Correct as at 3rd May 2024. It may be superseded at any time.

Extract taken from: Vehicle Inspection Portal > VIRMs > In-service certification (WoF and CoF) > Heavy vehicles > Vehicle exterior

2 Vehicle exterior

2-1 External projections

Reasons for rejection

Condition and performance

1. The risk of a component (Note 5) hooking a vehicle, or hooking or grazing a person, has not been minimised, eg a bonnet or bumper has been removed, exposing sharp, moving or hot components.

2. An ornamental object or fitting (Note 2) protrudes in such a way that it is likely to injure a person.

3. A protruding object or fitting that has a functional purpose (Note 3) is not installed so that the risk of causing injury to a person is minimised, eg the object or fitting:

a) is of excessively heavy construction for the purpose for which it has been fitted, or

b) has sharp corners, or

c) slopes forward, unless this is necessary to fit the contours of the vehicle, or

d) has an unnecessarily wide gap between the object or fitting and the front of the vehicle, or

e) exceeds the vehicle’s width by more than 100mm on either side, other than side mounted glass sheet transport racks and collapsible side mirrors, or

f) is a glass sheet transport rack that is not fitted with a front flaring to minimise the risk of injury to a person.

4. A protruding component, object or fitting is not securely attached to the vehicle.

5. A protruding object or fitting adversely affects the driver’s vision or control.

Modifications

6. A modification (Note 4) affects an external projection – including a protruding object or fitting that has a functional purpose and affects the driver’s vision or control of the vehicle, and

a) is not excluded from the requirements for specialist certification (Table 2-1-1), and

b) is missing proof of specialist or accepted overseas certification, ie:

i. the vehicle is not fitted with a valid vehicle certification plate (eg low volume vehicle plate or heavy vehicle certification plate/label), or

ii. the operator is not able to produce a valid modification declaration or authority card

iii. the vehicle has not been certified to an accepted overseas system as described in Technical bulletin 13 .

Note 1

The external projections requirements relate to the design and maintenance of objects and fittings that protrude from the exterior of the motor vehicle with regard to the safety of other motor vehicles, pedestrians and cyclists. The attachment of such objects and fittings to the vehicle is addressed in the Vehicle structure section of this manual.

Note 2

Ornamental object or fitting means an object or fitting that does not have a practical purpose, eg bonnet emblems.

Note 3

Functional object or fitting means an object or fitting that has a practical purpose, eg panniers, pack racks, spare wheel carriers, and so on.

Note 4

Modify means to change a vehicle from its original state by altering, substituting, adding or removing any structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with equivalent undamaged or new structures, systems, components or equipment.

Note 5

Components include damaged, corroded and exposed body panels.

Note 6

The following vehicles with a GVM of 2500kg or less must comply with a frontal impact occupant protection standard:

- Class MA motor vehicles manufactured on or after 1 March 1999

- Class MA motor vehicles that were less than 20 years old when they were first registered in New Zealand on or after 1 April 2002

- Class MB and MC motor vehicles manufactured on or after 1 October 2003.

Note 7

Rear bumper removal must still meet external projection requirements.

Table 2-1-1. Modifications that do not require specialist certification

Fitting of or modification to: | Specialist certification is not required provided that: |

|---|---|

Body kits and components |

See also Table 3-1-1. |

Side racks (for glass or other sheet materials) |

See also Table 3-1-1. |

Bumper bar (removal and change) (Note 7) |

See also Table 3-1-1. |

Auxiliary bars (including bull bars, nudge bars, external roll cages and A-frames [or similar]) |

Note that an auxiliary bar that does not meet the above minimum requirements is unlikely to meet LVV requirements and so cannot be certified. See also Table 3-1-1. |

| A-frames |

See also Table 3-1-1. |

| Bonnet emblems or badges |

|

| Bonnet pins |

|

| Ute trays | For vehicles first registered in New Zealand before 1 January 2021:

For vehicles first registered in New Zealand on or after 1 January 2021:

See also Table 3-1-1. |

Fitting of or modification to: | Specialist certification is never required: |

|---|---|

Aerials |

|

Roof-mounted solar panels | |

Trunk racks | |

Roof-mounted wheelchair winch | |

Roof racks (except heavy PSVs) | |

Additional or substituted rear-view mirrors | |

Any modification for the purposes of law enforcement or the provision of emergency services |

Summary of legislation

Applicable legislation

Permitted equipment

1. A motor vehicle may be fitted with a protruding ornamental or functional object or fitting.

Condition and performance

2. A protruding ornamental object or fitting must not be likely to injure a person.

3. A protruding object or fitting that has a functional purpose must be installed so that the risk of the object or fitting causing injury to a person is minimised.

4. Components of a motor vehicle, including damaged or corroded body panels, must be such that the risk of their hooking a vehicle, or hooking or grazing a person, is minimised.

5. A protruding object or fitting must not adversely affect driver vision or driver control.

Modifications

6. A modification that affects an external projection must be inspected and certified by a specialist certifier, unless the vehicle:

a) is excluded from the requirement for specialist certification (Table 2-1-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 29 April 2020 (see amendment details).

Page updated 14 September 2023 (see details).

2-2 Dimensions

The vehicle inspector need only inspect dimensions in detail if there is doubt about the vehicle’s compliance. |

Reasons for rejection

Mandatory equipment

1. A rigid vehicle (Note 1) with a GVM of 3501kg or more exceeds the dimension requirements set out in Table 2-2-3 and is not:

a) a specialist overdimension vehicle (Note 2), or

b) a vehicle designed primarily to transport an overdimension load, or

c) a vehicle operating on a valid permit, exemption or approval, or

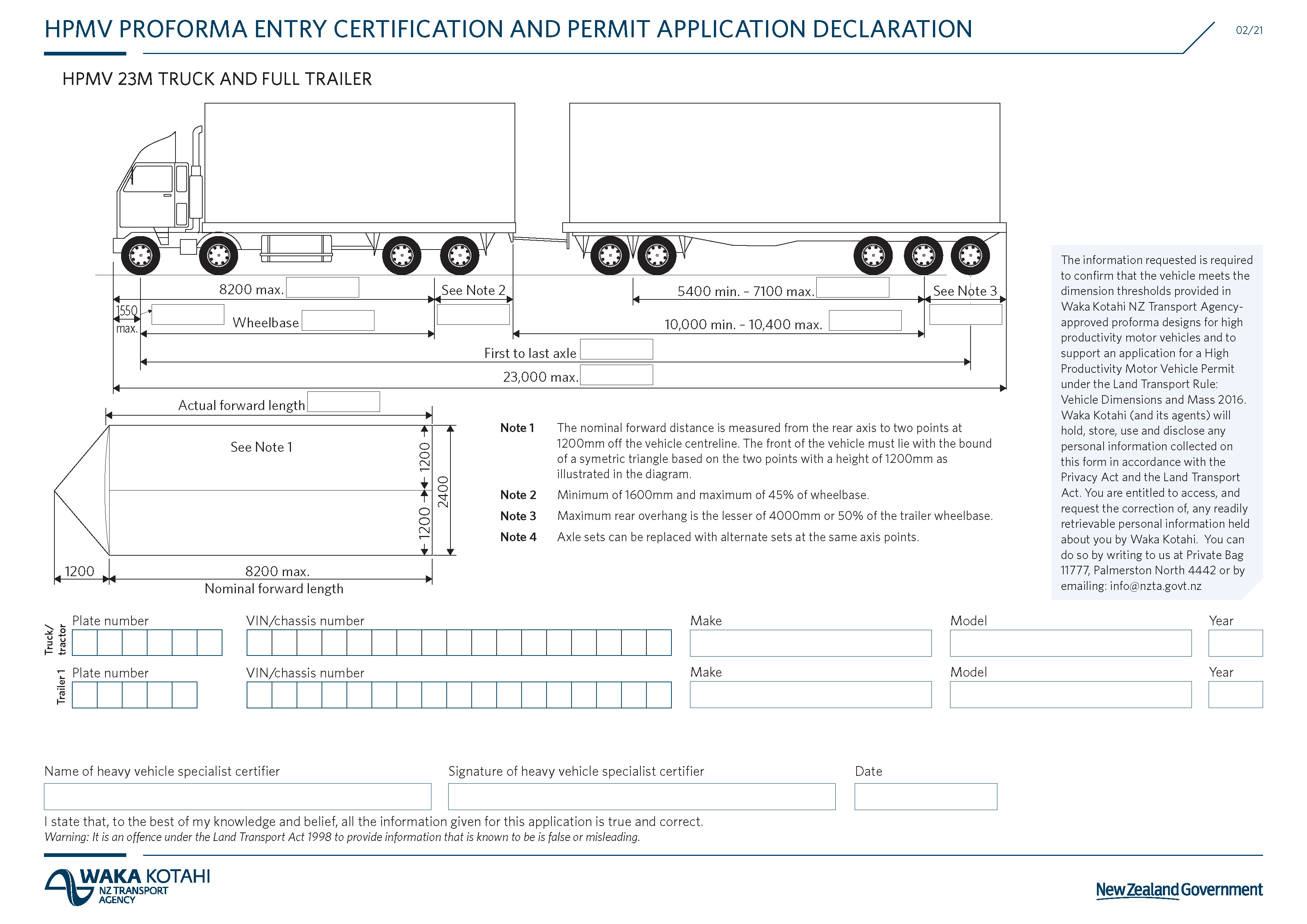

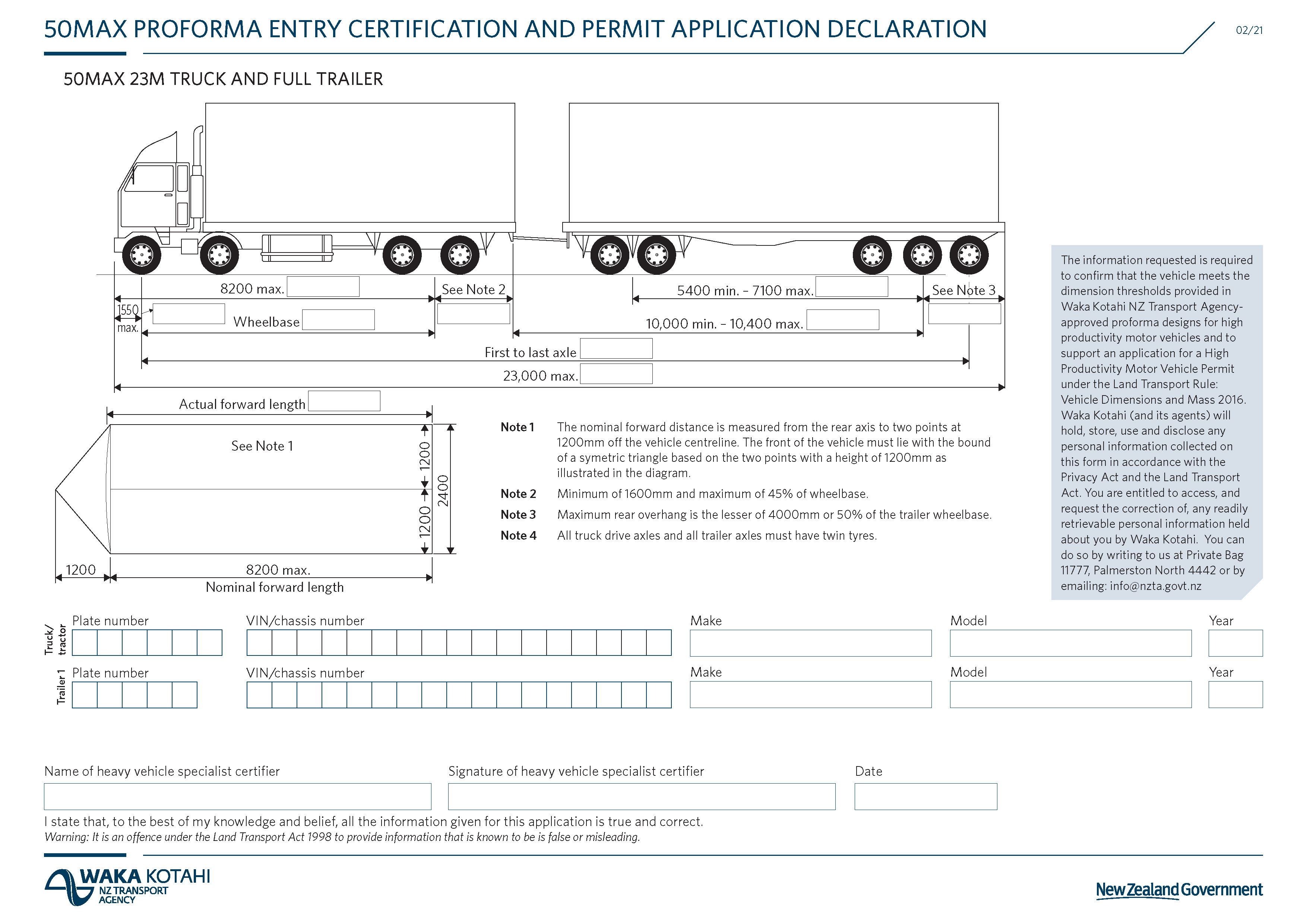

d) a vehicle presented with a completed 50MAX proforma entry certification and permit application declaration or HPMV proforma entry certification and permit application declaration signed by a heavy vehicle specialist certifier (Note 8) (Figure 2-2-5).

2. A rigid vehicle that exceeds the dimensions set out in Table 2-2-3 is not fitted with the appropriate hazard warning equipment set out in Table 2-2-4.

3. A required beacon cannot be activated and deactivated.

Note 1

Rigid vehicle means a vehicle with motive power, driver’s position and steering system, that does not have any pivot points to allow any part of the chassis of the vehicle to move or rotate in relation to any other part of the chassis of the vehicle; but includes a pivot steer vehicle.

Note 2

Specialist overdimension vehicle means a vehicle of which the primary purpose is to carry out a specialist function that requires overdimension equipment, and is not primarily designed to transport overdimension or overweight loads and the dismantling of the equipment would make it unusable for its intended purpose, or it would take more than four hours to dismantle the equipment. Additional operational requirements may apply, eg if operated at night.

Note 3

High-productivity motor vehicle (HPMV) means a heavy motor vehicle or heavy combination vehicle with or without a load:

a) exceeds a gross mass of 44,000kg, or

b) varies from a dimension requirement in Table 2-2-3, (other than width, height or ground clearance), or

c) both (a) and (b), and

d) operates on an HPMV permit issued by a road controlling authority.

Road controlling authority means the authority, body or person having control of the road (eg the Transport Agency, regional council or an authorized delegate)..

Note 4

An HPMV that does not comply with a dimension requirement in Table 2-2-3 may comply instead with a variation to that requirement as specified on the HPMV permit. The permit must be produced for inspection if required. Any other conditions specified on the permit are not required to be enforced at CoF.

Note 5

A bicycle rack fitted to the front of a vehicle of class MD3, MD4 or ME is not included in determining the overall length or forward distance of the vehicle provided the vehicle complies with the applicable swept path performance measures in section 3.5(2) of the Land Transport Rule: Vehicle Dimensions and Mass 2016.

Note 6

A high-productivity motor vehicle is not required to comply with the Hazard warning equipment requirements of Table 2-2-4.

Note 7

Instead of displaying a hazard warning flag or panel, the boom head of a mobile crane may be painted to delineate its excess front overhang, provided that the colour of the paint on the front face of the boom head is either white, yellow or red or a combination of these colours, so that the area on each side of the boom head that is painted covers an area of not less than 0.12 square metres (eg 400mm x 300 mm).

Note 8

The entry certification and permit application declaration forms can be downloaded from the Waka Kotahi website:

50MAX proforma entry certification and permit application declaration

HPMV proforma entry certification and permit application declaration

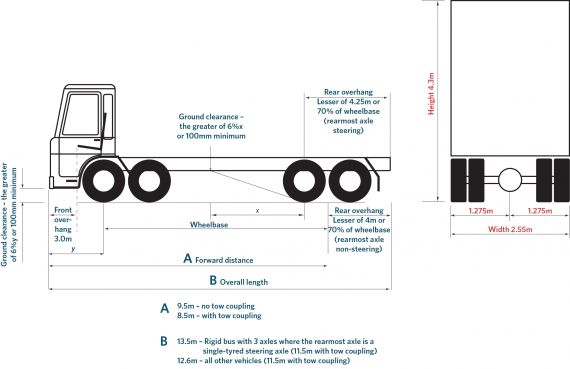

Table 2-2-3. Dimension requirements for heavy rigid vehicles

(see Note 4, Note 5)

Dimension | Maximum distance | Comments |

|---|---|---|

Width | 2.55m, or 1.275m from each side of the longitudinal centreline of the vehicle | Measurement does not include:

|

Overall length | 11.5m (tow coupling fitted) 12.6m (no tow coupling fitted) 13.5m (rigid bus with three axles where the rearmost axle is a single-tyred steering axle that is: a) either positively and continuously linked to the front steer (except may be locked for reverse and high-speed operation); or b) automatically locked at a speed of 30 km/h in the straight-ahead position and for reverse operations) 18m (articulated bus) | Measurement does not include:

|

Height | 4.3m | |

Forward distance | 8.5m (tow coupling fitted) 9.5m (no tow coupling fitted) 8.5m (for both front and rear sections of an articulated bus) | Forward distance is measured from:

Measurement does not include collapsible mirrors. A vehicle with a retractable axle must meet the dimension requirements whether the axle is in contact with the road or in the retracted position. |

Rear overhang | 4m or 70% of wheelbase (whichever is less) wheelbase where rearmost axle is a non-steering axle 4.25m or 70% of wheelbase (whichever is less) wheelbase where rearmost axle is a steering axle 4.5m or 72% of wheelbase (whichever is less) of a rigid bus that exceeds 12.6 in overall length 4m or 50% of forward distance (whichever is less) of an articulated bus 4m (for a vehicle first registered anywhere before 1 December 1989) | Rear overhang is measured from the rear axis to the rear of the vehicle. A vehicle with a retractable axle must meet the dimension requirements whether the axle is in contact with the road or in the retracted position. |

Ground clearance | The greater of 100mm or 6% of the distance from the nearest axle to the point where the ground clearance is measured | Measurement does not include flexible mudflaps, wheels, tyres or devices designed to discharge static electricity. |

Front overhang | 3m | Front overhang is measured from the front edge of the driver’s seat in the rearmost position to the front of the vehicle. |

Articulated vehicle point of attachment | No further rearward than centre of rear axle (where rear axle set consists of only one axle) No further than 300mm rearward of rear axis (where rear axle set consists of more than one axle) | Does not apply to articulated buses. |

Tow coupling position (articulated bus only) | 45% of wheelbase of the leading unit | The tow coupling position is the distance rearward from the vehicle’s rear axis to the centre of the tow coupling. |

Turning circle | 25m outside diameter 10.6m inside diameter (articulated bus only) | The vehicle must complete a 360-degree turn in either direction. No part of the vehicle (other than collapsible mirrors) must extend beyond the outside diameter or into the inside diameter. |

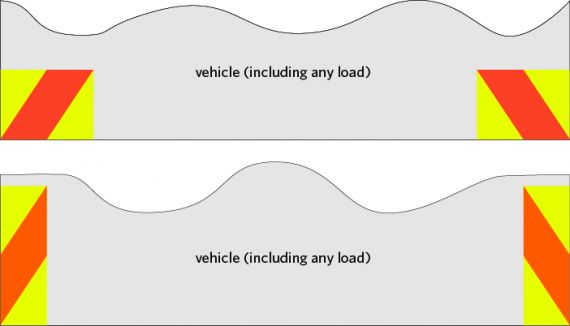

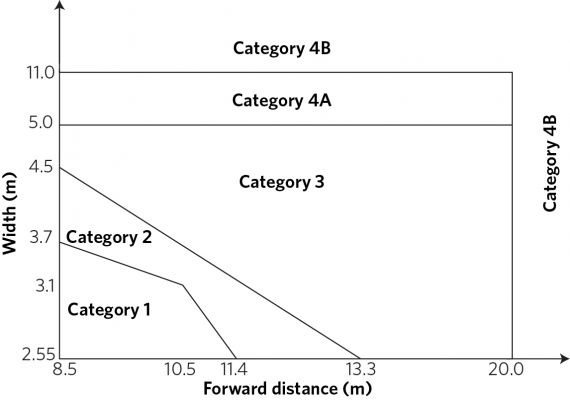

Table 2-2-4. Hazard warning equipment requirements for vehicles that exceed the dimensions in Table 2-2-3 (see Figure 2-2-3 for vehicle category thresholds) (Note 6)

Vehicle category | Dimension | Limits | Required hazard warning equipment |

|---|---|---|---|

Category 1 | Width/forward distance | 2.55m /11.4m, or 3.1m/10.5m, or 3.7m/8.5m, or |

1. Flags1 or panels2 fitted on each side at the front and rear as close as practical to the outside edge (for alternative requirements for a mobile crane see (Note 7)) 2. OVERSIZE sign3 fitted at the front and rear if more than 3.1m wide |

| Length | 25m, or | ||

| Front overhang | 7m, or | ||

| Rear overhang | 7m | ||

Category 2 (not including category 1) | Width/forward distance | 2.55m /13.3m, or 4.5m/8.5m, or |

1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge (for alternative requirements for a mobile crane see (Note 7))

2. OVERSIZE sign3 fitted at the front and rear if more than 3.1m wide 3. Amber beacon fitted so that it is visible to approaching traffic if the vehicle is more than 3.7m wide |

| Length | 35m, or | ||

| Front overhang | 10m, or | ||

| Rear overhang | 10m | ||

Category 3 (not including category 2) | Width/forward distance | 2.55m /20m 5m/20m 5m/8.5m | 1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge (for alternative requirements for a mobile crane see (Note 7)) 2. OVERSIZE sign3 fitted at the front and rear 3. Amber beacon fitted so that it is visible to approaching traffic if the vehicle is more than 3.7m wide |

| Front overhang | 10m, or | ||

| Rear overhang | 10m | ||

Category 4A (not including category 3) | Width/forward distance | 11m/20m 11m/8.5m | 1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge (for alternative requirements for a mobile crane see (Note 7)) 2. OVERSIZE sign3 fitted at the front and rear 3. Amber beacon fitted so that it is visible to approaching traffic if the vehicle is more than 3.7m wide |

| Front overhang | 10m, or | ||

| Rear overhang | 10m | ||

| Category 4B | Exceeding any limit in Category 4A | 1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge 2. OVERSIZE sign3 fitted at the front and rear 3. Revolving amber beacon fitted so that it is visible to approaching traffic if the vehicle is more than 3.7m wide | |

1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge (for alternative requirements for a mobile crane see (Note 7))

2. OVERSIZE sign 3 fitted at the front and rear

3. Revolving amber beacon fitted so that it is visible to approaching traffic if the vehicle is more than 3.7m wide

1 Flags:

- must be fluorescent yellow

- must be at least 400mm long x 300mm wide.

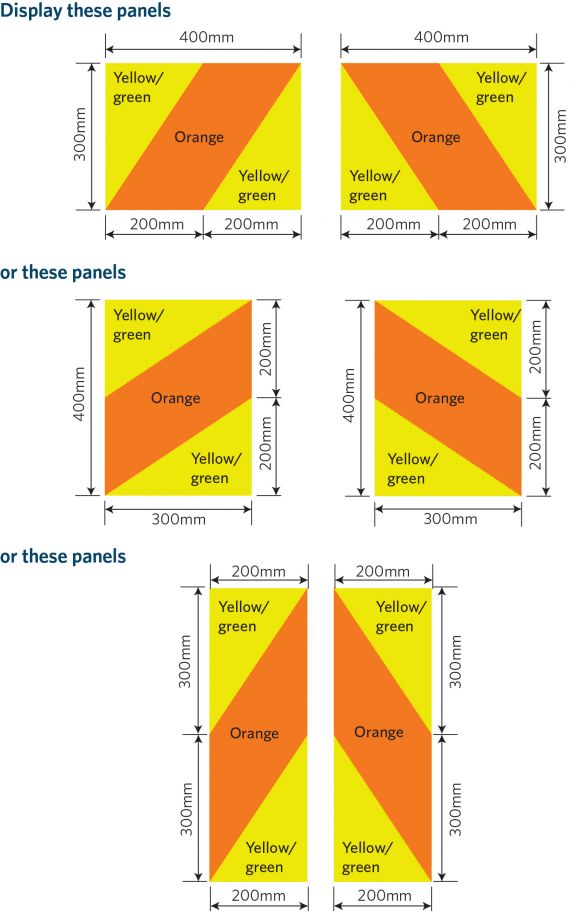

2 Hazard warning panels:

- must be reflective yellow-green with a reflective orange diagonal stripe

- comply with AS/NZS 1906.1:2007

- be frangible for those portions which extend beyond the vehicle’s limits (frangible means breakable or readily deformable)

- must be of at least the minimum dimensions and the colours specified in Table 2-2-4.

3 OVERSIZE sign:

- must be black lettering on a yellow-green background

- must be at least 300mm x 1100mm in size

- be frangible if any part of the sign extends beyond the body or load of the vehicle, whichever it is attached to (frangible means breakable or readily deformable)

- may be in two parts: OVER and SIZE.

Figure 2-2-1. Hazard panel details

Figure 2-2-2. Hazard panel location and orientation

Figure 2-2-3. Vehicle categories and width/forward distance thresholds

For the purposes of this figure, vehicles with a width less than 2.55m are deemed to have a width of 2.55m and vehicles with a forward distance of less than 8.5m are deemed to have a forward distance of 8.5m.

Figure 2-2-4. Dimensions for rigid heavy vehicles

(Note: Red text indicates a dimension change in VDAM 2016)

Figure 2-2-5. Sample 50MAX proforma entry certification and permit application declaration and HPMV proforma entry certification and permit application declaration

|

Summary of legislation

Applicable legislation

Mandatory equipment

1. A rigid vehicle, or an articulated bus, with a GVM of 3501kg or more that exceeds the dimensions in Table 2-2-3 must meet the requirements in Table 2‑2‑4.

2. A vehicle may exceed the dimensions in Table 2-2-3 only if it is a vehicle operating on a valid permit, exemption or approval.

Page amended 1 June 2019 (see amendment details).

2-3 Heavy vehicle equipment

Reasons for rejection

Mandatory equipment

1. An outrigger fitted to a vehicle does not have a locking device to prevent its inadvertent extension or separation .

2. The A vehicle recovery service hook truck or stinger-lift truck does not have its manufacturer’s stated lifting capacity clearly displayed, in kilograms, at the rear of the vehicle in letters and figures not less than 30mm high, rounded to the nearest 50kg

Condition and performance

3. A vehicle of class NB or class NC that is fitted with a swivelling (or knuckle boom) crane for loading the vehicle or a trailer towed by the vehicle does not have either:

a) a locking device fitted to each outrigger that is able to be seen in a locked position when an outrigger is retracted, or

b) a visual or audible alarm to warn the driver if an outrigger is not in the fully retracted position (Note 2).

4. An outrigger locking device is bent, worn or otherwise damaged or deteriorated so that it is not effective.

5. An outrigger locking device does not lock the outrigger in its retracted position.

Note 1 Definitions

Outrigger means, in relation to a vehicle fitted with a crane or a hoist, a device fitted to the vehicle that extends and stabilises the vehicle while the crane or hoist is in use.

Hook truck means a vehicle recovery service vehicle with a crane hoist that partially lifts the vehicle to be recovered, which is then towed in this position.

Stinger-lift truck means a recovery service vehicle with an arm that partially lifts the vehicle to be recovered, which is then towed in this position.

Vehicle recovery service vehicle means a vehicle used in a vehicle recovery service for towing or transporting on a road any motor vehicle; does not include a vehicle that is not designed or adapted for the purpose of towing or carrying motor vehicles.

Lifting gear means, in relation to a vehicle recovery service vehicle, any equipment used to lift another vehicle, and includes a towing connection.

Note 2

An alarm must be visible or audible from the driver’s seating position, and the alarm must operate when the vehicle’s engine is running, except when the parking brake is fully applied or when the gear selector of a vehicle with an automatic transmission is in the ‘park’ position.

Summary of legislation

Applicable legislation

Mandatory equipment

1. An outrigger fitted to a vehicle must have a locking device to prevent its inadvertent extension or separation.

2. The manufacturer’s stated lifting capacity of a hook truck or stinger-lift truck must be clearly displayed, in kilograms, at the rear of the vehicle in letters and figures not less than 30 mm high, rounded to the nearest 50kg.

Condition and performance

3. A vehicle of class NB or class NC that is fitted with a swivelling (or knuckle boom) crane for loading the vehicle or a trailer towed by the vehicle must be:

a) fitted with a locking device to each outrigger that is able to be seen in a locked position when an outrigger is retracted, or

b) equipped with a visual or audible alarm to warn the driver if an outrigger is not in the fully retracted position.

4. An alarm must be visible or audible from the driver’s seating position, and the alarm must operate when the vehicle’s engine is running, except when the parking brake is fully applied or when the gear selector of a vehicle with an automatic transmission is in the ‘park’ position.

5. An outrigger locking device must be effective.