Vehicle structure

3-1 Structure

Reasons for rejection

Mandatory equipment

1. A sliding chassis is not fitted with both:

a) a locking device to prevent inadvertent extension or separation, and

b) end stops at the end of the slideway to prevent separation of the sliding parts if the primary locking device fails.

Condition and performance

2. Refer to general vehicle pages.

3. The chassis (Note 1), body or other load-bearing structure of a vehicle, including a cab or a monocoque construction body, has damage so that the vehicle is no longer of adequate strength for all conditions of loading and operation for which the vehicle was constructed, such as:

a) deformation from original shape that has affected the vehicle’s structural integrity (Note 6) (Figure 3-1-4), or

b) cracking, or

c) significant corrosion or delamination, or

d) significant rust heave that exceeds the limits in (Figure 3-1-3), or

e) poor repairs that have not returned the structure to within safe tolerance of when it was manufactured, eg:

i. filler has been used to conceal corrosion damage or deformation of a component

ii. a high-strength steel component has been heated

iii. a component has been strengthened.

f) loose, broken or missing fasteners or rivets, or

g) damage that affects the integrity, operation or mounting of the following components:

i. steering and suspension system, or

ii. load anchorages

iii. seat or seatbelt anchorages, or

iv. brake system, or

v. mandatory lighting equipment, or

vi. towing connections, or

vii. transmission, or

viii. cab or vehicle body.

4. A body-to-chassis attachment, such as a weld, fastener, hinge, body guide or locking device, is:

a) missing, or

b) loose, or

c) broken, or

d) cracked, or

e) otherwise in poor condition.

5. A tipping body hinge, body guide or locking device has deteriorated so that it is not effective in securing the body to the chassis.

6. The locking of a sliding chassis locking device is either:

a) not readily verifiable by visual inspection, or

b) the vehicle is not equipped with a visible or audible alarm to warn the driver if the chassis is not locked in one of the locking positions (Note 5).

7. A sliding chassis locking device has wear or damage, such as a worn or bent pin, so that it is not effective.

8. A sliding chassis locking device does not operate correctly.

9. A sliding chassis end stop is:

a) missing, or

b) insecure, or

c) damaged.

10. A bin securing device does not operate correctly.

11. A vehicle which uses a wooden or wood laminate floor as a structural component of the chassis has:

a) deformation from original shape that has affected the vehicle’s structural integrity (Note 6) (Figure 3-1-4), or

b) significant cracking of the body structure or mounting points, or

c) significant corrosion of steel elements, delamination, or wood rotting or

d) significant rust heave in steel elements that exceeds the limits in (Figure 3-1-3), or

e) poor repairs that have not returned the structure to within safe tolerance of when it was manufactured, for example:

i. filler has been used to conceal any damage or deformation of a component

ii. a high-strength steel component has been heated

iii. a component has been strengthened.

Modification and repair

12. A modification or repair affects the vehicle structure and:

a) is not excluded from the requirements for HVS certification (Table 3-1-2), or

b) the modification is not for the purpose of law enforcement or the provision of emergency services, or

c) is missing proof of HVS certification, ie the vehicle has been modified or repaired and:

i. no LANDATA record has been entered, or

ii. no valid LT400 form from a HVS certifier of category HVEC, or HMCD has been presented.

Note 1 Definitions

Chassis means the structural lower part of a vehicle to which the running gear and, as applicable, engine, transmission, steering system and body may be attached.

Chassis assembly means a chassis with running gear attached and, as applicable, engine, transmission and steering system attached.

Body means the part of the vehicle that is designed for the use and accommodation of the occupants or to hold any goods.

Note 2

Rust stains can indicate fretting or movement between two components, eg as a result of loose fasteners or cracking.

Note 3

Chassis cracking is most likely to occur in the following areas:

- abrupt changes in chassis section

- adjacent to welds

- body mounting points

- adjacent to loose fasteners

- notches.

Note 4

Corrosion is most likely to occur in areas where moisture is retained, or when the vehicle is used to carry stock, fertiliser or corrosive cargo.

Note 5

An alarm must be visible or audible from the driver’s seating position, and the alarm must operate when the vehicle’s engine is running, except when the parking brake is fully applied or when the gear selector of a vehicle with an automatic transmission is in the ‘park’ position.

Note 6

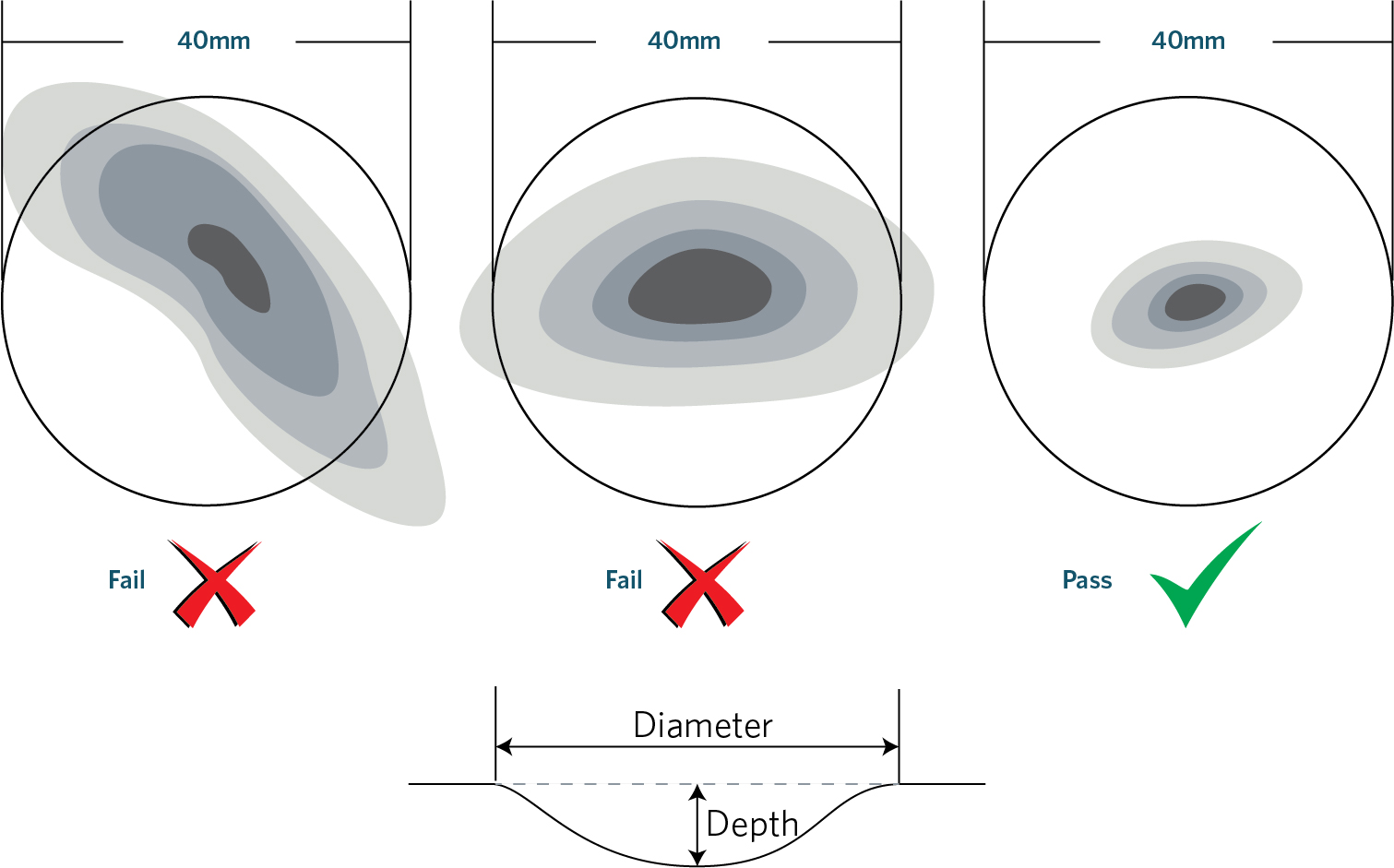

Dents smaller than 5mm deep and 40mm in diameter (to the outer edges of the crease), such as those caused by hail, in the pillars, cant rail or any other similar roof structure, should not be considered to affect the vehicles structural integrity. Any damage larger than above should be referred to a repairer for additional information (see Figure 3-1-4).

Note 7

Original equipment may include: tipper, tail lift, hi-ab, crane, compactor or similar equipment or body fitted and complied in Japan. For new vehicles see Technical bulletin (CoF) 8, for new and used vehicles from other markets see Entry certification Technical bulletin 41.

Note 8

Welding carried out as part of a chassis modification on or after 1 April 2005 required certification. However, that was not made clear in this VIRM. Consequently, welding carried out as part of a modification between 1 April 2005 and 31 December 2024 can remain uncertified provided the vehicle inspector is satisfied that the vehicles safety performance is unaffected.

Table 3-1-2. Requirements for HVS certification

HVS certification is required | HVS certification is not required |

|---|---|

1. Repairs to a structural component of a monocoque body. 2. From 1 January 2025 (Note 8) repairs or modifications to a chassis, including a chassis cross-member, which is: a) the first or last cross-member of the chassis b) a cross-member that is fitted within 500mm of an engine mount, transmission mount, or suspension support c) a cross-member to which a driveshaft centre bearing is fitted d) a cross-member that supports any of the following: i. ballrace turntable ii. tow coupling iii. fifth wheel iv. kingpin v. bolster attachment vi. hoist, hydraulic cylinder of a tipping body or any other device that may place a concentrated load on the chassis. 3. Modifications carried out on or after 1 April 2005 that may result in increased stress to a localised area of the chassis or significant redistribution of the load over the chassis (eg fitting of a hoist, crane, tipping body, or other special equipment, etc.). For modifications carried out before 1 April 2005 it is up to the vehicle inspector to determine if certification is required. Individual certification is only required when the vehicle inspector determines, on reasonable grounds, that the component presents a safety risk. 4. Modifications carried out on or after 1 November 2018 to structural reinforcements of the cab/body likely to affect occupant protection (eg cut-outs through pillars, roof rails, reinforcements (not merely stiffeners), etc) for modifications such as campervan, crewcab, truck/bus conversions. | 1. Repairs to a non-structural component of a monocoque body (eg a body panel). 2. Repairs to a first failure of a chassis cross-member except a repair listed in the left-hand column. 3. Repairs to a coaming rail that does not support a load anchorage point (including a stock crate J-hook) or that does not secure a load-rated curtain. 4. Any modification or repair likely to have been carried out before 1 January 1997 (modifications and repairs before this date generally required certification but for inspection purposes no evidence of this is required). 5. Any repair or modification not listed in the left-hand column unless the vehicle inspector considers that certification is required because the modification or repair has affected the vehicle’s safety performance (a second opinion from an expert may be needed). 6. Any used Japanese-market imported heavy vehicle that has original equipment fitted does not require HVS certification, provided the vehicle inspector is satisfied that the vehicle was registered in Japan in that configuration and no further modification has taken place. This applies to all makes of vehicles (Note 7). 7. There is evidence of an acceptable alternative certification of the modification from the company that carried out the modification (ie a statement of compliance or a second stage certification plate or label). See Technical bulletin 13: Acceptable overseas proof of modification. 8. Modifications to the structure of a cab on or before 31 October 2018. This is under a temporary class exemption from specialist certification until 1 October 2026 (see New Zealand Gazette notice 2021-au4295). Note: condition and performance reasons for rejection still apply. |

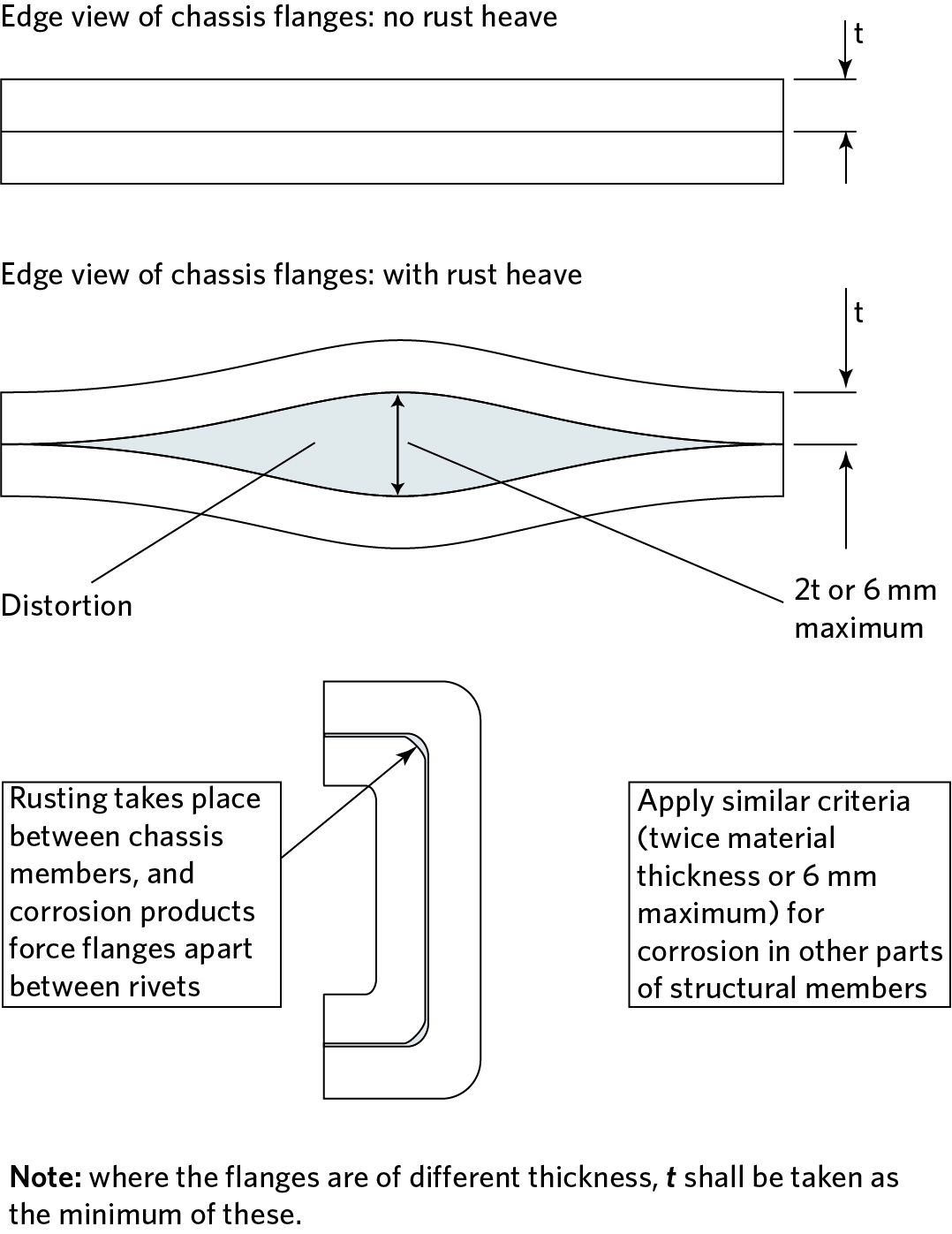

Figure 3-1-3. Rust heave limits

Rust heave beyond the limits described above is acceptable only if an HVS certifier with the HVEC category has confirmed in writing that at the time of inspection the identified chassis rust heave on the vehicle remains within safe tolerance of the vehicle’s state of manufacture. Confirmation from the HVS certifier should be kept with the checksheet. The identity of the HVS certifier must be recorded in the Landata GNOTE page. This assessment is only valid for that specific CoF inspection.

Regardless of any expiry date, an inspector may refer the vehicle to an HVS certifier if he/she suspects that the safety of the vehicle is compromised, eg due to excessive corrosion or chassis cracking. If the chassis is repaired, an LT400 is required.

Figure 3-1-4. Deformation limits

Summary of legislation

Applicable legislation

Mandatory equipment

1. A sliding chassis must be fitted with:

a) a locking device to prevent inadvertent extension or separation, and

b) endstops at the end of the slideway to prevent separation of the sliding parts if the primary locking device fails.

2. The body of a vehicle such as a tank body for transporting bulk liquid, a tipping body for transporting sand, grain or other bulk goods, or other types of body that are constructed to contain the transported goods without the use of lashings, chains or other devices, must be specifically designed to contain that type and size of load.

Condition and performance

3. The following must be of adequate strength for all conditions of loading and operation for which the vehicle was constructed:

a) the chassis and body of the vehicle

b) the body of a vehicle of monocoque construction

c) any other load-bearing structure.

4. The locking of a sliding chassis locking device must be readily verifiable by visual inspection or the vehicle must be equipped with a visual or audible alarm to warn the driver if the chassis is not in one of the locking positions.

5. An alarm must be visible or audible from the driver’s seating position, and the alarm must operate when the vehicle’s engine is running, except when the parking brake is fully applied or when the gear selector of a vehicle with an automatic transmission is in the ‘park’ position.

6. A sliding chassis locking device must be effective.

7. If a sliding chassis locking device incorporates a system that provides energy for its operation, the device must remain fully engaged in the locked position, or the locking action must be initiated immediately, if the energising system fails.

8. Load-securing equipment that is fitted to a vehicle must be constructed to ensure that the load can be securely contained on the vehicle under all conditions of loading and operation for which the vehicle was constructed.

Modification and repair

9. A modification or repair that affects the vehicle structure must be inspected and certified by an HVS certifier of category HVEC or HMCD unless the vehicle:

a) is excluded from the requirement for HVS certification (Table 3-1-2), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 10 March 2025 (see amendment details)