Correct as at 26th April 2024. It may be superseded at any time.

Extract taken: from Vehicle Inspection Portal > VIRMs > Entry certification > Inspection and certification > Vision

5 Vision

5-1 Glazing

Reasons for rejection

Mandatory and permitted equipment

1. A windscreen that is required to be made of laminated glass is not made of laminated glass.

2. A piece of glazing fitted to a vehicle of class LA, LB1, LB2, LC, LD, LE1 or LE2 is not made of a transparent material that does not shatter.

3. A vehicle or piece of glazing does not comply with a requirement relating to mandatory or permitted equipment set out in:

Compliance with approved standards

4. A piece of glazing that is required to comply with an approved glazing standard did not comply, or cannot be demonstrated to have complied, with at least one of the standards listed in Table 5-1-1 at the time the vehicle was manufactured or the glazing was fitted.

Condition, performance and modification

5. A piece of glazing does not comply with a requirement relating to condition, performance or modification set out in:

Note 1

For a vehicle manufactured before 1 January 1991, a glazing marking which contains one or more of the approved trade names in Table 5-1-2 is evidence that a piece of glazing complies with an approved glazing standard.

Note 2

Curved scenic skylights above the cant rail, curved windows at the front and rear corners, skylights, louvres and interior partitions in omnibuses (vehicles of class MD1, MD2, MD3, MD4 and ME) are not required to comply with approved glazing standards if they are made of transparent material that does not shatter.

Note 3

The 35% VLT limit on rear and rear-side windows of MA class vehicles only applies to modified glazing. If the glazing is OE, unmodified, and is marked as complying with an approved standard or trade name, the glazing may be passed even with a VLT of less than 35%.

Note 4

See Technical bulletin 13 for an explanation of policy and requirements relating to glazing on house-trucks.

Table 5-1-1. Approved glazing standards*

|

UN-ECE Regulation no. |

EEC/EC Directive |

FMVSS |

ADR |

Japan |

Others |

|---|---|---|---|---|---|

|

43 |

92/22 |

205 |

8 |

TS for window glass |

BS 857 |

Table 5-1-2. Approved trade names for glazing

| Armourfloat Armourplate Blindex Duolite Safety Duplate Safety Flolite Ford Indestructo Ford Safety Glass Ford Silver Arrow Glacetex |

Hankuk Glass Safety Heat Line HMC Glass Safety Hankuk TF5 HMC Glass Safety Hankuk TV5 Indestructo Nippon Safety NM Laminated Safety Glass FHP Peerless |

Plexite Safetyflex Safety MGB (Meloplate) Safety MGB (Melite Safety Plate) Sekurit Sigla Spectrofloat Splintex Sunmat Suntex Safety Glass |

Temperlite Temperlite Santa Marina Thorex Connex Triplex Triplex Plate Tuflite Tyneside Veracetex |

Table 5-1-3. Glossary of codes for safety glass

|

L = |

laminated glass |

|

LF = |

laminated float |

|

LP = |

laminated plate |

|

// or /// = |

laminated when near the |

|

L.76WHP = |

laminated, 0.76mm interlayer, suitable for all locations |

|

AS1 = |

laminated for use anywhere in the vehicle |

|

A |

the glass in the direction of the arrow complies with the 70% light transmission requirement |

Table 5-1-4. Glossary of codes for including laminated glass

|

L |

laminated glass |

|

F |

float glass |

|

P |

plate glass |

|

LF |

laminated float |

|

LP |

laminated plate |

|

/ |

toughened, when near the |

|

// or /// |

laminated, when near the |

|

TS |

toughened glass |

|

TP |

toughened plate |

|

T |

toughened or tempered |

|

Z |

zone tempered |

|

WHP |

complies with impact test (windscreen high performance laminated safety glass) |

|

DOT |

Department of Transport (USA) |

|

AS AS |

the glass, in the direction of the arrow, complies with the 70% light transmission requirement |

|

ANSI |

American National Standards Institute |

|

FMVSS codes |

|

|

AS1 |

for use anywhere in the vehicle |

|

AS2 |

for use anywhere in the vehicle other than windscreen |

|

AS3 |

for rear and rear side windows only |

|

AS4 and AS5 |

for glazing not used for driver’s vision (eg the rear window of heavy truck cabs or convertible tops, windows/doors in motorhome bodies, ute canopies, rear windows on buses, roof glazing etc) |

|

Glazing cut from mother sheet |

|

|

L.76WHP |

laminated, 0.76 mm interlayer, suitable for all locations |

|

L.38 |

laminated, 0.38 mm interlayer, must not be used for windscreens |

|

PCZ26.1 |

polycarbonate, meets requirements of ANSI Z26, must not be used for windscreens |

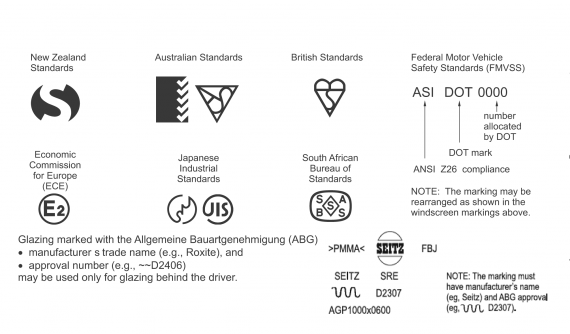

Figure 5-1-1 Approved standards markings

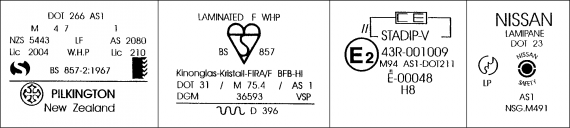

Figure 5-1-2. Typical laminated glazing markings

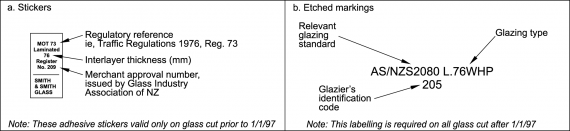

Figure 5-1-3. Typical markings required on glazing cut from mother sheet

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. Windscreens fitted to the following vehicles must be made of laminated glass:

a) vehicles of class MA, MB, MC and NA manufactured on or after 1 July 1986

b) vehicles of class MD1, MD2, MD3, MD4, ME, NB and NC manufactured on or after 1 July 1997

c) vehicles not covered by any of the defined vehicle classes manufactured on or after 1 January 2001.

2. All glazing fitted to vehicles of class LA, LB1, LB2, LC, LD, LE1 and LE2 must be made of a transparent material that does not shatter.

3. Vehicles and glazing must also comply with the requirements relating to mandatory and permitted equipment set out in the VIRM: In-service certification, section 5-1.

Compliance with approved standards

4. Windscreens fitted to the following vehicles must comply with one or more of the approved glazing standards in Table 5-1-1:

a) vehicles of group M and N manufactured on or after 1 January 1960 (Note 1)

b) vehicles not covered by any of the defined vehicle classes manufactured on or after 1 January 2001.

5. Glazing in locations other than windscreens fitted to the following vehicles must comply with one or more of the approved glazing standards in Table 5-1-1 (Note 4):

a) vehicles of group M (Note 2) and N manufactured on or after 1 February 1977 (Note 1)

b) vehicles not covered by any of the defined vehicle classes manufactured on or after 1 January 2001.

Condition, performance and modification

6. Glazing must comply with the requirements relating to condition, performance and modification set out in the VIRM: In-service certification, section 5-1 (Note 3).

5-2 Sunvisors

Vehicles must comply with the requirements relating to mandatory equipment, permitted equipment, condition, performance and modification set out in the VIRM: In-service certification, section 5-2.

There are no additional requirements in respect of sunvisors for the inspection and certification of vehicles for entry into service.

5-3 Windscreen wipe and wash

Vehicles must comply with the requirements relating to mandatory equipment, permitted equipment, condition, performance and modification set out in the VIRM: In-service certification, section 5-3.

There are no additional requirements in respect of windscreen wipe and wash systems for the inspection and certification of vehicles for entry into service.

5-4 Rearview mirrors

Reasons for rejection

Mandatory equipment

1. A vehicle does not comply with a requirement relating to mandatory equipment set out in:

Compliance with approved standards

2. A rear-view mirror that is required to comply with an approved rear-view mirror standard did not comply, or cannot be demonstrated to have complied, with at least one of the standards listed in Table 5-4-1 at the time the vehicle was manufactured or the rear-view mirror was fitted (Note 1).

Condition and performance

3. A rear-view mirror does not comply with a requirement relating to condition or performance set out in:

Note 1

The rear-view mirror standard must be recorded on the vehicle compliance checksheet. If a mirror does not have an approved standards marking but was fitted as original equipment, it must be recorded as ‘OE’, along with any identifying information, such as the make.

Table 5-4-1. Approved rear-view mirror standards*

UN-ECE Regulation no. | EEC/EC Directive | FMVSS | ADR | Japan |

|---|---|---|---|---|

46 | 71/127 | 111 | 14 | TS for installation position of outside rear-view mirrors |

* A rear-view mirror that is required to comply with an approved rear-view mirror standard must comply with at least one of the standards listed in the table.

- Rear-view mirror includes a camera monitor system that uses cameras that are mounted in order to have the same or a similar view as a rear-view mirror and that displays the images viewed by the camera on a monitor inside the vehicle that is visible to the driver.

See also Figure 5-4-1.

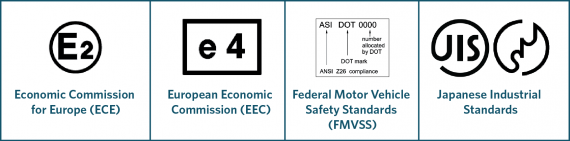

Figure 5-4-1. Typical standards markings

The following standard markings may assist in determining compliance with approved standards.

Summary of legislation

Applicable legislation

Mandatory equipment

1. Vehicles must comply with the requirements relating to mandatory equipment set out in:

Compliance with approved standards

2. The rear-view mirrors required to be fitted to group M and N vehicles manufactured on or after 1 January 1996 must comply with one or more of the approved rear-view mirror standards in Table 5-4-1 (Note 1).

Condition and performance

3. Rear-view mirrors must comply with the requirements relating to condition and performance set out in:

Page amended 1 May 2021 (see amendment details).