In-service certification (WoF and CoF) - Tractors

Correct as at 25th April 2024. It may be superseded at any time.

1 Introduction

Inspection and certification of tractors and self-propelled machines used in agricultural, land management and roading operations: Warrant of fitness requirements

This section specifies the requirements that are applicable to the inspection and certification of the following tractors and machines for the purpose of issuing a warrant of fitness (WoF).

1. Agricultural tractors:

- An agricultural tractor is defined as a vehicle that is designed and constructed principally for the purposes of towing an agricultural trailer or towing or powering an agricultural implement.

- An agricultural tractor may be capable of any speed, and includes a JCB Fastrac.

2. Tractors (other than agricultural tractors):

- A tractor is defined as a motor vehicle (other than a traction engine) that is designed exclusively for traction at speeds not exceeding 50km/h.

- A vehicle capable of traction at speeds exceeding 50km/h is not defined as a tractor. Such a vehicle requires a certificate of fitness (CoF) and is therefore not covered in this section.

3. Self-propelled agricultural machines (eg a combine or grape harvester):

- These vehicles are defined as being designed, constructed or adapted for agricultural purposes.

- Agricultural purposes only includes land cultivation, growing and harvesting crops, rearing livestock, operation or management of a farm, and any land management operations undertaken in connection with these, but does not include any purposes related to forestry.

4. Self-propelled machines used in non-agricultural land management or roading operations.

General requirements

1. This section applies to both light and heavy tractors and machines. Heavy tractors and machines are those that have a gross vehicle mass (GVM) exceeding 3500kg.

2. The table below specifies:

- What tractors and machines may be inspected for WoF, and

- What WoF expiry dates apply (refer to Introduction section 3.8.1 for full details), and

- What inspecting organisation and vehicle inspector authorisations are required.

Tractor or machine that may be inspected for WoF1 | WoF expiry | IO/VI authorisation required (inspection group) |

|---|---|---|

| 12 months2 | Agricultural motor vehicle (6)3, 4 |

| 12 months – vehicle is less than 6 years old from date of first registration 6 months – vehicle is 6 or more years old from date of first registration | Heavy vehicle exempt from CoF (5) |

| 12 months2 | Agricultural motor vehicle (6)3, 4 |

| 12 months – vehicle is less than 6 years old from date of first registration 6 months – vehicle is 6 or more years old from date of first registration | Heavy vehicle exempt from CoF (5) |

1 A tractor or machine requires a WoF only if it is operated above the 30km/h or 40km/h as specified in the table. 2 IMPORTANT: An agricultural tractor or machine only qualifies for a 12-month WoF if it is on inspection group 6 (agricultural motor vehicle). The vehicle inspector may need to tick the appropriate inspection group when prompted on the inspection screen. The prompt will only appear if the vehicle is correctly licensed as an agricultural motor vehicle. If a vehicle is not correctly licensed as an agricultural motor vehicle, it does not qualify for inspection group 6 and 12-month WoF, and the WoF expiry will default to 12 or 6 month WoFs applicable to non-agricultural tractors and machines. The owner should contact the NZTA on 0800 108 809 to get the vehicle correctly licensed as an agricultural motor vehicle. 3 Vehicle inspectors that have inspection group 5 authorisation will automatically qualify for inspection group 6 authorisation. 4 Most light agricultural tractors or machines cannot exceed 40km/h so cannot be inspected for WoF. If you are presented with a light agricultural tractor or machine that can exceed 40km/h, and you don’t have inspection group 5 or 6 authorisation, please contact the NZTA on 0800 587 287 to get the correct authorisation. | ||

3. Only a tractor or machine that has a registration plate attached to it may be inspected for a WoF.

4. Modifications that affect a safety requirement do not require low volume vehicle (LVV) or heavy vehicle specialist (HVS) certification unless otherwise specified. However, if the vehicle inspector has concerns about the modification, he must obtain additional information from a relevant person before passing the vehicle for WoF.

5. A tractor or machine is not required to have a vehicle identifier. If the tractor or machine has a vehicle identifier, such as the manufacturer’s serial number, it must be recorded on the checksheet and on the NZ Transport Agency computer system.

Page amended 11 November 2013 (see amendment details)

Page updated 18 October 2018 (see details)

2 Vehicle exterior

2-1 External projections

Reasons for rejection

Condition and performance

1. The risk of a component (Note 1) hooking a vehicle, or hooking or grazing a person, has not been minimised.

2. An ornamental object or fitting (Note 2) protrudes in such a way that it is likely to injure a person.

3. A protruding object or fitting that has a functional purpose (Note 2) is fitted in a way that does not reduce the risk of injury to a person.

4. A component, object or fitting is not securely attached to the vehicle.

5. A protruding object or fitting adversely affects the driver’s vision or control.

Note 1

Components include damaged, corroded and exposed body panels.

Note 2 Definitions

Ornamental object or fitting means an object or fitting that does not have a practical purpose, eg bonnet emblems. The external projections requirements relate to the design and maintenance of objects and fittings that protrude from the exterior of the motor vehicle with regard to the safety of other motor vehicles, pedestrians and cyclists.

Functional object or fitting means an object or fitting that has a practical purpose, eg counterweights, front-end loader attachments and so on.

Summary of legislation

Applicable legislation

Permitted equipment

1. A vehicle may be fitted with a protruding ornamental or functional object or fitting.

Condition and performance

2. A protruding ornamental object or fitting must not be likely to injure a person.

3. A protruding object or fitting that has a functional purpose must be installed so that the risk of the object or fitting causing injury to a person is minimised.

4. Components of a motor vehicle, including damaged or corroded body panels, must be such that the risk of their hooking a vehicle, or hooking or grazing a person, is minimised.

5. A protruding object or fitting must not adversely affect driver vision or driver control.

2-2 Dimensions

| The vehicle inspector only need inspect dimensions if there is doubt about the vehicle's compliance. |

Reasons for rejection

Mandatory equipment

1. A vehicle that exceeds the dimension requirements set out in Table 2-2-1 is not fitted with the appropriate hazard warning equipment set out in Table 2-2-2.

2. A required revolving amber beacon cannot be activated and deactivated.

Note 1 Definitions

The rear axis of a vehicle means:

- if the vehicle is fitted with only one non-steering axle: the centre of that axle

- if the rear axle set includes a steering axle: midway between the extreme non-steering axles of the set.

Wheelbase means the distance from the rear axis to the front axis (centre of the foremost axle)

Note 2

Agricultural motor vehicle:

a) means a motor vehicle that is designed, constructed, or adapted for agricultural purposes, and includes:

i) an agricultural trailer, and

ii) an agricultural tractor, but

b) does not include any vehicle that is:

i) of a class specified in section 3-2 of the Introduction, and

ii) designed or constructed for general road use.

Agricultural purpose includes:

a) land cultivation

b) growing and harvesting crops (including horticulture and viticulture)

c) rearing livestock

d) any land management operation undertaken in connection with the operation or management of a farm.

Agricultural purpose does not include forestry, or any land management operation not referred to in (a) to (d) above.

Agricultural tractor means a vehicle that is designed and constructed principally for the purposes of:

a) towing an agricultural trailer, or

b) drawing, or powering, an implement ordinarily used for an agricultural purpose.

Note 3

Agricultural motor vehicles with excess front overhang (over 4m): Instead of fitting flags or panels, front parts of the vehicle or front attachments may be painted with high-visibility paint.

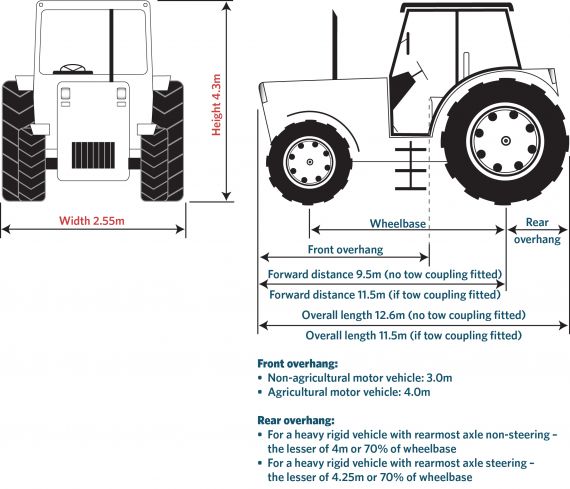

Table 2-2-1. Dimension requirements (see Figure 2-2-4)

Dimension | Maximum distance | Comments |

|---|---|---|

Width | 2.55m 1.275m from each side of the longitudinal centreline of the vehicle | Measurement does not include:

|

Overall length | 12.6m (no tow coupling fitted) 11.5m (tow coupling fitted) | Measurement does not include collapsible mirrors. |

Height | 4.3m | |

Forward distance | 9.5m (no tow coupling fitted) 8.5m (including tow coupling if fitted) |

|

Rear overhang | Vehicle GVM 3500kg or less: 4m Vehicle GVM greater than 3500 kg:

| Rear overhang is measured from the rear axis (Note 1) to the rear of the vehicle. |

Front overhang | Rigid non-agricultural motor vehicle: 3m Rigid agricultural motor vehicle: 4m | Front overhang is measured from the front edge of the driver’s seat in the rearmost position to the front of the vehicle. |

Ground clearance for vehicles with GVM greater than 3500kg. | Minimum is the greater of 100mm OR 6% of the distance from the nearest axle to the point where the ground clearance is measured. | Except when the vehicle is loading or unloading. Items excluded from ground clearance measurement are:

|

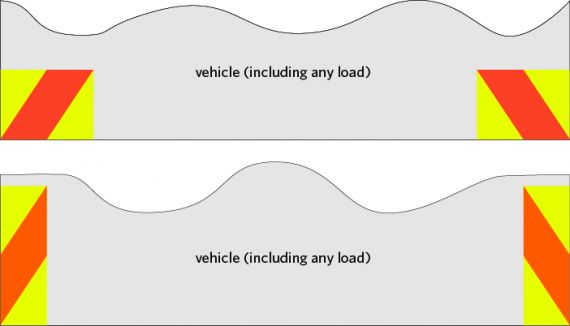

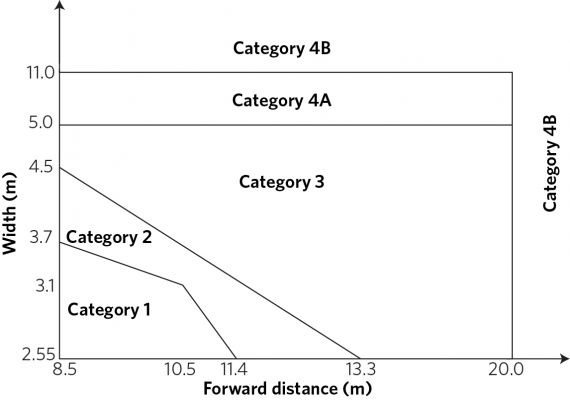

Table 2-2-2. Hazard warning equipment requirements for vehicles that exceed the dimensions in Table 2-2-1

Vehicle category | Dimension | Limits (up to and including) | Required hazard warning equipment |

|---|---|---|---|

Category 1 | Width/forward distance (see Figure 2-2-3) | 2.55m /11.4m, or 3.1m/10.5m, or 3.7m/8.5m, or | Flags1 or panels2 fitted on each side at the front and rear as close as practicable to the outside edge (for agricultural motor vehicles with excess front overhang, see (Note 3)). |

Length | 25m, or | ||

Front overhang | 7m, or | ||

Rear overhang | 7m | ||

Category 2 (not including category 1) | Width/forward distance (see Figure 2-2-3) | 2.55m /13.3m, or 4.5m/8.5m, or |

|

Length | 35m, or | ||

Front overhang | 10m, or | ||

Rear overhang | 10m | ||

Category 3 (not including category 2) | Width/forward distance (see Figure 2-2-3) | 2.55m /20m 5m/20m 5m/8.5m |

|

Front overhang | 10m, or | ||

Rear overhang | 10m | ||

Category 4A (not including category 3) | Width/forward distance (see Figure 2-2-3) | 11m/20m 11m/8.5m |

|

Front overhang | 10m, or | ||

Rear overhang | 10m | ||

| Category 4B | Exceeding any limit in Category 4A | 1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge 2. OVERSIZE sign3 fitted at the front and rear 3. Revolving amber beacon fitted so that it is visible to approaching traffic if the vehicle is more than 3.7m wide | |

* Additional operational requirements may apply, eg if operated at night.

1 Flags:

- must be fluorescent yellow

- must be at least 400mm long × 300mm wide.

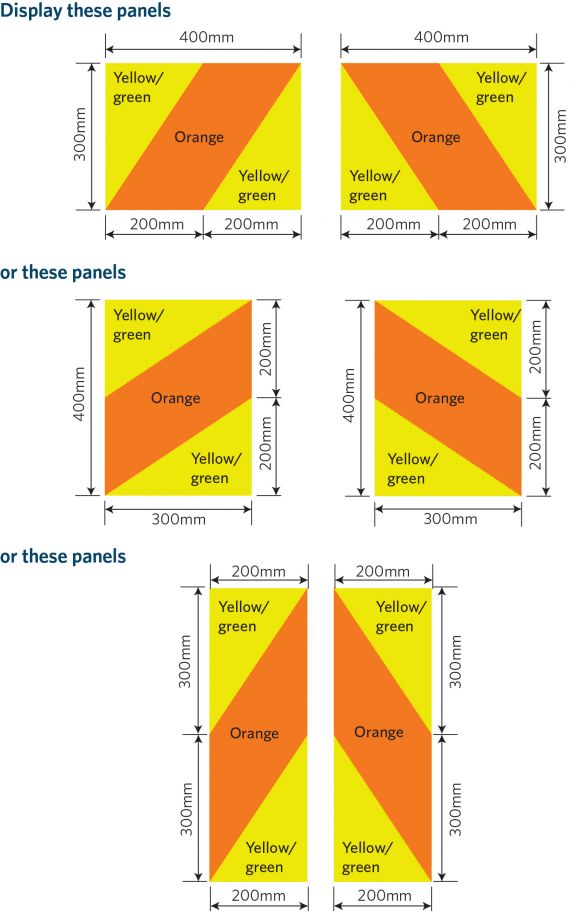

2 Hazard warning panels:

- must be reflective yellow green with a reflective orange diagonal stripe

- comply with AS/NZS 1906.1:2007

- be frangible for those portions which extend beyond the vehicle’s limits (frangible means breakable or readily deformable)

- must be of at least the minimum dimensions and the colours specified in Figure 2-2-1

- instead of displaying a hazard warning panel an agricultural tractor with a width exceeding 2.55m but less than 3.1m may instead be fitted with and use an amber beacon when operated on the road.

3 OVERSIZE sign:

- must be black lettering on yellow-green background

- must be at least 300mm × 1100mm in size

- be frangible if any part of the sign extends beyond the body or load of the vehicle, whichever it is attached to (frangible means breakable or readily deformable)

- may be in two parts: OVER and SIZE.

Figure 2-2-1. Hazard panel details

Figure 2-2-2. Hazard panel location and orientation

Figure 2-2-3. Vehicle categories and width/forward distance thresholds

Use this figure to determine vehicle category in Table 2-2-2.

For the purposes of this figure, vehicles with a width less than 2.55m are deemed to have a width of 2.55m and vehicles with a forward distance of less than 8.5m are deemed to have a forward distance of 8.5m.

Figure 2-2-4. Dimension requirements

(Note: Dimensions in red updated in VDAM 2016)

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle that exceeds the dimensions in Table 2-2-1 must be fitted with the equipment set out in Table 2-2-2.

Page amended 1 June 2019 (see amendment details).

3 Vehicle structure

3-1 Vehicle structure

Reasons for rejection

Condition

1. The structure of the tractor has visible:

a) deformation from the original shape that has affected the vehicle’s structural integrity (Note 1) (Note 3), or

b) cracking, or

c) fracture, or

d) corrosion, damage or repair that the inspector considers has caused weakening of a load-bearing structure.

2. A rollover protection structure or cab is not securely attached to the tractor.

Note 1

The structural inspection of a tractor or machine does not include the rollover protection structure (ROPS), which may be a roll bar or may be incorporated into the cab, except for its attachment to the vehicle body or chassis.

Note 2

Corrosion damage is where the metal has been eaten away, which is evident by pitting. The outward signs of such corrosion damage is typically displayed by the lifting or bubbling of paint. In extreme cases, the area affected by the corrosion damage will fall out and leave a hole.

Note 3

The vehicle inspector may request additional relevant information from a repairer or other relevant person. The vehicle inspector should withhold the WoF if there is reason to believe that the vehicle has:

a) structural damage, or

b) inadequate structural repair(s), or

c) corrosion damage

to the extent that it could affect the vehicle’s structural strength or one of the vehicle’s safety requirements. If the owner questions the decision, the vehicle inspector should recommend the vehicle owner obtain further written assessment from the equipment manufacturer or other suitable person.

Summary of legislation

Applicable legislation

Condition

1. The vehicle must be safe to be operated.

2. The components and materials must be fit for their purpose and within safe tolerance of their state when manufactured or modified.

4-1 Headlamps

Reasons for rejection

Mandatory and permitted equipment

1. A vehicle is not fitted with one pair of dipped-beam headlamps.

2. A vehicle is fitted with more than:

a) one pair of dipped-beam headlamps, or

b) two pairs of main-beam headlamps.

3. A vehicle is fitted with a headlamp that is not in a pair.

4. A retrofitted pair of headlamps is not fitted:

a) symmetrically, or

b) as far towards each side of the vehicle as is practicable.

5. A vehicle is fitted with a dipped-beam headlamp where the maximum intensity of the beam is projected to the right.

Condition

6. A lamp is insecure.

7. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A lens or reflector is damaged or has deteriorated so that light output is reduced.

9. A main-beam headlamp warning device is obscured from the driver’s vision.

10. A mandatory lamp is obscured or contains dirt or moisture in the form of large droplets, runs or puddles.

Performance

11. When switched on, a headlamp emits a light that is:

a) not substantially white or amber, or

b) not approximately equal in colour or intensity to the other lamp in a pair, or

c) not steady, or

d) not bright enough to illuminate the road ahead, eg due to modification, deterioration or an incorrect light source, or

e) too bright, eg due to the fitment of an HID or LED conversion kit (Note 6) or other incorrect light source.

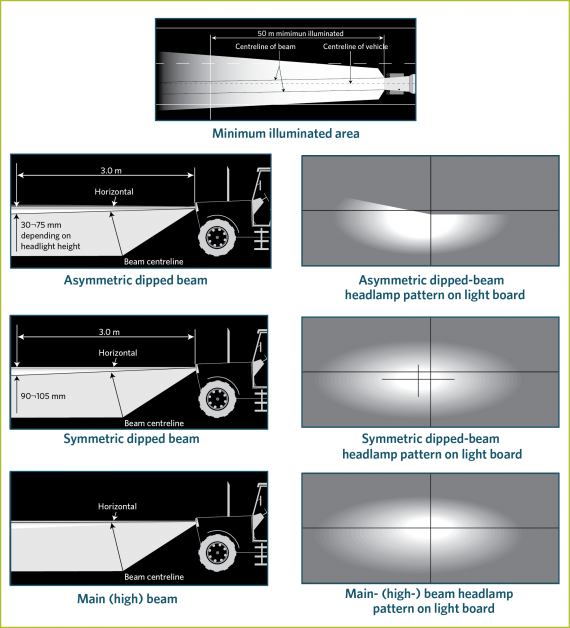

12. When the dipped-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than two lamps operate on dipped beam, or

c) the light beam produces an incorrect beam pattern, is not focused, or is reduced or altered, or

d) the centreline of the light beam is too far to the left or slopes down too far so that the headlamp is no longer capable of illuminating the road at least 50 m ahead (Figure 4-1-1), or

e) the centreline of the light beam:

i. projects to the right of the vehicle’s centreline, or

ii. does not dip at an angle specified in Table 4-1-1.

13. When the main-beam headlamps are switched on (with wheels pointing straight ahead):

a) a lamp does not operate, or

b) more than four lamps operate on main beam, or

c) the centreline of the light beam projects to the right of the vehicle’s centreline or up from the horizontal, or

d) the lamps are not capable of being switched to dipped beam or turned off from the driver’s seating position, or

e) a main-beam headlamp warning device does not indicate to the driver that the main-beam headlamps are switched on.

Note 1

If the dipped-beam headlamps are able to be adjusted from the driver’s seating position, the alignment must be checked with the adjustment at its highest position.

Note 2

If the vehicle is fitted with self-levelling suspension, the alignment must be checked with the suspension at its normal level.

Note 3 Definition

Headlamp means a lamp designed to illuminate the road ahead of a vehicle, and that is:

a) a dipped-beam headlamp (single lamp), or

b) a main-beam (high-beam) headlamp (single lamp), and includes a driving lamp, or

c) a combination of a dipped-beam headlamp and a main-beam headlamp (dual-lamp unit).

Note 4

If a headlamp is fitted with a readily removable cover, other than a clear protective cover, this must be removed for inspection of the headlamp.

Note 5

A vehicle originally manufactured with a headlamp arrangement that differs from what is required or permitted in this section may retain the original headlamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Note 6

A high-intensity discharge (HID or Xenon HID) or LED conversion kit consists of an HID or LED bulb which fits into the original headlamp unit in place of the original bulb with no change to the headlamp lens, reflector or housing.

It is illegal to fit an HID or LED conversion kit to a vehicle as it brings the headlamp out of standards compliance by producing poor beam patterns and light that is often far too bright to be safe. The bulbs can also produce light that is noticeably blue and not the required substantially white or amber colour. Vehicle and headlamp manufacturers do not permit this modification, and these kits cannot be LVV certified.

It is permitted to replace a complete halogen headlamp unit with a complete HID or LED headlamp unit. If the vehicle is required to meet an approved safety standard for headlamps, only approved headlamps can be retrofitted.

Table 4-1-1. Allowable dipped-beam headlamp alignment

Headlamp type | Distance from ground to centre of light source | Dip rate of beam centre: | |||

|---|---|---|---|---|---|

Percent (%) | mm/3m | Degrees (°) | |||

EITHER | Any headlamp dipped beam | N/A | As specified by the vehicle or headlamp manufacturer | ||

OR | Headlamp with symmetric dipped-beam pattern | N/A | 3.0–3.5 | 90–105 | 1.7–2.0 |

OR | Headlamp with asymmetric dipped-beam pattern and distance from ground to centre of light source | less than 0.8m | 1.0–1.5 | 30–45 | 0.57–0.85 |

0.8–1.2m | 1.0–2.0 | 30–60 | 0.57–1.15 | ||

more than 1.2m | 2.0–2.5 | 60–75 | 1.15–1.43 | ||

Table 4-1-2. Dipped-beam angle conversions

Percent (%) | mm/3m | Degrees (°) | Percent (%) | mm/3m | Degrees (°) | |

|---|---|---|---|---|---|---|

1.0 | 30 | 0.6 | 2.3 | 69 | 1.3 | |

1.1 | 33 | 0.6 | 2.4 | 72 | 1.4 | |

1.2 | 36 | 0.7 | 2.5 | 75 | 1.4 | |

1.3 | 39 | 0.7 | 2.6 | 78 | 1.5 | |

1.4 | 42 | 0.8 | 2.7 | 81 | 1.5 | |

1.5 | 45 | 0.9 | 2.8 | 84 | 1.6 | |

1.6 | 48 | 0.9 | 2.9 | 87 | 1.7 | |

1.7 | 51 | 1.0 | 3.0 | 90 | 1.7 | |

1.8 | 54 | 1.0 | 3.1 | 93 | 1.8 | |

1.9 | 57 | 1.1 | 3.2 | 96 | 1.8 | |

2.0 | 60 | 1.1 | 3.3 | 99 | 1.9 | |

2.1 | 63 | 1.2 | 3.4 | 102 | 1.9 | |

2.2 | 66 | 1.3 | 3.5 | 105 | 2.0 |

Figure 4-1-1. Headlamp beams

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A vehicle:

a) must be fitted with one pair of dipped-beam headlamps, and

b) may be fitted with one or two pairs of main-beam headlamps.

2. A warning device may be fitted that indicates that the main beam headlamps are switched on.

3. A retrofitted pair of headlamps must be symmetrically mounted as far towards each side of the vehicle as is practicable.

Prohibited equipment

4. A dipped-beam headlamp designed solely for a left-hand drive vehicle, where the maximum intensity of the beam is dispersed to the right, must not be fitted.

Condition

5. A headlamp must:

a) be in sound condition, and

b) not be obscured.

Performance

6. A headlamp must operate in a way that is appropriate for the lamp and the vehicle.

7. A headlamp must emit a steady light.

8. A headlamp must provide sufficient illumination and light output to illuminate the road ahead.

9. A pair of headlamps must emit light that is approximately of equal colour and intensity when switched on.

10. A headlamp must emit a beam that is substantially white or amber.

11. A main-beam headlamp must be capable of being dipped or turned off from the driver’s position.

12. A warning device that indicates that the main-beam lamps are in operation must be in good working order.

13. When the headlamps are switched on and the vehicle’s front wheels are pointing in the straight ahead position:

a) the centre of a headlamp beam must be either parallel to or to the left of the longitudinal centreline of the vehicle, and

b) the centre of a main-beam headlamp beam must be either parallel to or dipping down from the horizontal, and

c) the centre of a dipped beam headlamp beam must dip at an angle specified in Table 4-1-1.

14. The dipped-beam headlamps must illuminate the road ahead for 50 m in normal darkness.

15. A headlamp must be fitted with a light source that is specified by the vehicle manufacturer or the headlamp manufacturer.

Page amended 1 April 2021 (see amendment details).

4-5 Direction indicator lamps

Reasons for rejection

Mandatory and permitted equipment

1. A vehicle first registered in New Zealand before 1 January 2006 that is so constructed that the driver’s arm signals cannot be seen from behind the vehicle is not fitted with one pair of rear direction indicator lamps.

2. A vehicle first registered on or after 1 January 2006 is not fitted with one pair of rear direction indicator lamps.

3. A vehicle is fitted with more than:

a) two pairs of lamps at the rear (other than top-mounted lamps), or

b) one pair of top-mounted lamps at the rear, or

c) two pairs of forward-facing lamps, or

d) two side-facing lamps on each side of the vehicle.

4. A vehicle is fitted with a lamp that is not in a pair.

5. A retrofitted lamp, other than a top-mounted lamp, is mounted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the vehicle).

6. A pair of top-mounted lamps is not fitted as close as is practicable to the top corners of the bodywork.

7. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

8. A vehicle is not fitted with a suitable device that indicates to the driver that a lamp has failed.

Condition

9. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

10. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

11. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

12. A visual lamp-failure warning device is obscured from the driver in the driver’s seating position.

Performance

13. When switched on, a direction indicator lamp:

a) does not operate, or

b) does not begin flashing within one second of switching on, or

c) flashes:

i. faster than two flashes per second, or

ii. slower than one flash per second, or

iii. at a different rate from other lamps on the same side.

14. When switched on, a direction indicator lamp emits a light that is:

a) not substantially amber or red to the rear, or

b) not substantially white or amber to the front, or

c) not substantially amber to the side, or

d) not approximately equal in colour or intensity to the other lamp in a pair, or

e) not bright enough to be visible from 100 m in normal daylight and from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source, or

f) too bright, causing significant dazzle to other road users, eg due to an incorrect light source, or

g) altered, eg due to damage or modification.

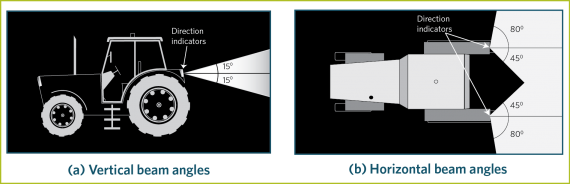

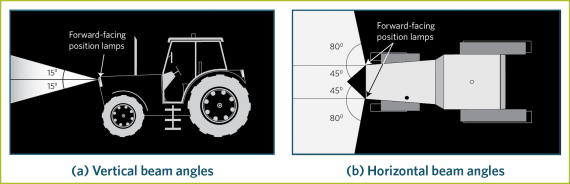

15. A mandatory lamp mounted outside the original position emits a light that is not visible within (Figure 4-5-1):

a) 15° above and below the horizontal, or

b) 45° inboard or 80° outboard.

16. A modification to the vehicle has reduced the visibility angles of a mandatory lamp to less than (Figure 4-5-1):

a) 15° above and below the horizontal, or

b) 45° inboard or 80° outboard.

17. On a vehicle of American specification fitted with combined stop and indicator lamps, the stop lamp function is not overridden by the indicator function.

18. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

19. A lamp failure warning device does not operate.

Note 1

Direction indicator lamp means a lamp designed to emit a flashing light to signal the intention of the driver to change the direction of the vehicle to the right or to the left.

Note 2

A permitted (ie non-mandatory) rear- or a side-facing direction indicator lamp that does not comply with equipment, condition and performance requirements must be made to comply or disabled so that it does not emit a light.

Note 3

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps are considered retrofitted (ie non-OE).

Note 4

Vehicles first registered in New Zealand before 27 February 2005 may have rear direction indicator lamps that also function as reversing lamps.

Note 5

A vehicle originally manufactured with a direction-indicator-lamp arrangement that differs from what is required or permitted in this section may retain the original direction indicator lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Figure 4-5-1. Direction indicator beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A vehicle first registered in New Zealand before 1 January 2006 must be fitted with one or two pairs of rearward-facing lamps if the vehicle is so constructed that it prevents an arm signal given by the driver from being seen behind the vehicle.

2. A vehicle first registered anywhere on or after 1 January 2006 must be fitted with one or two pairs of lamps fitted to the rear of the vehicle.

3. A vehicle may be fitted with an additional pair of lamps at the rear of the vehicle that must be symmetrically mounted as far towards the top corners of the bodywork of the vehicle as is practicable (top-mounted lamps).

4. A vehicle may be fitted with one or two pairs of forward-facing lamps.

5. A vehicle may be fitted with one or two side-facing lamps on each side.

6. A suitable device must be fitted that indicates to the driver the failure of a mandatory lamp.

7. A retrofitted pair of lamps must be mounted:

a) symmetrically as far towards each side of the vehicle as is practicable, and

b) at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the vehicle, not exceeding 2.1m.

8. On vehicles of American specification, the stop lamp and direction indicator lamp function may be combined in one lamp.

Condition

9. A direction indicator lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

10. A direction indicator lamp must operate in a way that is appropriate for the lamp and the vehicle.

11. A direction indicator lamp must emit a light that is substantially:

a) red or amber to the rear, and

b) white or amber to the front, and

c) amber to the side.

11. A lamp must flash at a fixed frequency in the range of 1 to 2 Hertz.

12. Each lamp in a pair must, when operated, emit a light of approximately equal intensity, colour and frequency.

13. The lamp-failure indicating device must function.

14. A lamp must emit a light that is visible from 100 m during normal daylight and 200 m in normal darkness.

15. A mandatory lamp must emit a light that is visible within angles of:

a) 15° above and below the horizontal, and

b) 45° inboard, and

c) 80° outboard.

16. If a vehicle of American specification is fitted with combined stop and indicator lamps, the indicator lamps must override the stop lamps so that the stop lamps operate as direction indicators.

17. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-6 Forward-facing position lamps

Reasons for rejection

Mandatory and permitted equipment

1. One pair of lamps is not fitted to:

a) a vehicle first registered in New Zealand on or after 1 January 1978 that exceeds 1.5m in width, or

b) a vehicle that exceeds 2m in width.

2. A vehicle is fitted with more than:

a) one pair of lamps (other than top-mounted lamps), or

b) two single lamps, or

c) one pair of top-mounted lamps.

3. A retrofitted lamp, other than a top-mounted lamp, is mounted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the vehicle).

4. A pair of top-mounted lamps is not fitted as close as is practicable to the top corners of the bodywork.

5. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

Condition

6. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

7. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

9. A mandatory lamp is obscured.

Performance

10. When switched on, a forward-facing position lamp does not operate.

11. When switched on, a forward-facing position lamp emits a light that is not:

a) substantially white or amber, or

b) diffuse, or

c) projected to the front, or

d) approximately equal in colour or intensity to the other lamp in a pair, or

e) steady, or

f) bright enough to be visible from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source.

12. A non-OE mandatory lamp mounted outside the original position emits a light that is not visible within (Figure 4-6-1):

a) 15° above and below the horizontal, or

b) 45° inboard or 80° outboard.

13. A modification to the vehicle has reduced the visibility angles of a mandatory lamp to less than (Figure 4-6-1):

a) 15° above and below the horizontal, or

b) 45° inboard or 80° outboard.

14. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Position lamp means a low intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps are considered retrofitted (ie non-OE).

Note 3

A vehicle originally manufactured with a forward-facing position lamp arrangement that differs from what is required or permitted in this section may retain the original forward-facing position lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Figure 4-6-1. Forward-facing position lamp beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. One pair of lamps must be fitted to:

a) a vehicle first registered in new Zealand on or after 1 January 1978 that exceeds 1.5m in width, or

b) a vehicle that exceeds 2m in width.

2. One or two lamps may be fitted to:

a) a vehicle that does not exceed 1.5m in width, or

b) a vehicle first registered in New Zealand before 1 January 1978 that does not exceed 2m in width.

3. A retrofitted pair of lamps must be symmetrically mounted as far towards each side of the vehicle as is practicable.

4. A retrofitted lamp must be mounted at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the vehicle, not exceeding 2.1m.

5. A vehicle may be fitted with one additional pair of forward-facing position lamps that must be symmetrically mounted as far towards the top corners of the vehicle as is practicable (top-mounted lamps).

Condition

6. A forward-facing position lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

7. A forward-facing position lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. A lamp must emit a light that is:

a) diffuse, and

b) substantially white or amber, and

c) steady, and

d) sufficient to indicate to other road users the presence and dimensions of the vehicle, and

e) visible from 200m in normal darkness, and

f) of approximately equal intensity and colour to the other lamp of a pair.

9. A mandatory lamp must be visible within angles of:

a) 15° above and below the horizontal, and

b) 45° inboard, and

c) 80° outboard.

10. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-7 Rearward-facing position lamps

Reasons for rejection

Mandatory and permitted equipment

1. A vehicle first registered in New Zealand on or after 1 January 1978 that is more than 1.5m wide is:

a) not fitted with one pair of lamps, or

b) fitted with more than two pairs of lamps (other than top-mounted lamps), or

c) fitted with a lamp that is not in a pair.

2. A vehicle first registered in New Zealand before 1 January 1978 or is less than 1.5m wide is:

a) not fitted with a single lamp or one pair of lamps, or

b) fitted with more than one single lamp, or

c) fitted with more than two pairs of lamps (other than top-mounted lamps).

3. A vehicle is fitted with more than one pair of top-mounted lamps.

4. A single lamp is fitted to the left of the centre of the vehicle.

5. A pair of top-mounted lamps is not fitted as close as is practicable towards the top corners of the bodywork.

6. A retrofitted lamp, other than a top-mounted lamp, is mounted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the vehicle).

7. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

Condition

8. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

9. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

10. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

11. A mandatory lamp is obscured.

Performance

12. When switched on, a mandatory lamp does not operate.

13. When switched on, a lamp emits a light that is not:

a) substantially red, or

b) diffuse, or

c) projected to the rear, or

d) approximately equal in colour or intensity to that of the other lamp in a pair, or

e) steady, or

f) bright enough to be visible from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source.

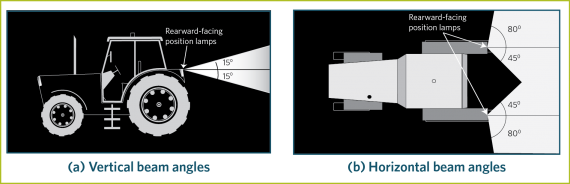

14. A non-OE mandatory lamp mounted outside the original position emits a light that is not visible within (Figure 4-7-1):

a) 15° above and below the horizontal, or

b) 45° inboard or 80° outboard.

15. A modification to the vehicle has reduced the visibility angles of a mandatory lamp to less than (Figure 4-7-1):

a) 15° above and below the horizontal, or

b) 45° inboard or 80° outboard.

14. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A permitted rearward-facing position lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps are considered retrofitted (ie non-OE).

Note 4

A vehicle originally manufactured with a rearward-facing position lamp arrangement that differs from what is required or permitted in this section may retain the original rearward-facing position lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Figure 4-7-1. Rearward-facing position lamp beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A vehicle first registered in New Zealand on or after 1 January 1978 and that is more than 1.5m wide must be fitted with one or two pairs of rearward-facing position lamps.

2. A vehicle that was first registered in New Zealand before 1 January 1978 or that does not exceed 1.5m in width must be fitted with:

a) one single rearward-facing position lamp in the centre or to the right of the centre of the vehicle, or

b) one or two pairs of rearward-facing position lamps.

3. A retrofitted pair of lamps must be mounted:

a) symmetrically as far towards each side of the vehicle as is practicable, and

b) at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the vehicle, not exceeding 2.1m.

4. A vehicle may be fitted with an additional pair of rearward-facing position lamps symmetrically mounted as far towards each side and top of the bodywork of the vehicle as possible (top-mounted lamps).

Condition

5. A rearward-facing position lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

6. A rearward-facing position lamp must operate in a way that is appropriate for the lamp and the vehicle.

7. A lamp must emit a light that is:

a) diffuse, and

b) substantially red.

8. A lamp must emit a steady light.

9. A lamp must provide sufficient light output to indicate to other road users the presence and dimensions of the vehicle.

10. A lamp must emit light that is visible from a distance of 200m in normal darkness.

11. A mandatory lamp must be visible within angles of 15° above and below the horizontal, and within 45° inboard and 80° outboard.

12. Each lamp in a pair must, when operated, emit a light of approximately equal intensity and colour.

13. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-8 Side-marker lamps

Reasons for rejection

Permitted and prohibited equipment

1. A vehicle that has a length of less than 6m is fitted with a side-marker lamp.

2. A vehicle is fitted with side-marker lamps that do not give an indication of the vehicle’s dimensions.

Condition

3. A lamp is insecure.

4. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

5. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

6. When switched on, a lamp emits a light that is not:

a) steady, or

b) diffuse, or

c) substantially red or amber to the rear, or

d) substantially white or amber to the front.

7. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1 Definitions

Side-marker lampmeans a position lamp designed to be fitted to the side of a vehicle or its load.

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A permitted side-marker lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

A vehicle originally manufactured with a side-marker lamp arrangement that differs from what is required or permitted in this section may retain the original side-marker position lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Permitted and prohibited equipment

1. A vehicle with a length of 6m or more may be fitted with one or more side-marker lamps on each side.

2. A vehicle with a length of less than 6m must not be fitted with side-marker lamps.

3. The position of the lamps must be such that it gives an indication of the vehicle’s dimensions.

Condition

4. A side-marker lamp must be in good condition.

Performance

5. A side-marker lamp must operate in a way that is appropriate for the lamp and for the vehicle.

6. A lamp must emit a light that is:

a) steady, and

b) diffuse, and

c) substantially red or amber to the rear, and

d) substantially white or amber to the front.

7. Where a side-marker lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-10 Stop lamps

Reasons for rejection

Mandatory and permitted equipment

1. A vehicle first registered in New Zealand on or after 1 January 1978 is:

a) not fitted with one pair of stop lamps, or

b) fitted with a stop lamp that is not in a pair.

2. A vehicle first registered in New Zealand before 1 January 1978 is:

a) not fitted with one single lamp or one pair of lamps, or

b) fitted with more than one single lamp.

3. A vehicle is fitted with more than:

a) two pairs of lamps other than top-mounted lamps, or

b) one pair of top-mounted lamps.

4. A retrofitted stop lamp other than a top-mounted lamp is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the vehicle).

5. A pair of top-mounted lamps is not fitted as far as is practicable towards the top corners of the bodywork of the vehicle.

6. A retrofitted pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

Condition

7. A lamp is insecure.

8. A lens is missing or has a hole, crack or other damage that allows moisture or dirt to enter.

9. A reflector is damaged or has deteriorated so that light output is reduced.

10. A mandatory lamp is obscured, or contains moisture in the form of large droplets, runs or puddles.

Performance

11. When the service brake is activated:

a) a mandatory lamp does not operate, or

b) a lamp does not remain steadily illuminated.

12. A lamp operates when the service brake is not applied.

13. A lamp emits a light that is:

a) not substantially red, or

b) not diffuse, or

c) not projected to the rear, or

d) not approximately equal in colour or intensity from the other lamp in a pair, or

e) not bright enough to produce a light that is visible from 100m in normal daylight, eg due to modification, deterioration, dirt or an incorrect light source.

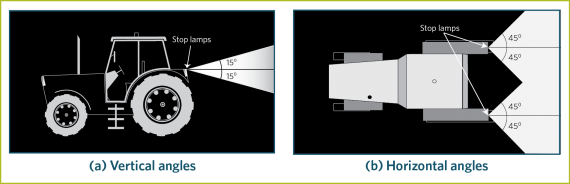

14. A non-OE mandatory lamp mounted outside the original position emits a light that is not visible within (Figure 4-10-1):

a) 15° above and below the horizontal, or

b) 45° inboard and outboard.

15. A modification to the vehicle has reduced the visibility angles of a mandatory lamp to less than (Figure 4-10-1):

a) 15° above and below the horizontal, or

b) 45° inboard and outboard.

16. On a vehicle of American specification fitted with combined stop and direction indicator lamps, the stop lamp function is not overridden by the indicator function.

17. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Stop lamp means a lamp that is designed to operate when the service brake is applied.

Note 2

A permitted stop lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

An original equipment (OE) lamp is one that is fitted by the vehicle manufacturer in the original position, or is an equivalent replacement or aftermarket lamp suitable for the position provided by the vehicle manufacturer for that lamp. All other lamps are considered retrofitted (ie non-OE).

Note 4

A vehicle originally manufactured with a stop-lamp arrangement that differs from what is required or permitted in this section may retain the original stop lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Figure 4-10-1. Stop lamp visibility angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A vehicle first registered in New Zealand on or after 1 January 1978 must be fitted with one or two pairs of stop lamps.

2. A vehicle first registered in New Zealand before 1 January 1978:

a) may be fitted with one stop lamp or one or two pairs of stop lamps, or

b) must be fitted with one stop lamp or one or two pairs of stop lamps if the vehicle is so constructed that it prevents the driver’s arm signal from being seen from behind the vehicle.

3. A retrofitted pair of stop lamps must be symmetrically mounted as far towards each side of the vehicle as is practicable.

4. A retrofitted stop lamp must be fitted at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the vehicle, not exceeding 2.1m.

5. A vehicle may be fitted at the rear with an additional pair of stop lamps provided they are positioned as close as is practicable to the top of the bodywork of the vehicle (top-mounted lamps).

Condition

6. A stop lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

7. A stop lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. The light emitted from a stop lamp must be diffuse light that is substantially red.

9. A required stop lamp must operate when a service brake is activated.

10. A required stop lamp must provide sufficient light output to be visible from 100m.

11. A stop lamp must emit a steady light.

12. A retrofitted mandatory stop lamp must emit a light that is visible within the angles of 15° above and below the horizontal, and 45° inboard and outboard.

13. If a vehicle of American specification is fitted with combined stop and direction indicator lamps, the indicator lamps must override the stop lamps so that the stop lamps will operate as direction indicators.

14. Where a stop lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 28 April 2014 (see amendment details).

4-12 Rear-reg.-plate illumination lamps

Reasons for rejection

Mandatory equipment

1. A vehicle is not fitted with at least one rear-registration-plate illumination lamp.

Condition

2. A lamp is insecure.

3. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

4. A reflector, or lens, is damaged or has deteriorated so that light output is reduced.

Performance

5. The lamp emits a light that is not:

a) substantially white, or

b) steady, or

c) diffuse.

6. The lamp does not illuminate the registration plate (eg either the lamp or plate have been moved, or the lamps orientation has been changed).

7. The light source of a lamp is visible from the rear of the vehicle.

Note 1

Rear-registration-plate illumination lamp means a lamp designed to illuminate the rear registration plate of a vehicle.

Note 2

A vehicle originally manufactured with a rear-registration-plate illumination lamp arrangement that differs from what is required or permitted in this section may retain the original rear-registration-plate illumination lamps provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle must be fitted with at least one rear-registration-plate illumination lamp.

Performance

2. A rear-registration-plate illumination lamp must operate in a way that is appropriate for the lamp and the vehicle.

3. A lamp must emit a diffuse light that is substantially white.

4. A rear-registration-plate illumination lamp must emit a steady light.

5. The light source of the lamp must not be visible from the rear of the vehicle.

6. A lamp must illuminate the figures and letters of the plate so that they are visible from 20m during normal darkness.

7. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 1 October 2021 (see amendment details).

4-13 Rear reflectors

Reasons for rejection

Mandatory and permitted equipment

1. A vehicle is:

a) not fitted with at least one rearward-facing reflector on each side, or

b) fitted with a rearward-facing reflector that is not in a pair.

2. A reflector is not positioned to the rear of the vehicle.

3. A retrofitted reflector is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5 m is not practicable due to the shape of the bodywork of the vehicle).

4. A retrofitted pair of reflectors is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the vehicle as is practicable.

Condition

5. A mandatory reflector’s ability to reflect light is affected by excessive:

a) fading, or

b) scratching or other damage.

6. A mandatory reflector is obscured.

Performance

7. The reflected light from a mandatory reflector is not visible from 100m.

8. The reflected light from a reflector is not red.

Note 1 Definitions

Reflector means a discreet item of lighting equipment that is designed to reflect incident light back towards the light source, but does not include reflective material (such as reflective tape).

Reflective material means any material that is designed to reflect incident light back towards the light source, and includes reflective tape, but does not include a reflector.

Note 2

A vehicle originally manufactured with a rear reflector arrangement that differs from what is required or permitted in this section may retain the original rear reflectors provided they remain fitted in their original position and perform as intended by the vehicle manufacturer.

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A vehicle must be fitted with at least one pair of rearward-facing reflectors at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the vehicle, not exceeding 2.1m.

2. A rearward-facing reflector must be positioned to the rear of the vehicle.

3. A reflector must be of an area that allows it to reflect light to improve the visibility of the vehicle to other road users, but it must not cause them undue dazzle or discomfort.

4. A retrofitted pair of reflectors must be symmetrically mounted as far towards each side of the vehicle as is practicable.

Condition

5. A mandatory reflector must be in good condition and not be obscured.

Performance

6. A reflector must operate in a way that is appropriate for the reflector and the vehicle.

7. A reflector must reflect white light as substantially red light.

8. A reflector must provide sufficient light reflection to fulfil its intended purpose.

5 Vision

5-1 Glazing

Reasons for rejection

Glazing condition

1. A piece of glazing is not mechanically sound, or is not securely affixed to the vehicle.

2. A windscreen or front-side window is so dirty or obstructed that the driver’s vision is unreasonably impaired.

3. A windscreen has damage that prevents the wiper blades from working properly.

4. A windscreen has scratches, discoloration or other defects that unreasonably impair the driver’s vision or compromise the strength of the windscreen.

Glazing performance

5. A modification has:

a) unreasonably impaired vision through a windscreen or a front-side window, or

b) adversely affected the strength or mechanical performance of the glazing.

Note 1

Damage includes any unrepaired damage and attempted visible repairs.

Note 2

Windscreen means all glazing extending across the front of the vehicle that is not parallel to the vehicle’s centreline but does not include a wind deflector.

Summary of legislation

Glazing condition

1. Glazing must be mechanically sound, strong and securely affixed to the vehicle.

2. A windscreen and front-side windows must be clean and free of obstruction to ensure the driver has sufficient vision through the glazing to operate the vehicle safely.

3. A windscreen must not have scratches and other defects that:

a) unreasonably impair vision, or

b) compromise its strength.

4. A laminated windscreen must not show signs of discoloration that could unreasonably impair the driver’s vision.

5. Glazing in roof panels may be tinted.

6. Overlays must not have any bubbling or other defects that could unreasonably impair vision.

Glazing performance

7. A modification must not:

a) unreasonably impair vision through a windscreen or a front-side window, nor

b) adversely affect the strength or mechanical performance of the glazing or the vehicle.

Page amended 1 June 2013 (see amendment details).

5-2 Sun visors

Reasons for rejection

Mandatory equipment

1. A vehicle with a windscreen is not fitted with a sun visor for the driver’s use if it is reasonable and practical to do so (Note 1).

Condition

2. A sun visor:

a) is insecurely mounted, or

b) for the driver cannot be adjusted from the normal driving position, or

c) cannot maintain its adjusted position, or

d) has been modified or has deteriorated, and the likelihood of injury to vehicle occupants has not been minimised.

Performance

3. A driver’s sun visor does not effectively aid the driver’s vision by intercepting the glare from the sun.

Note 1

Sun visor means any attachment mounted above the inside of the windscreen and provided for the purpose of shielding the eyes of the driver and other front passengers from solar glare.

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle with a windscreen must be fitted with a sun visor for the driver’s use if it is reasonable and practicable to do so (Note 1).

Permitted equipment

2. Additional sun visors may be fitted in other positions.

Sun visor performance

3. A driver’s sun visor must be effective.

5-3 Windscreen wipe and wash

Reasons for rejection

Mandatory equipment

1. A vehicle that has a windscreen is not fitted with a windscreen wipe system.

2. A vehicle manufactured on or after 1 January 2001 that is fitted with a windscreen is not fitted with a windscreen wash system.

3. A vehicle manufactured on or after 1 January 1960 is fitted with wipers that are not power driven.

Condition

Windscreen wipe system

4. The wiper operating device is missing.

5. A wiper arm or wiper blade is:

a) missing, or

b) insecure, or

c) damaged so as to affect the performance of the wipers.

6. The wiper operating mechanism is:

a) missing, or

b) insecure, or

c) damaged so as to affect the performance of the wipers.

Windscreen wash system

7. A wash system component is missing or insecure.

8. The wash operating device is missing.

Performance

Windscreen wipe system

9. A windscreen wiper does not wipe the windscreen effectively, preventing adequate forward vision by the driver.

10. The wipe operating device is unable to activate the wipe system.

Windscreen wash system

11. A windscreen wash nozzle does not discharge washer liquid directly onto the windscreen.

12. The wash operating device is unable to activate the wash system.

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle manufactured before 1 January 2001 that is fitted with a windscreen must have a windscreen wipe system.

2. A vehicle manufactured on or after 1 January 2001 that is fitted with a windscreen must have a windscreen wipe and wash system.

3. Windscreen wipers must be power driven, unless they follow OE specifications in a vehicle manufactured before 1 January 1960.

Permitted equipment

4. A vehicle may be fitted with a wash system when this is not required.

Condition

5. A vehicle’s windscreen wipe system must be efficient and within the vehicle manufacturer’s operating limits.

Performance

6. The equipment fitted must be capable of keeping an adequate area of the windscreen clean and clear so that the vehicle may be operated safely under all reasonably foreseeable conditions.

5-4 Rear-view mirrors

Reasons for rejection

Mandatory equipment

1. A vehicle fitted with a permanent cab is not fitted with a rear-view mirror.

2. A vehicle with tint film overlays on a rear or rear-side window is not fitted with an exterior rear-view mirror on each side.

Condition

3. A rear-view mirror:

a) is not mounted securely, or

b) cannot be adjusted, or

c) cannot maintain its adjusted position, or

d) is corroded or dirty, or

e) is damaged so that it increases the risk of injury to vehicle occupants.

Performance

4. A rear-view mirror:

a) does not provide a clear view to the rear of the vehicle, or

b) is not sufficiently isolated from vibrations.

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle must be fitted with a rear-view mirror.

2. A vehicle with tint film overlays on the rear or rear -side windows must be fitted with a left-hand and a right-hand exterior mirror.

Permitted equipment

3. Additional rear-view mirrors may be fitted.

Condition

4. A rear-view mirror must be:

a) securely attached so that the risk of injury is minimised, and

b) mounted so that vibration does not inhibit the driver’s required clear view to the rear, and

c) sufficiently adjustable, and able to maintain its position.

Performance

5. A rear-view mirror must provide a clear view to the rear of:

a) the motor vehicle itself, and

b) the vehicle’s load, and

c) any towed trailer and its load.

6. A rear-view mirror must be sufficiently isolated from vibrations.

6 Entrance and exit

6-1 Door and hinged panel retention systems

Reasons for rejection

Mandatory equipment

1. A vehicle fitted with doors used by the driver or passengers for entrance and exit of the vehicle does not have a door retention system.

Equipment condition

2. A hinge for a door or other hinged panel is not securely attached to both the vehicle body and to the door or other hinged panel, eg due to loose connections, corrosion or other damage.

3. A door used for entrance and exit of the driver or passengers cannot be opened from the inside.

Equipment performance

4. A door used for entrance and exit of the driver or passengers does not open or close easily, eg a door is sticking or requires unreasonable force to open.

5. A door or other hinged panel does not remain secure in a closed or locked position.

Note 1

Corrosion damage is where the metal has been eaten away, which is evident by pitting. The outward sign of such corrosion damage is typically displayed by the lifting or bubbling of paint. In extreme cases, the area affected by the corrosion damage will fall out and leave a hole.

Summary of legislation

Applicable legislation

- Land Transport Rule: Door Retention Systems 2001

- Land Transport Rule: Vehicle Standards Compliance 2002, section 7.4.

Mandatory equipment

1. A motor vehicle fitted with doors used by the driver or passengers for entrance and exit of the motor vehicle must have a door retention system.

Condition

2. A door retention system and its mountings must be safe and structurally sound.

3. A door used for the entrance and exit of the driver or passengers must be operable by any occupant seated by the door from inside the motor vehicle.

4. The vehicle must be designed and constructed using components and materials that are fit for their purpose, and within safe tolerance of their state when manufactured or modified.

Performance

5. A door retention system must be in good working order.

6. A door used for entrance and exit must open and close easily.

7. A door used for entrance and exit must remain secure in a closed position during the operation of the vehicle.

7-1 Seats and seat anchorages

Reasons for rejection

Mandatory equipment

1. The vehicle is not fitted with a driver’s seat.

2. A seat is not attached to the vehicle structure by seat anchorages.

Condition and performance

3. A seat frame or structure has been weakened, eg due to damage, corrosion or excessive wear.

4. The adjustment mechanism of a driver’s seat:

a) does not operate, or

b) is worn, causing excessive movement of the seat.

5. The attachment of the seat to the seat anchorage is loose or weakened by damage.

6. The attachment of the seat anchorage to the vehicle structure is loose or weakened by damage.

7. The driver’s seat is in such a condition that it does not allow the driver to have proper control of the vehicle.

Note 1

A seat may be capable of being rotated or placed to face in different directions.

Note 1

A seat may be capable of being rotated or placed to face in different directions.

Note 2

Corrosion damage is where the metal has been eaten away, which is evident by pitting. The outward sign of such corrosion damage is typically displayed by the lifting or bubbling of paint. In extreme cases, the area affected by the corrosion damage will fall out and leave a hole.

Summary of legislation

Applicable legislation

Mandatory equipment

1. A motor vehicle must be fitted with a driver’s seat.

2. A seat in a motor vehicle must be fitted to the vehicle structure by means of seat anchorages.

Condition and performance

3. Seats and seat anchorages must be safe, strong, in sound condition and compatible in strength with each other and with the vehicle structure.

4. The driver’s seat and its anchorages must be designed, constructed and maintained to enable the driver to have proper control of the vehicle.

5. Seats and seat anchorages must be securely attached to the vehicle structure.

6. When a seatbelt or any part of the seatbelt is integral to a seat, the seat and seat anchorages must be compatible in strength with the seatbelt or with that part of the seatbelt attached to the seat.

7-12 Speedometer

Reasons for rejection

Mandatory equipment

1. A vehicle first registered in New Zealand on or after 1 December 1951 that is capable of a speed exceeding 50km/h is not fitted with a speedometer, and the vehicle operator cannot produce acceptable written evidence (Note 2) that:

a) the speedometer has been removed for repair, or

b) there are no undue delays by the vehicle owner in having the speedometer replaced.

Condition and performance

2. A mandatory speedometer:

a) does not operate as intended when the vehicle is moving forward (Note 3), or

b) is obscured from the driver’s position, or

c) does not indicate the vehicle’s speed in km/h or mph.

3. Reason for rejection 2(a), 2(b) or 2(c) applies and the vehicle operator cannot produce acceptable written evidence (Note 2) that repair of the speedometer or associated equipment is impracticable or that a suitable replacement is not available.

Note 1

Speedometer means an instrument in a motor vehicle that is used to determine forward speed of the vehicle in kilometres per hour (km/h) or miles per hour (mph).

Note 2

Acceptable written evidence is documentation provided by the speedometer repairer or supplier. A copy of the documentation must be kept on file with the checksheet.

Note 3

If an odometer is not fitted, not working or unable to be read an appropriate note must be entered into the ‘Comments’ section of the checksheet and '000001' entered into the odometer field of the checksheet and '000001' entered into WoF online or LANDATA. This may display as “1” on some screens.

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle first registered in New Zealand on or after 1 December 1951 that is capable of a speed exceeding 50km/h must be fitted with a speedometer (Note 1).

2. A vehicle is not required to have a speedometer if the speedometer or associated equipment:

a) has been removed for repair and there are no undue delays by the vehicle owner in having it replaced, or

b) is out of repair, repair is impracticable and a suitable replacement is not available.

Performance

3. A mandatory speedometer must be in good working order and operate while the vehicle is moving forward.

Page amended 1 October 2022 (see amendment details)

7-13 Audible warning devices

Reasons for rejection

Mandatory equipment

1. A motor vehicle is:

a) not fitted with a horn, or

b) fitted with a bell, whistle or siren that is not part of an anti-theft car alarm, personal security alarm or a reversing warning device.

Performance

2. The horn does not operate when activated.

3. The horn operates when not activated.

4. The sound from the horn is not steady and continuous, eg the horn plays a tune.

5. The horn is not audible at a distance of 100m.

Summary of legislation

Applicable legislation

Mandatory equipment

1. A vehicle must be fitted with a device (horn) that is audible to other road users.

Permitted equipment

2. A vehicle may be fitted with a bell, whistle or siren that is part of an anti-theft car alarm, personal security alarm or a reversing warning device.

Performance

3. The device must be in good working order.

4. The device must be capable of giving a warning that is audible under normal traffic conditions from a distance of at least 100m.

8 Brakes

8-1 Service brake and parking brake

Reasons for rejection

Mandatory equipment

Service brake (Note 1)

1. A vehicle does not have a service brake that acts on the wheels as designed by the vehicle manufacturer.

2. A light tractor manufactured on or after 1 January 1990 and not capable of exceeding a speed of 40km/h does not have a service brake designed to act on the wheels that are intended to provide traction.

Parking brake (Note 1)

3. A vehicle does not have a parking brake.

4. A parking brake does not act on at least one complete axle.

5. Where dual wheels are fitted, a parking brake does not act on at least one axle that has dual wheels fitted.

Condition

Service brake

6. There is corrosion damage (Note 2) within 150mm of a brake component mounting point.

7. The service brake pedal:

a) is insecure, or

b) is spongy (indicating air in the system), or

c) creeps, or

d) has a non-slip surface which has deteriorated to such an extent that the brake cannot be safely applied, or

e) has excessive travel (pedal travel reduces after one or two applications).

8. The brake pedal locking attachment on a tractor with split brake pedals is insecure, damaged or has deteriorated to such an extent that it is no longer fit for purpose.

9. The brake master cylinder is:

a) leaking brake fluid, or

b) insecure, or

c) excessively corroded.

10. A brake valve is:

a) not operating (eg has a seized-load sensing valve), or

b) leaking brake fluid, or

c) insecure, or

d) excessively corroded.

11. A brake pipe (including connections) is:

a) leaking brake fluid, or

b) insecure, or

c) deformed from its original shape, or

d) chafed, or

e) excessively corroded, eg there are signs of pitting or a noticeable increase in the pipe’s outside diameter.

12. A flexible hydraulic brake hose (including connections):

a) is leaking brake fluid, or

b) is insecure, or

c) bulges under pressure, or

d) is twisted, stretched or chafed, or

e) has external sheathing which is cracked to the extent that the reinforcing cords are exposed, or

f) has metal connections that are excessively corroded, or

g) has an end fitting that is not attached to the hose by means of swaging, machine crimping or a similar process (Note 3).

13. A brake calliper:

a) shows visible signs of leaking, or

b) is insecure.

14. A brake backing plate is:

a) insecure, or

b) severely corroded, or

c) deformed from its original shape, or

d) cracked, or

e) contaminated by brake fluid, oil or grease.

15. A wheel cylinder:

a) shows visible signs of leaking, or

b) is insecure, or

c) is seized.

16. An ABS system component is damaged, insecure or missing.

17. A brake disc or drum is:

a) worn beyond manufacturer’s specifications (where visible without removing vehicle components), or

b) fractured or otherwise damaged (where visible without removing vehicle components), or

c) contaminated by brake fluid, oil or grease.

18. Brake friction material (where visible without removing vehicle components) is:

a) worn below manufacturer’s specifications, or

b) separating from the brake pad backing plate or brake shoe, or

c) contaminated by brake fluid, oil or grease.

19. A service brake component shows signs of heating or welding after original manufacture.

Parking brake

20. The parking brake lever:

a) has excessive travel, or

b) is insecure, or

c) mounting is damaged, corroded, distorted or fractured within 150mm of the lever mounting, or

d) mechanism or lever pivot bearing is worn or damaged so that the parking brake could be easily released by accident.

21. The parking brake cable:

a) is knotted, frayed or excessively corroded, or

b) has an auxiliary tensioner fitted, or

c) has otherwise deteriorated so that it may affect the parking brake performance.

22. A parking brake actuating rod or guide:

a) is excessively corroded, or

b) is excessively worn, or

c) has otherwise deteriorated so that it may affect the parking brake performance.

23. A parking brake component shows signs of heating or welding after original manufacture.

24. The locking mechanism on a service brake that is designed to be locked in applied position (Note 1):

a) is missing a component, or

b) does not operate, or operates incorrectly, or

c) is insecure, damaged or has significantly deteriorated.

Performance

Service brake

25. The service brake cannot be applied in a controlled and progressive manner.

26. When the service brake is applied without assistance from the engine, a vehicle does not stop within 7m from a speed of 30km/h (50% efficiency) except in the following cases:

a) a heavy vehicle manufactured before 1 February 1977 with a service brake that is designed to act on fewer than 4 wheels does not stop within 9m from a speed of 30km/h (40% average brake efficiency), or

b) a light tractor manufactured before 1 January 1990 does not stop in a manner that is reasonable for the type of service brake fitted.

27. When the service brake is applied:

a) the vehicle vibrates under braking to the extent that the control of the vehicle is adversely affected, or

b) the brake fails to release immediately after the brake pedal has been released, or

c) the directional control is affected (eg there is swerving to one side, or the brakes on one side apply more slowly than on the other side).

28. The ABS or brake system warning lamp or self-check system, if fitted, indicates a defect in the ABS or brake system (does not apply to brake pad wear warning systems).

Parking brake

29. When the parking brake is applied:

a) the vehicle does not stop within 18m from a speed of 30km/h (average brake efficiency of 20%), or

b) it does not hold the vehicle at rest on a slope of 1 in 5, or

c) it does not hold all the wheels on a common axle stationary against attempts to drive the vehicle away.

Note 1 Definitions

Service brake means a brake for intermittent use that is normally used to slow down and stop a vehicle. The service brake of a tractor which acts directly on the transmission or the rear wheels only is considered to act on all wheels if the transmission shifts automatically from two-wheel drive to four-wheel drive when the service brake is applied.

Parking brake means a brake readily applicable and capable of remaining applied for an indefinite period without further attention. A parking brake may be lever operated, or may be a transmission lock or a service brake that is capable of being locked in the applied position.

Note 2

Corrosion damage is where the metal has been eaten away, which is evident by pitting. The outward signs of such corrosion damage is typically displayed by the lifting or bubbling of paint. In extreme cases, the area affected by the corrosion damage will fall out and leave a hole.

Note 3

Hose end fittings that can be undone using hand tools are unacceptable.

Note 4