Correct as at 30th April 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > Heavy vehicles > Towing connections

12 Towing connections

12-2 Towbar

Reasons for rejection

Mandatory requirement

1. A towbar fitted to a heavy vehicle does not have evidence of certification, ie:

a) the towbar was fitted before the last CoF inspection, and after 1 January 1997, and no LANDATA record has been entered,

Note Before 1 January 1997 certification was required but for inspection purposes the LANDATA record need not be checked

or

b) the towbar was fitted after the last CoF inspection and

i. a valid LT400 form has not been presented, or

ii. the HVS certifier was not of category HVET or HMTD or

c) there is no valid certification plate/label attached to the vehicle as required in Table 12-2-1.

2. A towbar fitted to a heavy vehicle before 1 April 2006 for towing a light trailer has not been certified as complying with at least one of the following:

- NZS 5467: 1993

- NZS 5446: 1987

- NZS 5446: 1987, amended by Appendix A to Policy Statement 5 for towbars rated for a maximum towed mass of 2000 kg or less.

3. A towbar fitted to a heavy vehicle on or after 1 April 2006 for towing a light trailer has not been certified as complying with NZS 5467: 1993.

4. The certification label or plate:

a) is not indelible, or

b) is illegible, or

c) is not complete, or

d) has expired (where expiry date is required under Table 12-2-1), or

e) is not attached to the towbar in an easily visible position, or

f) does not match the vehicle, or

g) has obvious signs of tampering.

5. A 50mm or 1 7/8-inch-diameter tow ball for towing a light trailer is not marked with:

a) the ball size, that is 50mm or 1 7/8 inch, or

b) the ball rating in kilograms.

6. A high rise towball is fitted to a heavy vehicle (see Figure 12-1-1).

Mandatory equipment

7. A towbar does not have provision for securely fitting the safety chain from a trailer coupling, except for:

a) New Zealand Armed Forces vehicles

b) fire fighting vehicles.

Condition

8. The towbar or towbar mounting:

a) is not securely attached, or

b) has a bolt or nut that is missing or significantly corroded, or

c) has corrosion damage within 150mm of the mounting points, or

d) is cracked or distorted.

9. The towbar coupling (towball):

a) is not securely attached, or

b) is worn beyond manufacturer’s specifications, or

c) is significantly corroded, distorted or cracked, or

d) has a nut that is missing or significantly corroded.

Revoked certifications

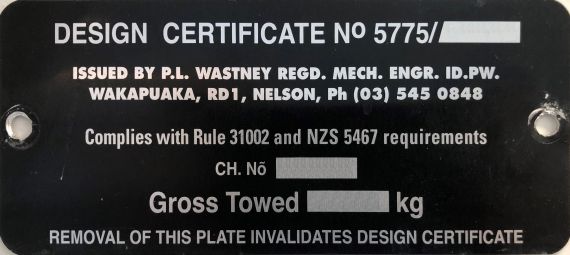

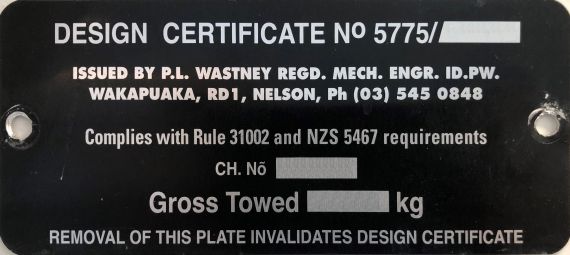

10. A towbar fitted to a heavy vehicle was last certified by Peter Wastney (PW) of Peter Wastney Engineering Ltd (for sample plates see Figure 12-1-2).

11. A towbar fitted to a heavy vehicle was last certified by Patrick Chu (ZC) of Transport and Structure Ltd (for sample plates see Figure 12-1-2).

Modification and repair

12. A modification or repair affects the towbar and:

a) is not excluded from the requirements for HVS certification (Table 12-2-2), or

b) is not for the purpose of law enforcement or the provision of emergency services, or

c) is missing proof of HVS certification, ie the vehicle has been modified or repaired, and:

i. no LANDATA record has been entered, or

ii.no valid LT400 form from an HVS certifier of category HVET or HMTD has been presented.

Note 1 Definitions

Coupling means that part of a vehicle that is specifically designed to enable it to be connected to another vehicle; does not include a structural member of the towing or towed vehicle (for example fifth wheel, hook, pin, ball or socket type).

Light trailer means a trailer that has a gross vehicle mass of 3500kg or less.

Towbar means that part of the towing vehicle to which a coupling for a light trailer is connected.

Table 12-2-1. Minimum information on towbar certification label/plate

NZS 5467 | NZS 5446 | NZS 5446 as amended by |

|---|---|---|

Manufacturer’s name or trademark Maximum towed mass (braked and unbraked) Model (vehicle make, model or part number) Maximum vertical load Certifier or agency approval number | Company or agency name Certifying engineer Vehicle VIN or chassis number Maximum towed mass (kg) Expiry date (if certified after August 1991) | Manufacturer’s name Towbar model number or part number Rating – maximum towed mass (MTM) in kg (maximum of 2000kg) |

Table 12-2-2. Requirements for HVS certification

HVS certification is required | HVS certification is not required |

|---|---|

1. Fitting of a towbar | 1. A replacement bolt-on 50mm or 1 7/8-inch-diameter tow ball 2. Any modification or repair likely to have been carried out before 1 January 1997 (modifications and repairs before this date generally required certification but for inspection purposes the LANDATA record need not be checked). 3. Any repair or modification not listed in the left-hand column unless the vehicle inspector considers that certification is required because the modification or repair has affected the vehicle’s safety performance (a second opinion from an expert may be needed, eg the manufacturer’s representative, or a reputable workshop). |

Figure 12-1-1. High rise towball

Figure 12-1-2. Sample certification plates (Peter Wastney Ltd and Patrick Chu (ZC) of Transport and Structure Ltd)

| Peter Wastney Ltd |

|---|

|

| Patrick Chu (ZC) of Transport and Structure Ltd |

|---|

|

Summary of legislation

Applicable legislation

- Land Transport Rule: Heavy Vehicles 2004

- Land Transport Rule: Passenger Service Vehicles 1999

- New Zealand Standard 5467: 1993, Code of Practice for Light Trailers

- New Zealand Standard 5446: 1987, Code of Practice for Heavy Motor Vehicle Towing Connections: Drawbar Trailers

- Policy Statement 5, Appendix A

- New Zealand Standard 5232: 1993, Specification for Ball-and-Socket Type Trailer Couplings.

Mandatory requirement

1. A towbar fitted to a heavy vehicle before 1 April 2006 must comply with and be certified to:

a) NZS 5467: 1993, or

b) NZS 5446: 1987, or

c) NZS 5446: 1987, amended by Appendix A to Policy Statement 5 for towbars rated for a maximum towed mass of 2000kg or less.

2. A towbar fitted to a vehicle on or after 1 April 2006 for towing a light trailer must comply with and be certified to NZS 5467: 1993.

Mandatory equipment

4. A towbar, if fitted to a vehicle, must have provision for securing the safety chain or cable from a trailer coupling, except if the vehicle is likely to tow any of the following trailers:

a) a trailer designed for armament purposes by the New Zealand Defence Force

b) a trailer pump for fire fighting purposes.

Condition

5. Towing connection components fitted to a vehicle must ensure that a secure connection can be maintained between the towing and towed vehicles under all conditions of loading and operation for which the vehicle was constructed.

Modification and repair

6. A modification or repair that affects the towbar must be inspected and certified by an HVS certifier of category HVET or HMTD unless the vehicle:

a) is excluded from the requirement for HVS certification (Table 12-2-2), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.="new">

Page amended 1 April 2023 (see amendment details)

12-3 Drawbeam

Reasons for rejection

Mandatory requirement

1. A drawbeam fitted to a heavy vehicle, other than a tractor to which section 12-4 applies or a recovery service vehicle, does not have evidence of certification to NZS 5446, ie

a) the drawbeam was fitted before the last CoF inspection, and after 1 January 1997, and no LANDATA record has been entered,

Note Before 1 January 1997 certification was required but for inspection purposes the LANDATA record need not be checked

or

b) the drawbeam was fitted after the last CoF inspection and

i. a valid LT400 form has not been presented, or

ii. the HVS certifier was not of category HVET or HMTD, or

c) there is no valid certification label or plate attached to the vehicle as required in Table 12-3-1.

2. The certification label or plate:

a) is not indelible, or

b) is illegible, or

c) is not complete, or

d) is not attached to the drawbeam in an easily visible position, or

e) does not match the vehicle, or

f) has obvious signs of tampering, or

g) has expired.

Mandatory equipment

3. A hook- or pin-type coupling does not have a locking device or a separate means of retaining this device in the locked position.

Condition and performance

4. A towing connection component is:

a) damaged, deformed, cracked or has significantly deteriorated, or

b) worn beyond manufacturer’s specifications, or

c) not securely attached, or

d) missing, or

e) not mounted in accordance with manufacturer’s specifications.

5. The towing pin diameter is worn to less than (Note 1):

a) 36.4mm for a 40mm pin, or

b) 46.4mm for a 50mm pin.

6. A towing hook, pin or ball has been repaired or welded.

7. Towing connection components fitted to a vehicle must ensure that a secure connection can be maintained between the towing and towed vehicles under all conditions of loading and operation for which the vehicle was constructed.

8. A drawbeam is sliding or adjustable.

9. Locking of the coupling is not readily verifiable by visual inspection.

10. A coupling locking device is in such condition that it is not effective.

Revoked certifications

11. A drawbeam fitted to a heavy vehicle was last certified by Peter Wastney (PW) of Peter Wastney Engineering Ltd (for sample plates see Figure 12-3-2).

12. A drawbeam fitted to a heavy vehicle was last certified by Patrick Chu (ZC) of Transport and Structure Ltd (for sample plates see Figure 12-3-2).

Modification and repair

(see Note 4)

13. A modification or repair affects the drawbeam and:

a) the modification is not for the purpose of law enforcement or the provision of emergency services, or

b) is missing proof of HVS certification, ie the vehicle has been modified or repaired, and:

i.no LANDATA record has been entered, or

ii. no valid LT400 form from a HVS Certifier of category HVET or HMTD has been presented.

Note 1

Manufacturer’s wear limits may be used instead of those stated.

Note 2 Definitions

Coupling means that part of a vehicle that is specifically designed to enable it to be connected to another vehicle; it does not include a structural member of the towing or towed vehicle (eg fifth wheel, hook, pin, ball or socket type).

Drawbeam means that part of the towing vehicle to which a coupling is fitted to enable a heavy trailer to be connected; it includes the attached coupling.

Full trailer means a trailer with two axle sets, the foremost of which is steered by a drawbar; includes a semi-trailer with non-steering axles coupled to a converter dolly.

Note 3

Some special-use vehicles, such as fertiliser trucks and trailers, are fitted with towing connections where the towing eye is fitted to the towing vehicle and the pin- or hook-type coupling to the trailer. This is permitted. In these cases, please refer to heavy trailer pages of section 8-3 for wear limits and other relevant requirements.

Note 4

A towing connection that was certified to New Zealand standard 5446: 1987 (superseded) before November 2007 may continue to comply with and be certified to that standard until the towing connection is modified.

Table 12-3-1. Minimum information on drawbeam certification label/plate

NZS 5446: 1987 | NZS 5446: 2007 |

|---|---|

Company or agency name Certifying engineer VIN/Chassis number Maximum towed mass (kg) Expiry date (if certified on or after 1 August 1991) | Person, company or agency name Certifier ID LT400 number* VIN/Chassis number Maximum towed mass Permitted static vertical load (where applicable)** Coupling D value (minimum) (where applicable)** Expiry date NZS 5446 |

*Prior to 1 December 2016 the engineer's job file number could have been used instead of the LT400 number.

**If these values are not applicable, ‘N/A’ must be used (from 1 October 2020). Prior to 1 October 2020 the plate may have a blank space or a zero, nil or N/A value.

For example:

- hinged drawbars do not have a vertical load rating

- most pintle hooks/eyes do not have a D value.

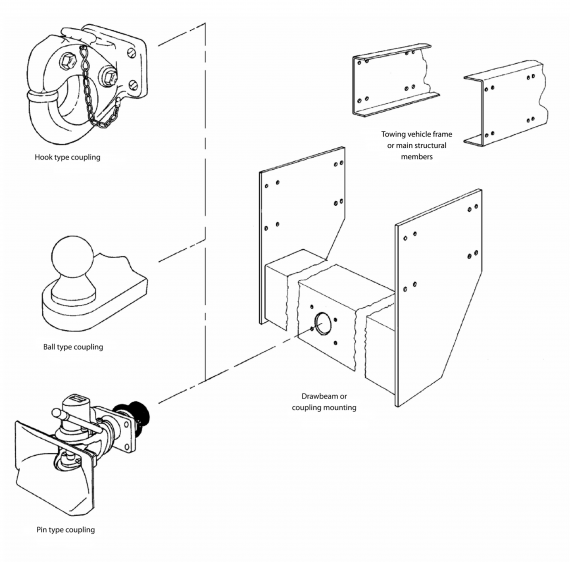

Figure 12-3-1. Drawbeam components

Reproduced from Figure 3 of NZS 5446: 2007 with the permission of Standards New Zealand under Licence 000711

Figure 12-3-2. Sample certification plates (Peter Wastney Ltd and Patrick Chu (ZC) of Transport and Structure Ltd)

| Peter Wastney Ltd |

|---|

|

| Patrick Chu (ZC) of Transport and Structure Ltd |

|---|

|

Summary of legislation

Applicable legislation

- Land Transport Rule: Vehicle Dimensions and Mass 2002

- Land Transport Rule: Heavy Vehicles 2004

- New Zealand Standard 5446: 1987, Code of Practice for Heavy Motor Vehicle Towing Connections: Drawbar Trailers

- New Zealand Standard 5446: 2007, Heavy Vehicle Towing Connections – Drawbeams and Drawbars.

Mandatory requirement

1. A drawbeam fitted to a vehicle used in a combination, (other than a tractor to which section 12-4 applies or a recovery service vehicle) must comply and be certified to NZS 5446.

Mandatory equipment

2. A hook- or pin-type coupling must have an effective locking device and a separate means of retaining this device in the locked position.

Condition and performance

3. Towing connection components fitted to a vehicle must ensure that a secure connection can be maintained between the towing and towed vehicles under all conditions of loading and operation for which the vehicle was constructed.

4. A drawbeam used for towing a full trailer must not be sliding or adjustable.

5. Locking of the coupling must be readily verifiable by visual inspection.

Modification and repair

6. A modification or repair that affects the drawbeam must be inspected and certified by an HVS certifier of category HVET or HMTD.

Page amended 1 April 2023 (see amendment details)

12-4 Heavy tractor towing connection

Reasons for rejection

Mandatory and permitted equipment

1. A tractor with a towing connection other than a three-point linkage does not have one or two attachment points to which safety chains from a trailer coupling can be securely attached.

Condition

2. A towing connection component including a safety chain attachment point is:

a) damaged, deformed, cracked or has significantly deteriorated, or

b) worn beyond manufacturer’s specifications, or

c) not securely attached, or

d) missing, or

e) not mounted in accordance with manufacturer’s specifications.

3. A coupling mechanism or safety locking device does not:

a) operate smoothly or effectively, or

b) fasten securely.

Note 1 Definitions

Heavy tractor means a motor vehicle (other than a traction engine) with a gross vehicle mass exceeding 3500 kg constructed principally for towing an agricultural trailer or powering agricultural implements. This definition applies to towing connections only.

Towing connection means the combination of components that enables one vehicle to tow or be towed by another vehicle; it includes a towbar, drawbar, drawbeam and coupling.

Three-point linkage means, for a tractor or agricultural trailer, a towing connection that has three points of attachment.

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A tractor may be fitted with towing connections, including three-point agricultural linkages.

2. A tractor with a towing connection other than a three-point linkage must have one or two points for attaching trailer safety chains that each has a strength of at least twice the maximum mass of any vehicles that may be towed by the tractor by means of that towing connection.

Condition

3. Towing connection components fitted to a vehicle must ensure that a secure connection can be maintained between the towing and towed vehicles under all conditions of loading and operations for which the vehicle was constructed.

12-5 Heavy vehicle fifth wheel or ball coupling (for towing a semi-trailer)

Reasons for rejection

Mandatory equipment

1. A fifth wheel is not designed to fit a 50mm or 90mm kingpin.

2. A fifth wheel or ball-type coupling fitted to a heavy vehicle does not have evidence of certification (unless excepted in Table 12-5-1), ie:

a) the coupling was fitted before the last CoF inspection, and after 1 January 1997, and no LANDATA record has been entered,

Note Before 1 January 1997 certification was required but for inspection purposes the LANDATA record need not be checked

or

b) the coupling was fitted after the last CoF inspection and

i. a valid LT400 form has not been presented, or

ii. the HVS certifier was not of category HVET or HMTD.

3. A 50mm-diameter fifth wheel, other than a rigid fifth wheel, has not been:

a) certified to NZS 5450: 1989, or

b) certified to all of the following:

i. Australian/New Zealand Standard 4968.1-2003, and

ii. Australian/New Zealand Standard 4968.2-2003, and

iii. Australian Standard 2174-2006, or

c) fitted by the vehicle manufacturer in compliance with UN/ECE Regulation 55 (if fitted to an imported vehicle).

4. A 90mm-diameter fifth wheel, other than a rigid fifth wheel, has not been certified to one of the following:

a) if fitted before 1 April 2005, NZS 5450

b) if fitted on or after 1 April 2005, both AS 2174 and AS/NZS 4968 (Note 1).

5. A rigid fifth wheel has not been certified to manufacturer’s specifications.

6. A vehicle that is fitted with a 90mm-diameter fifth wheel does not have ‘90mm fifth wheel’, where ‘90’ is at least 60mm high, clearly displayed in a position readily visible from the position from which the release handle of the fifth wheel is operated.

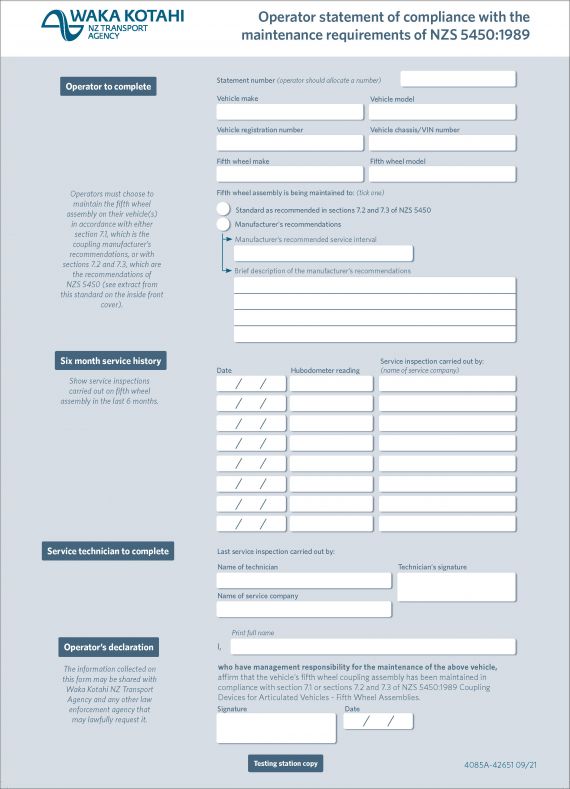

7. An ‘Operator Statement of Compliance with the Maintenance Requirements of NZS 5450: 1989’ (NZTA 4085A form) is:

a) not presented, or

b) incomplete (Note 2), or

c) not current, ie more than:

i. the time or distance specified by the fifth wheel manufacturer has elapsed or been travelled since the most recent inspection recorded on the form, or

ii. 30 days have lapsed or 15,000km has been travelled, whichever occurred sooner, since the most recent inspection recorded on the form, where manufacturer’s specifications are unavailable.

8. A vehicle is fitted with a ball-type coupling to tow a semi-trailer and:

a) is not certified to NZS 5446, or

b) does not have a valid certification label or plate attached to the vehicle as required in Table 12-5-2, or

c) is not part of a dedicated combination.

9. A required certification label or plate (ball-type couplings only):

a) is not indelible, or

b) is illegible, or

c) is not complete, or

d) is not attached to the vehicle in an easily visible position, or

e) does not match the vehicle, or

f) has obvious signs of tampering, or

g) has expired.

Condition and performance (Note 3)

10. A coupling or its mounting:

a) is not securely attached, or

b) bolt or nut is missing, significantly corroded or not suitable, or

c) is cracked, distorted or significantly corroded or has deteriorated, or

d) has corrosion damage within 150mm of the mounting points, or

e) pivot is seized, worn beyond manufacturer’s specifications, or not securely attached, or

f) is worn beyong manufacturer’s specifications.

11. The fifth wheel release mechanism:

a) is not in good condition, eg the handle is bent or damaged, or

b) does not operate freely (check only if presented without trailer attached).

12. The fifth wheel locking mechanism:

a) is not in good condition, eg jaws are worn beyond manufacturer’s specifications or out of adjustment, or

b) does not operate freely (check only if presented without trailer attached).

Modification and repair (Note 4)

13. A modification or repair affects the coupling and:

a) is not excepted from the requirements for HVS certification (Table 12-5-1), or

b) the modification is not for the purpose of law enforcement or the provision of emergency services, or

c) is missing proof of HVS certification, ie the vehicle has been modified or repaired, and:

i. no LANDATA record has been entered, or

ii. no valid LT400 form from an HVS certifier of category HVET or HMTD has been presented.

Note 1

AS/NZS 4968 supersedes AS 1773 and AS 1771.

Note 2

Where the service history is incomplete, the CoF inspector must note this on the CoF checksheet, but the vehicle is not required to be failed for this reason alone.

Note 3

Where a vehicle is presented in combination, the vehicles do not have to be separated, but a thorough visual inspection as far as practicable must be carried out.

Note 4

A towing connection that was certified to New Zealand standard 5446: 1987 (superseded) before November 2007 may continue to comply with and be certified to that standard until the towing connection is modified.

Note 5

While not included as an inspection item, a vehicle may not be towed using a fifth wheel coupled to another fifth wheel.

Note 6 Definitions

Fifth wheel means a device fitted to a vehicle to enable a semi-trailer to be connected to it by means of a kingpin so that the semi-trailer may be towed.

Coupling means that part of a vehicle that is specifically designed to enable it to be connected to another vehicle; it does not include a structural member of the towing or towed vehicle (eg fifth wheel, hook, pin, ball or socket type).

Dedicated combination means a combination of vehicles certified for use in combination where both vehicles are affixed with a plate clearly and indelibly marked with the VIN or chassis number of the other vehicle (the plate is fitted by the HVS certifying Eengineer).

Semi-trailer means a trailer with only one axle set that is partially superimposed on the towing vehicle so that a substantial part of the trailer and its load is borne by the towing vehicle.

Table 12-5-1. Requirements for HVS certification

HVS certification is required | HVS certification is not required |

|---|---|

1. Fitting of a coupling, other than a direct bolt-on replacement. 2. Modification or repair of a coupling, except when this is not required in the right-hand column. | 1. Fifth wheel or ball-type coupling that is a direct bolt-on replacement. 2. Any modification or repair likely to have been carried out before 1 January 1997 (modifications and repairs before this date required certification but for inspection purposes the LANDATA record need not be checked). 3. Any repair or modification not listed in the left-hand column unless the vehicle inspector considers that certification is required because the modification or repair has affected the vehicle’s safety performance (a second opinion from an expert may be needed, eg the manufacturer’s representative, or a reputable workshop). 4. A 50mm fifth wheel that complies with UN/ECE Regulation 55 fitted to an imported vehicle. |

Table 12-5-2. Minimum information on certification label/plate

NZS 5446: 1987 | NZS 5446: 2007 |

|---|---|

Company or agency name Certifying engineer VIN/Chassis number Maximum towed mass (kg) Expiry date (if certified on or after 1 August 1991) | Person, company or agency name Certifier ID Compliance certificate number (LT400) VIN/Chassis number Maximum towed mass Permitted static vertical load Coupling D value (minimum) Expiry date NZS 5446 |

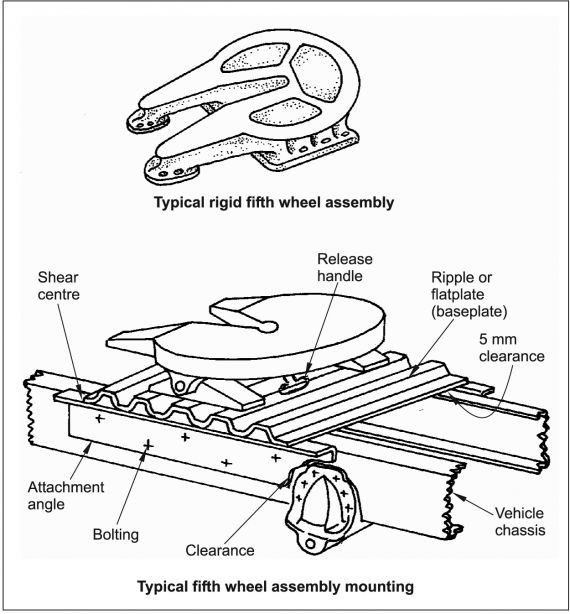

Figure 12-5-1. Fifth wheels

Figure 12-5-4. NZTA 4085A form (blank forms available from CoF inspecting organisations)

Summary of legislation

Applicable legislation

- Land Transport Rule: Heavy Vehicles 2004

- New Zealand Standard 5450: 1989, Coupling Devices for Articulated Vehicles – Fifth Wheel Assemblies

- Australian Standard 1773-1996: Articulated Vehicles – Fifth Wheel Assemblies

- Australian Standard 1771-1996: Installation of Fifth Wheel and Turntable Assemblies

- Australian Standard 2174-1994: Articulated Vehicles – Mechanical Coupling between Prime Movers and Semi-Trailers – Interchangeability Requirements

- Australian Standard 2174-2006:Articulated Vehicles – Mechanical coupling between prime movers and semitrailers – Interchangeability requirements

- Australian/New Zealand Standard 4968.1-2003: Heavy-road vehicles – Mechanical coupling between articulated vehicle combinations – Design criteria and selection requirements for fifth wheel, kingpin and associated equipment

- Australian/New Zealand Standard 4968.2-2003: Heavy-road vehicles – Mechanical coupling between articulated vehicle combinations – Testing and installation of fifth wheel and associated equipment

- New Zealand Standard 5446: 1987, Code of Practice for Heavy Motor Towing Connections – Drawbar Trailers

- New Zealand Standard 5446: 2007, Code of Practice for Heavy Motor Towing Connections – Drawbeams and Drawbars

- UN/ECE Regulation 55:Uniform Provisions Concerning the Approval of Mechanical Coupling Components of Combinations of Vehicles E/ECE/32 4 Rev.1/Add.54/Rev.1 E/ECE/TRANS/505A.

Mandatory equipment

1. A vehicle that is constructed to tow a semi-trailer must be fitted with either:

a) a 50mm-diameter fifth wheel, or

b) a 90mm-diameter fifth wheel, or

c) a ball-type coupling certified to NSZ 5446 and be operated as part of a dedicated combination.

2. A 50mm-diameter fifth wheel must comply with:

a) New Zealand Standard 5450: 1989, or

b) all of the following:

. Australian/New Zealand Standard 4968.1-2003: Heavy-road vehicles – Mechanical coupling between articulated vehicle combinations – Design criteria and selection requirements for fifth wheel, kingpin and associated equipment, and

ii. Australian/New Zealand Standard 4968.2-2003: Heavy-road vehicles – Mechanical coupling between articulated vehicle combinations – Testing and installation of fifth wheel and associated equipment, and

iii. Australian Standard 2174-2006: Articulated Vehicles – Mechanical coupling between prime movers and semitrailers – Interchangeability requirements, or

c) Despite the requirements in 2b) above, an imported vehicle that is constructed to tow a semi-trailer may be fitted with a 50mm diameter fifth wheel that complies with UN/ECE Regulation 55: Uniform Provisions Concerning the Approval of Mechanical Coupling Components of Combinations of Vehicles E/ECE/32 4 Rev.1/Add.54/Rev.1 E/ECE/TRANS/505A.3. A 90mm-diameter fifth wheel installed before 1 April 2005 must comply with NZS 5450: 1989.

4. A 90mm-diameter fifth wheel installed on or after 1 April 2005 and before 29 December 2007 must comply with:

a) Australian Standard 1773-1996, and

b) Australian Standard 1771-1996, and

c) Australian Standard 2174-1994.

5. A 90mm-diameter fifth wheel installed on or after 29 December 2007 must comply with:

a) AS/NZS 4968, and

b) AS 2174.

6. A vehicle that is fitted with a 90mm-diameter fifth wheel must have, clearly displayed in a position readily visible from the position from which the release handle of the fifth wheel is operated, ‘90mm fifth wheel’ where ‘90’ must not be less than 60mm high.

7. A rigid fifth wheel fitted to a vehicle must be installed and maintained in accordance with the fifth-wheel manufacturer’s instructions.

Condition and performance

8. Towing connection components fitted to a vehicle must ensure that a secure connection can be maintained between the towing and towed vehicles under all conditions of loading and operations for which the vehicle was constructed.

Modification and repair

9. A modification or repair that affects a coupling must be inspected and certified by a HVS Certifier of category HVET or HMTD unless the vehicle:

a) excepted from the requirement for HVS certification (Table 12-5-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 April 2023 (see amendment details).

Page updated 18 July 2023 (see details).