In-service certification (WoF and CoF) - Heavy PSVs

Correct as at 27th April 2024. It may be superseded at any time.

1-1 VIN and chassis number

Important Ensure that the VIN or chassis number is recorded in full on the checksheet. This number must be:

Also refer to Table 1-1-1. Location of New Zealand VIN numbers, Figure 1-1-1. Structure of a VIN issued by the NZ Transport Agency and Figure 1-1-2. Structure of a VIN issued by the vehicle manufacturer. |

Reasons for rejection

Mandatory requirements

1. A vehicle first registered or re-registered in New Zealand before 1 April 1994 does not have a VIN or chassis number (Note 1) (Note 3).

2. A vehicle first registered or re-registered in New Zealand from 1 April 1994 does not have a VIN number (Note 1) (Note 3).

3. A VIN number is not valid (Note 1) (Note 2).

Condition

4. A VIN or chassis number has been (Note 1) (Note 3):

a) removed, or

b) erased, or

c) altered, or

d) defaced, or

e) obscured, or

f) destroyed, or

g) obliterated, or

h) affixed unlawfully or by unauthorised persons.

Note 1

The vehicle inspector must notify Waka Kotahi using the vehicle report form if there is reason to believe that the VIN or chassis number has been tampered with in any way.

The vehicle inspector must not issue a WoF/CoF/permit until approved by Waka Kotahi. Approval will usually include the issue or re-issue of a new VIN plate.

The vehicle inspector must not issue a WoF/CoF/permit if there is reason to believe that the VIN or chassis number has been tampered with in any way.

Refer the vehicle to a VIN issuing agent (VTNZ, VINZ, NZAA, Drivesure, CVC, i4Checkpoint). They will inspect the vehicle and seek approval from Waka Kotahi to issue or re-issue a VIN plate. Once the vehicle has been approved the vehicle may continue through the inspection process.

Note 2

A valid VIN is a unique number that has been assigned to the vehicle in the vehicle’s country of origin or by a person appointed by the NZTA. It consists of 17 characters that never contain the letters I, O or Q, and that is capable of being decoded to provide identifying information about the vehicle.

Note 3

If the vehicle is failed because the VIN/chassis is missing or unreadable, then 'not found' must be recorded in place of the VIN number on the check sheet.

Table 1-1-1. Location of New Zealand VIN numbers

Vehicle | Permitted VIN locations |

|---|---|

Vehicles that are not forward controlled (passenger cars and off-road passenger vehicles) |

|

Forward-controlled vehicles |

|

Goods vehicles and light omnibuses | Vehicle with a separate chassis:

Vehicle without a separate chassis:

|

If the vehicle is unfamiliar, and the VIN or chassis number cannot be located, the vehicle inspector should contact the manufacturer’s agent or the local VIN issuing agent (VTNZ, VINZ, NZAA, Drivesure, CVC, i4Checkpoint).

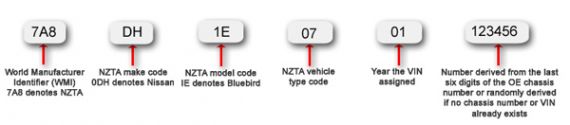

Figure 1-1-1. Structure of a VIN issued by the NZ Transport Agency

Pre-29 November 2009

Post-29 November 2009

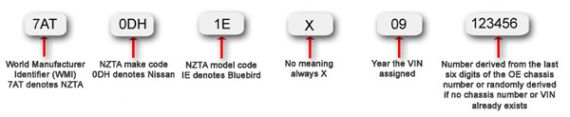

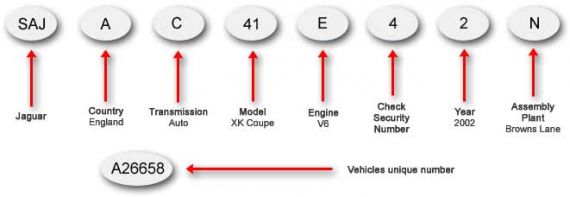

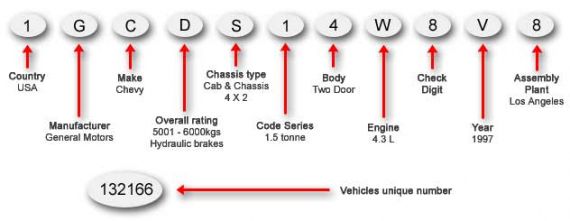

Figure 1-1-2. Structure of a VIN issued by the vehicle manufacturer

Car

Truck

Summary of legislation

Applicable legislation

Mandatory requirements

1. A vehicle first registered or re-registered in New Zealand before 1 April 1994 must have a chassis number or VIN.

2. A vehicle first registered or re-registered in New Zealand from 1 April 1994 must have a VIN.

Condition

3. A VIN or chassis number must not have been removed, erased, altered, defaced, obscured, destroyed, obliterated or affixed unlawfully, or be unauthorised.

Page amended 1 October 2022 (see amendment details).

1-2 Vehicle details

Reasons for rejection

1. The number on the registration plate(s) is not the same as stated on the licence label.

2. The licence label does not correctly describe the vehicle

- do not reject the vehicle if the label type is incorrect, eg 'B' or 'A'.

3. The WoF online or LATIS system does not correctly describe the vehicle.

Page added 1 October 2020 (see amendment details)

2 Vehicle exterior

2-1 External projections

Reasons for rejection

Condition and performance

1. The risk of a component (Note 5) hooking a vehicle, or hooking or grazing a person, has not been minimised, eg a bonnet or bumper has been removed, exposing sharp, moving or hot components.

2. An ornamental object or fitting (Note 2) protrudes in such a way that it is likely to injure a person.

3. A protruding object or fitting that has a functional purpose (Note 3) is not installed so that the risk of causing injury to a person is minimised, eg the object or fitting:

a) is of excessively heavy construction for the purpose for which it has been fitted, or

b) has sharp corners, or

c) slopes forward, unless this is necessary to fit the contours of the vehicle, or

d) has an unnecessarily wide gap between the object or fitting and the front of the vehicle, or

e) exceeds the vehicle’s width by more than 100mm on either side, other than side mounted glass sheet transport racks and collapsible side mirrors, or

f) is a glass sheet transport rack that is not fitted with a front flaring to minimise the risk of injury to a person.

4. A protruding component, object or fitting is not securely attached to the vehicle.

5. A protruding object or fitting adversely affects the driver’s vision or control.

Modifications

6. A modification (Note 4) affects an external projection – including a protruding object or fitting that has a functional purpose and affects the driver’s vision or control of the vehicle, and

a) is not excluded from the requirements for specialist certification (Table 2-1-1), and

b) is missing proof of specialist or accepted overseas certification, ie:

i. the vehicle is not fitted with a valid vehicle certification plate (eg low volume vehicle plate or heavy vehicle certification plate/label), or

ii. the operator is not able to produce a valid modification declaration or authority card

iii. the vehicle has not been certified to an accepted overseas system as described in Technical bulletin 13 .

Note 1

The external projections requirements relate to the design and maintenance of objects and fittings that protrude from the exterior of the motor vehicle with regard to the safety of other motor vehicles, pedestrians and cyclists. The attachment of such objects and fittings to the vehicle is addressed in the Vehicle structure section of this manual.

Note 2

Ornamental object or fitting means an object or fitting that does not have a practical purpose, eg bonnet emblems.

Note 3

Functional object or fitting means an object or fitting that has a practical purpose, eg panniers, pack racks, spare wheel carriers, and so on.

Note 4

Modify means to change a vehicle from its original state by altering, substituting, adding or removing any structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with equivalent undamaged or new structures, systems, components or equipment.

Note 5

Components include damaged, corroded and exposed body panels.

Note 6

The following vehicles with a GVM of 2500kg or less must comply with a frontal impact occupant protection standard:

- Class MA motor vehicles manufactured on or after 1 March 1999

- Class MA motor vehicles that were less than 20 years old when they were first registered in New Zealand on or after 1 April 2002

- Class MB and MC motor vehicles manufactured on or after 1 October 2003.

Note 7

Rear bumper removal must still meet external projection requirements.

Table 2-1-1. Modifications that do not require specialist certification

Fitting of or modification to: | Specialist certification is not required provided that: |

|---|---|

Body kits and components |

See also Table 3-1-1. |

Side racks (for glass or other sheet materials) |

See also Table 3-1-1. |

Bumper bar (removal and change) (Note 7) |

See also Table 3-1-1. |

Auxiliary bars (including bull bars, nudge bars, external roll cages and A-frames [or similar]) |

Note that an auxiliary bar that does not meet the above minimum requirements is unlikely to meet LVV requirements and so cannot be certified. See also Table 3-1-1. |

| A-frames |

See also Table 3-1-1. |

| Bonnet emblems or badges |

|

| Bonnet pins |

|

| Ute trays | For vehicles first registered in New Zealand before 1 January 2021:

For vehicles first registered in New Zealand on or after 1 January 2021:

See also Table 3-1-1. |

Fitting of or modification to: | Specialist certification is never required: |

|---|---|

Aerials |

|

Roof-mounted solar panels | |

Trunk racks | |

Roof-mounted wheelchair winch | |

Roof racks (except heavy PSVs) | |

Additional or substituted rear-view mirrors | |

Any modification for the purposes of law enforcement or the provision of emergency services |

Summary of legislation

Applicable legislation

Permitted equipment

1. A motor vehicle may be fitted with a protruding ornamental or functional object or fitting.

Condition and performance

2. A protruding ornamental object or fitting must not be likely to injure a person.

3. A protruding object or fitting that has a functional purpose must be installed so that the risk of the object or fitting causing injury to a person is minimised.

4. Components of a motor vehicle, including damaged or corroded body panels, must be such that the risk of their hooking a vehicle, or hooking or grazing a person, is minimised.

5. A protruding object or fitting must not adversely affect driver vision or driver control.

Modifications

6. A modification that affects an external projection must be inspected and certified by a specialist certifier, unless the vehicle:

a) is excluded from the requirement for specialist certification (Table 2-1-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 29 April 2020 (see amendment details).

2-2 Dimensions

Reasons for rejection

Mandatory requirement

1. A rigid vehicle (Note 1) with a GVM of 3501kg or more exceeds the dimension requirements set out in Table 2-2-3 and is not a vehicle operating on a valid permit, exemption or approval.

2. A bicycle rack on a public transport vehicle of class MD3, MD4 or ME is:

a) not centrally mounted from the longitudinal centre of the vehicle, or

b) more than 1200mm from the forwardmost point of the vehicle, or

c) wider than 2100mm (see Figure 2-2-2).

Note 1

Rigid vehicle means a vehicle that does not have any pivot points to allow any part of the chassis of the vehicle to move or rotate in relation to any other part of the chassis of the vehicle, and includes an articulated bus and a pivot steer vehicle.

Note 2

Road controlling authority means the authority, body or person having control of the road (eg Waka Kotahi, regional council or an authorized delegate).

Note 3

A bicycle rack fitted to the front of a vehicle of class MD3, MD4 or ME is not included in determining the overall length or forward distance of the vehicle provided the vehicle complies with the applicable low speed turning performance measures in section 3.5(2) of Land Transport Rule: Vehicle Dimensions and Mass 2016, or is exempted under Land Transport Rule: Vehicle Dimensions and Mass 2016 (Bicycle Racks on Urban Buses) Class Exemption Notice 2022

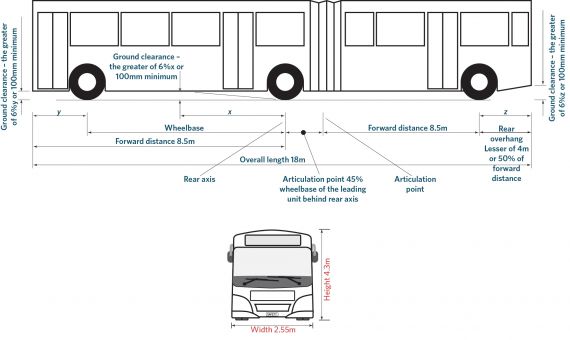

Table 2-2-3. Dimension requirements for heavy rigid vehicles

Dimension | Maximum distance | Comments |

|---|---|---|

Width | 2.55m , or 1.275m from each side of the longitudinal centreline of the vehicle | Measurement does not include:

|

Overall length | 11.5m (tow coupling fitted) 12.6m (no tow coupling fitted) 13.5m (rigid bus with three axles where the rearmost axle is a single-tyred steering axle that is: a) either positively and continuously linked to the front steer (except may be locked for reverse and high-speed operation); or b) automatically locked at a speed of 30 km/h in the straight-ahead position and for reverse operations) 18m (articulated bus) | Measurement does not include:

|

Height | 4.3m | |

Forward distance | 8.5m (tow coupling fitted) 9.5m (no tow coupling fitted) 8.5m (for both front and rear sections of an articulated bus) | Forward distance is measured from:

Measurement does not include collapsible mirrors. A vehicle with a retractable axle must meet the dimension requirements whether the axle is in contact with the road or in the retracted position. |

Rear overhang | The lesser of 4m or 70% of wheelbase where rearmost axle is a non-steering axle The lesser of 4.25m or 70% of wheelbase where rearmost axle is a steering axle The lesser of 4.5m or 72% of wheelbase of a rigid bus with overall length exceeding 12.6m The lesser of 4m or 50% of forward distance (articulated bus) 4m (for a vehicle first registered anywhere before 1 December 1989) | Rear overhang is measured from the rear axis to the rear of the vehicle. A vehicle with a retractable axle must meet the dimension requirements whether the axle is in contact with the road or in the retracted position. |

Ground clearance | The greater of 100mm or 6% of the distance from the nearest axle to the point where the ground clearance is measured | Measurement does not include flexible mudflaps, wheels, tyres or devices designed to discharge static electricity. |

Front overhang | 3m | Front overhang is measured from the front edge of the driver’s seat in the rearmost position to the front of the vehicle. |

Articulated vehicle point of attachment | No further rearward than centre of rear axle (where rear axle set consists of only one axle) No further than 300mm rearward of rear axis (where rear axle set consists of more than one axle) | Does not apply to articulated buses. |

Tow coupling position (articulated bus only) | 45% of wheelbase of the leading unit | The tow coupling position is the distance rearward from the vehicle’s rear axis to the centre of the tow coupling. |

Turning circle | 25m outside diameter 10.6m inside diameter (articulated bus only) | The vehicle must complete a 360-degree turn in either direction. No part of the vehicle (other than collapsible mirrors) must extend beyond the outside diameter or into the inside diameter. |

Figure 2-2-1. Dimensions for articulated bus

(Note: Dimensions in red updated in VDAM 2016)

Figure 2-2-2. Bicycle rack bus dimensions

Summary of legislation

Applicable legislation

Mandatory requirement

1. A rigid vehicle, or an articulated bus, with a GVM of 3501kg or more that exceeds the dimensions in Table 2-2-3 must be operating on a valid permit, exemption or approval.

Page amended 7 October 2022 (see amendment details).

3 Vehicle structure

3-1 Structure

Reasons for rejection

Mandatory equipment

1. An open-bodied vehicle that entered service as a PSV in New Zealand on or after 1 January 2001:

a) has side walls that are less than 450mm above the highest point of the uncompressed seat cushion on the open-bodied part of the vehicle, or

b) does not have a permanent framework in addition to the side walls to provide reasonable protection for the occupants in the case of the vehicle rolling over, or

c) on any upper deck does not have drains to prevent water from collecting on it or draining into the body of the vehicle.

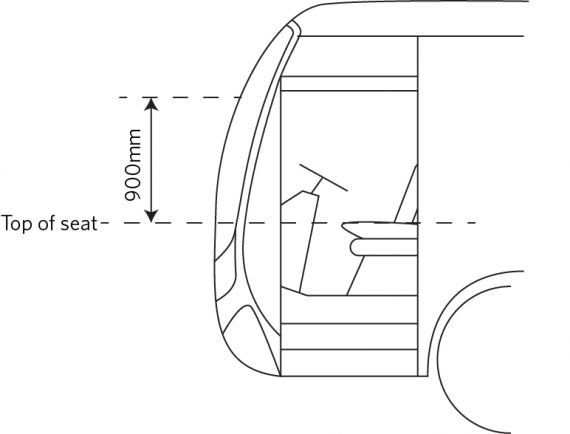

2. On a heavy open-bodied vehicle that entered service as a PSV in New Zealand on or after 1 July 2001:

a) a front screen to extend above the upper floor level:

i. is missing, or

ii. does not extend to at least 1m above the highest point of the uncompressed seat cushion, or

iii. does not extend to at least 1.95m above the upper floor level, or

b) a railing, or another structure, to extend above the side walls:

i. has a railing above the side walls through which a sphere of 125mm diameter can be passed, or

ii. has a railing that does not extend above the side walls to a height of at least 610mm above the highest point of the uncompressed seat cushion.

Condition

3. Refer to heavy vehicle pages.

4. The structural strength of a PSV has been reduced so that it does not provide reasonable protection for the occupants in the event of roof or wall deformation resulting from the vehicle rolling over, eg:

a) structural parts of the superstructure have been removed or substituted with parts that are of insufficient strength or not fit for purpose.

5. A body-to-chassis attachment, such as a weld, or fastener is:

a) missing, or

b) loose, or

c) cracked, or

d) broken, or

e) significantly corroded, or

f) otherwise in poor condition.

Modification

6. Refer to heavy vehicle pages.

Summary of legislation

Applicable legislation

Mandatory equipment

1. An open-bodied vehicle that entered service as a PSV in New Zealand on or after 1 January 2001 must:

a) on the open-bodied part of the vehicle have side walls that extend at least 450mm above the highest point of the uncompressed seat cushion, and

b) have a permanent framework to provide reasonable protection for the occupants in the case of the vehicle rolling over, and

c) on any upper deck have drains to prevent water from collecting on it or draining into the body of the vehicle.

2. A heavy open-bodied vehicle that entered service as a PSV in New Zealand on or after 1 July 2001 must have:

a) a front screen that extends at least 1m above the highest uncompressed seat cushion, and at least 1.95 m above the upper floor level, and

b) a railing, or another structure through which a sphere of 125mm diameter cannot be passed, that extends above the side walls to a height of 610mm above the highest point of the uncompressed seat cushion.

Condition

3. Refer to heavy vehicle pages.

4. The structural strength must be maintained throughout the service life of the PSV.

5. The superstructure must be of robust design, and made of materials fit for the purpose.

6. The body of a PSV must be fit for its purpose and securely fixed to the chassis.

7. The structural strength of a PSV must be sufficient to provide reasonable protection for the occupants in the event of roof or wall deformation resulting from the vehicle rolling over.

Modification and repair

8. Refer to heavy vehicle pages.

3-2 Stability

Reasons for rejection

Modification and repair

1. A modification or repair since 1 July 2000 affects the vehicle stability and:

a) is not excluded from the requirements for HVS certification (Table 3-2-1), or

b) the modification is not for the purpose of law enforcement or the provision of emergency services, or

c) is missing proof of HVS certification, ie:

i. the vehicle was modified or repaired before the last CoF inspection and no LANDATA record has been entered, or

ii. the vehicle was modified or repaired since the last CoF inspection and no valid LT400 form from an HVS certifier has been presented.

Table 3-2-1. Requirements for HVS certification

|

HVS certification is required |

HVS certification is not required |

|---|---|

|

1. Fitting of components to the roof, eg a roof rack or an air conditioning unit. 2. Changes in floor height or geometry, eg due to changes to suspension, wheel or tyre size. |

1. Any repair or modification not listed in the left-hand column unless the vehicle inspector considers that certification is required because the modification or repair has affected the vehicle’s safety performance (a second opinion from an expert may be needed). |

Summary of legislation

Applicable legislation

- Land Transport Rule: Passenger Service Vehicles 1999

- Land Transport Rule: Vehicle Standards Compliance 2002.

Modification and repair

1. A modification or repair, on or after 1 July 2000, that affects the stability of a heavy PSV must be inspected and certified by an HVS certifier, unless the vehicle:

a) is excluded from the requirements for HVS certification (Table 3-2-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 April 2023 (see amendment details)

3-3 Heavy PSV roof racks

Reasons for rejection

Mandatory requirement

1. A roof rack does not have a sign or plate on the left-hand side.

2. A roof rack sign or plate does not state:

a) the purpose of the roof rack, if other than for general baggage, or

b) the maximum weight it is allowed to carry, or

c) the manufacturer of the roof rack, or

d) at least one of the following:

i. the make, model and registration number of the PSV to which it is fitted

ii. vehicle identification number or chassis number of the PSV to which it is fitted

iii. if rated and certified either by the vehicle manufacturer or by a heavy vehicle specialist certifier for a vehicle model, the approval for that vehicle model.

Condition

3. The roof rack sign or plate is:

a) not securely fitted, or

b) not legible.

4. A roof rack that is fitted to a heavy PSV:

a) is not fitted as appropriate for that particular vehicle make and model, or

b) is not fitted securely, eg fastenings are missing, broken or loose, or

c) shows signs of significant deterioration that affects its ability to hold or retain the rated load.

Modification and repair

5. A modification or repair affects the roof rack, or a roof rack has been fitted, and:

a) is not excluded from the requirements for HVS certification (Table 3-3-1), or

b) the modification is not for the purpose of law enforcement or the provision of emergency services, or

c) is missing proof of HVS certification (other than one rated and certified by the vehicle manufacturer), ie:

i. the vehicle was modified or repaired before the last CoF inspection and no LANDATA record has been entered, or

ii. the vehicle was modified or repaired since the last CoF inspection and no valid LT400 form from a HVS certifier of category HVEC, HVMC or HVIC has been presented.

Table 3-3-1. Requirements for HVS certification

|

HVS certification is required |

HVS certification is not required |

|---|---|

|

Fitting a roof rack (other than one rated and certified by the vehicle manufacturer) |

Any repair or modification not listed in the left-hand column unless the vehicle inspector considers that certification is required because the modification or repair has affected the vehicle’s safety performance (a second opinion from an expert may be needed, eg the manufacturer’s representative or a reputable workshop). |

Summary of legislation

Applicable legislation

- Land Transport Rule: Passenger Service Vehicles 1999

- Land Transport Rule: Vehicle Standards Compliance 2002.

Mandatory requirement

1. A roof rack that is fitted to a heavy PSV must have a sign or plate on the left-hand side stating:

a) the purpose of the roof rack, if other than for general baggage, and

b) the maximum weight it is allowed to carry, and

c) the manufacturer of the roof rack, and

d) either:

i. the make, model and registration number of the PSV to which it is fitted, or

ii. vehicle identification number or chassis number of the PSV to which it is fitted, or

iii. if rated and certified by the vehicle manufacturer or a category HVEC, HVIC or HVMC heavy vehicle specialist certifier for a vehicle model, the approval for that vehicle model.

Condition

2.A roof rack fitted to a heavy PSV must:

a) be fitted and rated as appropriate for that particular make and model of PSV, or

b) be rated and certified by a category HVEC, HVIC, or HVMC heavy vehicle specialist certifier and fitted in accordance with their instructions.

3. A roof rack that is fitted to a heavy PSV must be fitted in accordance with instructions by a category HVEC, HVIC or HVMC heavy vehicle specialist certifier.

Modification

4. A modification that affects the roof rack of a heavy PSV, including the fitting of a roof rack, must be inspected and certified by an HVS certifier, unless the vehicle:

a) is excluded from the requirements for HVS specialist certification (Table 3-3-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 April 2023 (see amendment details)

4 Lighting

4-1 Headlamps

Reasons for rejection

Mandatory and permitted equipment

1. A vehicle other than class LE is not fitted with one pair of dipped-beam headlamps.

2. A vehicle other than class LE is fitted with more than:

a) one pair of dipped-beam headlamps (Note 10) , or

b) two pairs of dipped-beam headlamps if the vehicle was first registered anywhere between 1 January 1977 and 31 March 1980, or

c) two pairs of main-beam headlamps.

3. A vehicle other than class LE is fitted with a headlamp that is not in a pair.

4. A vehicle of class LE is not fitted with one dipped-beam headlamp.

5. A vehicle of class LE is fitted with more than:

a) two dipped-beam headlamps, or

b) two main-beam headlamps.

6. A vehicle (eg a vintage or veteran vehicle) does not meet standard headlamp requirements, and:

a) does not have a valid vehicle identity card with a lighting equipment endorsement, or

b) does not meet the conditions of the lighting equipment endorsement in its vehicle identity card.

7. A device that allows the headlamps to flash alternately is fitted to a vehicle that is not an emergency vehicle or a pilot vehicle.

8. A vehicle is fitted with a dipped-beam headlamp where the maximum intensity of the beam is projected to the right.

Condition

(see Note 5)

9. A lamp is insecure, obscured, or contains dirt or moisture in the form of large droplets, runs or puddles.

10. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

11. A lens or reflector is damaged or has deteriorated so that light output is reduced.

12. A main-beam headlamp warning device is obscured from the driver’s vision.

Performance

13. When switched on, a headlamp emits a light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity from the other lamp in a pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead, eg due to modification, deterioration or an incorrect light source, or

e) too bright, eg due to the fitment of an HID or LED conversion kit (Note 8) or other incorrect light source (see also reason for rejection 19 below).

14. When the dipped-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than two lamps operate on dipped beam, or

c) more than four lamps operate on dipped beam on a vehicle first registered anywhere between 1 January 1977 and 31 March 1980, or

d) the light beam produces an incorrect beam pattern, is not focused, or is reduced or altered, or

e) the centreline of the light beam is too far to the left or slopes down too far so that the headlamp is no longer capable of illuminating the road at least 50m ahead (Figure 4-1-2), or

f) the centreline of the light beam projects to the right of the vehicle’s centreline, or projects from the lamp at an angle other than:

i. as specified by the vehicle or lamp manufacturer, or

ii. as specified in Table 4-1-1.

15. When the main-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than two lamps operate on main beam on a class LE vehicle, or

c) more than four lamps operate on main beam on a vehicle of group M or N, or

d) a vehicle first registered anywhere between 1 February 1977 and 31 March 1980 has a second pair of dipped-beam headlamps that continue to operate, or

e) the centreline of the light beam projects to the right of the vehicle’s centreline or up from the horizontal, or

f) the light beam produces an incorrect beam pattern, is not focused or is reduced or altered, or

g) the lamps are not capable of being switched to dipped beam or turned off from the driver’s seating position, or

h) a main-beam headlamp warning device, if fitted as original equipment, does not indicate to the driver that the main-beam headlamps are switched on.

16. A device fitted to a vehicle that allows the headlamps to flash alternately:

a) does not indicate to the driver that the device is activated, or

b) flashes:

i. faster than two flashes per second, or

ii. slower than one flash per second, or

iii. at a varying frequency.

17. Where a headlamp comprises an array of light sources (eg LEDs) fewer than 75% of these operate.

Modifications

18. An overlay has been applied that reduces or distorts the light emitted from the lamp (eg a tinted cover).

19. A headlamp is retrofitted with a type of light source other than that specified by the vehicle manufacturer or the headlamp manufacturer (eg a headlamp designed for a halogen bulb is fitted with any other type of light source such as an HID or LED bulb, or any other light source such as LED strips or non-OEM angel eyes) (Note 8).

20. Retrofitted headlamps are not fitted:

a) as a pair, or

b) symmetrically, or

c) as far towards each side of the vehicle as is practicable.

21. A retrofitted dipped-beam headlamp on a vehicle with a GVM of 12,000 kg or less is positioned at a height exceeding 1.2m from the ground (Note 9).

Note 1

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps are considered retrofitted (ie non-OE).

Note 2

If the dipped-beam headlamps are able to be adjusted from the driver’s seating position, the alignment must be checked with the adjustment at its highest position.

Note 3

If the vehicle is fitted with self-levelling suspension, the alignment must be checked with the suspension at its normal level.

Note 4

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Headlamp means a lamp designed to illuminate the road ahead of a vehicle, and that is a:

a) dipped-beam headlamp (single lamp), or

b) main-beam (high-beam) headlamp (single lamp), and includes a driving lamp, or

c) combination of a dipped-beam headlamp and a main-beam headlamp (dual-lamp unit).

Dipped-beam headlamp means a headlamp that is designed to emit a dipped beam, which is a beam of light that is angled downwards in such a way that it prevents undue dazzle or discomfort to oncoming drivers and other road users.

Main-beam headlamp means a headlamp that is designed to illuminate the road over a long distance ahead of the vehicle.

Note 5

If a headlamp is fitted with a readily removable cover, other than a clear protective cover, this must be removed for inspection of the headlamp.

Note 6

A vehicle originally manufactured with a headlamp arrangement that differs from what is required or permitted in this section may retain the original headlamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 7

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle.

Note 8

A high-intensity discharge (HID or Xenon HID) or LED conversion kit consists of an HID or LED bulb which fits into the original headlamp unit in place of the original bulb with no change to the headlamp lens, reflector or housing.

It is illegal to fit an HID or LED conversion kit to a vehicle as it brings the headlamp out of standards compliance by producing poor beam patterns and light that is often far too bright to be safe. The bulbs can also produce light that is noticeably blue and not the required substantially white or amber colour. Vehicle and headlamp manufacturers do not permit this modification, and these kits cannot be LVV certified.

It is permitted to replace a complete halogen headlamp unit with a complete HID or LED headlamp unit. If the vehicle is required to meet an approved safety standard for headlamps, only approved headlamps can be retrofitted (see Figure 4-1-1).

Note 9

The dipped-beam headlamps may be positioned at a height exceeding 1.2m if a road maintenance implement (eg, snowplough or roadsweeper) fitted to the front of the vehicle would obscure headlamps placed at a height of 1.2m or less.

Note 10

It is acceptable for a pair of dipped-beam headlamps to consist of one symmetric and one asymmetric dipped-beam headlamp. However, in some cases this may result in one lamp being noticeably brighter than the other lamp in the pair. In that case, the vehicle inspector may determine that the dipped beams differ noticeably in light intensity, and the lamps fail the inspection. Note that a beamsetter’s luxmeter cannot measure the light intensity of a dipped beam headlamp.

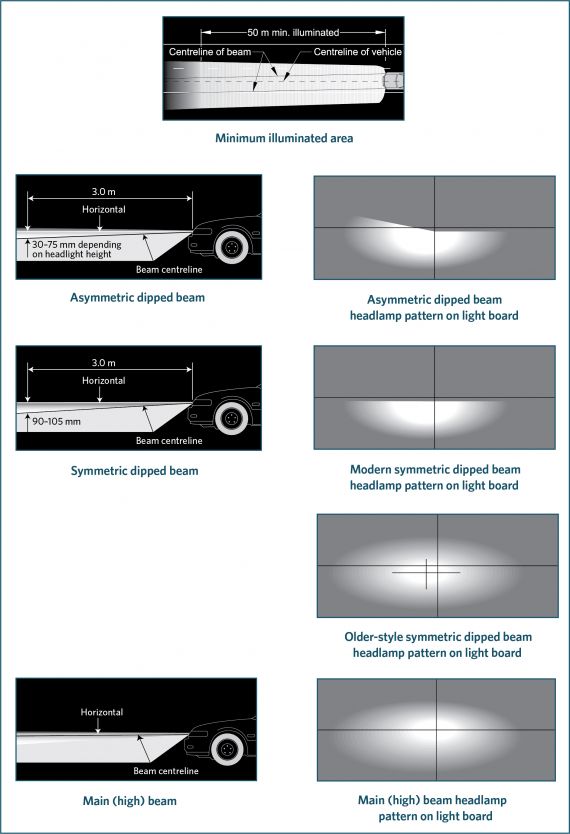

Table 4-1-1. Allowable dipped-beam headlamp alignment

Headlamp type | Distance from ground to centre of light source | Dip rate of beam centre: | |||

|---|---|---|---|---|---|

Percent (%) | mm/3 m | Degrees (°) | |||

EITHER | Any headlamp dipped beam | N/A | That specified by the vehicle or headlamp manufacturer | ||

OR | Headlamp with an older style symmetric dipped-beam pattern (see Figure 4-1-2) | N/A | 3.0–3.5 | 90–105 | 1.7–2.0 |

OR | Headlamp with a modern symmetric or asymmetric dipped-beam pattern and distance from ground to centre of light source (see Figure 4-1-2) | less than 0.8 m | 1.0–1.5 | 30–45 | 0.57–0.85 |

0.8–1.2 m | 1.0–2.0 | 30–60 | 0.57–1.15 | ||

more than 1.2 m | 2.0–2.5 | 60–75 | 1.15–1.43 | ||

Table 4-1-2. Dipped-beam angle conversions

Percent (%) | mm/3 m | Degrees (°) |

|---|---|---|

1.0 | 30 | 0.6 |

1.1 | 33 | 0.6 |

1.2 | 36 | 0.7 |

1.3 | 39 | 0.7 |

1.4 | 42 | 0.8 |

1.5 | 45 | 0.9 |

1.6 | 48 | 0.9 |

1.7 | 51 | 1.0 |

1.8 | 54 | 1.0 |

1.9 | 57 | 1.1 |

2.0 | 60 | 1.1 |

2.1 | 63 | 1.2 |

2.2 | 66 | 1.3 |

2.3 | 69 | 1.3 |

2.4 | 72 | 1.4 |

2.5 | 75 | 1.4 |

2.6 | 78 | 1.5 |

2.7 | 81 | 1.5 |

2.8 | 84 | 1.6 |

2.9 | 87 | 1.7 |

3.0 | 90 | 1.7 |

3.1 | 93 | 1.8 |

3.2 | 96 | 1.8 |

3.3 | 99 | 1.9 |

3.4 | 102 | 1.9 |

3.5 | 105 | 2.0 |

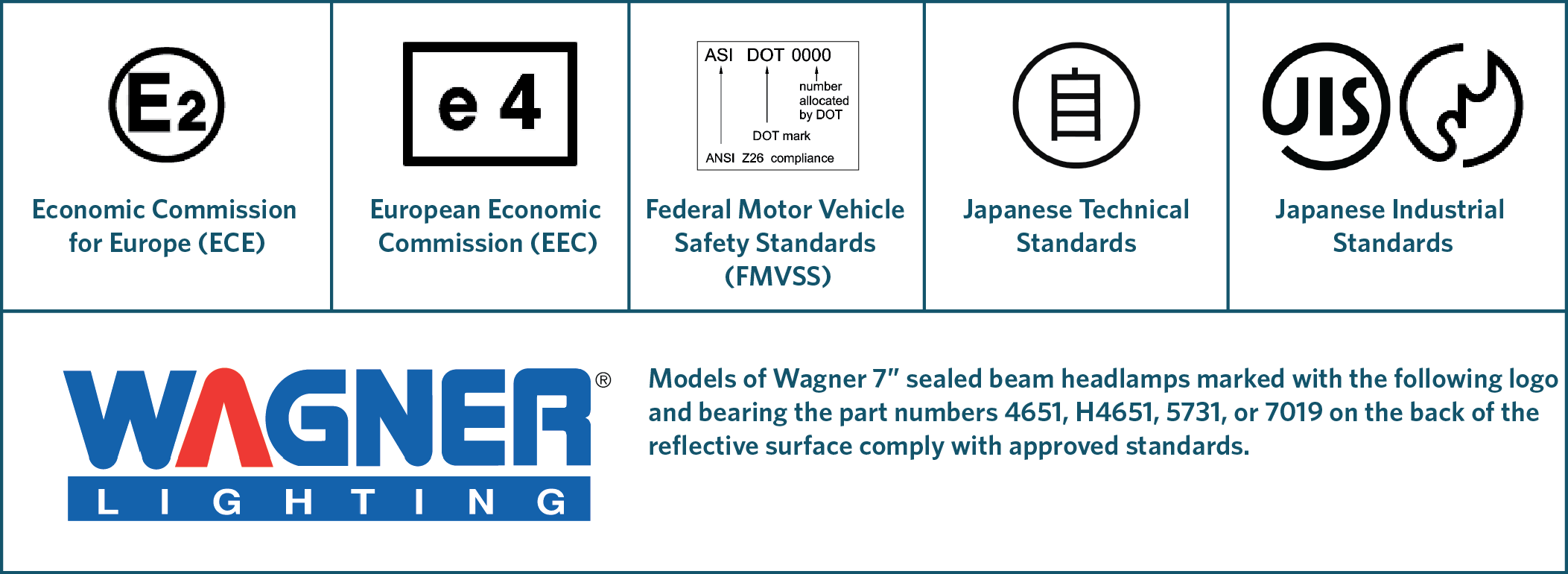

Figure 4-1-1. Approved headlamp standard markings

The following standard markings may assist in determining compliance with approved standards.

Vehicles required to comply with an approved headlamp standard are:

- vehicles of class MA and NA manufactured on or after 1 January 1992

- vehicles of class MB, MC, MD1, MD2, MD3, MD4, ME, NB and NC manufactured on or after 1 January 1996.

Figure 4-1-2. Minimum illuminated area

Summary of legislation

Applicable legislation

- Land Transport Rule: Vehicle Lighting 2004

- New Zealand Gazette, 28 August 1980, issue 103, page 2569.

Mandatory and permitted equipment

1. A vehicle other than of class LE:

a) must be fitted with one pair of dipped-beam headlamps, and

b) may be fitted with one or two pairs of main-beam headlamps.

2. A vehicle of class LE:

a) must be fitted with one or two dipped-beam headlamps, and

b) may be fitted with one or two main-beam headlamps.

3. A vehicle first registered anywhere between 1 February 1977 and 31 March 1980 may be fitted with a second pair of dipped-beam headlamps that:

a) do not operate when the main-beam headlamps are switched on, and

b) may operate independently of the first pair of dipped-beam headlamps.

4. A vehicle (eg a vintage or veteran vehicle) manufactured without lamps, or with lamps that cannot meet specified requirements, may obtain a WoF if:

a) the vehicle has a valid vehicle identity card with a lighting equipment endorsement, and

b) the vehicle meets the conditions of that endorsement.

5. A vehicle required to meet an approved safety standard for lighting must continue to meet an approved safety standard for lighting.

6. A retrofitted dipped-beam headlamp on a vehicle with a GVM of 12,000 kg or less must be fitted at a height not exceeding 1.2 m from the ground (Note 9).

7. A warning device may be fitted that indicates that the main-beam headlamps are switched on.

8. An emergency vehicle or a pilot vehicle may be fitted with a device that allows the headlamps to flash alternately, provided it is also fitted with equipment that indicates to the driver that the device is activated.

9. A retrofitted pair of headlamps must be symmetrically mounted as far towards each side of the vehicle as is practicable.

Prohibited equipment

10. A dipped-beam headlamp designed solely for a left-hand drive vehicle, where the maximum intensity of the beam is dispersed to the right, must not be fitted.

Condition (Note 5)

11. A headlamp must:

a) be in sound condition, and

b) not be obscured.

Performance

12. A headlamp must operate in a way that is appropriate for the lamp and the vehicle.

13. A headlamp must emit a steady light.

14. A headlamp must provide sufficient illumination and light output to illuminate the road ahead.

15. If fitted with a device that allows headlamps to flash alternately, the lamps must flash at a fixed frequency.

16. A pair of headlamps must emit light that is approximately of equal colour and intensity when switched on.

17. A headlamp must emit a beam that is substantially white or amber.

18. A main-beam headlamp must be capable of being dipped or turned off from the driver’s position.

19. A warning device that indicates that the main-beam lamps are in operation must be in good working order.

20. When the headlamps are switched on and the vehicle’s front wheels are pointing in the straight-ahead position:

a) the centre of a headlamp beam must be either parallel to or to the left of the longitudinal centreline of the vehicle, and

b) the centre of a main-beam headlamp beam must be either parallel to or dipping down from the horizontal, and

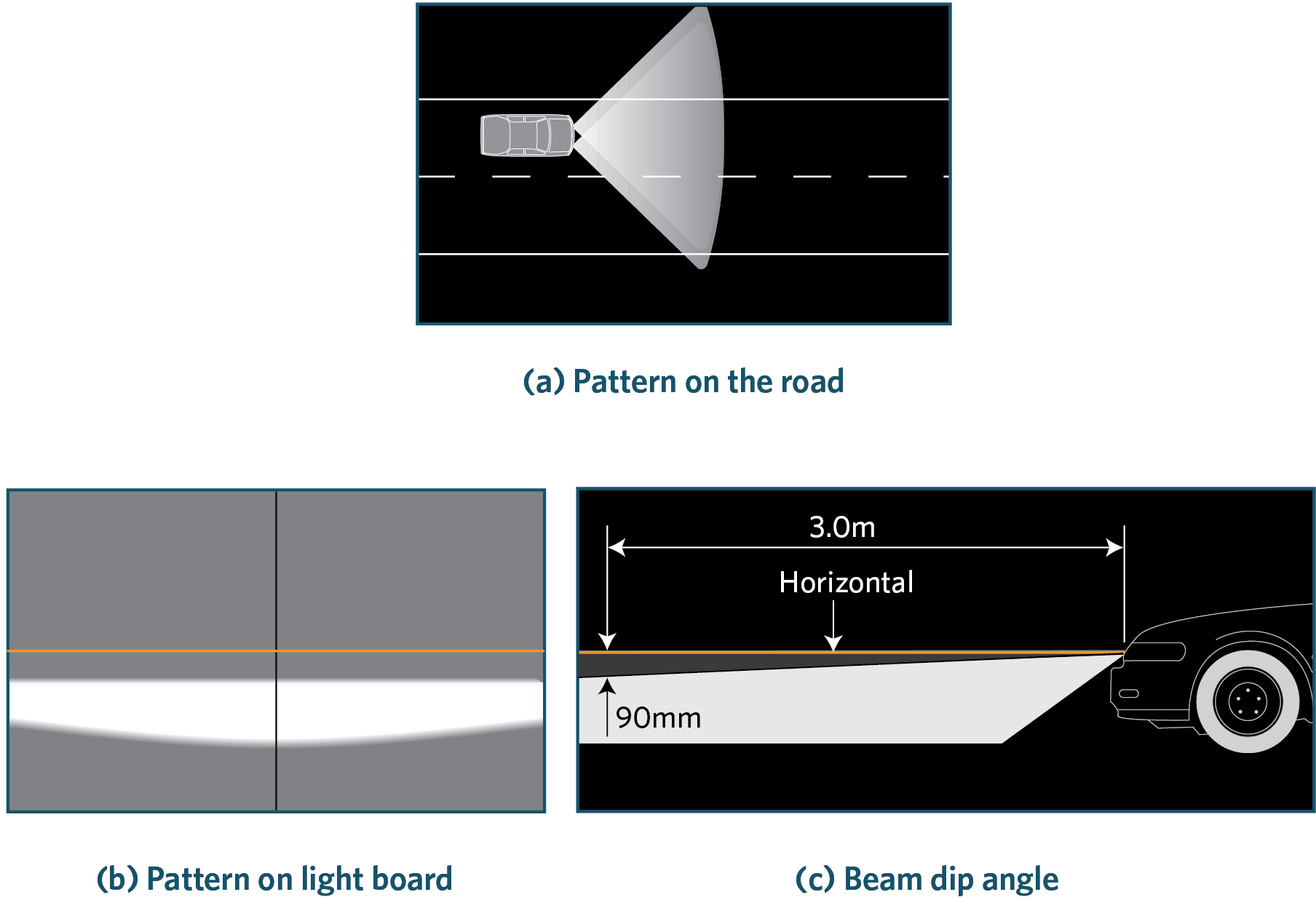

c) the centre of a dipped-beam headlamp beam must dip at an angle specified by the vehicle or lamp manufacturer, or:

i. 3–3.5% for a symmetric beam pattern, or

ii. 1–1.5% for an asymmetric beam pattern where the centre of the light source is less than 0.8 m from the ground, or

iii. 1–2% for an asymmetric beam pattern where the centre of the light source is 0.8–1.2 m from the ground, or

iv. 2–2.5% for an asymmetric beam pattern where the centre of the light source is above 1.2 m from the ground.

21. The dipped-beam headlamps must illuminate the road ahead for 50 m in normal darkness.

22. Where a headlamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

23. A device fitted to a vehicle that allows the headlamps to flash must:

a) make the headlamps flash alternately at a frequency of 1–2 Hertz, and

b) incorporate equipment that indicates to the driver that the device is activated.

24. A headlamp must be fitted with a light source that is specified by the vehicle manufacturer or the headlamp manufacturer.

Modifications (Note 4)

25. A headlamp that is affected by a modification must meet equipment, condition and performance requirements.

Page amended 1 April 2021 (see amendment details).

4-2 Front and rear fog lamps

Reasons for rejection

Permitted equipment

1. A group M or N vehicle is fitted with:

a) only one front fog lamp, or

b) more than one pair of front fog lamps.

2. A vehicle of class LE is fitted with more than two front fog lamps.

3. A vehicle is fitted with more than two rear fog lamps.

4. A retrofitted pair of fog lamps is not fitted:

a) symmetrically, or

b) as far towards each side of the vehicle as is practicable, or

c) positioned higher than the dipped-beam headlamps.

Condition

(see Note 3)

5. A lamp is insecure or contains moisture in the form of large droplets, runs or puddles .

6. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

7. A reflector is damaged or has deteriorated so that light output is reduced.

8. A fog lamp warning device, if fitted, is obscured from the driver’s vision.

Performance

9. When switched on, a front fog lamp does not operate (Note 5).

10. When switched on, a front fog lamp emits light that:

a) is not projected to the front, or

b) produces an incorrect beam pattern (Figure 4-2-1), or

c) is not substantially white or amber to the front, or

d) is not approximately equal in colour or intensity from the other lamp in the pair, or

e) is not steady, or

f) is not bright enough to illuminate the road ahead in conditions of severely reduced visibility, eg due to modification, deterioration, dirt or an incorrect light source, or

g) is too bright, and could dazzle other road users, eg due to the fitment of an HID or LED conversion kit (Note 6) or other incorrect light source, or

h) is altered, eg due to damage or modification, or

i) has a beam centre to the right of the vehicle’s centreline, or

j) has a beam that is not permanently dipped, or

k) has a beam centre that dips at an angle of less than 3% (Figure 4-2-1).

11. When switched on, a rear fog lamp emits light that is:

a) not projected to the rear, or

b) not diffuse, or

c) not substantially red, or

d) not approximately equal in colour or intensity from the other lamp in a pair, or

e) of variable intensity, or

f) not bright enough to indicate the presence of the vehicle from the rear in conditions of severely reduced visibility, eg due to modification, deterioration or an incorrect light source, or

g) altered, eg due to damage or modification.

12. A fog lamp cannot be switched off from the driver’s seating position.

13. Where a fog lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

14. A fog lamp warning device, if fitted, does not operate.

Note 1

Fog lamp means a high-intensity front or rear lamp designed to aid the driver or other road users in conditions of severely reduced visibility, including fog or snow, but not including clear atmospheric conditions under the hours of darkness.

Note 2

A rear fog lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

If a front fog lamp is fitted with a readily removable cover, other than a clear protective cover, this must be removed for inspection of the fog lamp.

Note 4

A vehicle originally manufactured with a front- or rear-fog-lamp arrangement that differs from what is required or permitted in this section may retain the original front or rear fog lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 5

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply, be removed from the vehicle, or be disabled so that it does not emit a light.

Note 6

A high-intensity discharge (HID or Xenon HID) or LED conversion kit consists of an HID or LED bulb which fits into the original fog lamp unit in place of the original bulb with no change to the lens, reflector or housing.

It is illegal to fit an HID or LED conversion kit to a vehicle as it brings the fog lamp out of specification by producing poor beam patterns and light that is often far too bright to be safe. The bulbs can also produce light that is noticeably blue and not the required substantially white or amber colour. Fog lamp manufacturers do not permit this modification, and these kits cannot be LVV certified.

It is permitted to replace a complete halogen fog lamp unit with a complete HID or LED fog lamp unit.

Figure 4-2-1. Front fog lamp characteristics

Summary of legislation

Applicable legislation

Permitted equipment

1. A vehicle other than class LE: one pair of front fog lamps.

2. A vehicle of class LE: one or two front fog lamps.

3. One or two rear fog lamps.

4. A retrofitted pair of fog lamps must be symmetrically mounted as far as is practicable towards each side of the vehicle.

5. A retrofitted front fog lamp must not be positioned higher than the dipped-beam headlamps.

6. A vehicle may be fitted with a warning device that indicates that a front or rear fog lamp is in operation.

Condition

7. A front fog lamp must be in sound condition.

8. A rear fog lamp must be in sound condition if it emits a light.

Performance

9. A fog lamp must operate in a way that is appropriate for the lamp and the vehicle.

10. A fog lamp must emit a steady light.

11. A front fog lamp must provide sufficient light output to illuminate the road ahead in conditions of severely reduced visibility.

12. A rear fog lamp must provide sufficient light output to indicate the presence of the vehicle on the road in conditions of severely reduced visibility.

13. The light emitted from a front fog lamp must be substantially white or amber.

14. The light emitted from a rear fog lamp must be diffuse and substantially red in colour.

15. A pair of fog lamps must emit light that is approximately equal in colour and intensity.

16. The centre of a front fog lamp beam must be parallel to or to the left of the longitudinal centreline of the vehicle.

17. The centre of a front fog lamp beam must be permanently dipped at an angle of at least 3%.

18. A fog lamp must be able to be turned off from the driver’s seating position.

19. A front or rear fog lamp warning device must be in good working order.

20. Where a fog lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

22. A fog lamp that is affected by a modification:

a) must meet equipment, condition and performance requirements, and

b) does not require LVV specialist certification.

Page amended 1 April 2024 (see amendment details).

4-3 Cornering lamps

Reasons for rejection

Permitted equipment

1. A vehicle is fitted with:

a) only one lamp, or

b) more than one pair of lamps, or

c) a lamp that either:

i. was not originally fitted by the vehicle manufacturer, or

ii. is not fitted in the original position.

Condition

2. A lamp is insecure.

3. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

4. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

Performance

5. When activated by switching on the direction indicator lamp or by turning the steering wheel, a cornering lamp:

a) does not operate, or

b) does not project in the direction of the turn.

6. A cornering lamp emits light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity from the other lamp in the pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead in the direction of the turn, eg due to modification, deterioration, dirt or or an incorrect light source, or

e) too bright causing dazzle to other road users, eg due to an incorrect light source or misalignment, or

f) altered, eg due to damage or modification.

7. Where a cornering lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Cornering lamp means a lamp designed to emit light at the front of a vehicle to supplement the vehicle’s headlamps by illuminating the road ahead in the direction of the turn.

Note 2

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps are considered retrofitted (ie non-OE).

Note 3

A vehicle originally manufactured with a cornering lamp arrangement that differs from what is required or permitted in this section may retain the original cornering lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 4

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be disabled so that it does not emit a light.

Summary of legislation

Applicable legislation

Permitted equipment

1. One pair of cornering lamps fitted as OE.

Condition

2. A cornering lamp must be in sound condition.

Performance

3. A cornering lamp must operate in a way that is appropriate for the lamp and the vehicle.

4. A cornering lamp must emit light that is substantially white or amber.

5. A pair of cornering lamps must emit light that is approximately equal in colour and intensity.

6. A cornering lamp must emit a steady light.

7. A cornering lamp must provide sufficient light output to illuminate the road ahead in the direction of the turn.

8. A cornering lamp must be correctly aligned.

9. Where a cornering lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

10. A cornering lamp that is affected by a modification:

a) must meet equipment, condition and performance requirements, and

b) does not require LVV specialist certification.

Page amended 1 December 2016 (see amendment details).

4-4 Daytime running lamps

Reasons for rejection

Permitted equipment

1. A vehicle other than class LE is fitted with:

a) only one lamp, or

b) more than one pair of lamps.

2. A vehicle of class LE is fitted with more than two lamps.

3. A lamp is fitted in a position other than at the front of the vehicle.

4. A retrofitted lamp is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

Condition

5. A lamp is insecure.

6. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

7. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

Performance

8. When switched on, a daytime running lamp does not operate (Note 4).

9. When switched on, a daytime running lamp emits light that is:

a) projected in a direction other than to the front, or

b) not substantially white or amber, or

c) not approximately equal in colour or intensity from the other lamp in the pair, or

d) not steady, or

e) not bright enough to make the vehicle more easily seen during the daytime, eg due to modification, deterioration, dirt or or an incorrect light source, or

f) too bright, causing significant dazzle to other road users, eg due to an incorrect light source, or

g) altered, eg due to damage or modification.

10. Where a daytime running lamp comprises an array of light sources, fewer than 75% of these operate.

11. A daytime running lamp continues to operate when the headlamps or fog lamps are switched on.

Note 1

Daytime running lamp means a lamp designed to emit a low-intensity light forward of a vehicle to make it more easily seen in the daytime.

Note 2

A vehicle originally manufactured with a daytime running lamp arrangement that differs from what is required or permitted in this section may retain the original daytime running lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 3

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 4

Some vehicles are equipped with OE or after-market daytime running lamps (DRLs) that also incorporate position lamp and direction indicator lamp functions. When the DRLs are on (when headlamps are off), and an indicator lamp is activated, the corresponding DRL is temporarily extinguished or dimmed. When the position lamps are on and an indicator lamp is activated, the corresponding position lamp may remain lit.

Summary of legislation

Applicable legislation

Permitted equipment

1. A vehicle other than class LE may have: one pair of daytime running lamps fitted to the front of the vehicle.

2. A vehicle of class LE may have one or two daytime running lamps fitted to the front of the vehicle.

3. A retrofitted lamp must be symmetrically mounted as far towards each side of the vehicle as is practicable.

Condition

4. A daytime running lamp must be in sound condition.

Performance

5. A daytime running lamp must operate in a way that is appropriate for the lamp and the vehicle.

6. A daytime running lamp must emit light that is substantially white or amber.

7. A pair of daytime running lamps must emit light that is of approximately equal colour and intensity.

8. A daytime running lamp must emit a steady light.

9. A daytime running lamp must provide sufficient light output to make the vehicle more easily seen during the daytime.

10. A daytime running lamp must be correctly aligned.

11. A daytime running lamp must not operate when a front fog lamp or a headlamp is in use.

12. Where a daytime running lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

13. A daytime running lamp that is affected by a modification:

a) must meet equipment, condition and performance requirements, and

b) does not require LVV specialist certification.

Page amended 1 December 2016 (see amendment details).

4-5 Direction indicator lamps

Reasons for rejection

Mandatory and permitted equipment

1. Refer to general vehicle pages.

2. A heavy vehicle of class MD3, MD4, ME, NB, or NC first registered on or after 1 January 1978 that exceeds 9.2m in length:

a) is not fitted with one side-facing direction indicator lamp on each side, at or near the front of the vehicle, or

b) is fitted with more than two side-facing direction indicator lamps on either side.

3. A retrofitted side-facing direction indicator lamp is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the vehicle).

4. A heavy vehicle is fitted at the rear with:

a) only one top-mounted lamp, or

b) more than one pair of top-mounted lamps, or

c) top-mounted lamps that are not mounted symmetrically as close as is practicable to the top corners of the bodywork.

5. A pair of forward-facing or rearward-facing direction indicator lamps (other than top-mounted lamps):

a) in the case of a vehicle with one pair, is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practical due to the shape of the bodywork of the vehicle), or

b) in the case of a vehicle with two pairs:

i. the lower pair is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practical due to the shape of the bodywork of the vehicle), or

ii. the other pair is fitted at a height from the ground exceeding 2.1m.

6. A heavy vehicle is fitted with top-mounted lamps at the front of the vehicle.

Condition

7. Refer to general vehicle pages.

Performance

8. Refer to general vehicle pages.

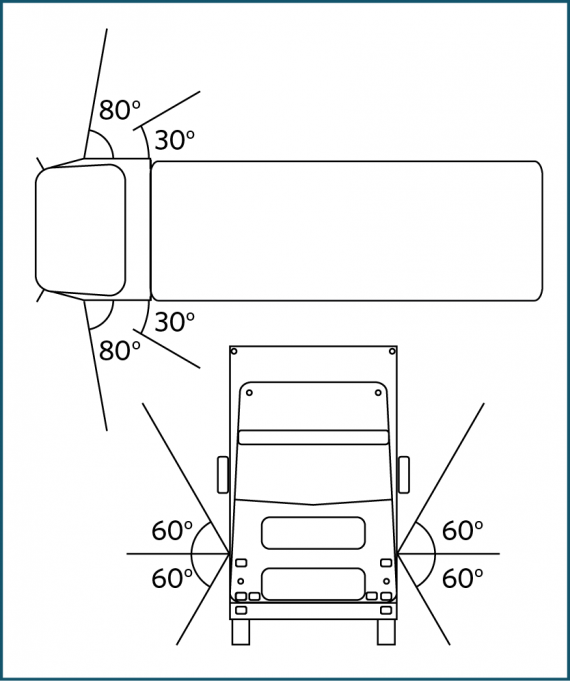

9. A mandatory side-facing direction indicator lamp is not visible from the side of the vehicle (Figure 4-5-2):

a) through an angle of 60° above and below a horizontal plane passing through the lamp, or

b) at least between an angle of 30° and 80° rearward of a vertical plane that is at right angles to the longitudinal centreline of the vehicle and passing through the lamp.

Note 1 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Direction indicator lamp means a lamp designed to emit a flashing light to signal the intention of the driver to change the direction of the vehicle to the right or to the left.

Note 2

A permitted (ie non-mandatory) rear or a non-OE side-facing direction indicator lamp that does not comply with equipment, condition and performance requirements must be made to comply or disabled so that it does not emit a light.

Note 3

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps, including those fitted by the body builder, are considered retrofitted (ie non-OE).

Note 4

Vehicles first registered in New Zealand before 27 February 2005 may have rear direction indicator lamps that also function as reversing lamps.

Note 5

A vehicle originally manufactured with a direction indicator lamp arrangement that differs from what is required or permitted in this section may retain the original direction indicator lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer. This does not include lamps fitted by a body builder.

Note 6

A forward-facing permitted direction indicator lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle.

Figure 4-5-2. Required angles for side-facing direction indicator lamps

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. Refer to general vehicle pages.

2. A heavy vehicle of class MD3, MD4, ME, NB, or NC first registered on or after 1 January 1978 that exceeds 9.2m in length must be fitted with one or two side-facing direction indicator lamps on each side, at or near the front of the vehicle.

3. A retrofitted side-facing direction indicator lamp must be mounted at a height not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the vehicle, not exceeding 2.1m.

4. A heavy vehicle may be fitted with an additional pair of direction indicator lamps at the rear of the vehicle that must be symmetrically mounted as near the top corners of the bodywork of the vehicle as is practicable (top-mounted lamps).

5. Forward-facing or rearward-facing direction indicator lamps (excluding top-mounted lamps) may be mounted as follows:

a) one pair at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the vehicle, not exceeding 2.1m, and

b) a second pair at a height from the ground not exceeding 2.1m.

Condition

6. Refer to general vehicle pages.

Performance

7. Refer to general vehicle pages.

8. A mandatory side-facing direction indicator must be visible from the side of the vehicle:

a) through an angle of 60° above and below the horizontal plane passing through the lamp, and

b) at least between an angle of 30° and 80° rearward of a vertical plane that is at right angles to the longitudinal centreline of the vehicle and passing through the lamp.

Modifications

9. Refer to general vehicle pages.

4-6 Forward-facing position lamps

Reasons for rejection

Mandatory and permitted equipment

1. Refer to general vehicle pages.

2. A heavy vehicle is fitted at the front with:

a) only one top-mounted lamp, or

b) more than one pair of top-mounted lamps, or

c) top-mounted lamps that are not mounted as close as is practicable to the top corners of the bodywork.

Condition

3. Refer to general vehicle pages.

Performance

4. Refer to general vehicle pages.

Note 1

The following total numbers of position lamps may generally be fitted to the front or rear of a vehicle:

Front of vehicle:

a) one pair of forward-facing position lamps below 1.5 m (usually the OE lamps)

b) one pair of forward-facing position lamps at the top corners

c) two cab roof lamps

d) 10 end-outline marker lamps fitted elsewhere on the outline of the vehicle or on the cab roof (for vehicles first

registered in New Zealand before 27 February 2005 there is no restriction on the number of forward-facing end-outline marker lamps that may be fitted).

Rear of vehicle:

a) two pairs of rearward-facing position lamps, one pair below 1.5 m and a second pair below 2.1 m, fitted symmetrically as

far as possible towards the extremities

b) one pair of rearward-facing position lamps at the top corners

c) six end-outline marker lamps elsewhere on the outline of the vehicle.

Note 2 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 3

A permitted forward-facing position lamp, fitted to a class NC vehicle first registered in New Zealand before 27 February 2005, that does not comply with condition and performance requirements must be made to comply or be disabled so that it does not emit a light. All other permitted forward-facing position lamps that do not comply with requirements must be made to comply or be removed from the vehicle.

Note 4

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps, including those fitted by the body builder, are considered retrofitted (ie non-OE).

Note 5

A vehicle originally manufactured with a position lamp arrangement that differs from what is required or permitted in this section may retain the original position lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer. This does not include lamps fitted by a body builder.

Summary of legislation

Applicable legislation

Permitted equipment

1. A heavy vehicle may be fitted with an additional pair of forward-facing position lamps that must be symmetrically mounted as near the top corners of the bodywork of the vehicle as is practicable (top-mounted lamps).

Condition

2. Refer to general vehicle pages.

Performance

3. Refer to general vehicle pages.

Modifications

4. Refer to general vehicle pages.

4-7 Rearward-facing position lamps

Reasons for rejection

Mandatory and permitted equipment

1. Refer to general vehicle pages.

2. A heavy vehicle is fitted at the rear with:

a) only one top-mounted lamp, or

b) more than one pair of top-mounted lamps, or

c) top-mounted lamps that are not mounted as close as is practicable to the top corners of the bodywork.

3. A rearward-facing position lamp (other than top-mounted lamps):

a) in the case of a vehicle with one or one pair, is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the vehicle), or

b) in the case of a vehicle with two pairs:

i. the lower pair is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the vehicle), or

ii. the other pair is fitted at a height from the ground exceeding 2.1m.

Condition

4. Refer to general vehicle pages.

Performance

5. Refer to general vehicle pages.

Note 1 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A permitted rearward-facing position lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps, including those fitted by the body builder, are considered retrofitted (ie non-OE).

Note 4

A vehicle originally manufactured with a position lamp arrangement that differs from what is required or permitted in this section may retain the original position lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer. This does not include lamps fitted by a body builder.

Summary of legislation

Applicable legislation

Permitted equipment

1. A heavy vehicle may be fitted with an additional pair of rearward-facing position lamps that must be symmetrically mounted as near the top corners of the bodywork of the vehicle as is practicable (top-mounted lamps).

2. Rearward-facing position lamps (excluding top-mounted lamps) may be mounted as follows:

a) one lamp or one pair at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the vehicle, not exceeding 2.1m, and

b) a second pair at a height from the ground not exceeding 2.1m.

Condition

3. Refer to general vehicle pages.

Performance

4. Refer to general vehicle pages.

Modifications

5. Refer to general vehicle pages.

4-8 Side-marker lamps

Reasons for rejection

Permitted equipment

1. A side-marker lamp is not positioned so that it gives an indication of the vehicle’s dimensions.

Condition

2. A lamp is insecure.

3. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

4. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

5. When switched on, a side-marker lamp emits a light that:

a) is not substantially white or amber to the front (for a vehicle manufactured before January 2006), or

b) is not substantially amber to the front (for a vehicle manufactured on or after January 2006), or

c) is not substantially red or amber to the rear, or

d) is not diffuse, or

e) is not approximately of the same colour and intensity on each side of the vehicle, or

f) does not remain steadily illuminated, or

g) is not bright enough to produce light that is visible from 100m in normal daylight and from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source.

6. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Modifications

7. A side-marker lamp that is affected by a modification must meet equipment, condition and performance requirements.

Note 1 Definitions

Side-marker lamp means a position lamp designed to be fitted to the side of a vehicle or its load.

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A permitted side-marker lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

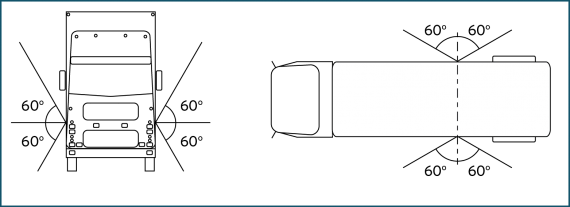

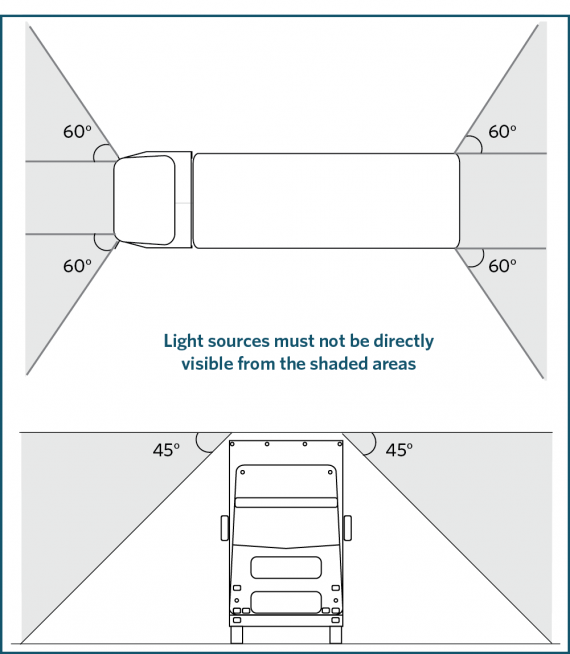

Figure 4-8-1. Visibility angles for side-marker lamps

Summary of legislation

Applicable legislation

Permitted equipment

1. A heavy vehicle may be fitted with one or more side-marker lamps.

2. A side-marker lamp must be positioned so that it gives an indication of the vehicle’s dimensions.

Condition

3. A side-marker lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

4. A side-marker lamp must operate in a way that is appropriate for the lamp and the vehicle.

5. A lamp must emit a light that is:

a) diffuse, and

b) substantially white or amber to the front (for a vehicle manufactured before January 2006), or

c) substantially amber to the front (for a vehicle manufactured on or after January 2006), or

d) substantially red or amber to the rear.

6. A lamp must emit a steady light.

7. A side-marker lamp must provide sufficient light output to indicate to other road users the presence and dimensions of the vehicle.

8. A side-marker lamp must emit a light that is visible from a distance of 100m in daylight and 200m during the hours of darkness.

9. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

10. A side-marker lamp that is affected by a modification must meet equipment, condition and performance requirements.

Page amended 14 October 2013 (see amendment details).

4-9 End-outline marker lamps

Reasons for rejection

Mandatory, permitted and prohibited equipment

1. A vehicle listed in Table 4-9-1:

a) is not fitted with the lamps required in Table 4-9-1, or

b) is fitted with lamps that exceed the numbers permitted in Table 4-9-1.

2. A vehicle not listed in Table 4-9-1 is fitted with end-outline marker lamps.

3. An end-outline marker lamp is not positioned so that it gives an indication of the vehicle’s dimensions, that is lamps, other than cab roof lamps, are fitted other than around the outline of the vehicle (Note 2).

Condition

4. A lamp is insecure or, if a mandatory lamp, obscured.

5. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

6. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

7. When switched on, a mandatory or a forward-facing end-outline marker lamp does not operate (Note 3).

8. When switched on, an end-outline marker lamp emits a light that is:

a) not substantially white or amber to the front, or

b) not substantially red to the rear, or

c) not diffuse, or

d) not projected to the front or rear, or

e) not approximately of the same colour or intensity as the other lamp if fitted in a pair, or

f) not steady, or

g) not bright enough to indicate the presence and dimensions of the vehicle to other road users.

9. A mandatory cab roof lamp is not bright enough to produce light that is visible from 100m in normal daylight and from 200m in normal darkness, eg due to modification, deterioration or an incorrect light source.

10. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

For vehicles manufactured before 1/5/2011, the following total numbers of position lamps may generally be fitted to the front or rear of a vehicle:

Front of vehicle:

a) one pair of forward-facing position lamps below 1.5m (usually the OE lamps)

b) one pair of forward-facing position lamps at the top corners

c) two cab roof lamps

d) 10 end-outline marker lamps fitted elsewhere on the outline of the vehicle or on the cab roof (for vehicles first

registered in New Zealand before 27 February 2005 there is no restriction on the number of forward-facing end-outline

marker lamps that may be fitted).

Rear of vehicle:

a) two pairs of rearward-facing position lamps, one pair below 1.5m and a second pair below 2.1m, fitted symmetrically as

far as possible towards the extremities

b) one pair of rearward-facing position lamps at the top corners

c) six end-outline marker lamps elsewhere on the outline of the vehicle.

Note 2 Definitions

End-outline marker lamp means a position lamp designed to be fitted near the outer extremity of the vehicle in addition to forward-facing and rearward-facing position lamps, and includes a cab roof lamp.

Position lamp means a low-intensity lamp that is designed to indicate the presence and dimensions of a vehicle to other road users, being:

a) a forward-facing position lamp (front side or park lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 3

A rearward-facing end-outline marker lamp, or a forward-facing end-outline marker lamp fitted to a class NC vehicle first registered in New Zealand before 27 February 2005, that does not comply with the equipment, condition and performance requirements, must be made to comply or be disabled so that it does not emit a light. All other permitted forward-facing end-outline marker lamps must be made to comply or be fully removed from the vehicle.

Note 4

A vehicle originally manufactured with an end-outline marker lamp arrangement that differs from what is required or permitted in this section may retain the original end-outline marker lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer. Lamps visible from the front and from the rear on the same side of the vehicle may be combined into one device.

Note 5

Vehicle manufacturer means the original vehicle manufacturer and the final stage manufacturer in the case of certain modified vehicles (see Technical bulletin 13: Acceptable overseas proof of modification).

Table 4-9-1. Fitting requirements for end-outline marker lamps

If the vehicle was: | Row | Characteristics of the heavy vehicle | Front | Rear | |

|---|---|---|---|---|---|

Mandatory lamps1,4 | Maximum permitted lamps2 | Maximum permitted lamps2 | |||

Vehicle manufactured before 1/4/20113 | A |

| 2 | 12 (No Limit if first registered before 27/2/2005) | 6 |

B | A vehicle with an overall width of 1.8 m or more (other than a vehicle in row A) | Not required | 6 | 4 | |

Vehicle manufactured from 1/4/2011 | C | A vehicle with an overall width exceeding 2.1m and with a GVM or GCM exceeding 12,000kg | 2 | 12 | 6 |

D | A vehicle with an overall width exceeding 2.1m (other than a vehicle in row C) | 2 | 6 | 4 | |

E | A vehicle with an overall width of 1.8 m or more (other than a vehicle in row C or D). | Not required | 6 | 4 | |

1 Vehicles in Table 4-9-2 are not required to be fitted with mandatory lamps.

2 Maximum permitted lamps are the maximum number of lamps allowed to be fitted, including mandatory lamps.

3 A vehicle manufactured before 1/4/2011 also has the option of complying with the requirements applicable to vehicles manufactured from 1/4/2011.

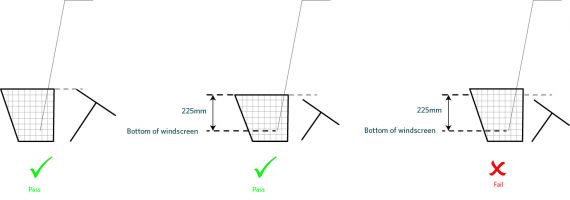

4 Mandatory lamps must be positioned at a height no lower than the top edge of the windscreen.