Correct as at 15th April 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > General trailers > Vehicle structure

3 Vehicle structure

3-1 Structure

Reasons for rejection

Condition

1. The structure of the vehicle (shaded areas of Figure 3-1-2) has visible:

a) deformation from the original shape that has affected the vehicle’s structural integrity (Note 2), or

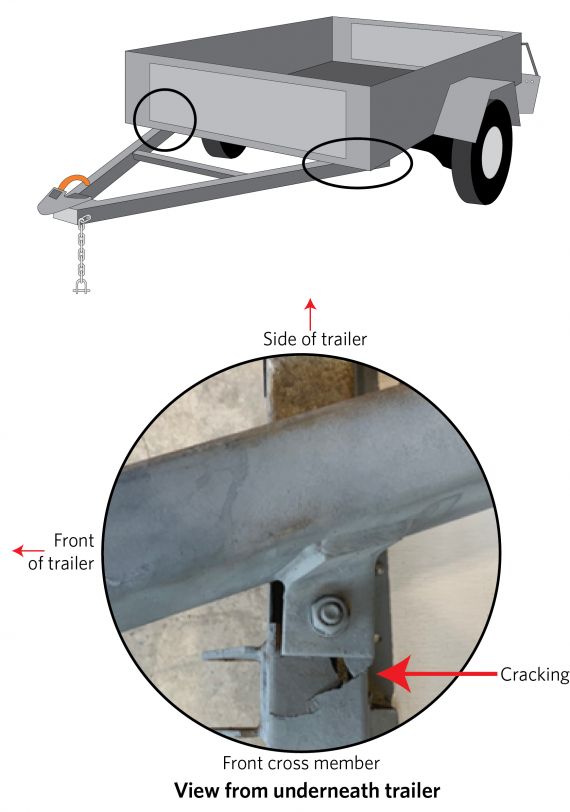

b) cracking (Note 3) (Figure 3-1-3), or

c) fracture, or

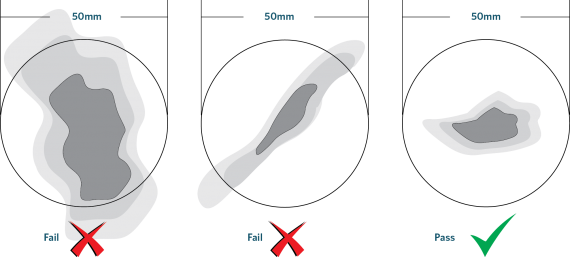

d) corrosion or wood rotting damage (Note 1) that is individually larger than 50mm in diameter (Figure 3-1-1), or

e) any corrosion or wood rotting that the inspector considers has caused weakening of the load-bearing structure, or

f) poor repairs (Note 1) that have not returned the structure to within a safe tolerance of when it was manufactured (Note 2), such as:

i. filler has been used in an attempt to conceal any damage or deformation of a component, or

ii. a high strength steel component has been heated.

2. A hinge for a panel is not securely attached to both the vehicle body and to the door or other hinged panel due to loose connections, corrosion, wood rotting or other damage.

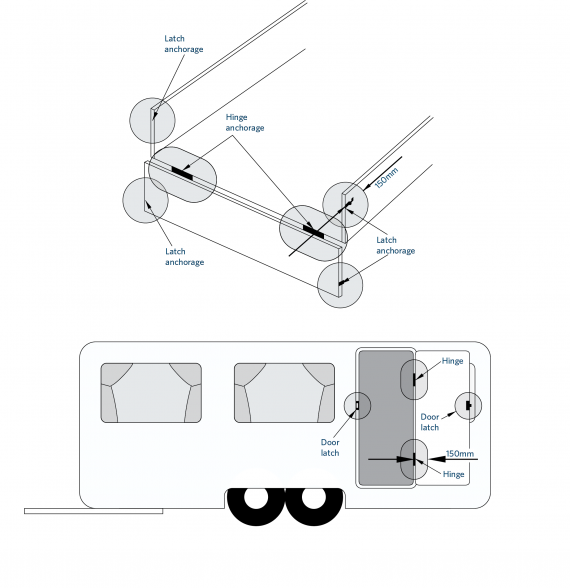

3. There is corrosion or wood rotting damage within 150mm of the hinge of a hinged panel (Figure 3-1-4).

4. There is corrosion or wood rotting damage within 150mm of the latch of a hinged panel (Figure 3-1-4).

5. A hinged panel does not remain secure in a closed or locked position.

6. The trailer is an unrepaired Trailpro 8x4 Tradesman (model number TP5) or a Trailpro 8x5 Tandem (model number TP8), with a bolt-through drawbar attachment (these trailers are subject to safety recall) (Note 4). See Figure 3-1-5 for advice on identifying these trailers. See Figure 3-1-6 and Figure 3-1-7 for advice on identifying repaired Trailpro trailers.

7. The trailer is a Trailpro Handyman (model number TP1) (Note 4).

Note 1

Corrosion or wood rotting damage is where a metal or wooden structure has been eaten away and could be seen as bubbling, or pitting of the steel or by water damage, delamination or swelling of a wooden surface. The outward signs of such damage is typically displayed by the lifting, bubbling or discolouring of painted surfaces. In extreme cases, the area affected by the damage will fall out and leave a hole.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with equivalent undamaged or new structures, systems, components or equipment.

Note 2

The vehicle inspector may request additional relevant information from a repairer or other relevant person.

Note 3

Special attention should be given to the point or points where the drawbar attaches to the body of the trailer. This is often the first point of structural failure on trailers.

Note 4

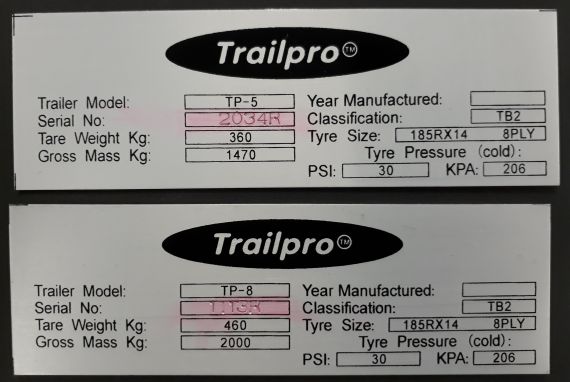

There is a safety risk with the Trailpro brand of light trailers which were sold through Bunnings NZ between 1 January 2006 and 12 October 2018. Bunnings is now recalling all Trailpro trailers, other than Trailpro 8x4 Tradesman (TP5) or 8x5 Tandem (TP8) models that have undergone Bunnings-approved repairs as part of an earlier recall. These can be identified by the serial number on the identification plate ending with an “R” (see Figure 3-1-6). A TP5 or TP8 trailer with a serial number ending with an “R” may be issued a WoF if it passes all other checks. More information can be found in the safety recall notice on the Transport Agency website.

Figure 3-1-1. Corrosion or wood rotting damage 50mm diameter limit

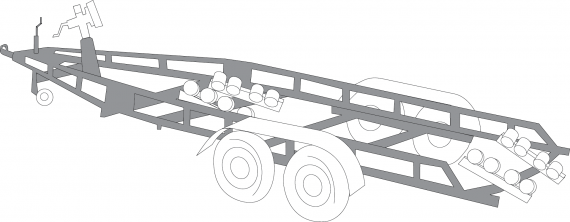

Figure 3-1-2. Shaded areas referred to in ‘Condition’ above

These include:

a) The chassis rails, cross members, subframes, suspension and body mounting points of a vehicle with a separate chassis, and

b) the load-bearing structure of a monocoque body, including body mounting points, and

c) the body fitted to a trailer where the structure supports the chassis, similar to a unitary body (for example, some livestock carriers, horse floats, and UK-sourced caravans with wooden or wood laminate structures).

Other sections also contain reasons for rejection and diagrams relating to specific vehicle components.

Figure 3-1-3. Drawbar attachment to trailer

Figure 3-1-4. Hinge and latch anchorages

No structural damage is allowed within 150mm of a circle around the outside of a hinge, latch or load anchorage component.

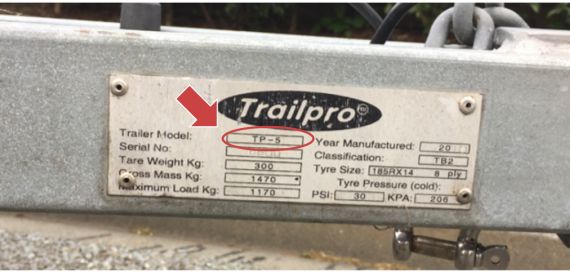

Figure 3-1-5. Identifying a Trailpro TP5 and TP8

Bunnings is currently working on a repair process and we will update this once that is in place.

Affected trailers are fitted with an identification plate which is located on the outside of the trailer drawbar near the tow coupling.

Location of the trailer identification plate

Identification plate similar showing model number

The identification tag may be missing, faded, damaged or obscured. All Trailpro models have drawbars that are bolted rather than welded to the trailer. The TP5 has a single axle and a tray size of 8'x4' (2.4m x 1.2m). The TP8 is a tandem axle model with a tray size of 8'x5' (2.4m x 1.5m).

Bolted through drawbar attachment to trailer

Broken drawbar (sitting on trailer)

Figure 3-1-6. Trailpro plate showing repaired status

Figure 3-1-7. New front mount of the repaired Trailpro 8x4 and 8x5 trailers

Summary of legislation

Applicable legislation

- Land Transport Rule: Vehicle Standards Compliance 2002, section 7.4

- Traffic Regulations 1976: regulation 80.

Permitted equipment

1. A trailer may be fitted with hinged panels.

Condition

2. A vehicle must:

a) not be so affected by corrosion or weakening of its structure, that is apparent by visual examination, so that the vehicle is unsafe to operate, and

b) be safe to be operated, and

c) have been constructed using components and materials that are fit for the purpose, and

d) be within safe tolerance of its state when manufactured or modified.

Page amended 1 October 2023 (see amendment details).