Towing connections

8-3 Drawbar

Reasons for rejection

Mandatory requirement

1. A drawbar fitted to a heavy trailer (other than an agricultural trailer to which section 8-5 applies) does not have evidence of certification as complying with NZS 5446, ie:

a) the drawbar was fitted before the last CoF inspection, and after 1 January 1997, and no LANDATA record has been entered, (Note Before 1 January 1997 certification was required but for inspection purposes the LANDATA record need not be checked), or

b) the drawbar was fitted after the last CoF inspection and:

i. a valid LT400 form has not been presented, or

ii. the HVS certifier was not of category HVET or HMTD, or

c) the drawbar is not fitted with a certification label (Table 8-3-1).

2. The certification label:

a) is not indelible, or

b) is illegible, or

c) is not complete, or

d) is not attached to the drawbar in an easily visible position, or

e) does not match the vehicle, or

f) has obvious signs of tampering, or

g) has expired.

3. For a pole trailer that carries its load as a rigid single span secured to both the towing vehicle and the pole trailer:

a) the maximum towed mass of the drawbar is not equal to or greater than the unladen mass of the pole trailer, or

b) the certification plate attached to the drawbar does not state that the maximum towed mass applies only when the trailer is unladen.

Mandatory and permitted equipment

4. A full trailer (other than a logging trailer, or a trailer designed for the through loading of livestock or goods, or a trailer with an adjustable drawbar fitted before 1 July 2002):

a) is fitted with a telescopic or sliding drawbar, or

b) has a drawbar with more than one on-road operating position.

5. A permitted retractable drawbar on a stock or goods trailer that is a full trailer has:

a) no locking pin holes, or

b) more than one set of locking pin holes, or

c) locking pin holes that are not positioned so that the drawbar is fully extended when locked.

6. A telescopic drawbar on a logging trailer that is a full trailer has more than:

a) one sliding position for long logs, or

b) two fixed positions for short logs, or

c) one fixed position for storage of the drawbar when it is out of use while the trailer is being transported.

7. A telescopic or sliding drawbar does not have endstops or a secondary locking device to prevent separation if the primary locking device fails.

8. A socket-type coupling does not have a locking device or a separate means of retaining this device in the locked position.

Condition and performance

9. A towing connection component is:

a) damaged, deformed, cracked or has significantly deteriorated, or

b) worn beyond manufacturer’s specifications, or

c) not securely attached, or

d) missing, or

e) not mounted in accordance with manufacturer’s specifications, or

f) not protected from striking the ground. < class="indent1"> 10. The towing eye:

a) is not protected from striking the ground, or

b) is worn beyond (Note 1):

i. 41.6mm for a 40mm towing eye, or

ii. 51.5mm for a 50mm towing eye, or

c) has been repaired, or

d) is the demountable type and has been welded, or

e) is the weld-in type and has been welded other than parallel to the shank (Figure 8-3-1) or as permitted by the towing eye manufacturer

f) is a bolt-in towing eye and shows evidence:

i. of looseness around the securing nut, split pin or washer, or

ii. in the form of witness or fretting marks between the mounting boss and tow eye, or

iii. that the retainer nut has been re-tightened, having been loose.

Note: it is vitally important that there be no re-tightening of this component should there be any movement detected as this can cause failure and result in the trailer separating from the towing vehicle.

11. Locking of the coupling is not readily verifiable by visual inspection.

12. A coupling locking device is in such condition that it is not effective.

13. A telescopic or sliding drawbar:

a) endstop is not substantial enough to be effective, or

b) locking device is in such condition that it is not effective.

14. A drawbar pivot (hinge) pin/bush clearance is more than 1/8th of the pin diameter (eg for a 24mm pin, the clearance is more than 3mm).

15. The drawbar or drawbar mounting has corrosion damage within 150mm of a mounting point.

16. A drawbar on a full trailer has more than one operating position.

Revoked certifications

17. A drawbar fitted to a heavy vehicle was last certified by Peter Wastney (PW) of Peter Wastney Engineering Ltd (for sample certification plates see Figure 8-3-3).

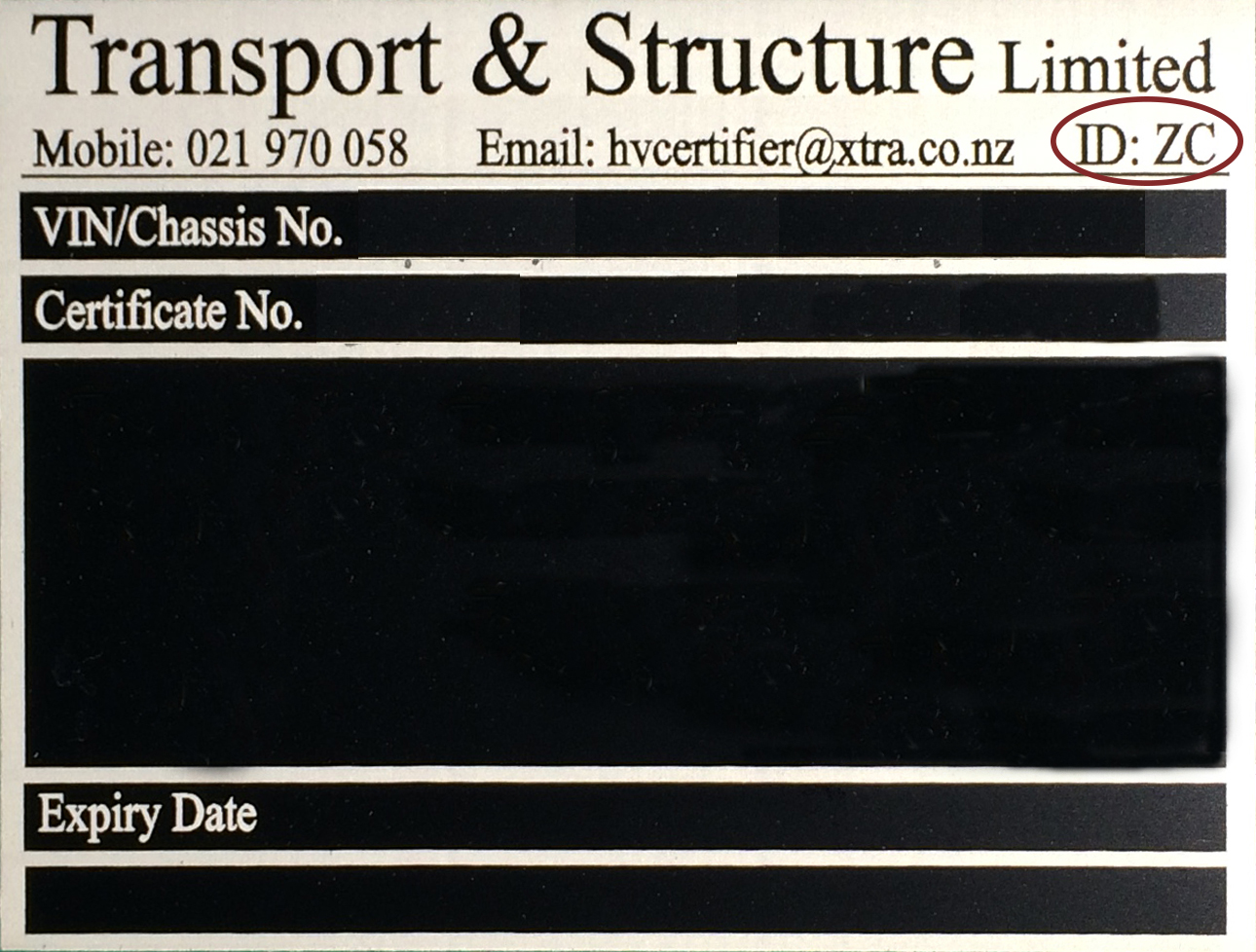

18. A drawbar fitted to a heavy vehicle was last certified by Patrick Chu (ZC) of Transport and Structure Ltd (for sample certification plates see Figure 8-3-3).

Modification and repair (Note 3)

19. A modification or repair affects the drawbar and:

a) is not for the purpose of law enforcement or the provision of emergency services, or

b) is missing proof of HVS certification, ie the vehicle has been modified or repaired, and:

i. no LANDATA record has been entered, or

ii. no valid LT400 form from an HVS certifier of category HVET or HMTD has been presented.

Note 2

Agricultural trailer means a trailer constructed to be operated in connection directly with the operation or management of a farm; does not include a logging trailer.

Coupling means that part of a vehicle that is specifically designed to enable it to be connected to another vehicle; does not include a structural member of the towing or towed vehicle (eg: fifth wheel, hook, pin, ball or socket type).

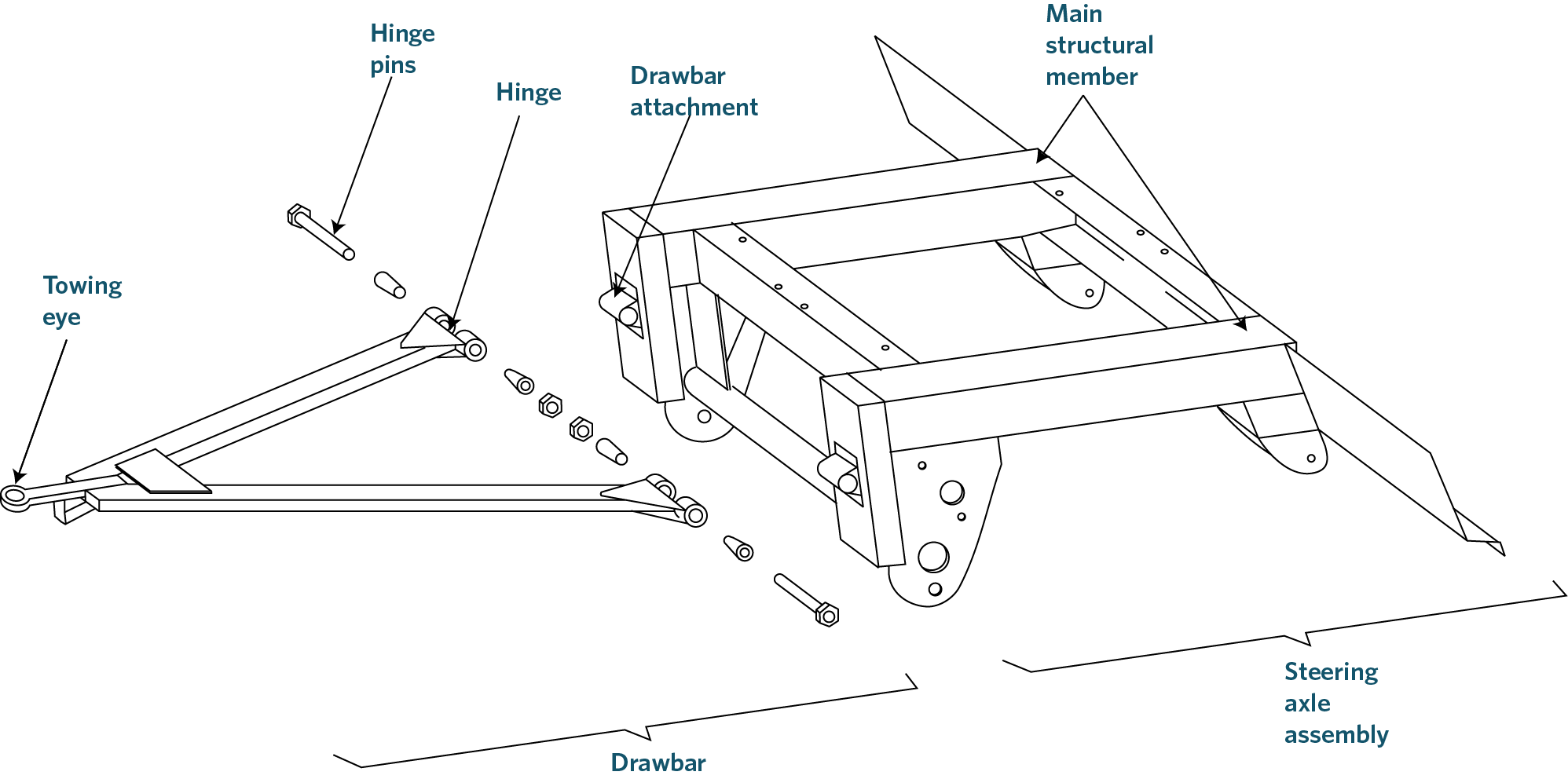

Drawbar means an assembly of components that includes the trailer coupling that connects the trailer to the coupling of the towed vehicle, hinges (where applicable), and the structural and other related components between the trailer coupling and trailer bogie or chassis.

Pole trailer means a trailer that is attached to a towing vehicle by a telescoping or sliding pole, and is designed to support a common long load spanning between the trailer and the towing vehicle.

Note 3

A towing connection that was certified to New Zealand Standard 5446: 1987 (superceded) before November 2007 may continue to comply with and be certified to that standard until the towing connection is modified.

Note 4

Some special-use vehicles, such as fertiliser trucks and trailers, are fitted with towing connections where the towing eye is fitted to the towing vehicle and the pin- or hook-type coupling to the trailer. This is permitted In these cases, please refer to section 8-4 for wear limits and other relevant requirements.

Table 8-3-1. Minimum information on drawbar certification label/plate

NZS 5446: 1987 | NZS 5446: 2007 | NZS 5446: 2024 |

Company or agency name Certifying engineer VIN/Chassis number Maximum towed mass (kg) Expiry date (if certified on or after 1 August 1991) | Person, company or agency name Certifier ID LT400 number* VIN/Chassis number Maximum towed mass Maximum static vertical load (where applicable)* Coupling D value (minimum) (where applicable)* Drawbar length Turntable lock (Yes/No) Expiry date NZS 5446 | Person, company or agency name Certifier ID LT400 number* VIN/Chassis number Maximum towed mass Maximum static vertical load (where applicable)* Coupling D value (minimum) (where applicable)* Drawbar length Turntable lock fitted (if applicable) Expiry date NZS 5446 |

*Prior to 1 December 2016 the engineer's job file number could have been used instead of the LT400 number.

**If these values are not applicable, ‘N/A’ must be used (from 1 October 2020). Prior to 1 October 2020 the plate may have a blank space or a zero, nil or N/A value.

For example:

- hinged drawbars do not have a vertical load rating

- most pintle hooks/eyes do not have a D value.

Figure 8-3-1. Permitted welding on towing eye shank

Figure 8-3-2. Drawbar components

Figure 8-3-3. Sample certification plates (Peter Wastney Ltd and Patrick Chu (ZC) of Transport and Structure Ltd)

| Peter Wastney Ltd |

|---|

|

| Patrick Chu (ZC) of Transport and Structure Ltd |

|---|

|

Summary of legislation

Applicable legislation

- Land Transport Rule: Heavy Vehicles 2004

- Land Transport Rule: Vehicle Dimensions and Mass 2002

- New Zealand Standard 5446: 1987, Code of Practice for Heavy Motor Vehicle Towing Connections: Drawbar Trailers

- New Zealand Standard 5446: 2007, Heavy Vehicle Towing Connections – Drawbeams and Drawbars

- New Zealand Standard 5446:2024, On-road heavy vehicle towing connections – Drawbeams and drawbars.

Mandatory requirement

1. A drawbar fitted to a vehicle used in a combination (other than an agricultural trailer to which section 8-5 applies) must comply with NZS 5446.

2. For a pole trailer that carries its load as a rigid single span secured to both the towing vehicle and the pole trailer:

a) the maximum towed mass of the drawbar must be equal to or greater than the unladen mass of the pole trailer, and

b) the certification plate attached to the drawbar must state that the maximum towed mass applies only when the trailer is unladen.

Mandatory and permitted equipment

3. A socket-type coupling must have an effective locking device and a separate means of retaining this device in the locked position.

4. A drawbar on a full trailer must not be extendable except as follows:

a) to facilitate the loading of livestock or goods, provided the drawbar has only one set of locking pin holes positioned so that the drawbar is fully extended when locked,

b) a logging trailer with a drawbar that has no more than:

i. one sliding position for long logs.

ii. one or two fixed positions for short logs.

iii. a fixed position for storage of the drawbar when it is out of use while the trailer is being transported.

5. A telescopic drawbar must have endstops or a secondary locking device to prevent separation if the primary locking device fails.

Condition

6. Towing connection components fitted to a vehicle must ensure that a secure connection can be maintained between the towing and towed vehicles under all conditions of loading and operation for which the vehicle was constructed.

7. A drawbar on a full trailer may have only one operating position.

8. Locking off the coupling must be readily verifiable by visual inspection.

Modification and repair

9. A modification or repair that affects the drawbar must be inspected and certified by an HVS certifier of category HVET or HMTD.

Page amended 10 March 2025 (see amendment details)