Correct as at 24th April 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > Heavy vehicles > Tyres, wheels and hubs

10 Tyres, wheels and hubs

10-1 Tyres and wheels

Reasons for rejection

Mandatory and permitted equipment

1. Refer to general vehicle pages.

2. On a groundspreader or dedicated groundsprayer fitted with multiple tyre sets that are made up of tyres of different size or construction:

a) the tyre sets are not fitted so that those fitted at one end of the axle mirror those fitted at the other end of the axle.

3. The tyres on an axle do not meet at least one of the following:

a) the tyre ply ratings:

i. are the same on a class MD3 vehicle

ii. differ by no more than two on a vehicle of other than class MD3

b) the tyre load indices:

i. differ by no more than two on a class MD3 vehicle

ii. differ by no more than six on a vehicle of other than class MD3

c) where no load index is indicated, the tyre load ratings (kg) on an axle differ by no more than 21% of the lowest rating.

Condition

4. Refer to general vehicle pages.

5. A tyre shows damage that is likely to compromise its ability to operate in a safe manner or lead to premature tyre failure, such as:

a) a lump or bulge that is likely to be caused by separation of the tyre structure, or

b) a cut or crack in a side wall or tread more than 25mm long that reaches the cords (see (Note 2) for visible cords in the tread area of heavy vehicle radial-ply tyres), or

c) exposed or cut cords (see (Note 2) for visible cords in the tread area of heavy vehicle radial-ply tyres), or

d) the tread of a retreaded tyre shows signs of separation, or

e) nails or other sharp objects embedded in the tyre, or

f) significant perishing, eg due to age, moisture or exposure.

Modification and repair

6. A modification or repair affects the tyres and wheels and:

a) is not excluded from the requirements for HVS certification (Table 10-1-4), or

b) the modification is not for the purpose of law enforcement or the provision of emergency services, or

c) is missing proof of HVS certification, ie the vehicle has been modified or repaired, and:

i. no LANDATA record has been entered, or

ii. no valid LT400 form from an HVS certifier of category HVEC or HMCD has been presented.

Note 1 Definitions

Central tyre inflation system means a type of tyre pressure control system that adjusts tyre pressure for the purpose of inflating and deflating tyres to improve tyre adhesion and reduce road surface damage and is under the central control of the driver or an automated system, or a combination of both the driver and an automated system (commonly known as ‘CTI’).

Dedicated groundsprayer means a self-propelled or trailing machine whose sole function is the application of chemicals or liquid fertiliser to crops or to the ground.

Groundspreader means a vehicle designed specifically for the carriage of powder or particulate artificial fertilisers on the road, and for the distribution of those fertilisers directly from the vehicle onto the land by means of a mechanical or pneumatic distributor that forms part of the vehicle.

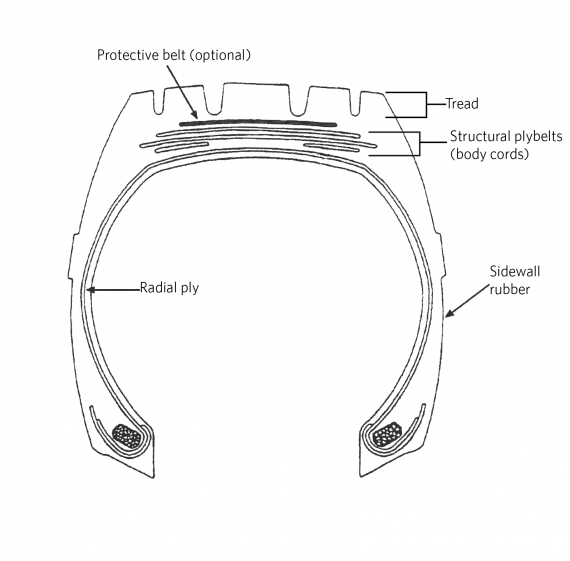

Protective belt, sometimes called a protective ply or breaker, means an optional layer of ply material (cords) located immediately under the tread to minimise damage to the structural belts beneath.

Note 2

Where a heavy vehicle radial-ply tyre has visible cords in the tread area, the vehicle inspector may pass such a tyre for CoF provided the tyre is in a safe condition, eg only the protective cord layer (protective belt, see Figure 10-1-5) is visible. When determining whether such a tyre is in a safe condition, the vehicle inspector may take into account written evidence from a person who has current specialist tyre knowledge and experience, particularly in heavy vehicle tyre inspection.

Table 10-1-4. Requirements for HVS certification

HVS certification is required | HVS certification is not required |

|---|---|

1. Increase of track width beyond vehicle manufacturer’s specified limits. 2. Fitting of tyres additional to the limit specified by the vehicle manufacturer. 3. Modified wheels (including fitting of different rims). | 1. Modified wheels with written evidence from the vehicle manufacturer that the complete assembly of tyre, hub and axle is within the vehicle manufacturer’s operating limits. Such approval is likely to contain the approved tyre and wheel sizes and the maximum track, separately for all axles, together with the maximum number of wheels fitted to one axle, and may also include a few restrictions such as reduced axle load and so on (see Technical bulletin (CoF) 2). 2. Retrofitting a tyre pressure control system in accordance with the equipment manufacturer’s instructions. 3. Fitting a regrooved tyre identified as specifically designed and constructed for the process of regrooving after manufacture. |

4. Any modification or repair likely to have been carried out before 1 January 1997 (modifications and repairs before this date generally required certification but for inspection purposes no evidence of this is required). 5. Any repair or modification not listed in the left-hand column unless the vehicle inspector considers that certification is required because the modification or repair has affected the vehicle’s safety performance (a second opinion from an expert may be needed, eg the manufacturer’s representative, or a reputable workshop). |

Figure 10-1-5. Cross-sectional representation of a heavy vehicle radial-ply tyre

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. Refer to general vehicle pages.

2. Individual tyres of multiple tyre sets on groundspreaders or dedicated groundsprayers may be of different sizes or construction in the same set, but each multiple tyre set must be the same as the other multiple tyre set on the same axle.

Condition

3. Refer to general vehicle pages.

4. A heavy vehicle radial-ply tyre may have visible cords in the tyre tread area provided the tyre is in a safe condition. To assess whether such a tyre is in a safe condition, the vehicle inspector may take into account written evidence from a person who has current specialist tyre knowledge and experience, particularly in heavy vehicle tyre inspection.

Modification and repair

5. A modification or repair that affects the tyres or wheels must be inspected and certified by an HVS certifier of category HVEC, HVMC or HVIC, unless the vehicle:

a) is excluded from the requirement for HVS certification (Table 10-1-4), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 April 2023 (see amendment details)

10-2 Hubs and axles

Reasons for rejection

Mandatory and permitted equipment (Note 1)

1. A rigid heavy vehicle is not supported by:

a) a single or twin-steer axle set at the front, or

b) a single, tandem or tri-axle set at the rear.

2. An axle set, other than a twin-steer axle set, is not load sharing.

3. The manufacturer’s plate for a tandem axle set (except for a tandem axle set in a heavy passenger service vehicle) with a twin-tyred axle and a large single-tyred axle (where these were fitted from 1 July 2002):

a) is missing, or

b) is not legible, or

c) does not show:

i. the load-share ratio of the axle set, or

ii. a ratio that is either 60:40 or 55:45, or

iii. the tyre size on each axle, or

iv. the maximum individual axle ratings, or

d) has details that do not match the vehicle.

4. A heavy vehicle is fitted with one or more rear steering axles, and the vehicle is not one of the following types:

a) a mobile crane

b) the rear unit of an articulated bus

c) a rigid vehicle without a heavy tow coupling, provided that no more than half of the axles within the rear axle set steer at any one time

d) a specialist vehicle designed to transport overdimension or overweight load, or to primarily carry out a specialist function that requires overdimension equipment.

5. A mobile crane does not have at least either a non-steering axle or a steering axle capable of being locked so that it is non-steering.

6. A heavy vehicle is presented towing an A-train or B-train and is fitted with a retractable axle in its rear axle set.

7. A device for altering the distribution of mass between axles has been fitted to the vehicle when:

a) the device does not lift an unpowered axle clear of the ground, or

b) the device reduces the mass carried by an unpowered axle without lifting it clear of the ground, but the device:

i. does not have a spring-loaded control, ie when the control is released, the mass on the unpowered axle does not revert to what it was before the operation of the control, or

ii. does not have a control with an automatic timing device with an activation time of not more than two minutes after which the mass on the unpowered axle reverts automatically to what it was before the operation of the control, and with a non-activation time of at least 30 seconds during which the control cannot be activated again.

8. A sliding axle set is not fitted with both:

a) an effective locking device to prevent inadvertent extension or separation, and

b) endstops at the end of the slideway to prevent separation of the sliding parts if the primary locking device fails.

Condition

9. Refer to general vehicle pages.

10. A sliding axle assembly has deteriorated, eg:

a) a chassis rail/guide, locking pin or other component is missing, deformed, cracked or otherwise worn or damaged, or

b) a locking pin is too small or too short, or

c) there is an air leak from the lock pin air ram.

11. A locking of a sliding axle locking device is either:

a) not readily verifiable by visual inspection, or

b) the vehicle is not equipped with a visual or audible alarm to warn the driver if the axle is not locked in one of the locking positions (Note 2).

12. A sliding axle locking device is bent, worn or otherwise damaged, or has deteriorated so that it is not effective.

13. A sliding axle locking device does not operate correctly.

14. A sliding axle endstop is:

a) missing, or

b) insecure, or

c) damaged.

Performance

15. Refer to general vehicle pages.

Modification and repair

16. A modification or repair affects the hubs or axles and:

a) is not excluded from the requirements for HVS certification (Table 10-2-2), or

b) the modification is not for the purpose of law enforcement or the provision of emergency services, or

c) is missing proof of HVS certification, ie the vehicle has been modified or repaired, and:

i. no LANDATA record has been entered, or

ii. no valid LT400 form from an HVS certifier of category HVEC or HMCD has been presented.

Note 1

For specialist overdimension vehicles, none of the equipment Reasons for rejection or Summaries of legislation apply except numbers 2 and 7, that is axle sets must be load sharing, and axle mass redistribution devices must meet specified requirements.

Note 2

An alarm must be visible or audible from the driver’s seating position, and the alarm must operate when the vehicle’s engine is running, except when the parking brake is fully applied or when the gear selector of a vehicle with an automatic transmission is in the ‘park’ position.

Note 3 Definitions

Load-sharing axle set means an axle set suspension system that has effective damping characteristics on all axles of the set and is built to divide the load between the tyres on the set so that no tyre carries a mass more than 10% greater than the mass it would carry if:

a) the load were divided in the axle set so that each tyre carries an equal load, or

b) the axle set is a tandem-axle set comprising a twin-tyred axle and a large single-tyred axle and is built to divide the load between the tyres on the set so that:

i. 60% of the load is borne by the twin-tyred axle and 40% of the load is borne by the large single-tyred axle, or

ii. 55% of the load is borne by the twin-tyred axle and 45% of the load is borne by the large single-tyred axle.

Retractable axle means an axle that has a convenient adjustment to allow the axle load distribution of the axle set to be varied substantially. An axle that is retracted is not considered to be part of the axle set.

Specialist overdimension vehicle means:

a) a vehicle designed primarily to transport overdimension or overweight loads, or

b) a vehicle whose primary purpose is to carry out a specialist function that requires overdimension equipment, and

i. dismantling of the vehicle’s equipment would make the equipment unusable for its intended purpose, or

ii. it would take more than four hours to dismantle the vehicle’s equipment.

Table 10-2-2. Requirements for HVS certification

HVS certification is required | HVS certification is not required |

|---|---|

1. An axle that is modified, including a replacement axle that is not identical to the one fitted by the vehicle manufacturer. 2. Fitting of an additional axle. 3. A retractable axle. | 1. Any modification or repair likely to have been carried out before 1 January 1997, (modifications and repairs before this date generally required certification but for inspection purposes no evidence of this is required). 2. Any repair or modification not listed in the left-hand column unless the vehicle inspector considers that certification is required because the modification or repair has affected the vehicle’s safety performance (a second opinion from an expert may be needed, eg the manufacturer’s representative, reputable workshop). |

Summary of legislation

Applicable legislation

Mandatory and permitted equipment (Note 1)

1. A rigid heavy vehicle must be supported by a front single or twin-steer axle set, and by a rear single, tandem or tri-axle set.

2. The axle sets, except a twin-steer axle set, of a heavy vehicle must be load sharing.

3. A tandem-axle set (except for a tandem axle set in a heavy passenger service vehicle) with a large single-tyred axle must have a manufacturer’s indelible plate clearly visible to the person weighing the vehicle that specifies the:

a) load-share ratio of the axle set of 60:40 or 55:45, and

b) tyre size on each axle, and

c) maximum individual axle ratings.

4. A heavy vehicle must not have any rear steering axles, except if the vehicle is:

a) a mobile crane, or

b) the rear unit of an articulated bus, or

c) a rigid vehicle without a heavy tow coupling provided no more than half the axles within the rear axle set steer at any one time, or

d) a specialist vehicle designed to transport overdimension or overweight loads, or to primarily carry out a specialist function that requires overdimension equipment.

5. A mobile crane must have at least one rear axle capable of being locked so that it is non-steering.

6. A heavy vehicle not towing an A-train or B-train may have a retractable axle in its rear axle set.

7. A device for altering the distribution of mass between axles may only be fitted to a vehicle if the device:

a) lifts an unpowered axle clear of the ground, or

i. reduces the mass carried by an unpowered axle without lifting it clear of the ground, and

ii. is a control that is spring loaded, so that when the control is released the mass on the unpowered axle reverts to what it was before the operation of the controls, or

b) has a control with an automatic timing device with an activation time of not more than two minutes after which the mass on the unpowered axle reverts automatically to what is was before the operation of the control, and with a non-activation time of at least 30 seconds during which the control cannot be activated again.

8. A sliding axle set must be fitted with both:

a) an effective locking device to prevent inadvertent separation or extension, and

b) endstops at the end of the slideway to prevent the separation of the sliding parts if the primary locking device fails.

Permitted equipment

9. A vehicle may be fitted with a ballrace turntable.

Condition

10. Refer to general vehicle pages.

11. An axle fitted to a vehicle must have adequate strength and performance characteristics for all conditions of loading and operation for which the vehicle was constructed.

12. The locking of a sliding axle locking device must be readily verifiable by visual inspection, or the vehicle must be equipped with a visual or audible alarm to warn the driver if the equipment is not locked in one of the locking positions.

Performance

13. An alarm must be visible or audible from the driver’s seating position , and the alarm must operate when the vehicle’s engine is running, except when the parking brake is fully applied or when the gear selector of a vehicle with an automatic transmission is in the ‘park’ position.

14. If the sliding axle set locking device incorporates a system that provides energy for its operation, the device must remain fully engaged in the locking position, or the locking action must be initiated immediately, if the energising system fails.

15. Refer to general vehicle pages.

Modification and repair

16. A modification or repair that affects the hubs or axles must be inspected and certified by an HVS certifier of category HVEC or HMCD unless the vehicle:

a) is excluded from the requirement for HVS certification (Table 10-2-2), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 April 2023 (see amendment details)

10-3 Mudguards

Reasons for rejection

Mandatory equipment

1. A mudguard over a road wheel is missing where it is reasonable and practicable to fit a mudguard, unless the vehicle is:

a) in an unfinished condition legally used under the authority of trade plates, or

b) not capable of exceeding a speed of 30km/h, or

c) has a valid mudguard exemption issued by the New Zealand Hot Rod Association (Figure 10-3-4).

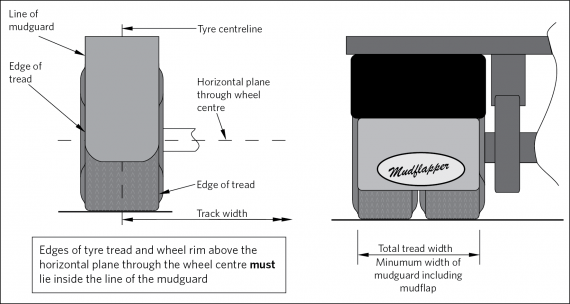

2. A mudguard does not cover the full tread width (Note 2) of a tyre or tyres fitted to a road wheel (Figure 10-3-1 and Figure 10-3-2), except when the mudguard is fitted to a vehicle designed for industrial purposes and it is not practicable to fit a full mudguard due to the vehicle’s construction.

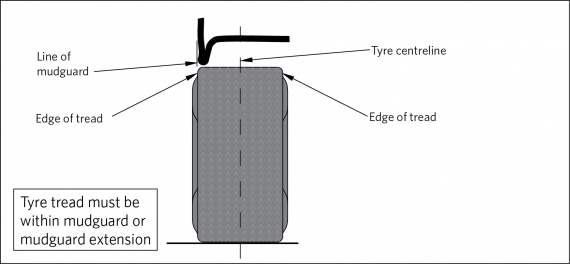

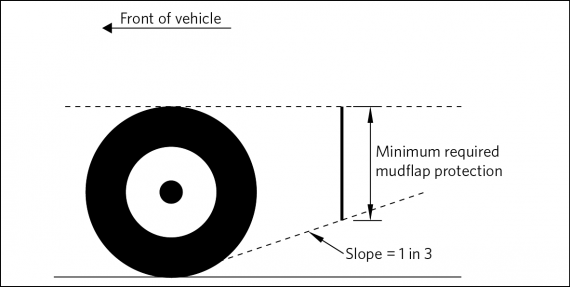

3. On a vehicle with twin or close-spaced multiple tyres a mudguard fitted over a wheel on the rear axle is more than one-third higher than the horizontal distance between the vertical lines of the lowest point of the mudguard and the centre of the wheel (Figure 10-3-3), except when:

a) the mudguard is fitted to a vehicle designed for industrial purposes and it is not practicable to fit a full mudguard due to the vehicle’s construction.

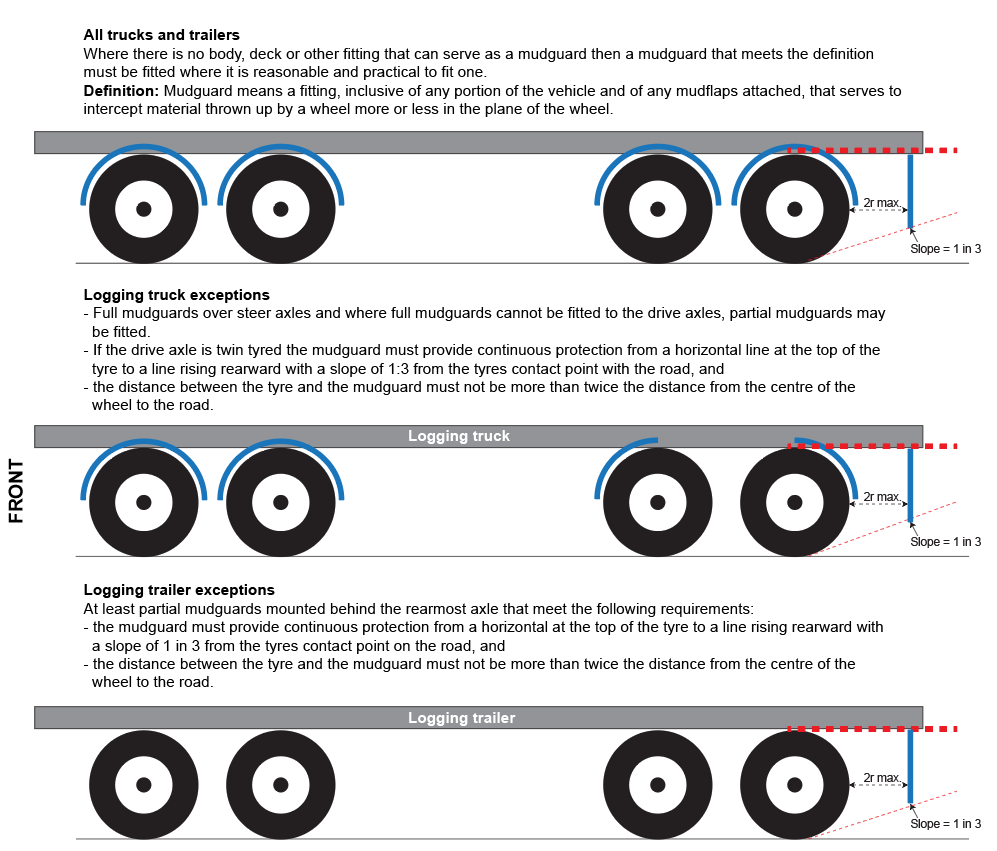

4. A truck used for transporting round timber does not have mudguards over steer axles (Figure 10-3-6).

5. A truck used for transporting round timber does not have at least partial guards fitted to the front and rear tyres of the drive axle set (Figure 10-3-6).

Mudguard condition

6. A mudguard is not securely fixed to the vehicle.

7. A mudguard is so constructed or damaged that it is likely to present a hazard to road users (Note 2).

Modification (see also Introduction 3.1.2: Note 3)

8. A modification affects a mudguard, and:

a) is not excluded from the requirements for LVV specialist certification (Table 10-3-1), and

b) is missing proof of LVV specialist or accepted overseas certification, ie:

i. the vehicle is not fitted with a valid LVV certification plate, or

ii. the operator is not able to produce a valid modification declaration or authority card, or

iii. the vehicle has not been certified to an accepted overseas system as described in Technical bulletin 13.

Note 1 Definitions

Mudguard means a fitting, inclusive of any portion of the vehicle and of any mudflaps attached, that serves to intercept material thrown up by a wheel more or less in the plane of the wheel.

Tyre tread means the portion of a tyre that contacts the road.

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

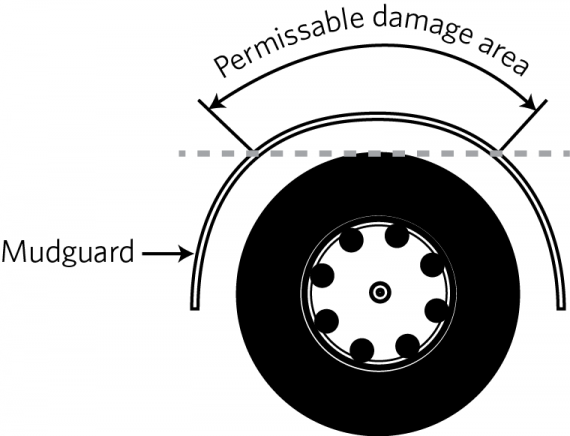

Note 2

Damage on full mudguards fitted to logging trucks is permissible if it is above a horizontal line on top of the tyre (Figure 10-3-5), and that damage is unlikely to result in the mudguard presenting a hazard to road users.

Table 10-3-1. Modifications that do not require LVV certification

Fitting of or modification to | LVV certification is not required provided that: |

|---|---|

Modified mudguards, including flared wheel arches or the addition of mudguard extensions |

Note: Mudguards flared via rolling do not require certification. |

Fitting of or modification to | LVV certification is never required: |

|---|---|

Any modification for the purposes of law enforcement or the provision of emergency services |

|

Figure 10-3-1. Position of individual mudguard in relation to tyre tread

Figure 10-3-2. Position of body panel mudguard in relation to tyre tread

Figure 10-3-3. Size and position of mudguards for the rear wheels of a vehicle fitted with dual wheels or close-spaced multiple wheels

Figure 10-3-4. LVV Authority Card: New Zealand Hot Rod Association

Figure 10-3-5. Permissible damage area on logging truck mudguards (Note 2)

Figure 10-3-6. Heavy vehicle mudguard requirements (Note 1)

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle must be fitted with a mudguard over each road wheel if it is reasonable and practicable to do so (Note 1).

2. A mudguard must cover no less than the width of the tyre tread on each road wheel (Figure 10-3-1 and Figure 10-3-2).

3. A vehicle fitted with twin tyres or close-spaced multiple tyres must be fitted with a mudguard over each wheel on the rear axle that provides continuous protection from a horizontal line tangent to the top of the tyre tread (Note 2) to a line with a slope of 1 in 3 rising rearward from the tyre’s contact point on the road (Figure 10-3-3).

4. A vehicle designed for industrial purposes may be fitted with partial mudguards if the vehicle’s construction makes it impracticable to fit full mudguards.

5. The following vehicles are not required to be fitted with mudguards:

a) a vehicle in an unfinished condition used under the authority of trade plates and operated in accordance with the Compliance Rule

b) a vehicle not capable of exceeding a speed of 30 km/h

c) a vehicle with a valid LVV authority card (Figure 10-3-4).

Mudguard condition

6. A mudguard must be securely fixed to the vehicle and must be constructed so that it does not present a hazard to road users.

Modification

7. A modification that affects a mudguard must be inspected and certified by a Low Volume Vehicle specialist certifier, unless the vehicle:

a) is excluded from the requirement for LVV certification (Table 10-3-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 April 2021 (see amendment details).