Vehicle structure

3-1 Structure (incl. frontal impact)

Reasons for rejection

Condition

1. The structure of the vehicle (shaded areas of Figure 3-1-2) has visible:

a) deformation from the original shape that has affected the vehicle’s structural integrity (Note 1) (Note 3) (Note 9) (Figure 3-1-4), or

b) cracking, or

c) fracture, or

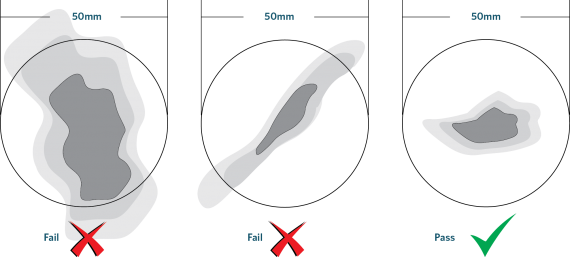

d) corrosion or wood rotting damage (Note 2) that is individually larger than 50mm in diameter (Figure 3-1-1), or

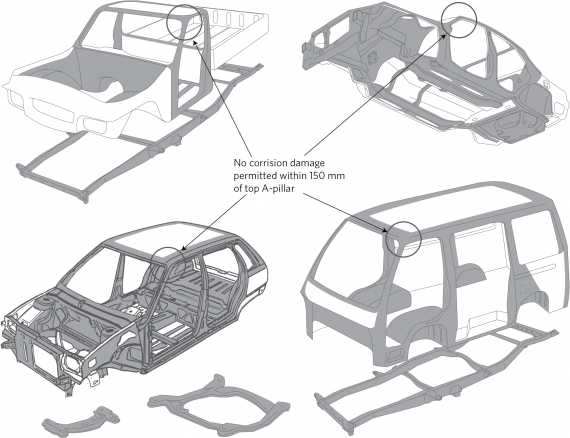

e) corrosion or wood rotting damage within 150mm of the top of an A-pillar (Figure 3-1-2), or

f) any corrosion or wood rotting that the inspector considers has caused weakening of a load-bearing structure (Note 6), or

g) poor repairs that have not returned the structure to within a safe tolerance of when it was manufactured (Note 3) (Note 6), eg:

i. filler has been used in an attempt to conceal any damage or deformation of a component

ii. a high strength steel component has been heated

iii. a component has been strengthened.

Modification

- see Note 5 and Introduction 3.1.2: Note 3)

2. The performance of the frontal impact occupant protection system may have been affected by a modification, including an added or removed object, fitting or component, after the vehicle was manufactured if the vehicle has a GVM of 2500 kg or less and:

a) is:

i. a class MA motor vehicle manufactured from 1 March 1999, or

ii a class MA motor vehicle that was less than 20 years old when it was first registered in New Zealand on or after 1 April 2002, or

iii a class MB or MC motor vehicle manufactured from 1 October 2003, and

b) is not excluded from the requirements for LVV specialist certification (Table 3-1-1).

3. A modification affects the vehicle structure – including an object or fitting affixed after manufacture that is welded to the chassis, sub-frame, cross-member or body of a monocoque structure (Note 7), and

a) is not excluded from the requirements for LVV specialist certification (Table 3-1-1), and

b) is missing proof of LVV specialist or accepted overseas certification, ie:

i. the vehicle is not fitted with a valid LVV vehicle certification plate, or

ii. the operator is not able to produce a valid modification declaration or authority card

iii. the vehicle has not been certified to an accepted overseas system as described in Technical bulletin 13 .

Note 1

The structure of a vehicle may incorporate crumple zones that form part of a frontal impact occupant protection system.

Note 2

Corrosion or wood rotting damage is where a metal or wooden structure has been eaten away and could be seen as bubbling, or pitting of the steel or by water damage, delamination or swelling of a wooden surface. The outward signs of such damage is typically displayed by the lifting, bubbling or discolouring of painted surfaces. In extreme cases, the area affected by the damage will fall out and leave a hole.

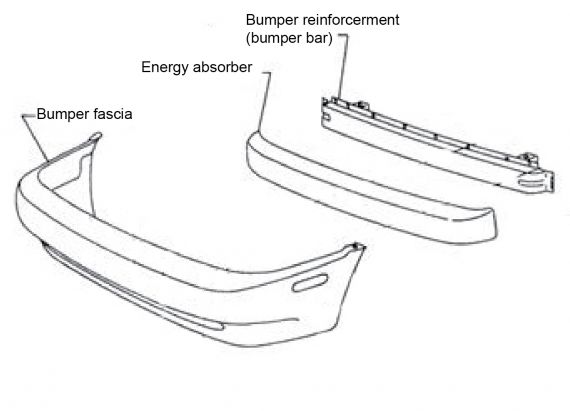

Bumper bar means either the part inside a plastic bumper or a complete metal bumper as used on older vehicles. The bumper fascia (bumper cover) is not part of the bumper structure. It is the bumper reinforcement (also known as the bumper bar ) that is the actual bumper bar for inspection purposes (see Figure 3-1-3).

Note 3

The vehicle inspector may request additional relevant information from a repairer or other relevant person. The vehicle inspector should withhold the warrant of fitness if there is reason to believe that the vehicle has:

a) structural damage, or

b) inadequate structural repair(s), or

c) corrosion or wood rotting damage

to the extent that it could affect the vehicle’s structural strength or one of the vehicle’s safety requirements.

Note 5 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with equivalent undamaged or new structures, systems, components or equipment.

Note 6

Where the inspector is presented with a Nissan Terrano or Nissan Mistral vehicle of the type that is fitted with a two-layer (double skin) floor panel, the inspection procedure in Technical bulletin 2 must be followed.

Note 7

A body lift on a body/chassis vehicle (commonly a 4x4) always requires LVV certification.

Note 8

Rear bumper removal must still meet external projection requirements.

Note 9

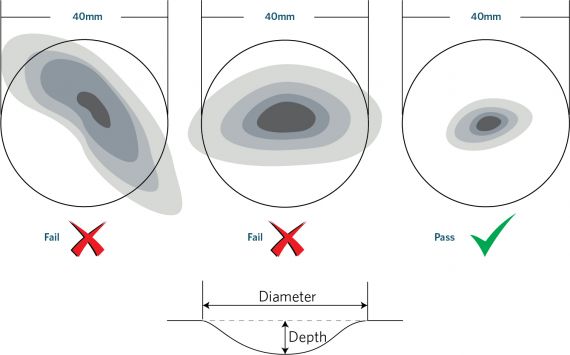

Dents smaller than 5mm deep and 40mm in diameter (to the outer edges of the crease), such as those caused by hail, in the pillars, cant rail or any other similar roof structure, should not be considered to affect the vehicles structural integrity. Any damage larger than above should be referred to a repairer for additional information (see Figure 3-1-4).

Table 3-1-1. Modifications that do not require LVV certification

Fitting of or modification to: | LVV certification is not required provided that: |

|---|---|

Addition of side windows into a panel van or goods van |

The modification was carried out on or after 1/3/1999, and the modification has not weakened the vehicle structure (Note 10). |

Aftermarket sunroof or roof vent/hatch | The fitting has not weakened the vehicle structure (Note 10) |

| A-frames |

See also Table 2-1-1 |

Auxiliary bars (including bull bars, nudge bars, external roll cages and winches) |

Note that an auxiliary bar that does not meet the above minimum requirements is unlikely to meet LVV requirements and so cannot be certified. See also Table 2-1-1 |

| Body kits | Fitting, removal or modification does not weaken the vehicle structure (Note 10). See also Table 2-1-1 |

| Bumper bar (removal and change) |

See also Table 2-1-1 |

Campervan conversions |

See also Table 7-1-1 and Table 7-5-1 |

| Cargo hoist/cargo lift platform |

See also Table 7-1-1 |

Fibreglass replacement panels (that are substituted for OE panels) |

See also Table 2-1-1 |

| Gear shift lever location |

See also Table 7-1-1 |

| Glass racks | Fitting, removal or modification does not weaken the vehicle structure (Note 10). See also Table 2-1-1 |

Seatbelt anchorages retrofitted after 1 January 1992 in vehicles of classes MA, MB, MC or after 1 March 1999, in vehicles of other classes |

|

Suspension braces (strut tower braces) |

See also Table 9-1-1 |

Front-mounted intercooler |

|

| Snorkels |

Note: it is recommended that snorkels are fitted with high strength adhesives rather than screws. |

Stereo equipment and speakers |

If fitted to the rear parcel shelf :

If fitted to a part of the vehicle other than the rear parcel shelf:

See also Table 7-1-1 and Table 7-5-1 |

| Ute trays | For vehicles registered in New Zealand on or after 1 January 2021: The fitting has not weakened the vehicle structure (Note 10); and the tray has no sharp edges and radiuses of not less than 3mm on every external edge. See also Table 2-1-1 |

| Wheelchair stowing devices | The device:

|

Fitting of or modification to: | LVV certification is never required: |

|---|---|

Roof mounted solar panels |

|

Roof racks | |

Towbars | |

Any modification for the purposes of law enforcement or the provision of emergency services |

Note 4

The following vehicles with a GVM of 2500kg or less must comply with a frontal impact occupant protection standard:

- Class MA motor vehicles manufactured on or after 1 March 1999

- Class MA motor vehicles that were less than 20 years old when they were first registered in New Zealand on or after 1 April 2002

- Class MB and MC motor vehicles manufactured on or after 1 October 2003.

Note 10

Heating, drilling, welding or cutting the vehicle structure, modifying a roof bow, or modifying any part of the structure would be considered to weaken it. Cutting a single layer of unstressed panel of sheet metal (i.e. roof) is not considered to weaken the vehicle structure. Drilling a hole suitable for a child restraint top tether does not require LVV certification.

Note 11

A pedestrian trap is any part of a vehicle that may hook, catch or pull/push a pedestrian into or under a vehicle. Vehicle components should be shaped to reduce injury to a pedestrian and to move the pedestrian away from the vehicle in the event of an incident.

Figure 3-1-1. Corrosion damage 50mm diameter limit

Figure 3-1-2. Corrosion damage as referred to in Condition above

These include chassis, cross-members and sub-frames, load-bearing monocoque body structures, body mounts and the body on a vehicle with a separate chassis. Other sections also contain Reasons for rejection and diagrams relating to specific vehicle components. See figures for corrosion limits to hinge and latch anchorages (section 6-1), seatbelt anchorages (section 7-5), and front or rear suspension anchorages (section 9-1).

Note that the diagram has been updated to take into account the more modern vehicle structures of common vehicles.

Figure 3-1-3. Bumper components

The bumper fascia (bumper cover) is not part of the bumper structure. It is the bumper reinforcement (also known as the bumper bar) that is the actual bumper bar for inspection purposes.

Figure 3-1-4. Deformation limits

Summary of legislation

Applicable legislation

Condition

1. The vehicle must be safe to be operated.

2. The components and materials must be fit for their purpose and within safe tolerance of their state when manufactured or modified.

3. The performance of a motor vehicle in relation to protecting occupants in a frontal impact collision must not be reduced below a safe tolerance by any factors, including corrosion, structural damage, material degradation, inadequate repair, the fitting of additional equipment, or the removal of equipment, taking into account:

a) the function of the additional equipment fitted to the motor vehicle after manufacture, and the measures taken to minimise the risk of injury from the equipment;

b) evidence that the motor vehicle is within the manufacturer’s operating limits.

Modification

4. A modification that affects the integrity of the vehicle structure must be inspected and certified by an LVV specialist certifier, unless the vehicle:

a) is excluded from the requirement for LVV specialist certification (Table 3-1-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 April 2024 (see amendment details)