Correct as at 4th May 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > Motorcycles > Vision

5 Vision

5-1 Glazing

Reasons for rejection

Permitted equipment

1. Any glazing is not a transparent material that does not shatter.

Glazing condition

2. A piece of glazing is not mechanically sound, or is not securely affixed to the vehicle.

3. A windscreen (Note 1) (not a wind deflector) or front side window is so dirty or obstructed that the driver’s vision is impaired.

4. A windscreen (not a wind deflector) has damage that prevents the wiper blades from working properly.

5. A windscreen has scratches, discolouration or other defects that unreasonably impair the driver’s vision or compromise the strength of the windscreen.

Condition within the critical vision area (CVA)

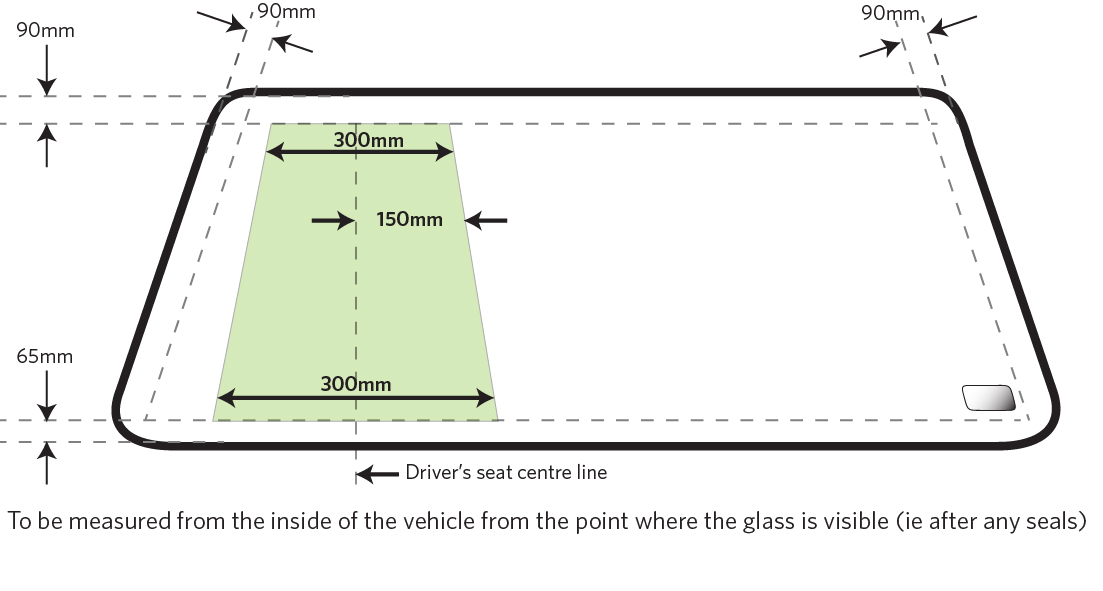

6. The critical vision area (CVA) of a windscreen (Figure 5-1-1) is damaged (Note 2) (apart from scratching and surface pitting that does not affect the driver’s vision such as small stone marks).

Condition outside the CVA (Note 10)

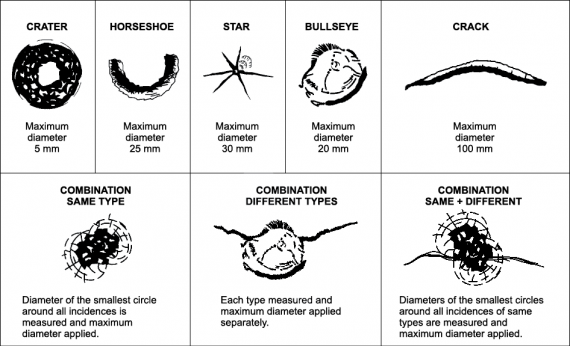

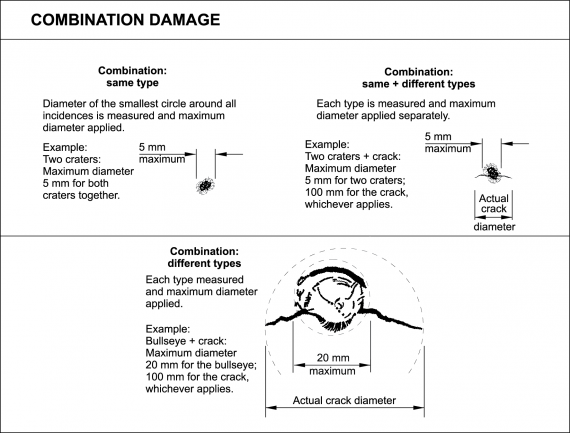

7. A windscreen (not a wind deflector) has damage of a type and exceeding the dimensions in Figure 5-1-2.

8. Any damage to a windscreen (not a wind deflector) that extends through more than one layer of glass.

Glazing performance

9. The overall visible light transmittance (VLT) (Note 4) of a windscreen is less than 70%.

10. The overall VLT of a front side window is less than 35%.

11. Glazing has a mirrored effect sufficient to dazzle other road users (unless it is OE and has an approved standard marking).

12. A modification:

a) unreasonably impairs the rider’s vision through the windscreen or front side window, or

b) adversely affects the strength or mechanical performance of the glazing on the vehicle.

Permitted modifications

13. A modification that affects glazing is not within the limits in Table 5-1-1.

Windscreen repair

14. A windscreen that has been rejected for a WoF or CoF has been repaired and re-presented without the required documentation (Note 5)

Note 1

Windscreen means all glazing extending across the front of a vehicle that is not parallel to the vehicle’s centreline but does not include a wind deflector.

Note 2

Damage includes any unrepaired damage and attempted visible repairs.

Note 3

Laminated glass means glazing consisting of two or more pieces of sheet glass, plate glass or float glass bonded together by one or more intervening layers of plastic material.

Note 4

Visible light transmittance (VLT) is the proportion of visible light that passes through glazing, measured perpendicular to the glazing. Overall VLT is the VLT of the glazing together with any overlays.

Note 5

When a windscreen has been rejected for a WoF or CoF, repaired, and then re-presented for inspection, the repair must be certified to AS/NZS2366 1999, AS2366 1990 or NZS5470 1993. Proof of certification is the receipt issued in accordance with the relevant standard by the repairer. For AS/NZS2366 1999, the windscreen repair invoice must include:

a) invoice number

b) date of repair

c) date of invoice (if different from date of repair)

d) trading name and address of repairer

e) name or identification of person performing the repair

f) make of vehicle

g) registration number of vehicle, or if registration number is unavailable, then the vehicle identification number (VIN) or chassis number

h) details of work carried out

i) type and location of repaired damage on the windscreen (it is recommended that this be marked on a schematic windscreen on the invoice form)j) in the case of repairs performed to this standard, a statement that the repairs have been made in accordance and comply with AS/NZS 2366.1 using a repair system that complies with AS/NZS 2366.2.

Note 6

Overlay means a transparent, translucent or opaque self-adhesive or clinging film that is applied to large areas, or the whole, of a piece of glazing, including anti-glare band overlays, stoneguard overlays.

Note 7

Sticker means a self-adhesive or clinging film, with or without print on it, that is applied for purposes such as advertising, identification, information, or for aesthetic or legal reasons.

Note 8

Anti-glare band overlay means a tinted overlay that is transparent and that is applied along the top edge of the windscreen for the purpose of reducing glare from the sun.

Note 9

Stoneguard overlay means a clear overlay that is transparent and that is applied along the bottom edge of the windscreen for the purpose of preventing damage to the windscreen from stones and other debris thrown up by other vehicles.

Note 10

Any OE opaque edging (usually black) is not considered part of the windscreen when determining the boundaries of the CVA, or the areas permitted for stickers, print on an anti-glare band, or radio antennae.

Table 5-1-1. Permitted modifications

Fitting of or modification to: | Modification permitted provided that: |

|---|---|

Overlays (Note 6) |

– have any bubbling or other defects that could unreasonably impair vision, or – have a mirrored effect that is sufficient to dazzle other road users, or – affect the performance of any high-mounted stop lamps fitted to the vehicle. |

Windscreens (Note 1): | |

Stickers (Note 7) |

– a licence label – a road user licence label – a WoF label – an alternative fuel sticker – a parking permit or other document issued by the local authority – learner L-plates (in sticker format) provided the driver’s vision is not unreasonably affected. |

Anti-glare band overlay (Note 8) |

– does not extend below the bottom edge of the vehicle’s OE sun visors when they are folded down as far as possible towards the windscreen, and – does not contain print below a line that is 100 mm below and parallel to the top edge of the windscreen. |

Radio antennae |

|

Front side windows: | |

Transparent overlays |

|

Stickers |

|

Radio antennae |

|

Rear and rear side windows (behind the driver’s seat): | |

Overlays and other modifications |

|

Stickers |

|

Radio antennae |

|

Monsoon shields |

|

Electric demisters | |

Sunroofs: overlays and stickers applied anywhere on the glazing, radio antennae and electric demisters | |

Any modification for the purposes of law enforcement or the provision of emergency services | |

Figure 5-1-1. Windscreen critical vision area (CVA)

Figure 5-1-2. Types and maximum sizes of windscreen damage (Note 2).

(see also Figure 5-1-3)

Figure 5-1-3. Types and maximum sizes of windscreen damage (incl. actual maximum sizes)

Note Due to different screen resolutions and sizes the image may not be displayed at actual size.

Summary of legislation

Applicable legislation

Permitted glazing

Glazing markings

1. All glazing must be transparent material of a kind that does not shatter.

Glazing condition

2. Glazing must be mechanically sound, strong, and securely affixed to the vehicle.

3. A windscreen and front side windows must be clean and free of obstruction to ensure the driver has sufficient vision through the glazing to operate the vehicle safely.

4. A windscreen must not have scratches and other defects that:

a) unreasonably impair vision, or

b) compromise its strength.

5. A laminated windscreen must not show signs of discolouration that could unreasonably impair the driver’s vision.

Glazing performance

6. A windscreen visible light transmittance (VLT) must be at least 70%.

7. Front side windows VLT must be at least 35%.

8. Glazing must not have a mirrored effect sufficient to dazzle other road users.

9 A modification must not:

a) unreasonably impair vision through the windscreen or a front side window, or

b) adversely affect the strength or mechanical performance of the glazing on the vehicle.

Permitted modifications

10. A modification that affects glazing is permitted if within the limits in Table 5-1-1.

Windscreen repair

11. A repair to a windscreen carried out on or after 1 January 1997 must comply with whichever of the following standards is applicable at the date of repair:

a) New Zealand Standard 5470: 1993, Code of Practice for Automotive Windscreen Repair (superseded by Australian Standard/New Zealand Standard 2366: 1999, Windscreen Repairs), or

b) Australian Standard 2366-1990, Repair of Laminated Glass Windscreens Fitted to Road Vehicles (superseded by Australian Standard/New Zealand Standard 2366: 1999, Windscreen Repairs).

5-2 Sun visors

Reasons for rejection

Condition

1. A sun visor (Note 1):

a) is insecurely mounted, or

b) cannot maintain its adjusted position, or

c) has been modified (Note 1) or has deteriorated, and the likelihood of injury to vehicle occupants has not been minimised.

Note 1 Definitions

Sun visor means any attachment mounted above the inside of the windscreen and provided for the purpose of shielding the eyes of the driver and other front seat passengers from solar glare.

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Summary of legislation

Applicable legislation

Permitted equipment

1. A motorcycle may be fitted with one or more sun visors.

Condition

2. The condition of a sun visor must be such that the likelihood of injury to occupants is minimised.

Modification

3. A sun visor that is not OE or that is affected by a modification:

a) must meet the requirements for condition, and

b) does not require LVV specialist certification.

5-3 Windscreen wipe and wash

Reasons for rejection

Mandatory equipment

1. A vehicle of class LC or LD manufactured on or after 1 January 2000 that is fitted with a windscreen (not a wind deflector) is not fitted with a windscreen wipe and wash system.

Condition

Windscreen wipe system

2. The wiper operating device is missing.

3. A wiper arm or wiper blade is:

a) missing, or

b) insecure, or

c) damaged so as to affect the performance of the wipers.

4. The wiper operating mechanism is:

a) missing, or

b) insecure, or

c) damaged so as to affect the performance of the wipers.

Windscreen wash system

5. A wash system component is missing or insecure.

6. The wash operating device is missing.

Performance

Windscreen wipe system

7. A windscreen wiper does not wipe the windscreen effectively, preventing adequate forward vision by the driver.

8. The wipe operating device is unable to activate the wipe system.

Windscreen wash system

9. A windscreen wash nozzle does not discharge washer liquid directly onto the windscreen.

10. The wash operating device is unable to activate the wash system.

Modifications

11. A modification affects a windscreen wipe system, and:

a) is not excluded from the requirements for LVV specialist certification (Table 5-3-1), and

b) is missing proof of LVV specialist or accepted overseas certification, ie:

i. the vehicle is not fitted with a valid LVV certification plate, or

ii. the operator is not able to produce a valid modification declaration or authority card , or

iii. the vehicle has not been certified to an accepted overseas system as described in Technical bulletin 13 .

Table 5-3-1. Modifications that do not require LVV certification

Fitting of or modification to: | LVV certification is never required: |

|---|---|

Any modification for the purposes of law enforcement or the provision of emergency services |

|

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle of class LC or LD manufactured on or after 1 January 2000 that is fitted with a windscreen must have a windscreen wipe and wash system.

Permitted equipment

2. A vehicle may be fitted with a wash system when this is not required.

Condition

3. A windscreen wipe and wash system that is fitted to a vehicle of class LC or LD manufactured on or after 1 January 2000 must be efficient and within the vehicle manufacturer’s operating limits.

Performance

4. A windscreen wipe and wash system that is fitted to a vehicle of class LC or LD manufactured on or after 1 January 2000 must be capable of keeping an adequate area of the windscreen clean and clear so that the vehicle may be operated safely under all reasonably foreseeable conditions.

Modifications

5. An OE windscreen washing or wiping system may be removed from a vehicle manufactured before 1 January 2000.

6. A modification to the windscreen wipe system must be inspected and certified by an LVV specialist certifier unless the vehicle:

a) is excluded from the requirement for LVV specialist certification (Table 5-3-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition, and performance.

Page amended 1 December 2016 (see amendment details).

5-4 Rear-view mirrors

Reasons for rejection

Mandatory equipment

1. The vehicle is not fitted with at least one rear-view mirror.

Condition

2. A rear-view mirror:

a) is not mounted securely, or

b) cannot be adjusted, or

c) cannot maintain its adjusted position, or

d) is corroded or dirty, or

e) is damaged so that it increases the risk of injury to vehicle occupants.

Performance

3. A rear-view mirror:

a) does not provide a clear view to the rear of the vehicle, or

b) is not sufficiently isolated from vibrations.

Modifications

4. Additional rear-view mirrors have been fitted or a modification affects rear-view mirrors, and:

a) is not excluded from the requirements for LVV specialist certification (Table 5-4-1), and

b) is missing proof of LVV specialist or accepted overseas certification, ie:

i. the vehicle is not fitted with a valid LVV certification plate, or

ii. the operator is not able to produce a valid modification declaration or authority card , or

iii. the vehicle has not been certified to an accepted overseas system as described in Technical bulletin 13 .

Table 5-4-1. Modifications that do not require LVV certification

Fitting of or modification to: | LVV certification is never required: |

|---|---|

Additional or substituted rear-view mirrors, or removal of a non-mandatory mirror |

|

Any modification for the purposes of law enforcement or the provision of emergency services |

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle must be fitted with at least one rear-view mirror.

Permitted equipment

2. Additional rear-view mirrors may be fitted.

Condition

3. A rear-view mirror must be:

a) securely attached so that the risk of injury is minimised, and

b) mounted so that vibration does not inhibit the driver’s required clear view to the rear, and

c) sufficiently adjustable, and able to maintain its position.

Performance

4. A rear-view mirror must provide a clear view to the rear of:

a) the motor vehicle itself, and

b) the vehicle’s load, and

c) any towed trailer and its load.

5. A rear-view mirror must be sufficiently isolated from vibrations.

Modifications

6. The fitting of additional rear-view mirrors, or a modification that affects rear-view mirrors must be inspected and certified by an LVV specialist certifier, unless the vehicle:

a) is excluded from the requirement for LVV specialist certification (Table 5-4-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 December 2016 (see amendment details).