In-service certification (WoF and CoF) - General trailers

Correct as at 19th April 2024. It may be superseded at any time.

2 Vehicle exterior

2-1 External projections

Reasons for rejection

Condition and performance (Note 1)

1. The risk of a component (Note 2) hooking a vehicle, or hooking or grazing a person, has not been minimised.

2. An ornamental object or fitting (Note 3) protrudes in such a way that it is likely to injure a person.

3. A protruding object or fitting (Note 4) that has a functional purpose is not installed so that the risk of causing injury to a person is minimised, eg the object or fitting:

a) is of excessively heavy construction for the purpose for which it has been fitted, or

b) has sharp corners, or

c) exceeds the vehicle’s width by more than 100mm on either side.

4. A protruding component, object or fitting is not securely fitted.

5. A protruding object or fitting adversely affects the driver’s vision or control.

Note 1

The external projections requirements relate to the design and maintenance of objects and fittings that protrude from the exterior of the motor vehicle with regard to the safety of other motor vehicles, pedestrians and cyclists. The attachment of such objects and fittings to the vehicle is addressed in the Vehicle structure section of this manual.

Note 2

Components include damaged, corroded and exposed body panels.

Note 3

Ornamental object or fitting means any object or fitting that does not have a practical purpose.

Note 4

Functional object or fitting means an object or fitting that has a practical purpose, eg load restraints.

Summary of legislation

Applicable legislation

Permitted equipment

1. A motor vehicle may be fitted with a protruding ornamental or functional object or fitting.

Condition and performance

2. A protruding ornamental object or fitting must not be likely to injure a person.

3. A protruding object or fitting that has a functional purpose must be installed so that the risk of the object or fitting causing injury to a person is minimised.

4. Components of a motor vehicle, including damaged or corroded body panels, must be such that the risk of their hooking a vehicle, or hooking or grazing a person, is minimised.

5. A protruding object or fitting must not adversely affect driver vision or driver control.

2-2 Dimensions

Reasons for rejection

Mandatory equipment

1. A trailer with a GVM of 3500kg or less exceeds the dimension requirements set out in Table 2-2-1 and is not fitted with the appropriate hazard warning equipment set out in Table 2-2-2.

2. A trailer with a GVM of 3500kg or less exceeds the dimensions set out in Table 2-2-1 and is not:

a) a specialist overdimension trailer (Note 6), or

b) a trailer designed primarily to transport an overdimension load, or

c) a trailer operating on a valid permit, exemption or approval.

Note 1

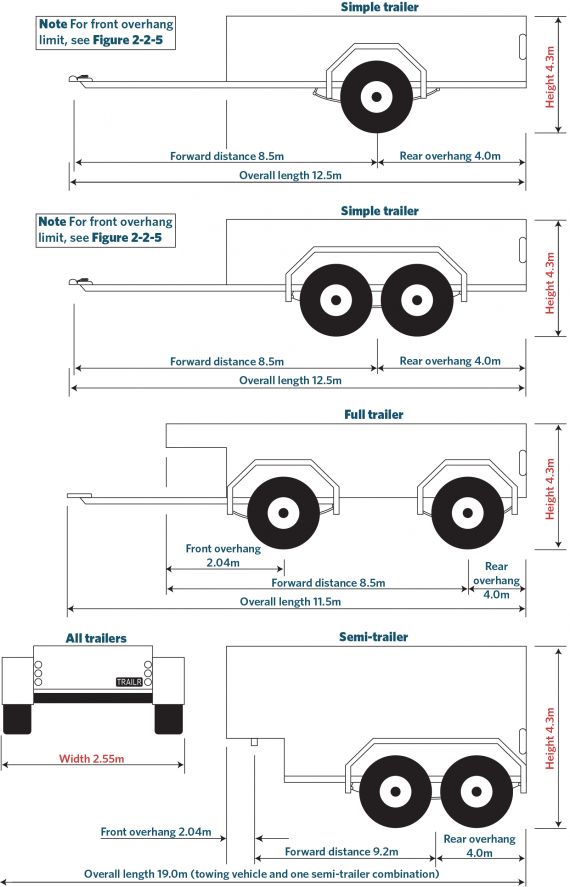

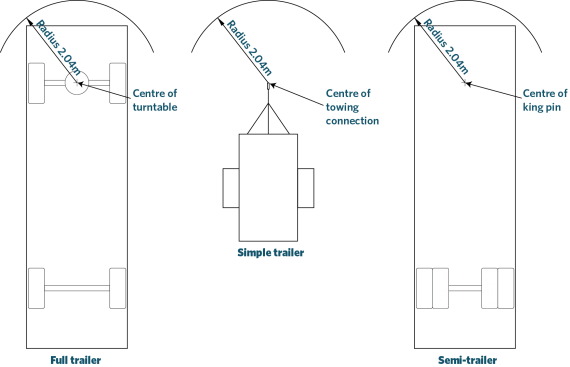

Definitions of trailer types:

- simple trailer means a trailer (other than a semi-trailer) that has only one axle set

- full trailer means a trailer with two axles sets, the foremost of which is steered by a drawbar, and includes a semi-trailer with non-steering axles (Note 4) coupled to a converter dolly

- semi-trailer means a trailer with only one axle set where the point of attachment to the towing vehicle or leading trailer:

a) is no further rearward than the rearmost axle of the towing vehicle or rearmost axle of the leading trailer, or

b) if the towing vehicle is a rigid vehicle (Note 5) and has more than one axle in its rear axle set, is no more than 300mm rearward of the rear axis of the towing vehicle.

Note 2

An over-dimension trailer is one that is either:

a) fitted with an over-dimension piece of equipment, or

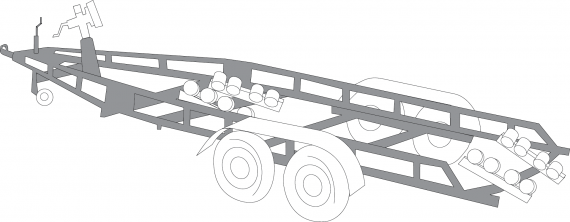

b) designed to carry an over-dimension load that cannot be divided, eg glider trailers and large boat trailers, or

c) a specialist overdimension trailer.

Operational requirements for such trailers are given in Factsheet 53a – Overdimension vehicles and loads.

Note 3

Rear axis of a vehicle means:

a) trailers with one non-steering axle: centre of that axle

b) trailers with a non-steering axle set consisting of two axles: midway between those two axles if each axle has an equal number of tyres on it, or two-thirds of the distance from the lesser-tyred axle towards the greater-tyred axle, if one axle has twice as many tyres on it as the other axle.

Note 4

Non-steering axle means any axle of a vehicle, the wheels of which remain substantially parallel with the longitudinal centreline of the vehicle while the vehicle is turning.

Note 5

Rigid vehicle means a vehicle with motive power, driver’s position and steering system, that does not have any pivot points to allow any part of the vehicle chassis to move or rotate in relation to any other part of the vehicle chassis, but includes a pivot steer vehicle.

Note 6

Specialist overdimension trailer means a trailer where its primary purpose is to carry out a specialist function that requires overdimension equipment, and the dismantling of the equipment would make it unusable for its intended purpose, or it would take more than four hours to dismantle the equipment.

Table 2-2-1. Dimension requirements

Note All measurements must be taken with the vehicle combination in a straight line.

Dimension | Maximum distance | Comments |

|---|---|---|

Width | 2.55m 1.275m from each side of the longitudinal centreline of the trailer | Measurement does not include:

|

Overall length | 12.5m (simple trailers) 11.5m (full trailers) | For a full trailer, measurement is to the centre of the towing eye. |

Height | 4.3m | |

Forward distance | 8.5m (simple and full trailers) 9.2m (semi-trailer) | Forward distance is measured from:

|

Rear overhang | 4m | Rear overhang is measured from the rear axis to the rear of the vehicle or its load, whichever is greater. |

Front overhang | 2.04m radius arc ahead of:

| Front overhang (Figure 2-2-5) is measured from:

|

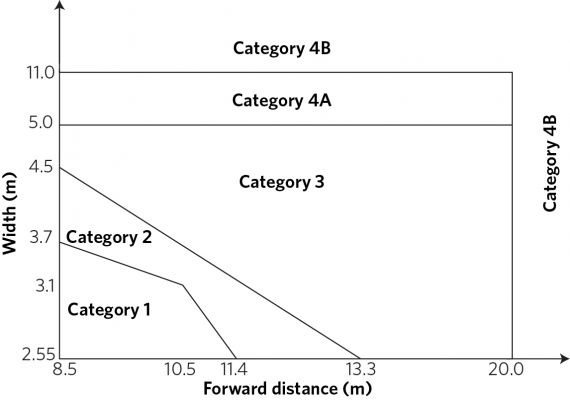

Table 2-2-2. Hazard warning equipment requirements for vehicles that exceed the dimensions in Table 2-2-1 (see Figure 2-2-3 for vehicle category thresholds)

Vehicle category (See Figure 2-2-3) | Dimension | Limits (up to and including) | Required hazard warning equipment |

|---|---|---|---|

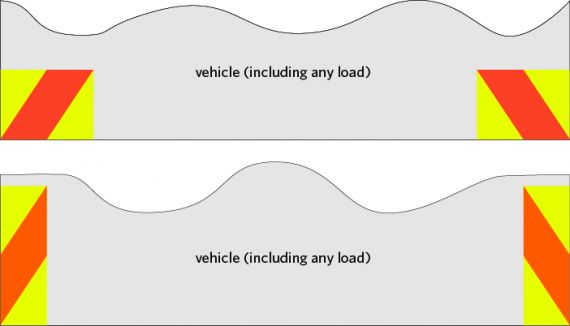

Category 1 | Width/forward distance | 2.55m /11.4m, or 3.1m/10.5m, or 3.7m/8.5m, or | 1. Flags1 or panels2 fitted on each side at the front and rear as close as practical to the outside edge |

| Length | 25m, or | ||

| Front overhang | 7m, or | ||

| Rear overhang | 7m | ||

Category 2 | Width/forward distance | 2.55m /13.3m, or 4.5m/8.5m, or | 1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge 2. OVERSIZE sign3 fitted at the front and rear if more than 3.1m wide |

| Length | 35m, or | ||

| Front overhang | 10m, or | ||

| Rear overhang | 10m | ||

Category 3 | Width/forward distance | 2.55m /20m 5m/20m 5m/8.5m | 1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge 2. OVERSIZE sign3 fitted at the front and rear |

| Front overhang | 10m, or | ||

| Rear overhang | 10m | ||

Category 4A | Width/forward distance | 11m/20m 11m/8.5m | 1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge 2. OVERSIZE sign3 fitted at the front and rear |

| Front overhang | 10m, or | ||

| Rear overhang | 10m | ||

| Category 4B | Exceeding any limit in Category 4A | 1. Panels2 fitted on each side at the front and rear as close as practical to the outside edge 2. OVERSIZE sign3 fitted at the front and rear 3. Revolving amber beacon fitted so that it is visible to approaching traffic if the vehicle is more than 3.7m wide | |

- Additional operational requirements may apply, eg if operated at night.

1 Flags:

- must be fluorescent yellow

- must be at least 400mm long x 300mm wide

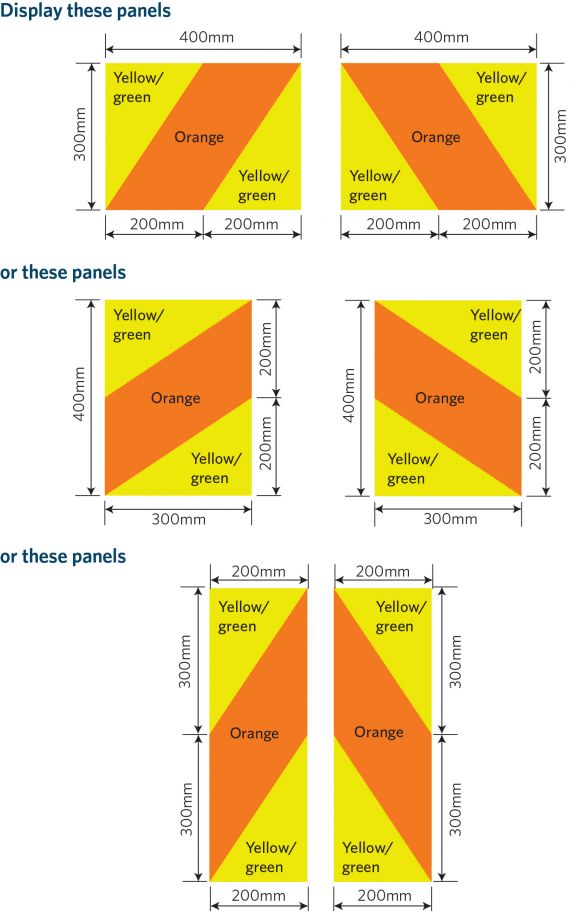

2 Hazard warning panels:

- must be reflective yellow-green with a reflective orange diagonal stripe

- comply with AS/NZS 1906.1:2007

- be frangible for those portions which extend beyond the vehicle’s limits (frangible means breakable or readily deformable)

- must be of at least of the minimum dimensions and the colours specified in Figure 2-2-1

3 OVERSIZE sign:

- must be black lettering on a yellow-green background

- must be at least 300mm x 1100mm in size

- be frangible if any part of the sign extends beyond the body or load of the vehicle, whichever it is attached to (frangible means breakable or readily deformable)

- may be in two parts: OVER and SIZE.

Figure 2-2-1. Hazard panel details

Figure 2-2-2. Hazard panel location and orientation

Figure 2-2-3. Vehicle categories and width/forward-distance thresholds.

Use this figure to determine the correct category referred to in Table 2-2-2.

For the purposes of this figure, vehicles with a width less than 2.55m are deemed to have a width of 2.55m and vehicles with a forward distance of less than 8.5m are deemed to have a forward distance of 8.5m.

Figure 2-2-4. Trailer dimensions

(Note: Dimensions in red updated in VDAM 2016)

Figure 2-2-5. Measurement of front overhang

Summary of legislation

Applicable legislation

Mandatory equipment

1. A trailer with a GVM of 3500kg or less that exceeds the dimensions in Table 2-2-1 must meet the requirements in Table 2-2-2.

Page amended 1 June 2019 (see amendment details).

2-3 Glazing

Reasons for rejection

Glazing condition

1. Glazing is damaged (Note 1), has deteriorated or is modified (Note 2) so that its strength or mechanical performance is adversely affected.

2. Glazing is not securely affixed to the vehicle.

3. Glazing has a mirrored effect sufficient to dazzle other road users.

Note 1

Damage includes any unrepaired damage and attempted visible repairs.

Note 2 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing any structure, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with equivalent undamaged new structures, systems, components or equipment.

Summary of legislation

Applicable legislation

Permitted glazing

1. Trailers may be fitted with any type of glazing, including plastic glazing.

Glazing condition

2. Glazing must be mechanically sound, strong and securely affixed to the vehicle.

3. Glazing must not have a mirrored effect sufficient to dazzle other road users.

3 Vehicle structure

3-1 Structure

Reasons for rejection

Condition

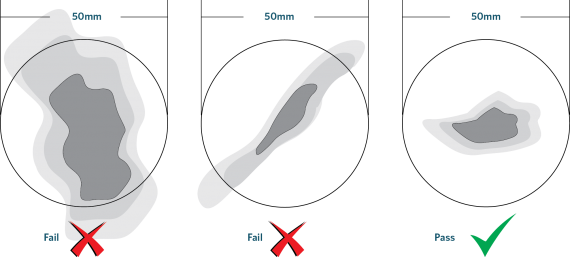

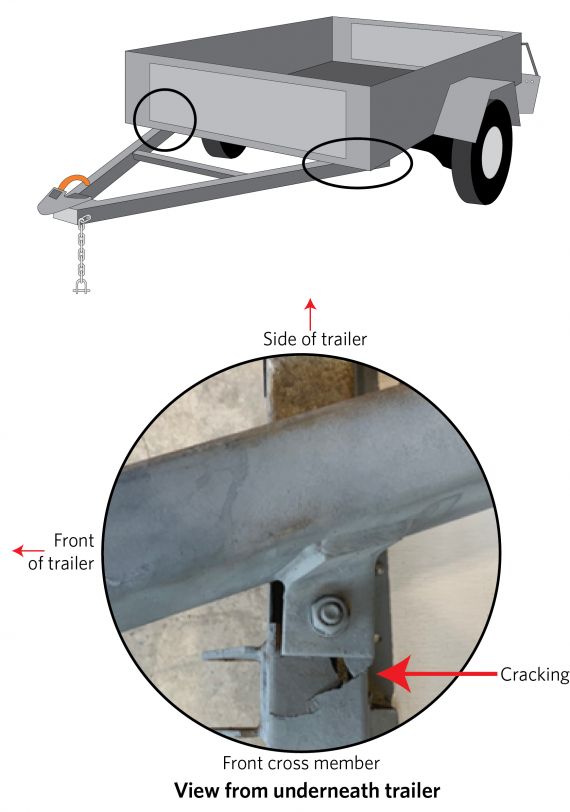

1. The structure of the vehicle (shaded areas of Figure 3-1-2) has visible:

a) deformation from the original shape that has affected the vehicle’s structural integrity (Note 2), or

b) cracking (Note 3) (Figure 3-1-3), or

c) fracture, or

d) corrosion or wood rotting damage (Note 1) that is individually larger than 50mm in diameter (Figure 3-1-1), or

e) any corrosion or wood rotting that the inspector considers has caused weakening of the load-bearing structure, or

f) poor repairs (Note 1) that have not returned the structure to within a safe tolerance of when it was manufactured (Note 2), such as:

i. filler has been used in an attempt to conceal any damage or deformation of a component, or

ii. a high strength steel component has been heated.

2. A hinge for a panel is not securely attached to both the vehicle body and to the door or other hinged panel due to loose connections, corrosion, wood rotting or other damage.

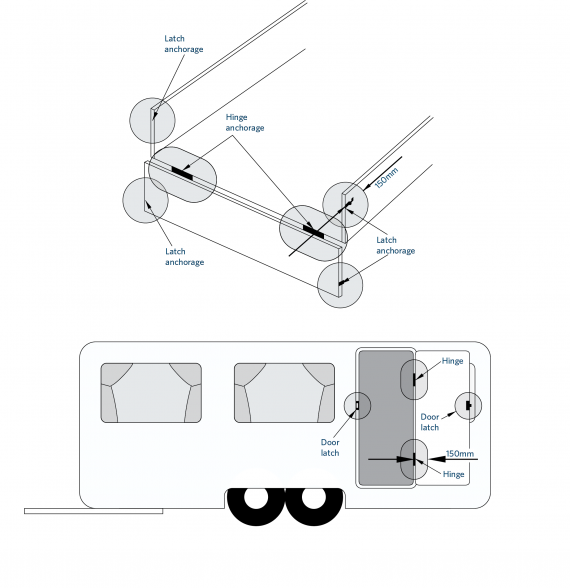

3. There is corrosion or wood rotting damage within 150mm of the hinge of a hinged panel (Figure 3-1-4).

4. There is corrosion or wood rotting damage within 150mm of the latch of a hinged panel (Figure 3-1-4).

5. A hinged panel does not remain secure in a closed or locked position.

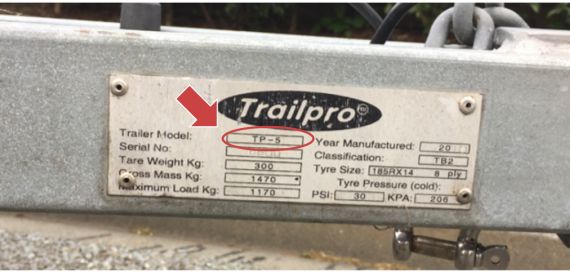

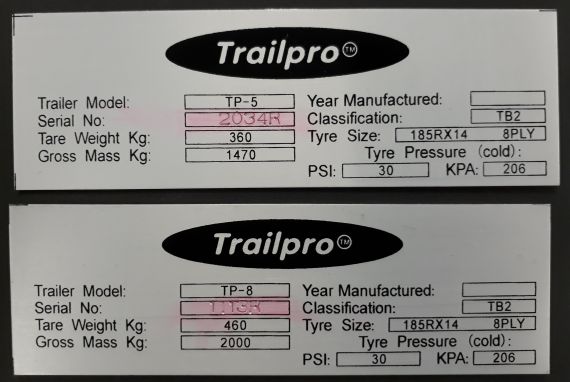

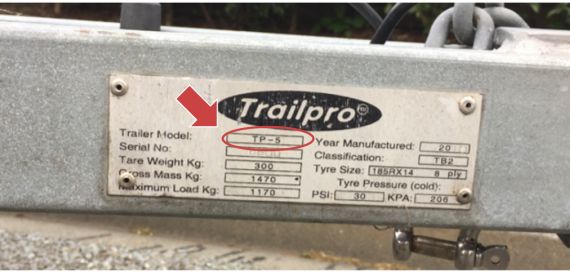

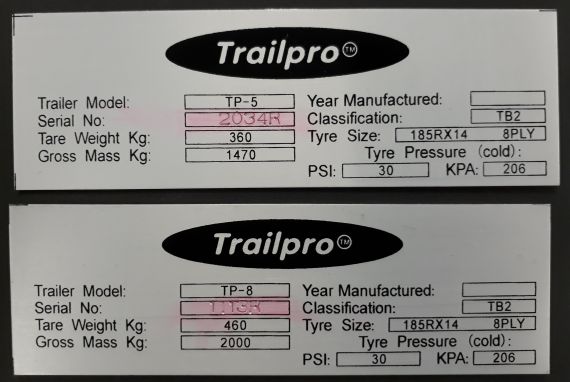

6. The trailer is an unrepaired Trailpro 8x4 Tradesman (model number TP5) or a Trailpro 8x5 Tandem (model number TP8), with a bolt-through drawbar attachment (these trailers are subject to safety recall) (Note 4). See Figure 3-1-5 for advice on identifying these trailers. See Figure 3-1-6 and Figure 3-1-7 for advice on identifying repaired Trailpro trailers.

7. The trailer is a Trailpro Handyman (model number TP1) (Note 4).

Note 1

Corrosion or wood rotting damage is where a metal or wooden structure has been eaten away and could be seen as bubbling, or pitting of the steel or by water damage, delamination or swelling of a wooden surface. The outward signs of such damage is typically displayed by the lifting, bubbling or discolouring of painted surfaces. In extreme cases, the area affected by the damage will fall out and leave a hole.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with equivalent undamaged or new structures, systems, components or equipment.

Note 2

The vehicle inspector may request additional relevant information from a repairer or other relevant person.

Note 3

Special attention should be given to the point or points where the drawbar attaches to the body of the trailer. This is often the first point of structural failure on trailers.

Note 4

There is a safety risk with the Trailpro brand of light trailers which were sold through Bunnings NZ between 1 January 2006 and 12 October 2018. Bunnings is now recalling all Trailpro trailers, other than Trailpro 8x4 Tradesman (TP5) or 8x5 Tandem (TP8) models that have undergone Bunnings-approved repairs as part of an earlier recall. These can be identified by the serial number on the identification plate ending with an “R” (see Figure 3-1-6). A TP5 or TP8 trailer with a serial number ending with an “R” may be issued a WoF if it passes all other checks. More information can be found in the safety recall notice on the Transport Agency website.

Figure 3-1-1. Corrosion or wood rotting damage 50mm diameter limit

Figure 3-1-2. Shaded areas referred to in ‘Condition’ above

These include:

a) The chassis rails, cross members, subframes, suspension and body mounting points of a vehicle with a separate chassis, and

b) the load-bearing structure of a monocoque body, including body mounting points, and

c) the body fitted to a trailer where the structure supports the chassis, similar to a unitary body (for example, some livestock carriers, horse floats, and UK-sourced caravans with wooden or wood laminate structures).

Other sections also contain reasons for rejection and diagrams relating to specific vehicle components.

Figure 3-1-3. Drawbar attachment to trailer

Figure 3-1-4. Hinge and latch anchorages

No structural damage is allowed within 150mm of a circle around the outside of a hinge, latch or load anchorage component.

Figure 3-1-5. Identifying a Trailpro TP5 and TP8

Bunnings is currently working on a repair process and we will update this once that is in place.

Affected trailers are fitted with an identification plate which is located on the outside of the trailer drawbar near the tow coupling.

Location of the trailer identification plate

Identification plate similar showing model number

The identification tag may be missing, faded, damaged or obscured. All Trailpro models have drawbars that are bolted rather than welded to the trailer. The TP5 has a single axle and a tray size of 8'x4' (2.4m x 1.2m). The TP8 is a tandem axle model with a tray size of 8'x5' (2.4m x 1.5m).

Bolted through drawbar attachment to trailer

Broken drawbar (sitting on trailer)

Figure 3-1-6. Trailpro plate showing repaired status

Figure 3-1-7. New front mount of the repaired Trailpro 8x4 and 8x5 trailers

Summary of legislation

Applicable legislation

- Land Transport Rule: Vehicle Standards Compliance 2002, section 7.4

- Traffic Regulations 1976: regulation 80.

Permitted equipment

1. A trailer may be fitted with hinged panels.

Condition

2. A vehicle must:

a) not be so affected by corrosion or weakening of its structure, that is apparent by visual examination, so that the vehicle is unsafe to operate, and

b) be safe to be operated, and

c) have been constructed using components and materials that are fit for the purpose, and

d) be within safe tolerance of its state when manufactured or modified.

Page amended 1 October 2023 (see amendment details).

4 Lighting

4-1 Headlamps

Reasons for rejection

Prohibited equipment

1. A trailer is fitted with headlamps (Note 1).

Note 1

Headlamp means a lamp designed to illuminate the road ahead of a vehicle, and that is a:

a) dipped-beam headlamp (single lamp), or

b) main-beam (high-beam) headlamp (single lamp), and includes a driving lamp, or

c) combination of a dipped-beam headlamp and a main-beam headlamp (dual-lamp unit).

Summary of legislation

Applicable legislation

Prohibited equipment

1. A trailer must not be fitted with a headlamp (Note 1).

4-2 Front and rear fog lamps

Reasons for rejection

Permitted equipment

1. A trailer is fitted with:

a) a front fog lamp (Note 1), or

b) more than two rear fog lamps.

2. A pair of fog lamps is not fitted:

a) symmetrically, or

b) as far towards each side of the trailer as practicable.

Condition (Note 2)

3. A lamp is insecure or contains moisture in the form of large droplets, runs or puddles.

4. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

Performance (Note 2)

5. When switched on, a rear fog lamp emits light that is:

a) not projected to the rear, or

b) not diffuse, or

c) not substantially red, or

d) not approximately equal in colour or intensity from the other lamp in a pair, or

e) not steady, or

f) not bright enough to indicate the presence of the trailer from the rear in conditions of severely reduced visibility, eg due to modification, deterioration, dirt or an incorrect light source, or

g) altered, eg due to damage or modification.

6. A fog lamp cannot be switched off from the driver’s seating position.

7. Where a fog lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Fog lamp means a front or rear lamp designed to aid the driver or other road users in conditions of severely reduced visibility, including fog or snow, but not including clear atmospheric conditions under the hours of darkness.

Note 2

A rear fog lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Summary of legislation

Applicable legislation

Permitted equipment

1. One or two rear fog lamps (Note 1).

2. A pair of lamps must be symmetrically mounted as far as is practicable towards each side of the vehicle.

Prohibited equipment

3. A trailer must not be fitted with front fog lamps.

Condition

4. A rear fog lamp must be in sound condition if it emits a light.

Performance

5. A rear fog lamp must operate in a way that is appropriate for the lamp and the vehicle.

6. A rear fog lamp must emit a steady light.

7. A rear fog lamp must provide sufficient light output to indicate the presence of the trailer on the road in conditions of severely reduced visibility.

8. The light emitted from a rear fog lamp must be diffused and substantially red in colour.

9. A pair of fog lamps must emit light that is approximately equal in colour and intensity.

10. A fog lamp must be able to be turned off from the driver’s seating position.

11. Where a fog lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 28 April 2013 (see amendment details).

4-3 Cornering lamps

Reasons for rejection

Prohibited equipment

1. A trailer is fitted with cornering lamps (Note 1).

Note 1

Cornering lamp means a lamp that is designed to emit light at the front of a vehicle to supplement the vehicle’s headlamps by illuminating the road ahead in the direction of the turn.

Summary of legislation

Applicable legislation

Prohibited equipment

1. A trailer must not be fitted with cornering lamps (Note 1).

4-4 Daytime running lamps

Reasons for rejection

Prohibited equipment

1. A trailer is fitted with daytime running lamps (Note 1).

Note 1

Daytime running lamp means a lamp designed to emit a low-intensity light forward of a vehicle to make it more easily seen in the daytime.

Summary of legislation

Applicable legislation

Prohibited equipment

1. A trailer must not be fitted with daytime running lamps (Note 1).

4-5 Direction indicator lamps

Reasons for rejection

Mandatory and permitted equipment

1. A trailer is not fitted with one pair of lamps at the rear if the trailer is one of the following:

a) a trailer first registered in New Zealand on or after 1 April 2012, or

b) a trailer first registered in New Zealand before 1 April 2012 that is so constructed that the driver’s arm signals cannot be seen from behind the trailer.

2. A trailer is fitted with more than:

a) two pairs of lamps at the front, or

b) two pairs of lamps at the rear, or

c) two side-facing lamps on each side of the trailer.

3. A trailer is fitted with a lamp that is not in a pair.

4. A lamp is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the trailer).

5. A pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the trailer as practicable.

Condition

6. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

7. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

9. When switched on, a direction indicator lamp:

a) does not operate, or

b) does not begin flashing within one second of switching on, or

c) flashes:

i. faster than two flashes per second, or

ii. slower than one flash per second, or

iii. at a different rate from other lamps on the same side.

10. When switched on, a direction indicator lamp emits a light that is:

a) not substantially white or amber to the front, or

b) not substantially amber or red to the rear, or

c) not substantially amber to the side, or

d) not approximately equal in colour or intensity from the other lamp in a pair, or

e) not bright enough to be visible from 100m in normal daylight and from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source, or

f) too bright causing significant dazzle to other road users, eg due to an incorrect light source, or

g) altered, eg due to damage or modification.

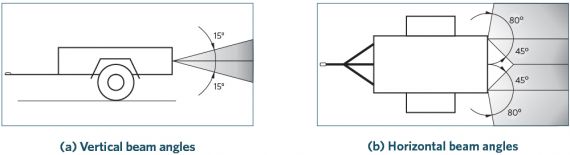

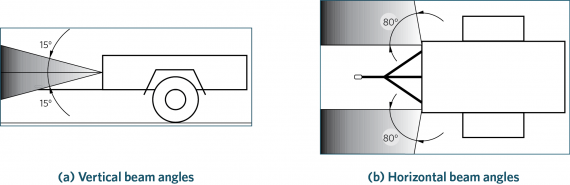

11. A mandatory lamp emits a light that is not visible within (Figure 4-5-1):

a) 15˚ above and below the horizontal, or

b) 45˚ inboard and 80˚ outboard.

12. On a trailer of American origin fitted with combined stop and indicator lamps, the stop lamp function is not overridden by the indicator function.

13. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Direction indicator lamp means a lamp designed to emit a flashing light to signal the intention of the driver to change the direction of the vehicle to the right or to the left.

Note 2

A permitted (ie non-mandatory) rear- or side-facing direction indicator lamp that does not comply with condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Note 3

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle.

Figure 4-5-1. Direction indicator beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A trailer may be fitted with:

a) one or two pairs of lamps at the front, and

b) one or two pairs of lamps at the rear, and

c) one or two side-facing lamps at each side.

2. One or two pairs of lamps must be fitted to the rear of the trailer if the trailer:

a) was first registered in New Zealand on or after 1 April 2012, or

b) was first registered before 1 April 2012 and is so constructed that it prevents an arm signal given by the driver from being seen from behind the vehicle combination.

3. A pair of lamps must be symmetrically mounted as far towards each side of the trailer as is practicable.

4. A lamp must be fitted at a height from the ground not exceeding 1.5m, or if this is not possible due to the shape of the bodywork, not exceeding 2.1m.

5. On trailers of American origin, the stop lamp and direction indicator lamp functions may be combined in one lamp.

Condition

6. A direction indicator lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

7. A direction indicator lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. A direction indicator lamp must emit a light that is substantially:

a) white or amber to the front, and

b) red or amber to the rear, and

c) amber to the side.

9. A lamp must flash at a fixed frequency in the range of 1–2 Hertz.

10. Each lamp in a pair must, when operated, emit a light of approximately equal intensity, colour and frequency.

11. A lamp must emit a light that is visible from 100m during normal daylight and 200 m in normal darkness.

12. A retrofitted mandatory lamp must emit a light that is visible within angles of:

a) 15˚ above and below the horizontal, and

b) 45˚ inboard, and

c) 80˚ outboard.

13. If a trailer of American origin is fitted with combined stop and indicator lamps, the indicator lamps must override the stop lamps so that the stop lamps operate as direction indicators.

14. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 28 April 2013 (see amendment details).

4-6 Forward-facing position lamps

Reasons for rejection

Mandatory and permitted equipment

1. A trailer that is more than 2m wide is not fitted with one pair of lamps.

2. A trailer is fitted with more than two lamps.

3. A trailer less than 2m wide is fitted with a single lamp on the left side of the vehicle.

4. A pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the trailer as practicable.

Condition

5. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

6. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

7. A lamp’s reflector is damaged or has deteriorated so that light output is reduced.

Performance

8. When switched on, a forward-facing position lamp does not operate.

9. When switched on, a forward-facing position lamp emits a light that is:

a) not substantially white or amber, or

b) not diffuse, or

c) not projected to the front, or

d) not approximately equal in colour or intensity from the other lamp in a pair, or

e) not steady, or

f) not bright enough to be visible from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source.

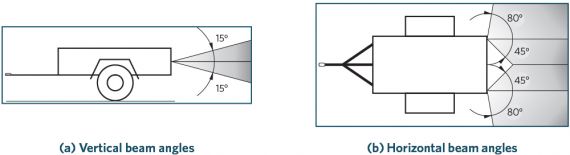

10. A mandatory lamp emits a light that is not visible within (Figure 4-6-1):

a) 15˚ above and below the horizontal, or

b) 80˚ outboard.

11. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle.

Figure 4-6-1. Forward-facing position lamp beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A trailer more than 2m wide must be fitted with one pair of forward-facing position lamps.

2. A trailer 2m wide or less may be fitted with:

a) one forward-facing position lamp on the right side of the trailer, or

b) two forward-facing position lamps.

3. A lamp must be positioned to the front of the vehicle.

Condition

4. A forward-facing position lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

5. A forward-facing position lamp must operate in a way that is appropriate for the lamp and the vehicle.

6. A lamp must emit a light that is:

a) diffuse, and

b) substantially white or amber, and

c) steady, and

d) sufficient to indicate to other road users the presence and dimensions of the trailer, and

e) of approximately equal intensity and colour to the other lamp in a pair.

7. A mandatory lamp must be visible within angles of:

a) 15˚ above and below the horizontal, and

b) 80˚ outboard.

8. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 28 April 2013 (see amendment details).

4-7 Rearward-facing position lamps

Reasons for rejection

Mandatory and permitted equipment

1. A trailer first registered in New Zealand before 1 January 1978 is not fitted with:

a) one single rearward-facing position lamp (Note 1) in the centre or to the right of the centre of the trailer, or

b) one pair of rearward-facing position lamps.

2. A trailer first registered in New Zealand on or after 1 January 1978:

a) that is less than 1.5m wide is not fitted with one single rearward-facing position lamp in the centre or to the right of the centre of the trailer, or with one pair of rearward-facing position lamps, or

b) that is more than 1.5m wide is not fitted with one pair of rearward-facing position lamps.

3. A trailer is fitted with more than:

a) one single lamp, or

b) two pairs of lamps.

4. A lamp is mounted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the trailer).

5. A pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the trailer as is practicable.

Condition

6. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

7. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

9. When switched on, a mandatory lamp does not operate.

10. When switched on, a lamp emits a light that is:

a) not substantially red, or

b) not diffuse, or

c) not projected to the rear, or

d) not approximately equal in colour or intensity from the other lamp in a pair, or

e) not steady, or

f) not bright enough to be visible from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source.

11. A mandatory lamp emits a light that is not visible within (Figure 4-7-1):

a) 15˚ above and below the horizontal, or

b) 45˚ inboard or 80˚ outboard

12. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamp).

Note 2

A permitted (ie non-mandatory) rearward-facing position lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Figure 4-7-1. Rearward-facing position lamp beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A trailer first registered in New Zealand on or after 1 January 1978 and that is more than 1.5m wide must be fitted with one or two pairs of rearward-facing position lamps (Note 1).

2. A trailer first registered in New Zealand before 1 January 1978 or that does not exceed 1.5m in width must be fitted with:

a) one single rearward-facing position lamp in the centre or on the right side of the trailer, or

b) one or two pairs of rearward-facing position lamps.

3. A pair of lamps must be symmetrically mounted as far towards each side of the trailer as is practicable.

4. A lamp must be fitted at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the trailer, not exceeding 2.1m.

Condition

5. A rearward-facing position lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

6. A rearward-facing position lamp must operate in a way that is appropriate for the lamp and the vehicle.

7. A lamp must emit a diffuse light that is substantially red.

8. A lamp must emit a steady light.

9. A lamp must provide sufficient light output to indicate to other road users the presence and dimensions of the trailer.

10. A lamp must emit light that is visible from a distance of 200m in normal darkness.

11. A retrofitted mandatory lamp must be visible within angles of 15˚ above and below the horizontal, and within 45˚ inboard and 80˚ outboard.

12. Each lamp in a pair must, when operated, emit a light of approximately equal intensity and colour.

13. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 28 April 2013 (see amendment details).

4-8 Side-marker lamps

Reasons for rejection

Permitted equipment

1. A side-marker lamp is not positioned so that it gives an indication of the vehicle’s dimensions.

Condition

2. A lamp is insecure.

3. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

4. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

5. When switched on, a mandatory lamp does not operate.

6. When switched on, a side-marker lamp emits a light that:

a) is not substantially white or amber to the front, or

b) is not substantially red or amber to the rear, or

c) is not diffuse, or

d) is not approximately of the same colour and intensity on each side of the vehicle, or

e) does not remain steadily illuminated, or

f) is not bright enough to produce light that is visible from 100m in normal daylight and from 200m in normal darkness, eg due to modification, deterioration, dirt or an incorrect light source.

7. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1 Definitions

Side-marker lamp means a position lamp designed to be fitted to the side of a vehicle or its load.

Position lamp means a low-intensity lamp that is designed to indicate to road users the presence and dimensions of a vehicle, being:

a) a forward-facing position lamp (front side lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp.

Note 2

The position of a mandatory side-marker lamp need only be approximate as long as it indicates the vehicle’s presence and approximate dimensions when viewed from the side.

Note 3

A permitted side-marker lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

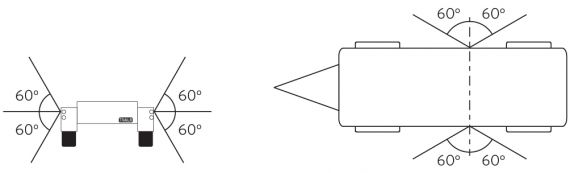

Figure 4-8-1. Visibility angles for side-marker lamps

Summary of legislation

Applicable legislation

Permitted equipment

1. A light trailer may be fitted with side-marker lamps.

2. A side-marker lamp must be positioned so that it gives an indication of the vehicle’s dimensions.

Condition

3. A side-marker lamp must be in sound condition.

Performance

4. A side-marker lamp must operate in a way that is appropriate for the lamp and the vehicle.

5. A lamp must emit a light that is:

a) diffuse, and

b) substantially white or amber to the front, and

c) substantially red or amber to the rear.

6. A lamp must emit a steady light.

7. A side-marker lamp must provide sufficient light output to indicate to other road users the presence and dimensions of the vehicle.

8. A side-marker lamp must emit a light that is visible from a distance of 100m in daylight and 200m during the hours of darkness.

9. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

10. A side-marker lamp that is affected by a modification must meet equipment, condition and performance requirements.

4-9 End-outline marker lamps

Reasons for rejection

Permitted and prohibited equipment

1. A light trailer with an overall width of 1.8m or more is fitted with more than:

a) four forward-facing lamps, or

b) two rearward-facing lamps.

2. A light trailer with an overall width of less than 1.8m is fitted with end-outline marker lamps.

3. An end-outline marker lamp is not positioned so that it gives an indication of the vehicle’s dimensions, ie lamps are fitted other than around the outline of the vehicle.

Condition

4. A lamp is insecure.

5. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

6. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

7. When switched on, a forward-facing end-outline marker lamp does not operate (Note 2).

8. When switched on, an end-outline marker lamp emits a light that is:

a) not substantially white or amber to the front, or

b) not substantially red to the rear, or

c) not diffuse, or

d) not projected to the front or rear, or

e) not approximately of the same colour and intensity as the other lamp if fitted in a pair, or

f) not steady, or

g) not bright enough to indicate the presence and dimensions of the vehicle to other road users.

9. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

End-outline marker lamp means a position lamp designed to be fitted near the outer extremity of the vehicle in addition to forward-facing and rearward-facing position lamps, and includes a cab roof lamp.

Position lamp means a low-intensity lamp that is designed to indicate the presence and dimensions of a vehicle to other road users, being:

a) a forward-facing position lamp (front side or park lamp), or

b) a rearward-facing position lamp (rear side lamp or tail lamp), or

c) a side-marker lamp, or

d) an end-outline marker lamp (including cab roof lamps).

Note 2

A forward-facing permitted lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle. A rearward-facing end-outline marker lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Summary of legislation

Applicable legislation

Permitted and prohibited equipment

1. A light trailer with an overall width of 1.8m or more may be fitted with a maximum of:

a) four forward-facing lamps, and

b) two rearward-facing lamps.

2. A light trailer with an overall width of less than 1.8m must not be fitted with end-outline marker lamps.

3. An end-outline marker lamp must be positioned so that it gives an indication of the vehicle’s dimensions.

Condition

4. An end-outline marker lamp must be in sound condition.

Performance

5. An end-outline marker lamp must operate in a way that is appropriate for the lamp and the vehicle.

6. A lamp must emit a light that is:

a) diffuse, and

b) substantially white or amber to the front, and

c) substantially red to the rear.

7. A lamp must emit a steady light.

8. An end-outline marker lamp must provide sufficient light output to indicate to other road users the presence and dimensions of the vehicle.

9. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Modifications

10. An end-outline marker lamp that is affected by a modification must meet equipment, condition and performance requirements.

4-10 Stop lamps

Reasons for rejection

Mandatory and permitted equipment

1. A trailer first registered in NZ on or after 1 April 2012:

a) is not fitted with one pair of stop lamps, or

b) is fitted with more than two pairs of stop lamps, or

c) is fitted with a stop lamp that is not in a pair.

2. A trailer first registered in New Zealand on or after 1 January 1978:

a) is not fitted with one pair of stop lamps (Note 1) if the trailer is so constructed that the driver’s arm signals or the towing vehicle’s stop lamps cannot be seen from behind the trailer, or

b) is fitted with more than two pairs of stop lamps, or

c) is fitted with a stop lamp that is not in a pair.

3. A trailer first registered in New Zealand before 1 January 1978:

a) is not fitted with one stop lamp if the trailer is so constructed that the driver’s arm signals or the towing vehicle’s stop lamps cannot be seen from behind the trailer, or

b) is fitted with more than four stop lamps.

4. A stop lamp is fitted at a height from the ground exceeding 1.5m (or 2.1m where fitting below 1.5m is not practicable due to the shape of the bodywork of the trailer).

5. A pair of lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the trailer as practicable.

Condition

6. A lamp is insecure or, if a mandatory lamp, contains moisture in the form of large droplets, runs or puddles.

7. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

8. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

9. When the service brake is activated:

a) a mandatory lamp does not operate, or

b) a lamp does not remain steadily illuminated.

10. A lamp operates when the service brake is not activated.

11. A lamp emits a light that is:

a) not substantially red, or

b) not diffuse, or

c) not projected to the rear, or

d) not approximately equal in intensity from the other lamp in a pair, or not bright enough to produce a light that is visible from 100m in normal daylight, eg due to modification, deterioration, dirt or an incorrect light source.

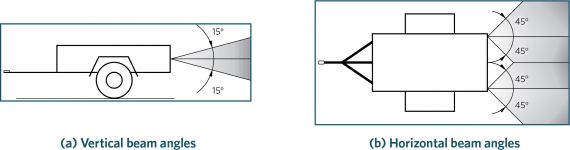

12. A mandatory lamp emits a light that is not visible within (Figure 4-10-1):

a) 15˚ above and below the horizontal, or

b) 45˚ inboard and outboard

13. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

14. On a trailer of American origin fitted with combined stop and direction indicator lamps, the stop lamp function is not overridden by the indicator function.

Note 1

Stop lamp means a lamp that is designed to operate when the service brake is activated.

Note 2

A permitted (ie non-mandatory) stop lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Figure 4-10-1. Stop lamp beam angles

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A trailer first registered in NZ before 1 January 1978 must be fitted with one stop lamp, or one or two pairs of stop lamps, if the trailer is so constructed that the driver’s arm signals or the towing vehicle’s stop lamps cannot be seen from behind the trailer.

2. A trailer first registered in NZ between 1 January 1978 and 31 March 2012 must be fitted with one or two pairs of stop lamps if the trailer is so constructed that the driver’s arm signals or the towing vehicle’s stop lamps cannot be seen from behind the trailer.

3. A trailer first registered in NZ on or after 1 April 2012 must be fitted with one or two pairs of stop lamps.

4. A pair of stop lamps must be symmetrically mounted as far towards each side of the trailer as is practicable.

5. A stop lamp must be fitted at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the trailer, not exceeding 2.1m.

Condition

6. A stop lamp must:

a) be in sound condition, and

b) not be obscured (if a mandatory lamp).

Performance

7. A stop lamp must operate in a way that is appropriate for the lamp and the vehicle.

8. The light emitted from a stop lamp must be diffuse light that is substantially red.

9. A required stop lamp must operate when a service brake is activated.

10. A required stop lamp must provide sufficient light output to fulfil its intended purpose.

11. A stop lamp must emit a steady light.

12. A mandatory stop lamp must emit a light that is visible within the angles of 15˚ above and below the horizontal, and 45˚ inboard and outboard.

13. If a trailer of American origin is fitted with combined stop and direction indicator lamps, the indicator lamps must override the stop lamps so that the stop lamps will operate as direction indicators.

14. Where a stop lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 28 April 2013 (see amendment details).

4-11 High-mounted stop lamps

Reasons for rejection

Permitted equipment

1. A trailer is fitted with more than two high-mounted stop lamps (Note 1).

2. A lamp is not fitted in a central high-mounted position.

Condition

3. A lamp is insecure.

4. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

5. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

6. When the service brake is activated, a lamp does not remain steadily illuminated.

7. A lamp operates when the service brake is not activated.

8. A lamp emits a light that:

a) is not substantially red, or

b) is not diffuse, or

c) is not projected to the rear, or

d) has insufficient light output to produce a light that is visible from 100m in normal daylight, eg due to modification, deterioration, dirt or an incorrect light source.

9. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Stop lamp means a lamp that is designed to operate when the service brake is activated.

High-mounted stop lamp means a stop lamp that is designed to be fitted in a central, high-mounted position at the rear of the vehicle.

Note 2

A high-mounted stop lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Summary of legislation

Applicable legislation

Permitted equipment

1. A trailer may be fitted with one or two high-mounted stop lamps (Note 1).

2. A lamp must be fitted in a central high-mounted position at the rear of the trailer.

Condition

3. A high-mounted stop lamp must be in good condition.

Performance

4. A high-mounted stop lamp must operate in a way that is appropriate for the lamp and the vehicle.

5. The light emitted from a high-mounted stop lamp must be diffuse light that is substantially red.

6. A high-mounted stop lamp must emit a steady light.

7. Where a high-mounted stop lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-12 Rear-registration-plate illumination lamps

Reasons for rejection

Mandatory equipment

1. A trailer is not fitted with at least one rear-registration-plate illumination lamp (Note 1).

Condition

2. A lamp is insecure.

3. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

4. A reflector, or lens, is damaged or has deteriorated so that light output is reduced.

Performance

5. The lamp emits a light that is not:

a) substantially white, or

b) steady, or

c) diffuse.

6. The lamp does not illuminate the registration plate (eg either the lamp or plate have been moved, or the lamps orientation has been changed).

7. The light source of a lamp is visible from the rear of the trailer.

Note 1

Rear-registration-plate illumination lamp means a lamp designed to illuminate the rear registration plate of a vehicle.

Summary of legislation

Applicable legislation

Mandatory equipment

1. At least one rear-registration-plate illumination lamp (Note 1).

Performance

2. A rear-registration-plate illumination lamp must operate in a way that is appropriate for the lamp and the vehicle.

3. A lamp must emit a diffuse light that is substantially white.

4. A rear-registration-plate illumination lamp must emit a steady light.

5. The light source of the lamp must not be visible from the rear of the trailer.

6. A lamp must illuminate the figures and letters of the plate so that they are visible from 20m during normal darkness.

7. Where a lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

Page amended 1 October 2021 (see amendment details).

4-13 Rear reflectors

Reasons for rejection

Mandatory and permitted equipment

1. A trailer:

a) is not fitted with at least one red rearward-facing reflector on each side (Note 1), or

b) is fitted with a red rearward-facing reflector that is not in a pair.

2. A reflector is not positioned to the rear of the trailer.

3. A reflector is fitted at a height from the ground exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the trailer, exceeding 2.1m.

4. A trailer equipped with a jinker pole that extends behind its rear lamps is not fitted with one red rearward-facing reflector at the rear extremity of the pole.

5. A pair of reflectors is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the trailer as is practicable.

Condition

6. A mandatory reflector’s ability to reflect light is affected by excessive:

a) fading, or

b) scratching or other damage.

7. A mandatory reflector is obscured.

Performance

8. The reflected light from a mandatory reflector is not visible from 100m.

9. The reflected light from a reflector is not red.

Note 1

Reflector means a distinct item of lighting equipment that is designed to reflect incident light back towards the light source, but does not include reflective material (such as reflective tape).

Reflective material means any material that is designed to reflect incident light back towards the light source, and includes reflective tape, but does not include a reflector.

Summary of legislation

Applicable legislation

Mandatory and permitted equipment

1. A trailer must be fitted with at least one pair of rearward-facing reflectors (Note 1) at a height from the ground not exceeding 1.5m, or if this is not practicable due to the shape of the bodywork of the trailer, not exceeding 2.1m.

2. A trailer equipped with a jinker pole that extends behind its rear lamps must also be fitted with one red reflector at the rear extremity of the pole.

3. A rearward-facing reflector must be positioned to the rear of the trailer.

4. A reflector must be of an area that allows it to reflect light to improve the visibility of the trailer to other road users without causing undue dazzle or discomfort.

5. A pair of reflectors must be symmetrically mounted as far towards each side of the trailer as is practicable.

Condition

6. A reflector must be in good condition and not be obscured.

Performance

7. A reflector must operate in a way that is appropriate for the reflector and the vehicle.

8. A reflector must reflect white light as substantially red light.

9. A reflector must provide sufficient light reflection to fulfil its intended purpose.

4-14 Reversing lamps

Reasons for rejection

Permitted equipment

1. A trailer is fitted with more than two reversing lamps at the rear of the trailer (Note 1).

2. A pair of reversing lamps is not:

a) symmetrically mounted, or

b) mounted as far towards each side of the trailer as practicable.

Condition

3. A lamp is insecure.

4. A lens is missing, or has a hole, crack or other damage that allows moisture or dirt to enter.

5. A reflector is damaged or has deteriorated so that light output is reduced.

Performance

6. A lamp controlled by gear engagement continues to display a light to the rear when the reverse gear is disengaged.

7. A lamp controlled by a manual switch continues to display a light to the rear while the headlamps are switched on.

8. When engaged, a lamp emits light that is not:

a) substantially white, or

b) steady, or

c) diffuse or a dipped beam.

9. Where a lamp comprises an array of light sources (eg LEDs), fewer than 75% of these operate.

Note 1

Reversing lamp means a lamp designed to illuminate the area behind the vehicle while it is reversing and to warn other road users that the vehicle is reversing or about to reverse.

Note 2

A reversing lamp that does not comply with equipment, condition and performance requirements must be made to comply or be disabled so that it does not emit a light.

Summary of legislation

Applicable legislation

Permitted equipment

1. One or two reversing lamps fitted at the rear of the trailer (Note 1).

2. A pair of reversing lamps must be symmetrically mounted as far towards each side of the trailer as is practicable.

Condition

3. A reversing lamp must be in good condition.

Performance

4. A reversing lamp must operate in a way that is appropriate for the lamp and the vehicle.

5. A reversing lamp, when operated, must emit a diffuse light or a dipped beam of light that is substantially white.

6. A reversing lamp must emit a steady light.

7. A reversing lamp may operate only when the reverse gear is engaged or the headlamps are turned off.

8. Where a reversing lamp comprises an array of light sources (eg LEDs), at least 75% of these must operate.

4-15 Cosmetic lamps

Reasons for rejection

Permitted equipment

1. A cosmetic lamp (ie one not listed in Table 4-15-1) that is fitted to a vehicle:

a) has a part of its light-emitting surface positioned within 250mm of any mandatory lamp, or

b) is not mounted in a fixed position, or

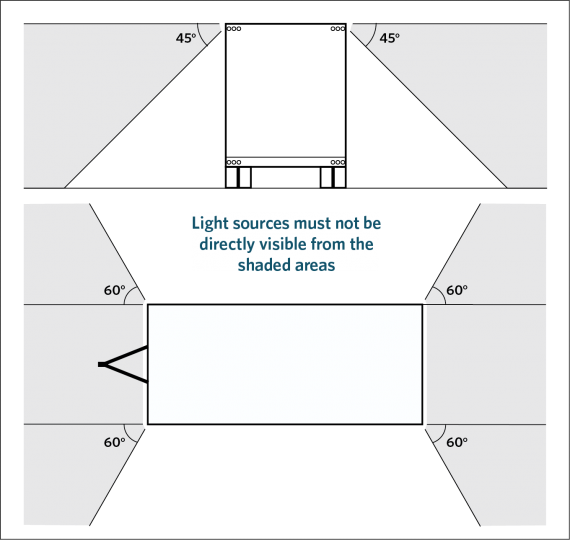

c) is positioned so that its light-emitting surface is visible within the shaded areas in Figure 4-15-1.

2. A work lamp that is fitted to a vehicle is wired in such a way that the switch or circuit for any mandatory or optional lamp controls it.

Performance

3. When switched on, a cosmetic lamp with a light-emitting surface not visible within the shaded areas in Figure 4-15-1 emits a light that:

a) is not diffuse, or

b) flashes or otherwise varies in intensity or colour, or

c) revolves, rotates or otherwise moves, or

d) is too bright and likely to dazzle other road users, or

e) is likely to cause confusion about the orientation of the vehicle, or

f) is red when seen directly from the front, or

g) is not red or amber when seen directly from the rear.

4. A side-facing reflector on a vehicle reflects white light shining on it as anything other than white or amber light

Note 1

A rear or side cosmetic lamp that does not comply with requirements for condition or performance must be made to comply, or be disabled so that it does not emit a light.

Note 2

Lamp means a device designed to emit light, and includes an array of separate light sources that appear as a continuous illuminated surface.

Cosmetic lamp means any lamp that is not listed in Table 4-15-1.

Work lamp means a high-intensity lamp that is not necessary for the operation of the vehicle but is designed to illuminate the area or scene and include scene lamps, spot lamps and alley lamps.

Scene lamp means a work lamp designed to provide a fixed or movable beam of light to illuminate the area around the vehicle or the vehicle itself.

Alley lamp means a work lamp designed primarily to provide a fixed or movable beam of light to the side of the vehicle it is fitted to.

Reflective material (or retroreflective material) means any material that is designed to reflect incident light back towards a light source or in a specific direction; but does not include a reflector.

Note 3

A forward-facing cosmetic lamp that does not comply with the equipment, condition and performance requirements must be made to comply or be removed from the vehicle.

Table 4-15-1. Lamps that are not cosmetic lamps

Lamps covered in the VIRM | Other lighting equipment not requiring inspection |

|---|---|

Headlamps Stop lamps High-mounted stop lamps Direction indicator lamps Position lamps Rear-registration-plate illumination lamps Rear reflectors Fog lamps Daytime running lamps Cornering lamps Reversing lamps PSV interior lamps Work lamps | Interior lamps Flashing or revolving beacons Illuminated vehicle-mounted signs |

Figure 4-15-1. Visibility angles for cosmetic lamps

Summary of legislation

Applicable legislation

Permitted equipment

1. A vehicle may be fitted with one or more lamps not specified in Table 4-15-1, provided they are fitted so that light sources are not visible in those regions specified in Figure 4-15-1.

2. A cosmetic lamp must be fitted in a fixed position on the vehicle and positioned so that no part of the light source is situated within 250mm of a mandatory lamp.

3. A work lamp that is fitted to a vehicle is wired in such a way that the switch or circuit for any mandatory or optional lamp controls it.

Performance

4. A cosmetic lamp must:

a) only emit light that is diffuse, and

b) not emit light that flashes or otherwise varies in intensity or colour, and

c) be fitted in a way, and be of a luminance that ensures that it does not dazzle, confuse or distract other road users, and

d) not emit a light that revolves, rotates or otherwise moves, and

e) not cause confusion as to the orientation of the vehicle, and

f) not emit a red light that is directly visible from the front of the vehicle, and

g) not emit a light other than red or amber if the light is directly visible from the rear of the vehicle.

5. A side-facing reflector on a vehicle must reflect white light shining on it as white or amber light.

5 Brakes

5-1 Service brake, parking brake and breakaway brake

Reasons for rejection

Mandatory equipment

1. If fitted to a trailer:

a) a service brake does not act on each road wheel of at least one axle, or

b) a parking brake does not act on each wheel of at least one axle.

2. Where the vehicle inspector is able to identify the laden weight (Note 6) of the trailer and its load, the trailer is not fitted with a service brake, parking brake, or breakaway brake, as required by Table 5-1-1.

3. An agricultural trailer with a laden weight (Note 6) of more than 2000kg that does not comply with braking requirements is not fitted with two safety chains that cross each other when the trailer is connected (refer to section 8, Towing connections).

Condition

Service brake

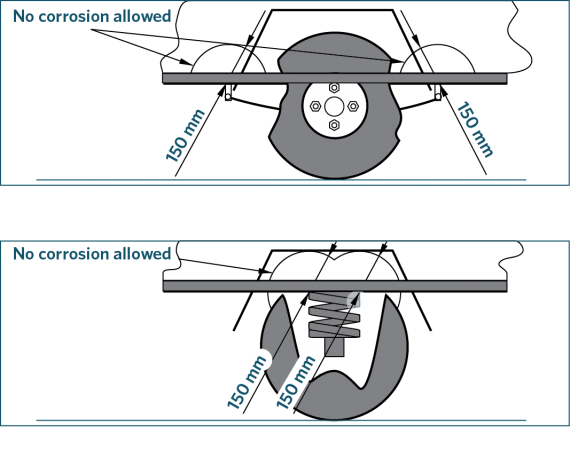

4. There is corrosion damage (Note 1) within 150mm of a brake component mounting point.

5. A vacuum hose or pipe (including connections) is:

a) insecure, or

b) leaking, or

c) damaged (cracked, chafed, twisted, stretched or corroded, eg showing signs of pitting or a noticeable decrease in the pipe’s outside diameter)

6. The brake vacuum servo (brake booster) is:

a) not functioning fully or adequately, or

b) leaking, or

c) insecure.

7. The brake master cylinder is:

a) leaking brake fluid, or

b) insecure, or

c) excessively corroded, or

d) reservoir fluid level is below the minimum indicator where this is visible externally.

8. A brake valve is:

a) not operating (eg has a seized load sensing valve), or

b) leaking brake fluid, or

c) insecure, or

d) excessively corroded.

9. A brake pipe (including connections) is:

a) leaking brake fluid, or

b) insecure, or

c) deformed from its original shape, or

d) chafed, or

e) corrosion damaged, eg there are signs of pitting or a noticeable increase in the pipe’s outside diameter.

10. A flexible hydraulic brake hose (including connections):

a) is leaking brake fluid, or

b) is insecure, or

c) bulges under pressure, or

d) is twisted, stretched or chafed, or

e) external sheathing is cracked to the extent that the reinforcing cords are exposed, or

f) has metal connections that are excessively corroded, or

g) has an end fitting that is not attached to the hose by means of swaging, machine crimping or a similar process (Note 2).

11. The service brake cable:

a) is knotted, frayed or excessively corroded, or

b) has an auxiliary tensioner fitted, or

c) has otherwise deteriorated so that it may affect the parking brake performance.

12. A service brake actuating rod or guide:

a) is excessively corroded, or

b) is excessively worn, or

c) has otherwise deteriorated so that it may affect the parking brake performance.

13. A brake calliper:

a) shows visible signs of leaking, or

b) is insecure, or

c) is seized.

14. A brake backing plate is:

a) insecure, or

b) severely corroded, or

c) deformed from its original shape, or

d) cracked, or

e) contaminated by brake fluid, oil or grease.

15. A wheel cylinder:

a) shows visible signs of leaking, or

b) is insecure, or

c) is seized.

16. An ABS system component is damaged, insecure or missing.

17. A brake disc or drum is:

a) worn beyond manufacturer’s specifications (where visible without removing vehicle components)

(Note 3), or

b) fractured or otherwise damaged (where visible without removing vehicle components) (Note 3), or

c) contaminated by brake fluid, oil or grease.

18. A brake friction material (where visible without removing vehicle components) (Note 3) is:

a) worn below manufacturer’s specifications, or

b) is separating from the brake pad backing plate or brake shoe, or

c) is contaminated by brake fluid, oil or grease.

19. A service brake component shows signs of heating or welding after original manufacture.

Parking brake

20. The parking brake lever:

a) travels excessively, or

b) is insecure, or

c) mounting is damaged, corroded, distorted or fractured within 150mm of the lever mounting, or

d) mechanism or lever pivot bearing is worn or damaged so that the parking brake could be easily released by accident.

21. The parking brake cable:

a) is knotted, frayed or excessively corroded, or

b) has an auxiliary tensioner fitted, or

c) has otherwise deteriorated so that it may affect the parking brake performance.

22. A parking brake actuating rod or guide:

a) is excessively corroded, or

b) is excessively worn, or

c) has otherwise deteriorated so that it may affect the parking brake performance.

23. A parking brake component shows signs of heating or welding after original manufacture.

Performance

Service brake

- See Note 4

24. The service brake is not able to be applied in a controlled and progressive manner.

25. When the service brake is applied and without assistance from the towing vehicle’s engine:

a) the combined effort of the trailer and towing vehicle brakes does not stop the vehicle combination within 7m from a speed of 30km/h (average brake efficiency of 50%), or

b) the vehicle vibrates under braking to the extent that control of the vehicle is adversely affected, or

c) (direct trailer brake) the brake fails to release immediately after the towing vehicle’s brakes are released, or

d) (indirect trailer brake) the brake fails to release when the towing vehicle stops decelerating, or the directional control is affected, eg swerving to one side, or the brakes on one side apply more slowly than on the other side, or

e) the brake balance, during the entire brake application, varies by more than 20% between wheels on a common axle.

26. The ABS or brake system warning lamp or self-check system, if fitted, indicates a defect in the ABS or brake system (this does not apply to brake pad wear warning systems).

Parking brake

27. When the park brake is applied:

a) the vehicle does not stop within 18m from a speed of 30km/h (average brake efficiency of 20%), or

b) it does not hold the vehicle at rest on a slope of 1 in 5, or

c) it does not hold all the wheels on a common axle stationary against attempts to drive the vehicle away.

Breakaway brake

28. The breakaway brake does not automatically and immediately apply when the trailer is disconnected from the towing vehicle (Note 5).

Note 1

Agricultural trailer means a trailer that is used exclusively for agricultural or land management purposes, and that is operated on the road only for the following purposes:

a) during delivery from a manufacturer to the manufacturer’s representative, or

b) while being delivered to or from an agricultural show for display or demonstration purposes, or

c) while being taken to or from a farm, or from one part of a farm to another part of that farm.

Axle means a transverse shaft or housing on which a vehicle’s wheels are mounted.

Brake friction material means a brake component having a friction surface that is designed to be preferentially sacrificed.

Breakaway brake means a service brake or parking brake fitted to a trailer that ensures, under all conditions of use, that, if the trailer is unintentionally disconnected from its towing vehicle, the brake will automatically and immediately apply and will remain applied for at least 15 minutes.

Corrosion damage is where the metal has been eaten away, which is evident by pitting. The outward signs of such corrosion damage is typically displayed by the lifting or bubbling of paint. In extreme cases, the area affected by the corrosion damage will fall out and leave a hole.

Direct trailer service brake means a service brake fitted to a trailer that allows the driver of a towing vehicle, by operating the service brake of the towing vehicle, to directly and progressively regulate the trailer brake effort.

Engine brake is a modification to a diesel engine used to increase the retardation force provided by the engine on deceleration.

Friction surface means any surface of a brake component that is designed to convert kinetic energy to heat.

Indirect trailer service brake means a service brake fitted to a trailer where the action of the driver of a towing vehicle applying the brakes of that vehicle results in a reaction by the trailer that is used to progressively regulate the trailer brake effort.

Laden weight means the weight of the vehicle and its load for the time being carried.

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Parking brake means a brake readily applicable and capable of remaining applied for an indefinite period without further attention.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Service brake means a brake for intermittent use that is normally used to slow down and stop a vehicle.

Note 2

Hose end fittings that can be undone using hand tools are unacceptable.

Note 3

If a brake is fitted with an inspection port plug, this must be removed for inspection of the brake components.

Note 4

The recommended method of checking operation of the brakes is to check the braking components’ condition, jacking the vehicle whilst the hand brake is applied and checking to see if the wheels can be turned. This method ensures that all the components are in a state that when the trailer is laden the components will perform in a way that generates adequate brake force to stop the trailer and combination within the legal requirements.

Note 5

A breakaway brake, if fitted, must be tested, but is not required to be functional on a trailer with a laden weight of 2500kg or less that is fitted with one or two compliant safety chains as required in Table 5-1-1. The vehicle inspector should advise the vehicle operator if the breakaway brake is not functional.

Note 6

Laden weight means the weight of the trailer and its load, if any, for the time being carried. A vehicle inspector may be presented with a trailer (usually unladen, such as a boat, car or horse trailer) that has a laden weight below 2000kg, but that is likely to have a laden weight exceeding 2000kg when it carries its normal load. In such a case, the vehicle inspector should make the vehicle operator aware, for example by putting a note on the checksheet, that the trailer may not comply with safety chain or brake requirements when the trailer carries its normal load.

Table 5-1-1. Trailer brake requirements

Type of brake required | Laden weight (Note 5) of the trailer | ||

|---|---|---|---|

2000kg or less | 2001–2500kg | 2501-3500kg | |

Service brake | Not required but, if fitted, must act on each wheel of at least one axle | Required; either direct or indirect service brake must act on each wheel of at least one axle | Required; direct service brake must act on each wheel of at least one axle, or an indirect service brake that complies with UN/ECE Regulation No.13 (see Technical bulletin 15: Identifying compliant hitches and brake systems) Note: A compliant brake system requires a brake on each wheel of the trailer. |

Parking brake | Not required | Not required | Required; must act on at least one complete axle |

Breakaway brake (Note 1) (Note 4) | Required unless fitted with an appropriate coupling and safety chain | Required, unless fitted with an appropriate coupling and two safety chains | Required, unless fitted with an appropriate coupling and two safety chains (Note: If a breakaway brake is fitted, safety chains are still recommended but not required) |

Summary of legislation

Applicable legislation

Mandatory equipment

1. A trailer must be fitted with a service brake, parking brake, or breakaway brake depending on the laden weight (Note 6) of the trailer, as listed in Table 5-1-1.

2. An agricultural trailer with a laden weight (Note 6) of more than 2000kg that does not comply with brake requirements must be fitted with two safety chains that cross each other when the trailer is connected (refer to section 8, Towing connections).

Permitted equipment

3. A trailer may be fitted with a type of brake that is not required to be fitted to the trailer.

Condition

4. A brake must be in good condition.

5. The brake friction surfaces must be within safe tolerance of their state when manufactured, and must not be scored, weakened or damaged to the extent that the safety performance of the brake is adversely affected.

Performance

6. The service brake must be able to be applied in a controlled and progressive manner.

7. When a vehicle’s brake is applied:

a) the vehicle or its controls must not vibrate to the extent that control of the vehicle is adversely affected, and

b) the braking effort on each wheel must provide stable and efficient braking without adverse effect on the directional control of the vehicle, and

c) if the vehicle is equipped with an anti-lock braking system (ABS), the wheels must not lock, other than when the speed of the vehicle falls below the ABS activation parameters set by the vehicle manufacturer.

8. The trailer’s and towing vehicle’s service brakes must together stop the vehicle combination within a distance of 7m from a speed of 30km/h without damage to, or permanent deformation of, either the coupling system or the structure of either vehicle, and without assistance from the compression of the towing vehicle’s engine or other retarders.

9. A trailer parking brake must stop the trailer within a distance of 18m from a speed of 30km/h, or hold the trailer at rest on a slope of 1 in 5.

10. A breakaway brake must automatically and immediately apply when the trailer unintentionally disconnects from the towing vehicle, and must remain applied for at least 15 minutes.

Page amended 1 April 2023 (see amendment details).

6 Steering and suspension

6-1 Steering and suspension systems

Reasons for rejection

Condition

1. A ballrace turntable is:

a) not securely fastened, eg bolts or fasteners are loose, or

b) worn beyond manufacturer’s tolerances, or

c) cracked or distorted, or

d) corroded or has deteriorated so that it is no longer safe.

2. A steering linkage or joint:

a) is insecure, or

b) is damaged, significantly corroded, distorted or cracked, or

c) shows signs of welding or heating after original manufacture, or

d) has play beyond manufacturer’s specifications, or

e) does not operate smoothly without roughness or stiffness, or

f) is fouling on the vehicle structure, wheel tyre or brake system component.

3. A steering arm or associated component:

a) is insecure, or

b) is damaged, significantly corroded, distorted or cracked, or

c) shows signs of welding or heating after original manufacture.

4. A kingpin or outer ball joint:

a) is insecure, or

b) is damaged, significantly corroded, distorted or cracked, or

c) shows signs of welding or heating after original manufacture, or

d) has play beyond the manufacturer’s specifications, or

e) does not operate smoothly without roughness or stiffness.

5. A lock stop is loose or damaged.

6. A steering or suspension component mounting point:

a) is insecure, or

b) has corrosion damage (Note 2), buckling or fractures within 150mm of a mounting point (Figure 6-1-1).

7. A suspension component (including air suspension):

a) is insecure, or

b) is damaged, significantly corroded, distorted or cracked, or

c) shows signs of welding or heating after original manufacture, or

d) has play beyond manufacturer’s specifications, or

e) does not operate smoothly without roughness or stiffness, or

f) has excessive leakage of air or damping fluid (Technical bulletin 9), or

g) shows excessive play, roughness or stiffness in a strut upper support bearing, or

h) is a flexible bush that is significantly cracked, damaged or perished.

8. Air bag bellows has obvious external damage - protruding, exposed or worn cords.

9. There is corrosion damage (Note 2) within 150mm of a suspension component mounting point.

Performance

10. During operation:

a) the vehicle veers significantly to one side, or

b) the vehicle requires unreasonable force to steer, or

c) the steering is unreasonably stiff or rough.

Note 1 Definitions

Steering system means those components, parts and systems that connect the driver’s controls to the vehicle’s wheels or tracks by means of which the direction of motion of a vehicle is controlled.

Note 2

Corrosion damage is where the metal has been eaten away, which is evident by pitting. The outward signs of such corrosion damage is typically displayed by the lifting or bubbling of paint. In extreme cases, the area affected by the corrosion damage will fall out and leave a hole.

Note 3