether at least half of the total area of an average cross-section of a tyre so inflated.

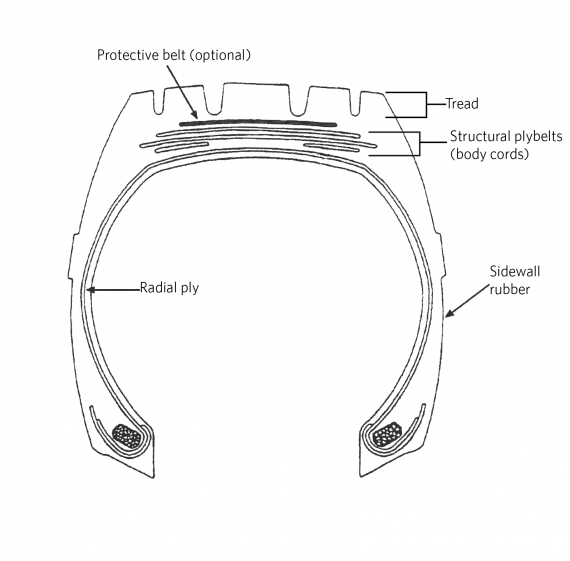

Protective belt, sometimes called a protective ply or breaker, means an optional layer of ply material (cords) located immediately under the tread to minimise damage to the structural belts beneath.

Radial ply means a pneumatic tyre structure in which the ply cords, which extend from bead to bead, are laid at approximately 90 degrees to the centreline of the tread, the carcass being stabilised by an essentially inextensible circumferential belt.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Rim means that part of the wheel on which the tyre is mounted and supported.

Speed category means a code allocated to a tyre by a tyre manufacturer that indicates the maximum vehicle speed for which the use of the tyre is rated. It is either marked on the tyre or can be obtained from the tyre manufacturer or a reference guide.

Tube means an inflatable elastic liner, in the form of a hollow ring fitted with an inflation valve assembly, designed for insertion into certain tyre assemblies to provide a cushion of air or gas that, when inflated, supports the wheel (also known as an ‘inner tube’).

Tyre carcass means that structural part of a pneumatic tyre other than the tread and outermost rubber of the sidewalls that, when inflated, contains the gas that supports the load.

Tyre load rating means the maximum load a tyre can carry at the corresponding cold inflation pressure prescribed by the tyre manufacturer and the speed indicated by its speed category symbol.

Wheel means a rotating load-carrying member between the tyre and the hub, which usually consists of two major parts, the rim and the wheel disc, and which may be manufactured as one part, or permanently attached to each other, or detachable from each other.

Wheel centre-disc means that part of the wheel that is the supporting member between the hub and the rim.

Note 3

The tyre load index and speed category are usually marked on the tyre. Where the tyre is not marked, the load and speed rating information must be obtained from the tyre manufacturer or a reference guide of tyre ratings before the tyre can be passed.

Note 4

Sometimes a retreaded or repaired tyre has had its speed rating removed. Where a tyre has been repaired or retreaded in accordance with standard NZS 5423 (Repairing and retreading car, truck and bus tyres), the tyre must be marked with NZS 5423 and, if a car tyre, have the speed rating removed. In such a case, a missing speed rating is acceptable for WoF/CoF (unless the inspector believes on reasonable grounds that the tyre would not have had the required minimum speed rating for the vehicle in the first place).

Note 5

Where a heavy vehicle radial-ply tyre has visible cords in the tread area, the vehicle inspector may pass such a tyre for CoF provided the tyre is in a safe condition, eg only the protective cord layer (protective belt, see Figure 10-1-1) is visible. When determining whether such a tyre is in a safe condition, the vehicle inspector may take into account written evidence from a person who has current specialist tyre knowledge and experience, particularly in heavy vehicle tyre inspection.

Table 10-1-1. Tyre speed symbol categories

|

Speed symbol – speed category (km/h) |

|||||||

|---|---|---|---|---|---|---|---|

|

A1 – 5 |

A5 – 25 |

B – 50 |

F – 80 |

L – 120 |

Q – 160 |

U – 200 |

Y – 300 |

|

A2 – 10 |

A6 – 30 |

C – 60 |

G – 90 |

M – 130 |

R – 170 |

H – 210 |

ZR – over 240 |

|

A3 – 15 |

A7 – 35 |

D – 65 |

J – 100 |

N – 140 |

S – 180 |

V – 240 |

|

|

A4 – 20 |

A8 – 40 |

E – 70 |

K – 110 |

P – 150 |

T – 190 |

W – 270 |

|

Figure 10-1-1. Cross-sectional representation of a heavy vehicle radial-ply tyre

Summary of legislation

Applicable legislation

Mandatory equipment

Tyres

1. Tyres must be compatible with the vehicle to which they are fitted.

2. Tyres on the same axle must be of the same size designation and construction, and of the same tread pattern type.

3. Asymmetric tyres must be fitted in axle sets in accordance with manufacturer’s instructions.

4. A unidirectional tyre must be fitted to a wheel position corresponding to its direction of rotation.

5. The speed category of a tyre must be compatible with the maximum legal speed limit for the vehicle, or the vehicle’s maximum speed.

6. A forklift must not be fitted with a metal tyre or other non-pneumatic tyre (Note 1), or with a tyre with studs, cleats, lugs or other gripping devices.

Wheels

7. A wheel must be:

a) sufficiently strong for the type of vehicle to which it is fitted, and

b) compatible with the vehicle to which it is fitted, and

c) compatible with the tyre rim profile, flange height and valve fitment.

8. There must be adequate clearance for the brake, hub, suspension and steering mechanism, and body parts.

Permitted equipment

9. A forklift may be fitted with retreaded tyres.

Condition

Tyres (excluding spare tyres and space-saver tyres)

10. A tyre must be of good quality and construction, fit for its purpose and maintained in a safe condition.

11. A tyre must not have worn, damaged or visible cords apparent by external examination.

12. A heavy vehicle radial-ply tyre may have visible cords in the tyre tread area provided the tyre is in a safe condition. To assess whether such a tyre is in safe condition, the vehicle inspector may take into account written evidence from a person who has current specialist tyre knowledge and experience, particularly in heavy vehicle tyre inspection.

13. A tyre must have a tread pattern depth of not less than 1.5mm (excluding any tie-bar or tread-depth indicator strip) around the whole circumference of the tyre:

a) within all principal grooves that contain tread-depth indicators, or

b) if the tyre does not normally have tread-depth indicators, across at least three-quarters of the tyre tread width.

14. The regrooving of a tyre is permitted only if the tyre is identified as being specifically designed for regrooving after manufacture.

15. A tyre that is fitted to a forklift must be maintained at a safe inflation pressure.

Spare tyre

16. If the forklift carries a spare tyre, the tyre must be securely attached on or in the vehicle.

Wheels

17. The components of the wheel assembly must be in good condition.

18. The wheel must be securely attached to the hub.

Page amended 1 November 2015 (see amendment details).