Tyres, wheels and hubs

7-2 Hubs and axles

Reasons for rejection

Mandatory requirement (Note 2)

1. A semi-trailer with a quad-axle set containing a steering axle does not have evidence of certification, ie:

a) the steering axle was fitted before the last CoF inspection and there is no LANDATA record of the certification, or

b) the steering axle was fitted after the last CoF inspection and:

i. a valid LT400 form is not presented, or

ii. the HVS certifier was not of category HVEC or HMCD .

Mandatory and permitted equipment (Note 2)

2. A heavy trailer, other than a semi-trailer that is not part of an A-train or B-train, is fitted with a steering axle in its rear-axle set.

3. On a semi-trailer that is not part of an A-train or B-train more than half the axles steer at any time.

4. A semi-trailer with a quad-axle set does not have one or two steering axles that are capable of turning in both directions, being:

a) the rearmost axle, or

b) the two rearmost axles, or

c) the foremost and the rearmost axles.

5. A heavy trailer is fitted with an axle set other than one permitted in Table 7-2-1.

6. An axle set, other than a twin-steer axle set, is not load sharing.

7. The manufacturer’s plate for a tandem axle set with a twin-tyred axle and a large single-tyred axle (where these were fitted from 1 July 2002):

a) is missing, or

b) is not legible, or

c) does not show:

i. the load-share ratio of the axle set, or

ii. a ratio that is either 60:40 or 55:45, or

iii. the tyre size on each axle, or

iv. the maximum individual axle ratings, or

d) has details that do not match the vehicle.

8. A heavy trailer is presented as part of an A-train or B-train and is fitted with a retractable axle in its rear-axle set.

9. A sliding axle set is not fitted with both:

a) an effective locking device to prevent inadvertent extension or separation, and

b) endstops at the end of the slideway to prevent the separation of the sliding parts if the primary locking device fails.

Condition

10. Refer to general trailer pages.

11. A sliding axle assembly has deteriorated, eg:

a) a chassis rail/guide, locking pin or other component is missing, deformed, cracked or otherwise worn or damaged, or

b) a locking pin is too small or too short, or

c) there is an air leak from the lock pin air ram.

Performance

12. Refer to general trailer pages.

13. The locking of a sliding axle locking device is not readily verifiable by visual inspection.

14. A sliding axle locking device has wear or damage, such as a worn or bent pin, so that it is not effective.

15. A sliding axle locking device does not operate correctly.

16. A sliding axle endstop is:

a) missing, or

b) insecure, or

c) damaged.

Modification and repair

17. A modification or repair affects the hubs and axles and:

a) is not excluded from the requirements for HVS certification (Table 7-2-2), or

b) is not for the purpose of law enforcement or the provision of emergency services, or

c) is missing proof of HVS certification, ie the vehicle has been modified or repaired, and:

i. no LANDATA record has been entered, or

ii. no valid LT400 form from an HVS certifier of category HVEC or HMCD has been presented.

Note 1 Definitions

Retractable axle means an axle that has a convenient adjustment to allow the axle load distribution of the axle set to be varied substantially. An axle that is retracted is not considered to be part of the axle set.

Load-sharing axle set means an axle set suspension system that has effective damping characteristics on all axles of the set and is built to divide the load between the tyres on the set so that no tyre carries a mass more than 10% greater than the mass it would carry if:

a) the load were divided in the axle set so that each tyre carries an equal load, or

b) the axle set is a tandem-axle set comprising a twin-tyred axle and a large single-tyred axle and is built to divide the load

between the tyres on the set so that:

i. 60% of the load is borne by the twin-tyred axle and 40% of the load is borne by the large single-tyred axle, or

ii. 55% of the load is borne by the twin tyred axle and 45% of the load is borne by the large single-tyred axle.

Specialist overdimension vehicle means:

a) a vehicle designed primarily to transport overdimension or overweight loads, or

b) a vehicle whose primary purpose is to carry out a specialist function that requires overdimension equipment, and:

i. dismantling of the vehicle’s equipment would make the equipment unusable for its intended purpose, or

ii. it would take more than four hours to dismantle the vehicle’s equipment.

Note 2

For specialist overdimension vehicles, none of the ‘Mandatory requirement’ or ‘Mandatory permitted equipment’ Reasons for rejection apply except number 6, ie axle sets must be load sharing.

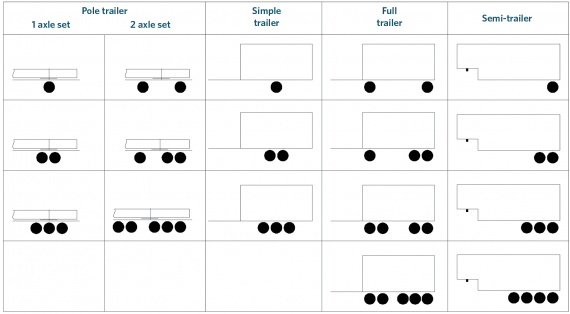

Table 7-2-1. Permitted axle sets for heavy trailers (see Figure 7-2-1)

Trailer type | Permitted axle sets | ||

|---|---|---|---|

Semi-trailer | Single axle; tandem axle set; tri-axle set; quad-axle set (not in A-train or B-train) | ||

Full trailer | Front Single axle; tandem axle set Must be connected to the drawbar steering system | Rear Single axle; tandem axle set; tri-axle set (only with front tandem axle set) | |

Simple trailer | Single axle; tandem axle set; tri-axle set | ||

Pole trailer | One axle set | Single axle; tandem axle set; tri-axle set | |

Two axle sets | Front Single axle; tandem axle set Must be connected to the drawbar steering system | Rear Single axle; tandem axle set; tri-axle set (only with front tandem axle set) | |

Table 7-2-2. Requirements for HVS certification

HVS certification is required | HVS certification is not required |

|---|---|

1. An axle that is modified, including a replacement axle that is not identical to the one fitted by the vehicle manufacturer 2. Fitting of an additional axle 3. Steering axles in a quad-axle set of a semi-trailer (unless the vehicle is a specialist overdimension vehicle) 4. A retractable axle | 1. Steering axles in a quad-axle set of a specialist overdimension vehicle 2. Any modification or repair likely to have been carried out before 1 January 1997 (modifications and repairs before this date generally required certification but for inspection purposes no evidence of this is required). 3. Any repair or modification not listed in the left-hand column unless the vehicle inspector considers that certification is required because the modification or repair has affected the vehicle’s safety performance (a second opinion from an expert may be needed, eg the manufacturer’s representative, or a reputable workshop). |

Figure 7-2-1. Permitted axle configurations

Summary of legislation

Applicable legislation

Mandatory requirement (Note 2)

1. A semi-trailer with a quad-axle set containing a steering axle must be certified by a HVS certifier.

Mandatory and permitted equipment (Note 2)

2. A heavy trailer must not have any rear-steering axles, unless the trailer is a semi-trailer that is not part of an A-train or B-train, provided no more than half the axles within the rear-axle set steer at any time.

3. A semi-trailer with a quad-axle set must have one or two steering axles capable of turning on both directions, being:

a) the rearmost axle, or

b) the two rearmost axles, or

c) the foremost and the rearmost axles.

4. A heavy trailer must be fitted with a permitted axle set as listed in Table 7-2-1.

5. A heavy trailer not part of an A-train or B-train may be fitted with a retractable axle in its rear-axle set.

6. A sliding axle set must have:

a) an effective locking device to prevent inadvertent separation or extension, and

b) endstops at the end of the slideway to prevent the separation of the sliding parts if the primary locking device fails.

Condition

7. Refer to general trailer pages.

8. An axle fitted to a vehicle must have adequate strength and performance characteristics for all conditions of loading and operation for which the vehicle was constructed.

Performance

9. Refer to general trailer pages.

10. The locking of a sliding axle locking device must be readily verifiable by visual inspection.

11. If the sliding axle set locking device incorporates a system that provides energy for its operation, the device must remain fully engaged in the locking position, or the locking action must be initiated immediately, if the energising system fails.

Modification and repair

12. A modification or repair that affects the hubs or axles must be inspected and certified by an HVS certifier of category HVEC or HMCD unless the vehicle:

a) is excluded from the requirement for HVS certification (Table 7-2-2), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 April 2023 (see amendment details).