Lighting

4-1 Headlamps

Reasons for rejection

Mandatory and permitted equipment (Note 6)

1. A forklift that is likely to be operated during the hours of darkness (where the vehicle inspector can determine that) is not fitted with either:

a) one pair of dipped-beam headlamps, or

b) one pair of forward-facing work lamps (Note 1).

2. A forklift is fitted with more than:

a) one pair of dipped-beam headlamps, or

b) two pairs of main-beam headlamps.

3. A forklift is fitted with a headlamp that is not in a pair.

4. A retrofitted pair of headlamps is:

a) not fitted symmetrically, or

b) not fitted as far towards each side of the vehicle as is practicable.

5. A forklift is fitted with a dipped-beam headlamp where the maximum intensity of the beam is projected to the right.

Condition

6. A lamp is insecure.

7. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A lens or reflector is damaged or has deteriorated so that light output is reduced.

9. A mandatory lamp is obscured or contains dirt or moisture in the form of large droplets, runs or puddles.

10. A main-beam headlamp warning device is obscured from the driver’s vision.

Performance

11. When switched on, a headlamp emits a light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity to the other lamp in a pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead or be visible from 100m during the hours of darkness, eg due to modification, deterioration or an incorrect light source, or

e) too bright, eg due to the fitment of an HID or LED conversion kit (Note 7) or other incorrect light source, or

12. When the dipped-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than two lamps operate on dipped beam, or

c) the light beam produces an incorrect beam pattern, is not focused, or is reduced or altered, or

d) the centreline of the light beam (Figure 4-1-1, Table 4-1-1):

i. projects too far to the left, or

ii. projects to the right of the vehicle’s centreline, or

iii. slopes down too far so that the headlamp is no longer capable of illuminating the road ahead for safe vehicle operation, or

iv. is too high causing dazzling to other road users.

13. When the main-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than four lamps operate on main beam, or

c) the centreline of the light beam projects to the right of the vehicle’s centreline or up from the horizontal (Figure 4-1-2), or

d) the lamps are not capable of being switched to dipped beam or turned off from the driver’s seating position, or

e) a main-beam headlamp warning device does not indicate to the driver that the main-beam headlamps are switched on.

14. On a forklift with no headlamps, when the forward-facing work lamps are switched on a mandatory lamp does not operate.

15. On a forklift with no headlamps, when the forward-facing work lamps are switched on a lamp emits a light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity to the other lamp in a pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead, eg due to modification, deterioration or an incorrect light source, or

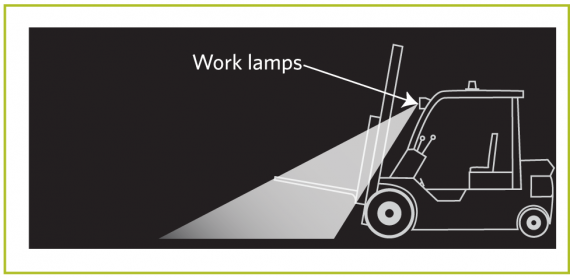

e) not aligned appropriately, causing dazzling to other road users or insufficient light illuminating the road ahead for safe vehicle operation (Figure 4-1-3).

Note 1 Definitions

Work lamp means a high-intensity lamp, which is not necessary for the operation of the vehicle but is designed to illuminate a work area or scene, and includes a scene lamp, a spot lamp and an alley lamp. In the case of a forklift without headlamps, forward-facing work lamps must be fitted to illuminate the road ahead during the hours of darkness.

Headlamp means a lamp designed to illuminate the road ahead of a vehicle, and that is a:

a) dipped-beam headlamp (single lamp), or

b) main-beam (high-beam) headlamp (single lamp), and includes a driving lamp, or

c) combination of a dipped-beam headlamp and a main-beam headlamp (dual-lamp unit).

Note 2

If the dipped-beam headlamps are able to be adjusted from the driver’s seating position, the alignment must be checked with the adjustment at its highest position.

Note 3

If the vehicle is fitted with self-levelling suspension, the alignment must be checked with the suspension at its normal level.

Note 4

If a headlamp is fitted with a readily removable cover, other than a clear protective cover, this must be removed for inspection of the headlamp.

Note 5

A vehicle originally manufactured with a headlamp arrangement that differs from what is required or permitted in this section may retain the original headlamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 6

A forklift that has no or non-compliant headlamps may be issued with a WoF provided the forklift:

a) complies with all other applicable WoF requirements, and

b) is not operated during the hours of darkness.

Note 7

A high-intensity discharge (HID or Xenon HID) or LED conversion kit consists of an HID or LED bulb which fits into the original headlamp unit in place of the original bulb with no change to the headlamp lens, reflector or housing.

It is illegal to fit an HID or LED conversion kit to a vehicle as it brings the headlamp out of standards compliance by producing poor beam patterns and light that is often far too bright to be safe. The bulbs can also produce light that is noticeably blue and not the required substantially white or amber colour. Vehicle and headlamp manufacturers do not permit this modification, and these kits cannot be LVV certified.

It is permitted to replace a complete halogen headlamp unit with a complete HID or LED headlamp unit. If the vehicle is required to meet an approved safety standard for headlamps, only approved headlamps can be retrofitted.

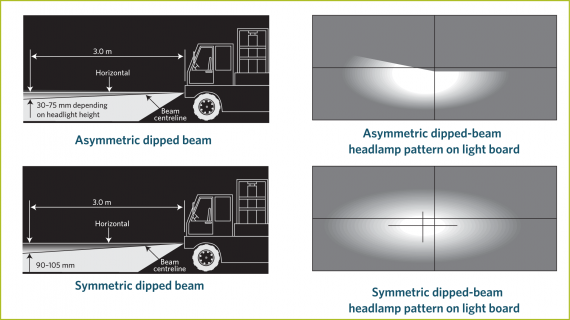

Table 4-1-1. Recommended dipped-beam headlamp alignment

Headlamp type | Distance from ground to centre of light source | Dip rate of beam centre: | |||

|---|---|---|---|---|---|

Percent (%) | mm/3m | Degrees (°) | |||

EITHER | Any headlamp dipped beam | N/A | That specified by the vehicle or headlamp manufacturer | ||

OR | Headlamp with symmetric dipped-beam pattern | N/A | 3.0–3.5 | 90–105 | 1.7–2.0 |

OR | Headlamp with asymmetric dipped-beam pattern and distance from ground to centre of light source | less than 0.8m | 1.0–1.5 | 30–45 | 0.57–0.85 |

0.8–1.2m | 1.0–2.0 | 30–60 | 0.57–1.15 | ||

more than 1.2m | 2.0–2.5 | 60–75 | 1.15–1.43 | ||

Figure 4-1-1. Headlamp dipped beam patterns and recommended dip-rates

Figure 4-1-2. Headlamp high-beam pattern

Figure 4-1-3. Work lamp beam pattern

Summary of legislation

Applicable legislation

Mandatory and permitted equipment (Note 6)

1. A forklift that is operated in the hours of darkness must be fitted with

a) one pair of dipped-beam headlamps, or

b) one pair of forward-facing work lamps (Note 1).

2. A forklift may be fitted with one or two pairs of main-beam headlamps.

3. A warning device may be fitted that indicates that the main-beam headlamps are switched on.

4. A retrofitted pair of headlamps must be symmetrically mounted as far towards each side of the vehicle as is practicable.

Prohibited equipment

5. A dipped-beam headlamp designed solely for a left-hand drive vehicle, where the maximum intensity of the beam is dispersed to the right, must not be fitted.

Condition

6. A headlamp or a mandatory forward-facing work lamp must:

a) be in sound condition, and

b) not be obscured.

Performance

7. A lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. A lamp must emit a steady light.

9. A lamp must provide sufficient illumination and light output to illuminate the road ahead.

10. A pair of lamps must emit light that is approximately of equal colour and intensity when switched on.

11. A lamp must emit a beam that is substantially white or amber.

12. A main-beam headlamp must be capable of being dipped or turned off from the driver’s position.

13. A warning device that indicates that the main-beam lamps are in operation must be in good working order.

14. When the headlamps are switched on and the vehicle’s front wheels are pointing in the straight-ahead position:

a) the centre of a headlamp beam must be either parallel to or to the left of the longitudinal centreline of the vehicle, and

b) the centre of a main-beam headlamp beam must be either parallel to or dipping down from the horizontal.

15. The dipped-beam headlamps must be visible from 100m in normal darkness.

16. A headlamp must be fitted with a light source that is specified by the vehicle manufacturer or the headlamp manufacturer.

Page amended 1 April 2021 (see amendment details).