Correct as at 25th April 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > General trailers > Tyres, wheels and hubs

7 Tyres, wheels and hubs

7-1 Tyres and wheels

Reasons for rejection

Mandatory equipment

Tyres

1. Tyres on the same axle are not of the same:

a) size designation (see Table 7-1-2), or

b) carcass type (ie mixed steel ply, fabric radial ply, bias/cross ply, run-flat), or

c) same tread pattern type (mixed asymmetric, directional, normal highway, traction, winter tyre tread (Figure 7-1-2).

2. The tyres on an axle of a light trailer do not meet at least one of the following:

a) the tyre ply ratings are the same, or

b) the tyre load indices differ by no more than 2 (Note 3).

3. An asymmetric tyre is fitted to a vehicle with the ‘inside’ tyre wall facing outwards.

4. A directional tyre is fitted contrary to its correct direction of rotation.

5. A tyre has a speed category that is less than the speed limit for the vehicle or less than the vehicle’s maximum speed if this is less than the speed limit (Note 3) (Note 34

6. The vehicle has one or more of the following types of tyre fitted:

a) a space-saver tyre, or

b) a non-pneumatic tyre, or

c) a tyre with studs, cleats, lugs or other gripping devices, or

d) a tyre that is not compatible with the vehicle to which it is fitted, eg a tyre is marked with any of the following:

i. ‘NOT FOR HIGHWAY USE’

ii. ‘NHS’ (Not for Highway Service)

iii. ‘ADV’ (Agricultural Drawn Vehicle)

iv. ‘RACING PURPOSES ONLY’.

7. A tyre has had any of the following information removed or concealed so that the tyre can no longer be identified (Figure 7-1-3):

- manufacturer

- brand

- model

- load rating

- speed rating

- standards markings (where applicable)

- direction of rotation (where applicable).

Wheels

8. A wheel is not compatible with the tyre fitted to it for rim profile, flange height or valve fitment.

9. A wheel is:

a) not compatible with the vehicle to which it is fitted, or

b) not correctly attached to the vehicle.

Condition

Tyres (excluding spare tyres and space-saver tyres)

10. There are signs that a tyre is fouling on another part of the vehicle.

11. A tyre shows damage that is likely to compromise its ability to operate in a safe manner or lead to premature tyre failure, such as:

a) a lump or bulge that is likely to be caused by separation or partial failure of the tyre structure, or

b) a cut or crack in a sidewall or tread more than 25mm long that reaches the cords, or

c) exposed or cut cords, or

d) the tread of a retreaded tyre shows signs of separation, or

e) nails or other sharp objects embedded in the tyre, or

f) significant perishing, eg due to age, moisture or exposure.

12. A tyre has a string-type repair visible from the outside.

13. A tyre, other than a winter tyre (Note 2), does not have a tread pattern depth (Technical bulletin 7) of at least 1.5mm (excluding any tie-bar or tread-depth indicator strip) around the whole circumference of the tyre:

a) within all the principal grooves that normally contain moulded tread depth indicators, or

b) if the tyre does not normally have moulded tread-depth indicators (such as some retreaded or vintage tyres), across at least three-quarters of the tread width.

14. A winter tyre (Note 2) does not have a tread depth of at least 4mm (excluding any tie-bar or tread-depth indicator strip) within all principal grooves that normally contain moulded tread-depth indicators and around the whole circumference of the tyre.

15. A tyre not identified as designed for regrooving has had its tread depth increased by regrooving.

16. A tyre is noticeably under- or over-inflated.

Spare tyres

17. A spare tyre, if carried, is not:

a) securely attached by a device that is in good condition and correctly applied, or

b) stowed in a closed compartment separate from the occupant space (eg if the manufacturer’s attachment device is missing or faulty) .

Wheels

18. There are signs that a wheel is fouling on another part of the vehicle.

19. A wheel is:

a) cracked, or

b) significantly damaged, distorted or has deteriorated, or

c) not securely attached to the hub.

20. An alloy wheel has poor visible repairs.

21. A wheel nut is:

a) missing, or

b) loose, or

c) deteriorated, or

d) the incorrect type, or

e) has insufficient thread engagement to the wheel stud, or

f) is an aftermarket wheel nut made from aluminium.

Note 1

Asymmetric tyre means a tyre which, through tread pattern, is required to be fitted to a vehicle so that one particular sidewall faces outwards.

Construction in relation to a tyre:

a) for a pneumatic tyre, the type of tyre carcass (including ply orientation and ply rating or load index) [does not include tyre tread], or

b) for any other tyre, characteristics relating to size, shape and material.

Cross ply means a pneumatic tyre structure in which the ply cords in the tyre carcass extend to the beads and are laid at alternate angles, which are substantially less than 90 degrees, to the centreline of the tread. This tyre structure is also referred to as ‘bias ply’ or ‘diagonal ply’.

Directional tyre, also known as unidirectional tyre, means a tyre with a tread pattern that is designed to run in only one direction. A directional tyre usually has an arrow marked on the side wall indicating the direction it is designed to run.

Load index is an assigned number ranging from 0 to 279 that corresponds with the maximum load-carrying capacity of the tyre. Most passenger car tyre load indices range from 62 (= 265kg) to 126 (= 1700kg).

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Pneumatic tyre means a tyre that, when in use, is inflated by air or gas introduced from time to time under pressure so as to enclose, under normal inflation, a cushion of air or gas forming altogether at least half of the total area of an average cross-section of a tyre so inflated.

Ply rating is an index of tyre strength used to identify a given tyre with its recommended maximum permitted load when used for a specific service. It does not necessarily represent the actual number of plies in a tyre. Common ply ratings are 2, 4, 6, 8, 10 and 12. Commercial (eg truck) tyres often have a ply rating rather than a load index.

Principal grooves means the wide grooves in the tyre tread which have the tread wear indicators located inside them. Any other grooves are secondary grooves which may wear out during the service life of the tyre.

Radial ply means a pneumatic tyre structure in which the ply cords, which extend from bead to bead, are laid at approximately 90 degrees to the centreline of the tread, the carcass being stabilised by an essentially inextensible circumferential belt.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Rim means that part of the wheel on which the tyre is mounted and supported.

Run-flat tyre (also known as self-supporting tyre) means a tyre that is so constructed that in case of a puncture the basic tyre functions are still provided for a short distance (at least 80km) and at a reduced speed (usually 80km/h), allowing the vehicle to be safely driven to a place of repair. Some run-flat tyres are identified by an ‘F’ within the size designation.

Space saver tyre (temporary-use spare tyre) means a combination tyre and wheel designed and constructed solely for temporary use under restricted driving conditions, and not intended for use under normal driving conditions.

Speed category means a code allocated to a tyre by a tyre manufacturer that indicates the maximum vehicle speed for which the use of the tyre is rated.

Tread means that part of a pneumatic tyre which comes into contact with the ground.

Tread-depth indicator (or tread-wear indicator) means the projections within the principal grooves designed to give a visual indication of the degree of wear of the tread. To help locate these on a tyre, inspectors should look for a ‘![]() ’ or ‘TWI’ mark on the outer edge of the tyre side wall (most tyres have these marks).

’ or ‘TWI’ mark on the outer edge of the tyre side wall (most tyres have these marks).

Tube means an inflatable elastic liner, in the form of a hollow ring fitted with an inflation valve assembly, designed for insertion into certain tyre assemblies to provide a cushion of air or gas that, when inflated, supports the wheel (also known as an ‘inner tube’).

Tyre carcass means that structural part of a pneumatic tyre other than the tread and outermost rubber of the sidewalls that, when inflated, contains the gas that supports the load.

Tyre load rating means the maximum load a tyre can carry at the corresponding cold inflation pressure prescribed by the tyre manufacturer and the speed indicated by its speed category symbol. It is usually indicated by the load index or ply rating.

Wheel means a rotating load-carrying member between the tyre and the hub, which usually consists of two major parts, the rim and the wheel disc, and which may be manufactured as one part, or permanently attached to each other or detachable from each other.

Wheel centre-disc means that part of the wheel that is the supporting member between the hub and the rim.

Wheel spacer means an additional component used for the purpose of positioning the wheel centre-disc relative to the hub, or in multiple wheel sets, for the purpose of positioning the wheel centre-disc relative to another wheel.

Note 2

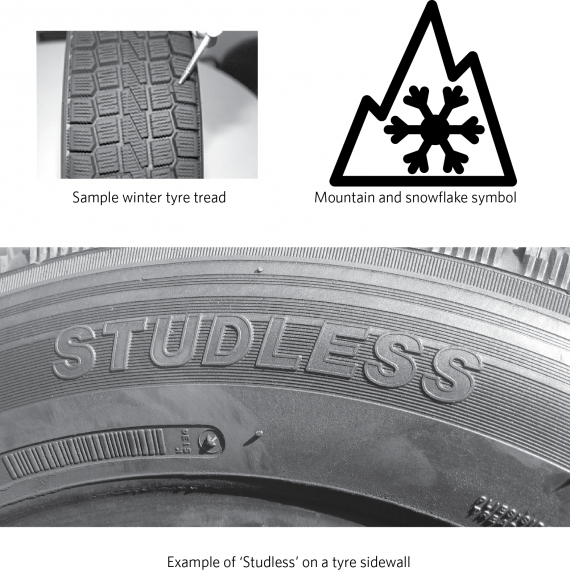

Winter tyre means a tyre which is principally designed to be operated at temperatures of less than 7°C. A winter tyre can be identified by its distinctive tyre tread pattern consisting of deep tread blocks with wavy sipes and is always marked with the word ‘STUDLESS’ and/or a symbol of a snowflake and mountain on the sidewall (see Figure 7-1-2).

Note 3

The tyre load index and speed category are usually marked on the tyre. Where the tyre is not marked, the load and speed rating information must be obtained from the tyre manufacturer or a reference guide of tyre ratings before the tyre can be passed.

Note 4

Sometimes a retreaded or repaired tyre has had its speed rating removed. Where a tyre has been repaired or retreaded in accordance with standard NZS 5423 (Repairing and retreading car, truck and bus tyres), the tyre must be marked with NZS 5423 and, if a car tyre, have the speed rating removed. In such a case, a missing speed rating is acceptable for WoF/CoF (unless the inspector believes on reasonable grounds that the tyre would not have had the required minimum speed rating for the vehicle in the first place).

Table 7-1-1. Tyre speed symbol categories

Speed symbol – speed category (km/h) | |||||||

|---|---|---|---|---|---|---|---|

A1 – 5 | A5 – 25 | B – 50 | F – 80 | L – 120 | Q – 160 | U – 200 | Y – 300 |

A2 – 10 | A6 – 30 | C – 60 | G – 90 | M – 130 | R – 170 | H – 210 | ZR – over 240 |

A3 – 15 | A7 – 35 | D – 65 | J – 100 | N – 140 | S – 180 | V – 240 | |

A4 – 20 | A8 – 40 | E – 70 | K – 110 | P – 150 | T – 190 | W – 270 | |

Table 7-1-2. Tyre interchangeability – imperial and metric

Imperial sizing | Metric sizing |

|---|---|

10/70R22.5 | 255/70R22.5 |

11/70R22.5 | 275/70R22.5 |

12/70R22.5 | 305/70R22.5 |

15R22.5 | 385/65R22.5 |

16.5R22.5 | 425/65R22.5 |

18R22.5 | 445/65R22.5 |

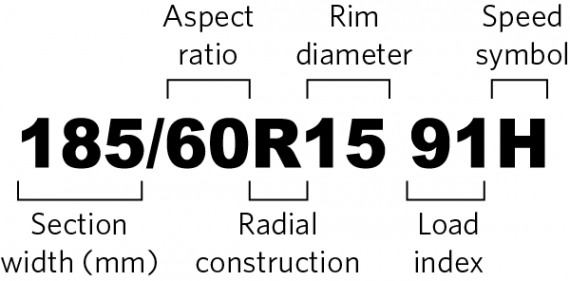

Figure 7-1-1. Tyre markings

Figure 7-1-2. How to identify a winter tyre

Note For WoF purposes, a tyre is considered to be a winter tyre only if it has BOTH a winter tyre tread AND a studless marking and/or mountain/snowflake symbol.

Figure 7-1-3. Example of tyre with manufacturer/brand/model information removed

The circled areas show where information has been removed so that the tyre can no longer be identified.

Summary of legislation

Applicable legislation

Mandatory equipment

Tyres

1. Tyres must be compatible with the vehicle to which they are fitted.

2. Tyres on the same axle must be of the same size designation and construction, and of the same tread pattern type.

3. Asymmetric tyres must be fitted in axle sets in accordance with manufacturer’s instructions.

4. A directional tyre must be fitted to a wheel position corresponding to its direction of rotation.

5. The speed category of a tyre must be compatible with the maximum legal speed limit for the vehicle, or the vehicle’s maximum speed (Note 3) (Note 4).

6. A vehicle must not be fitted with a metal tyre or other non-pneumatic tyre, or with a tyre with studs, cleats, lugs or other gripping devices.

Wheels

7. A wheel must be:

a) sufficiently strong for the type of vehicle to which it is fitted, and

b) compatible with the vehicle to which it is fitted, and

c) compatible with the tyre rim profile, flange height and valve fitment.

8. There must be adequate clearance for the brake, hub, suspension and steering mechanism and body parts.

Permitted equipment

9. A vehicle may be fitted with retreaded tyres.

Condition

Tyres (excluding spare tyres and space-saver tyres)

10. A tyre must be of good quality and construction, fit for its purpose, and maintained in a safe condition.

11. A tyre must not have worn, damaged or visible cords apparent by external examination.

12. A tyre must have a tread pattern depth of not less than 1.5mm (excluding any tie-bar or tread-depth indicator strip) around the whole circumference of the tyre:

a) within all principal grooves that contain tread-depth indicators, or

b) if the tyre does not normally have tread-depth indicators, across at least three-quarters of the tyre tread width.

13. A winter tyre (Note 2) must have a tread pattern depth of not less than 4mm (excluding any tie-bar or tread-depth indicator strip) within all principal grooves that contain moulded tread-depth indicators and around the circumference of the tyre.

14. The regrooving of a tyre is permitted only if the tyre is identified as having been specifically designed for regrooving after manufacture.

15. A tyre that is fitted to a vehicle must be maintained at a safe inflation pressure.

Spare tyre

16. If the vehicle carries a spare tyre, the tyre must be securely attached on or in the vehicle.

Wheels

17. The components of the wheel assembly must be in good condition.

18. The wheel must be securely attached to the hub.

Page amended 1 November 2018 (see amendment details).

7-2 Hubs and axles

Reasons for rejection

Condition

1. A hub (Note 1):

a) is not securely attached to the vehicle, or

b) has a visible crack, or

c) is significantly damaged, distorted or has deteriorated, or

d) has a broken or missing wheel stud.

2. A wheel bearing:

a) has play beyond the manufacturer’s specifications, or

b) is over-tight or binding, or

c) feels/sounds rough when rotated.

3. An axle:

a) is insecure, eg has loose U-bolts, or

b) is visibly cracked, or

c) is significantly damaged, distorted or has deteriorated, or

d) shows signs of welding or heating after original manufacture, or

e) shows signs of fouling the vehicle structure or a brake, suspension or steering component.

Performance

4. The geometry of a hub or axle causes the vehicle to veer significantly to one side.

Note 1

Hub means that part of a vehicle that is attached to the axle and rotates on, or with, the axle, and to which the wheel is attached, and includes any bearings.

Summary of legislation

Applicable legislation

Condition

1. The components of the assembly must be in good condition.

2. The hub and axle must be sufficiently strong for the type of vehicle to which they are fitted.

3. The hub and axle must have suitable and correctly adjusted geometry.

Page amended 1 April 2024 (see amendment details).

7-3 Mudguards

Reasons for rejection

Mandatory equipment

1. A mudguard (Note 1) over a road wheel is missing where it is reasonable and practicable to fit a mudguard, unless the trailer is:

a) in an unfinished condition legally used under the authority of trade plates, or

b) is towed by a vehicle that is not capable of exceeding a speed of 30 km/h.

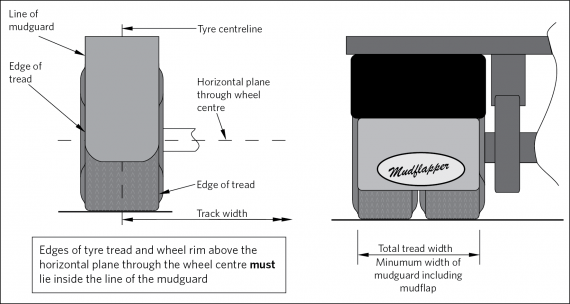

2. A mudguard does not cover the full tread (Note 1) width of a tyre or tyres fitted to a road wheel (Figure 7-3-1), except on a trailer designed for industrial purposes where it is not practicable to fit a full mudguard due to the vehicle’s construction.

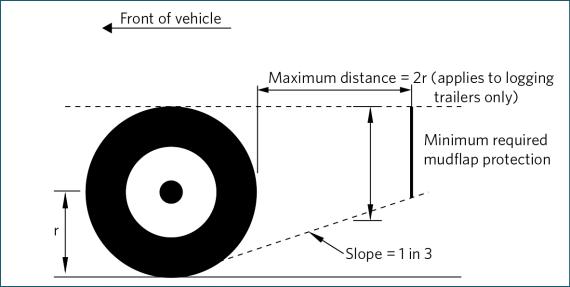

3. A trailer used for transporting round timber is not fitted with at least partial mudguards mounted behind the rearmost axle that meet the following requirements (Figure 7-3-2):

- the mudguard must provide continuous protection from a horizontal at the top of the tyre to a line rising rearward with a slope of 1 in 3 from the tyres contact point on the road, and

- the distance between the tyre and the mudguard must not be more than twice the distance from the centre of the wheel to the road.

4. On a vehicle with twin or close-spaced multiple tyres a mudguard fitted over a wheel on the rear axle is more than one-third higher than the horizontal distance between the vertical lines of the lowest point of the mudguard and the centre of the wheel (Figure 7-3-2), except when the mudguard is fitted to a vehicle designed for industrial purposes and it is not practicable to fit a full mudguard due to the vehicle’s construction.

Mudguard condition

5. A mudguard is not securely fixed to the vehicle.

6. A mudguard is so constructed or damaged that it is likely to present a hazard to road users.

Note 1

Mudguard means a fitting, inclusive of any portion of the vehicle and of any mudflaps attached, that serves to intercept material thrown up by a wheel more or less on the plane of the wheel.

Tyre tread means the portion of a tyre that contacts the road.

Figure 7-3-1. Position of mudguard in relation to tyre tread

Figure 7-3-2. Size and position of mudguards for the rear wheels of a trailer fitted with dual wheels or close-spaced multiple wheels and logging trailers

Summary of legislation

Applicable legislation

Mandatory equipment

1. A trailer must be fitted with a mudguard (Note 1) over each road wheel if it is reasonable and practicable to do so.

2. A mudguard must cover no less than the width of the tyre tread on each road wheel (Figure 7-3-1).

3. A trailer fitted with twin tyres or close-spaced multiple tyres must be fitted with a mudguard over each wheel on the rear axle that provides continuous protection from a horizontal line tangent to the top of the tyre tread (Note 1) to a line with a slope of 1 in 3 rising rearward from the tyre’s contact point on the road (Figure 7-3-2).

4. A trailer designed for industrial purposes may be fitted with partial mudguards if the vehicle’s construction makes it impracticable to fit full mudguards.

5. A trailer used for transporting round timber that cannot be fitted with mudguards over each road wheel must have at least partial mudguards mounted behind its rearmost axle that comply with the following (Figure 7-3-2):

a) the mudguard must provide continuous protection from a horizontal line tangent to the top of the tyre tread to a line with a slope of 1 in 3 rising rearward from the tyre’s contact point on the road, and

b) the distance between the tyre and the mudguard must not be more than twice the tyre rolling radius.

6. The following trailers are not required to be fitted with mudguards:

a) a vehicle in an unfinished condition used under the authority of trade plates and operated in accordance with the Compliance Rule

b) a trailer towed by a vehicle that is not capable of exceeding a speed of 30 km/h.

Mudguard condition

7. A mudguard must be securely fixed to the vehicle and must be constructed so that it does not present a hazard to road users.