Brakes

5-1 Brakes (General)

Certifier categories: HVEK | HMKD

Reasons for rejection

1. A vehicle that is not an armoured vehicle used exclusively by the NZ Defence Force, a steam powered vehicle, a vehicle with self laying tracks, a traction engine, a mechanically propelled roller, a tractor or machine used solely in farm or roading operations, whether for traction or otherwise, and not capable of a speed exceeding 30km/h, together with any trailer used on the road only while drawn by that tractor or machine, a vehicle normally propelled by mechanical power while it is being temporarily towed without the use of its own power or an agricultural trailer, does not have a service brake, a parking brake and an emergency brake unless it is a semi trailer first registered before 1 November 1990.

2. A semi trailer first registered before 1 November 1990 is not fitted with a service brake.

3. A vehicle that does not require a service brake, a parking brake and an emergency brake does not have a means for the driver to control the movement of the vehicle, stop it and hold it stationary under all conditions of use.

3. A brake is not easily adjustable to compensate for wear or does not have a means of automatic adjustment.

4. A brake is not maintained in good condition and efficient working order.

5. A brake is out of adjustment so that the braking effect across an axle is not approximately equivalent and there is no system operating where the braking effect is modulated by a control device to prevent wheel lock up or improve stability.

6. A brake is not maintained within safe tolerance of the vehicle manufacturer’s specifications.

7. The brake friction material is not secure, not in good condition or has defects that may adversely affect the performance of the brake.

8. A vehicle's brake is applied on a hard, dry, level surface that is free of loose material, and without assistance from the compression of the vehicle's engine or other auxiliary braking device that is not part of the vehicle's service brake the vehicle or its controls vibrates so as to noticeably and adversely affect the control of the vehicle.

9. A vehicle's brake is applied on a hard, dry, level surface that is free of loose material, and without assistance from the compression of the vehicle's engine or other auxiliary braking device that is not part of the vehicle's service brake the braking effect on each braked wheel of the vehicle does not provide stable and efficient braking without adverse effect on the directional control of the vehicle.

10. A vehicle's brake is applied on a hard, dry, level surface that is free of loose material, and without assistance from the compression of the vehicle's engine or other auxiliary braking device that is not part of the vehicle's service brake and if the vehicle is equipped with an anti-lock braking system, any of the vehicle's rotationally sensed wheels lock when the speed of the vehicle is above the ABS-activation parameters set by the vehicle manufacturer.

11. Except for brake pad warning systems, a warning system that is fitted to a vehicle and is part of, or associated with the use of, a brake component or system does not function correctly.

12. The service brake of a vehicle is not able to be applied by the driver from the driver's normal driving position in a controlled and progressive manner.

13. The service brake of a vehicle, not being a heavy haulage trailer or a military trailer, has a device fitted by which the driver would be able to adjust the brake force distribution between the axles or between the vehicles that are used in a combination vehicle.

14. The service brake of a vehicle, whether or not it is being operated as a combination vehicle, has more than one control except where it is being operated in a combination and is fitted with a trailer-brake hand control.

15. A vehicle that has been converted to dual steering does not have its service brake replicated on the other side of the vehicle.

16. A service brake is not capable of stopping the vehicle at any load condition up to the gross vehicle mass or gross combination mass, as applicable, either within a distance (s) in metres calculated by the following equation: s = 0.15v+(v2/130) where the speed of the vehicle (v) in km/h before the start of braking is at least the lesser of 50 km/h or 80% of the maximum speed of the vehicle, or within a distance of 7m from a speed of 30 km/h, measured from the point at which movement of the brake control commences and finishing at the point when the vehicle comes to a complete stop.

17. A vehicle of class MD3, MD4, ME, NB, NC, TC or TD, first registered in New Zealand on or after 1 November 1990, does not have a service brake that acts on each wheel.

18. The parking brake of a vehicle, whether or not it is being operated as a combination vehicle, is not able to be applied by the driver from the normal driving position using one control only except for a class TC vehicle.

19. A class TC vehicle is not able to have its parking brake activated by the driver from the normal driving position and the vehicle is not part of a dedicated combination and does not have an air brake or a brake that is operated with the assistance of compressed air or it is not fitted with a temporary park brake that complies with the Rule or the control is not fitted in a readily accessible position or the towing vehicle is not fitted with appropriate signage.

20. The parking brake of a vehicle first registered in New Zealand on or after 1 November 1990 does not act on at least 40% of the wheels.

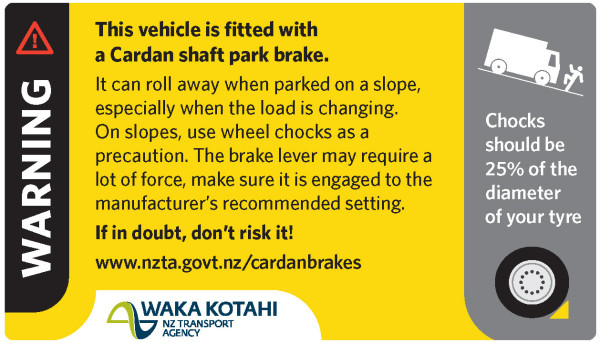

21. A class NB or NC vehicle fitted with a transmission/Cardan shaft park brake does not have a warning label, visible to the driver, advising that a transmission/Cardan shaft park brake is fitted to this vehicle (see Figure 5-1-1).

22. The parking brake of a vehicle, other than a semi-trailer, is not, at any load condition up to the gross vehicle mass or gross combination mass, as applicable, capable of stopping the vehicle within a distance of 18m from a speed of 30 km/h, or holding the vehicle stationary on a slope of 18% whether facing uphill or downhill.

23. A semi-trailer first registered in New Zealand on or after 1 November 1990, does not have a parking brake that generates a deceleration load of at least 20% of the maximum weight that can be carried on the axle or axle set.

24. A vehicle does not have an emergency brake that operates either in combination with the parking brake or the service brake of a powered vehicle, if the vehicle is fitted with a full dual-circuit service brake, and either one of those circuits activates the brake on all the front wheels and the other circuit activates the brake on all the rear wheel or each circuit activates the brake on at least 1/3 of the wheels.

25. For a powered vehicle first registered in New Zealand during the period beginning on 1 November 1990 and ending on 31 December 1994, the brake remains unmodified since the vehicle was manufactured, the vehicle has a mechanically-operated parking brake acting on the transmission and the vehicle does not have either a dual-line service brake that is fitted with a tandem/dual master cylinder or a single-line hydraulic service brake that is divided into two independent circuits through an excess flow prevention valve, and the brake fluid reservoir is fitted with a low-level warning device.

25. The emergency brake of a trailer does not operate immediately and automatically to stop and hold the trailer stationary if it becomes disconnected from the towing vehicle.

26. The emergency brake of a semi-trailer does not, as far as is practicable, act on the wheels that remain in contact with the ground if the semi-trailer becomes disconnected from the towing vehicle during operation.

27. The emergency brake of a vehicle first registered in New Zealand on or after 1 November 1990 does not act as directly as practicable on those wheels without the interposition of any differential gearing.

28. The emergency brake of a vehicle, other than a semi trailer, first registered in New Zealand on or after 1 November 1990 is not capable of stopping the vehicle at any load condition up to the gross vehicle mass or gross combination mass, as applicable, within a distance of 18 m from a speed of 30 km/h.

29. The emergency brake of a semi trailer, first registered in New Zealand on or after 1 November 1990, is not capable of generating brake forces to the sum of at least 20% of the maximum weight that can be carried on the axle or axle set.

30. An imported vehicle, other than a trailer, first registered in NZ on or after 1 July 2008 does not meet one of the approved brake standards in the Rule.

31. A vehicle used in combination, manufactured in NZ and first registered on or after 1 July 2008, is not certified to Schedule 5 of the Rule using:

a) manual calculations, or

b) the version of the approved proprietary software, with NZ compatibility requirements superimposed (Note 3), or

c) the NZ brake calculator current at the time of certification.

32. a vehicle not used in combination, manufactured in NZ and first registered on or after 1 July 2008 is not certified to Schedule 5 or Section 6 (Note 1) of the Rule.

33. A vehicle has been fitted with a retarder or an engine brake on or after 1 March 2007 that does not have a control that can be operated from the driver's normal driving position.

34. A vehicle has been fitted with a retarder or an engine brake on or after 1 March 2007 that is not designed so that its operation does not cause wheelslip that could result in loss of directional control of the vehicle.

35. A vehicle has been fitted with a retarder or an engine brake on or after 1 March 2007 and the retardation cannot be regulated by the driver using the control to prevent wheelslip that could result in loss of directional control of the vehicle.

36. A retarder or an engine brake of a powered vehicle, which activates the brake of a trailer that is being towed, may cause wheelslip on the vehicle that could result in loss of directional control.

37. A trailer is fitted with a device that allows the release of its parking brake even when the brake of the trailer is not connected to the brake of the towing vehicle but it does not ensure that the parking brake of the trailer is automatically applied when the trailer's brake is reconnected to the brake of the towing vehicle and the parking brake is reapplied.

38. A vehicle is fitted with a device that can be operated by the driver from the driver's normal driving position to keep the vehicle stationary temporarily but the device does not allow the safe operation of the service or parking brake of the vehicle.

39. A device in requirement 35 which can only be de-activated by the driver does not have a label permanently attached displaying the words: “NOT FOR PARKING”.

40. A device in requirement 35 that can be de-activated by the control system of the vehicle does not have either a label permanently attached displaying the words: “NOT FOR PARKING” or an audible warning device that operates when the driver's door is open while the device is activated and the parking brake is not fully applied.

41. A vehicle of class MD3, MD4, ME, NB or NC manufactured or modified in New Zealand on or after 1 July 2008 in a way that affects the performance of a brake, and that does not have a towing connection to tow a heavy trailer does not comply with requirement 40.

42. A heavy vehicle not fitted with a towing connection does not demonstrate compliance of the service brake with the requirements in requirements 7(b) and 11(a) by either certification for compliance with the requirements in Schedule 5 or stopping tests (Note 1).

43. An imported vehicle of class MD3, MD4, ME, NB or NC first registered in New Zealand on or after 1 July 2008 and that does not have a towing connection to tow a vehicle of class TC or class TD does not comply with one or more of the approved vehicle standards in requirement 23.

44. The brake of a heavy vehicle that has been fitted with a towing connection to tow a vehicle of class TC or class TD do not comply with requirement 42.

45. A vehicle imported into or manufactured in New Zealand prior to 1 March 2007 and certified for compliance with one of the codes or specifications in Schedules 1 to 4 does not comply with that code or specification, if that vehicle (Note 2):

a) has been modified on or after 1 March 2007, and/or

b) Is not being operated in a combination that has a gross mass exceeding 39,000kg but not exceeding 44,000kg.

46. A vehicle in requirement 42 first registered in New Zealand after 1 March 2007 and before 1 July 2008 that is being operated in a combination vehicle that has a gross mass exceeding 39,000kg but not exceeding 44,000kg, does not comply with:

a) the New Zealand Heavy Vehicle Brake Code, Second Edition (1997) in Schedule 4, or

b) the Interim Specification for Heavy Vehicle Braking in Schedule 1, or

c) the requirements with which a vehicle of the same class must comply if first registered in New Zealand or modified in New Zealand on or after 1 July 2008.

47. An imported vehicle of class NB or class NC to which 41 applies that is first registered in New Zealand on or after 1 July 2008 does not comply with:

a) at least one of the approved vehicle standards in requirement 23 (a) or (b), and

b) requirement 47, or

c) all of the following:

i. one or more of the approved vehicle standards in requirement 23(c), (d), (e), (f) and (g), and

ii. be fitted with an anti-lock braking system except for a logging vehicle, provided that the standard with which it complies does not require an ABS function, and

iii. requirement 47.

48. A vehicle of class NB or class NC in requirement 42 that is manufactured in New Zealand and is first registered on or after 1 July 2008, or a vehicle of class NB or class NC modified in New Zealand on or after that date, does not comply with requirements 61 to 64.

49. A vehicle in requirements 44, 45 or 46 that is fitted with an air brake does not, when the trailer becomes disconnected from the towing vehicle, have a means by which:

a) the air brake of the towing vehicle is protected from the loss of air pressure, or

b) the air brake of the trailer is activated.

50. A vehicle of class TC or class TD in requirement 42 first registered or modified in New Zealand on or after 1 July 2008 does not comply with the requirements in 61 to 64.

51. A vehicle of class TC or TD, certified for compliance with one of the codes or specifications in Schedules 1 to 4 before 1 March 2007 does not continue to comply with that code or specification and that vehicle:

a) has not been modified on or after 1 March 2007, or

b) is being operated in a combination vehicle that has a gross mass exceeding 39,000kg, but not exceeding 44,000kg.

52. A vehicle of class TC or TD, first registered in New Zealand or modified on or after 1 March 2007 and before 1 July 2008 that is being operated in a combination vehicle with a gross mass exceeding 39,000 kg but not exceeding 44,000 kg, does not comply with either:

a) the New Zealand Heavy Vehicle Brake Code, Second Edition (1997) in Schedule 4, or

b) the Interim Specification for Heavy Vehicle Braking in Schedule 1, or

c) requirements 61to 64.

53. A vehicle of class TC or class TD first registered in New Zealand on or after 1 July 2008, or modified on or after that date, does not comply with the requirements in requirements 61 to 64.

54. An air-braked vehicle of class TC or TD, except a vehicle that complies with the Interim Specification for Heavy Vehicle Braking in Schedule 1, or a vehicle that has an electronic control device which is capable of regulating and optimising vehicle deceleration according to an electric signal provided by the driver's brake control, does not have a threshold pressure between 55 and 80 kPa (inclusive).

55. An anti-lock braking system of a vehicle of class NB, NC, TC or TD first registered in New Zealand on or after 1 July 2008, or that was fitted to a vehicle of those classes in New Zealand on or after that date, is not capable of continuously controlling and adjusting the braking effort on the wheels during braking to prevent:

a) the wheels from locking, or

b) the loss of directional control of the vehicle that could be caused by the application of the brake.

56. A control device in requirement 54 does not meet the technical requirements in

a) one or more of the approved vehicle standards in requirement 23, if those standards specify requirements for that device, or

b) requirements 56 to 59.

57. A control device to which requirement 55(b) applies does not act on each axle or is not capable of modulating the brake force separately for:

a) each axle set, or

b) each side of all axle sets except steering axles.

58. A control device to which requirement 55(b) applies does not have sensors to monitor the rotational speed of the wheels.

59. The wheel sensors are not fitted to at least one wheel on each side of all axle sets.

60. If an axle set consists of more than one axle, wheel sensors are not fitted as follows:

a) if the axle set consists of two axles designed to carry the same or a similar load, the sensors are fitted at least to the axle on which the wheels are more likely to lock during braking, or

b) if the axle set consists of two axles and they are designed to carry significantly different loads, the sensors are fitted at least to the axle that carries the greater load, or

c) if the axle set consists of more than two axles and they are designed to carry the same or a similar load, the sensors are fitted at least to the axle on which the wheels are neither the most likely nor the least likely to lock during braking, or

d) if the axle set consists of more than two axles and one of them is designed to carry a significantly greater load than other axles in the set, the sensors are fitted at least to the axle that carries the greatest load, or

e) if the axle set consists of more than two axles and two or more of them carry a greater load than the remaining axle or axles in the set, the sensors are fitted at least to an axle:

i. that is one of the axles carrying a greater load, and

ii. the wheels of which are most likely to lock

f) if the axle set consists of more than two axles and two or more of them carry a greater load than the remaining axle or axles in the set and the likelihood that their wheels will lock is similar, the sensors are fitted to any of the axles that carries the greater load, or

g) if the axle set consists of two or more axles that carry a similar load, and the likelihood that their wheels will lock is similar, the sensors are fitted to any of the axles.

61. A control device in 53 that is fitted to a trailer of class TC or class TD does not:

a) comply with the requirements in 53 to 60, without being connected to the control device of the towing vehicle, or

b) be capable of being supplied with power for its operation by means of an electric cable from the towing vehicle.

62. The power connection between vehicles that can be operated in a combination vehicle does not comply with Parts 1 and 2 of ISO 7638: 1997, Road vehicles – Electrical connectors for braking systems.

63. A vehicle first registered on or after 1 July 2008 is fitted with brake hoses or tubes that do not meet one of the approved standard in the Rule.

64. A vehicle modified on or after 1 July 2008 is fitted with brake hoses or tubes that are not OE and do not meet one of the approved standard in the Rule.

65. A vehicle has been modified in such a way that it no longer complies with the Rule.

66. A vehicle has been modified in a way that may affect compliance with this Rule, such as by alteration of a vehicle's wheelbase, fitment of an additional axle, removal of an axle, replacement of an axle with one that is not of the same make and model, or replacement of the brake of an axle with one that is not of the same make and model and the performance of the brake has not been checked and modified if necessary to ensure continued compliance with this Rule.

67. A vehicle that is modified has not been either modified so as to continue to meet the technical and performance requirements of the approved standard with which the vehicle originally complied or to comply with all other applicable requirements in this Rule.

68. A repair to a brake, or to a vehicle that affects its braking performance, does not comply with this Rule or with Land Transport Rule: Vehicle Repair 1998.

69. A brake lining or a brake pad on an axle has been replaced but all the brake linings or brake pads on that axle were not replaced or all the replacement brake linings and brake pads on that axle were not of the same make, type and grade.

70. A component used in a repair does not have equivalent performance characteristics to that of the original component.

71. A repair or adjustment of a brake does not ensure that the brake:

a) complies with this Rule, or

b) complies with Land Transport Rule: Vehicle Repair 1998.

72. A person who modifies a vehicle so as to affect the braking performance of the vehicle has not:

a) ensured that the modification does not prevent the vehicle from complying with this Rule, or

b) notified the operator that the vehicle must be inspected and, if necessary, certified by a person or organisation appointed to carry out specialist inspection and certification of heavy vehicle brakes (refer to Technical bulletin 4).

73. A vehicle inspector or inspecting organisation has certified a motor vehicle under Land Transport Rule: Vehicle Standards Compliance 2002 and they had reason to believe that the vehicle did not comply with this Rule.

74. During the certification of a vehicle, compliance of a vehicle's brakes with the performance requirements in this Rule has not been verified by means of appropriate tests, using approved testing devices and following correct test procedures.

75. For a vehicle to which requirement 11 applies, if a certifier an excessive delay between the time the driver starts to brake and when effective braking starts, has not verified compliance with the stopping-distance requirements by measuring the stopping distance as specified in requirement 13.

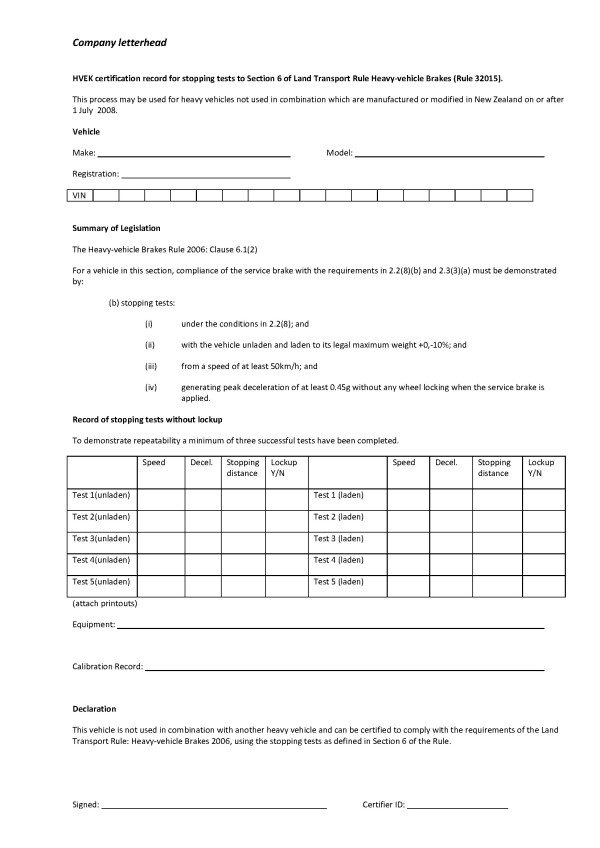

Note 1

Where a non-towing vehicle is being complied using Section 6 of the Rule instead of Schedule 5, the format below must be used with the certifier’s letterhead to record the test results used to prove compliance as part of certification.

Note 2

Where a heavy vehicle first registered in New Zealand prior to 1/3/07 has been certified to Schedule 1 to 4 and is unmodified - but the brake friction material is unknown or unavailable - the vehicle can be re-certified to its original category with an alternative friction material provided it passes the certification requirements with the alternative material.

Note 3

Any proprietary software you use to calculate and commission the vehicle's brake system must be native to that system (approved by the manufacturer) and approved by NZTA.

Figure 5-1-1. Cardan shaft park brake warning sticker

Summary of legislation

Applicable legislation

Heavy Vehicle Brakes

1. A vehicle, other than an armoured vehicle used exclusively by the NZ Defence Forces, a steam powered vehicle, a vehicle with self laying tracks, a traction engine, a mechanically propelled roller, a tractor or machine used solely in farm or roading operations, whether for traction or otherwise, and not capable of a speed exceeding 30km/h, together with any trailer used on the road only while drawn by that tractor or machine, a vehicle normally propelled by mechanical power while it is being temporarily towed without the use of its own power, an agricultural trailer, must have a service brake, a parking brake and an emergency brake, except for a semitrailer first registered before 1 November 1990 that must have a service brake only.

2. Vehicles exempt the requirements in 1 must have a means by which the driver of the vehicle can control its movement and can stop and hold the vehicle stationary under all conditions of use.

3. A brake must:

a) be easily adjustable to compensate for wear or have a means of automatic adjustment, and

b) be maintained in good condition and efficient working order

4. A brake that simultaneously applies braking pressure on two wheels with a common axis must be adjusted or fitted so that the braking effect is approximately the same on both wheels when the brake is applied by the driver, except if the braking effect is modulated by a control device to prevent the wheels locking or to improve stability.

5. A brake must be maintained within safe tolerance of its state when manufactured, having regard to the vehicle manufacturer's or brake manufacturer's specifications.

6. The friction materials of a brake must be:

a) secure, and

b) in good condition, and

c) free of defects that could noticeably and adversely affect the performance of the brake.

7. When a vehicle's brake is applied on a hard, dry, level surface that is free of loose material, and without assistance from the compression of the vehicle's engine or other auxiliary braking device that is not part of the vehicle's service brake:

a) the vehicle or its controls must not vibrate so as to noticeably and adversely affect the control of the vehicle, and

b) the braking effect on each braked wheel of the vehicle must provide stable and efficient braking without adverse effect on the directional control of the vehicle, and

c) if the vehicle is equipped with an anti-lock braking system, the vehicle's rotationally sensed wheels must not lock, when the speed of the vehicle is above the ABS-activation parameters set by the vehicle manufacturer.

8. Except for brake pad warning systems, a warning system that is fitted to a vehicle and is part of, or associated with the use of, a brake component or system must function correctly.

Requirements for different types of brake

Service brake

9. The service brake of a vehicle:

a) must be able to be applied by the driver from the driver's normal driving position in a controlled and progressive manner, and

b) except for a heavy haulage trailer or a military trailer, must not have any device fitted by which the driver would be able to adjust the brake force distribution between the axles or between the vehicles that are used in a combination vehicle.

10. The service brake of a vehicle, whether or not it is being operated as a combination vehicle, must have one control only:

a) except where it is being operated in a combination and is fitted with a trailer-brake hand control, or

b) unless the vehicle has been converted to dual steering, in which case the service brake control assembly must be replicated on the other side of the vehicle.

11. A service brake must be capable of stopping the vehicle at any load condition up to the gross vehicle mass or gross combination mass, as applicable, either:

a) within a distance(s) in metres calculated by the following equation: s = 0.15v+(v2/130) where the speed of the vehicle (v) in km/h before the start of braking is at least the lesser of 50km/h or 80% of the maximum speed of the vehicle, or

b) within a distance of 7m from a speed of 30km/h.

12. A service brake of class MD3, MD4, ME, NB, NC, TC and TD vehicles first registered in New Zealand on or after 1 November 1990 must act on each wheel

13. The stopping distances in 11 are to be measured from the point at which movement of the brake control begins to the point at which the vehicle is brought to a complete stop.

Parking brake

14. The parking brake of a vehicle, whether or not it is being operated as a combination vehicle, must be able to be applied by the driver from the normal driving position using one control only except for a class TC vehicle may be fitted to the vehicle if:

a) the vehicle is part of a dedicated combination and does not have an air brake or a brake that is operated with the assistance of compressed air, and

b) the vehicle is fitted with a temporary park brake that complies with the Rule, and

c) the control is fitted in a readily accessible position, and

d) the towing vehicle is fitted with appropriate signage

15. The parking brake of a vehicle first registered in New Zealand on or after 1 November 1990 must act on at least 40% of the wheels.

16. The parking brake of a vehicle, other than a semi-trailer, must, at any load condition up to the gross vehicle mass or gross combination mass, as applicable, be capable of:

a) stopping the vehicle within a distance of 18 m from a speed of 30 km/h, or

b) holding the vehicle stationary on a slope of 18% whether facing uphill or downhill.

17. For a semi-trailer first registered in New Zealand on or after 1 November 1990, the total brake forces generated by the parking brake must be at least 20% of the maximum weight that can be carried on the axle or axle set.

Emergency brake

18. The emergency brake of a vehicle may be combined with either:

a) the parking brake, or

b) the service brake of a powered vehicle, if the vehicle is fitted with a full dual-circuit service brake, and either:

i. one of those circuits activates the brake on all the front wheels and the other circuit activates the brake on all the rear wheels, or

ii. each circuit activates the brake on at least 1/3 of the wheels, or

c) the service brake of a powered vehicle first registered in New Zealand during the period beginning on 1 November 1990 and ending on 31 December 1994, if the brake has not been modified since the vehicle was manufactured, the vehicle is fitted with a mechanically-operated parking brake acting on the transmission and the vehicle has either:

i. a dual-line service brake that is fitted with a tandem/dual master cylinder, or

ii. a single-line hydraulic service brake that is divided into two independent circuits through an excess flow prevention valve, and the brake fluid reservoir is fitted with a low-level warning device.

19. The emergency brake of a trailer must operate immediately and automatically to stop and hold the trailer stationary if it becomes disconnected from the towing vehicle.

20. The emergency brake of a semi-trailer must, as far as is practicable, act on the wheels that remain in contact with the ground if the semi-trailer becomes disconnected from the towing vehicle during operation.

21. The emergency brake of a vehicle first registered in New Zealand on or after 1 November 1990 must:

a) act as directly as practicable on those wheels without the interposition of any differential gearing

b) be capable of:

i. stopping the vehicle at any load condition up to the gross vehicle mass or gross combination mass, as applicable, within a distance of 18m from a speed of 30km/h, or

ii. for a semi-trailer, generating brake forces the sum of which is at least 20% of the maximum weight that can be carried on the axle or axle set.

Approved vehicle standards for brakes

22. A vehicle or its brake entering the fleet on or after 1 July 2008 must comply with the version of an approved vehicle standard that is:

a) applicable in the relevant standard-setting jurisdiction to the date of manufacture of the vehicle or its brake equipment, or as specified in the standard, or

b) a more recent version of that standard, if the safety performance of the vehicle is not adversely affected.

23. The approved vehicle standards for brakes are:

a) Council Directive of 26 July 1971 on the approximation of the laws of the Member States relating to the braking devices of certain categories of motor vehicles and of their trailers (71/320/EEC)

b) UN/ECE Regulation No. 13: Uniform provisions concerning the approval of vehicles of categories M, N and 0 with regard to braking E/ECE324E/ECE/TRANS/505/Rev.1/Add.12)

c) Federal Motor Vehicle Safety Standard No. 105: Hydraulic and electric brake systems

d) Federal Motor Vehicle Safety Standard No. 121: Air brake systems

e) Australian Design Rule 35, Commercial Vehicle Brake Systems

f) Technical Standard for Brake Systems of Trucks and Buses (Japan)

g) Technical Standard for Anti-Lock Brake System (Japan)

24. An approved vehicle standard in 23 includes all amendments to that standard.

25. A vehicle, or its brake, is deemed to comply with an applicable approved vehicle standard, if it:

a) complied with that standard when the vehicle was manufactured, and

b) is currently within safe tolerance of its state when manufactured.

Approved standards for brake hoses and tubing

26. A hose or other flexible tubing forming part of the compressed air or vacuum lines of a vehicle brake must:

a) comply with one or more of the approved vehicle standards in 2.6(2), or

b) comply with a more recent version of that standard, if the safety performance of the vehicle is not adversely affected, or

c) be of a make or kind approved by the Transport Agency for the purpose to which it is applied.

27. The approved vehicle standards for brake hoses and flexible tubing are:

a) SAE J844: Non-metallic Air Brake System Tubing

b) SAE J1394: Metric Non-metallic Air Brake System Tubing

c) SAE J1402: Automotive Air Brake Hose and Hose Assemblies

d) SAE J1403: Vacuum Brake Hose (supersedes SAE 40 R3)

e) British Standard AU 110: 1965, Specification for rubber hoses and hose assemblies for automotive air pressure brakes systems (withdrawn, revised)

f) British Standard AU 109: 1965, Specification for vacuum brake hose (heavy duty) of oil-resistant rubber (withdrawn)

g) Japan Industrial Standard D2606-80: Rubber hose for automotive air brake system

h) DIN 74324-1: 1996, Air braking systems – Thermoplastic tubing – Requirements and tests

i) DIN 73378: 1996, Polyamide tubing for motor vehicles

j) Federal Motor Vehicle Safety Standard No. 106: Brake hoses.

28. An approved standard in 27 includes all amendments to that standard.

Retarders and engine brakes

29. A vehicle may be fitted with a retarder or engine brake to control the speed of the vehicle.

30. A retarder or an engine brake fitted on or after 1 March 2007 must:

a) have a control that can be operated from the driver's normal driving position, and

b) be designed so that:

i. its operation does not cause wheelslip that could result in loss of directional control of the vehicle, or

ii. the retardation can be regulated by the driver using the control to prevent wheelslip that could result in loss of directional control of the vehicle.

31. A retarder or an engine brake of a powered vehicle, which activates the brake of a trailer that is being towed, must not cause wheelslip on the vehicle that could result in loss of directional control.

Additional brake control devices

32. A powered vehicle that is being operated as a combination vehicle may be fitted with a trailer-brake hand control.

33. A trailer-brake hand control:

a) must be capable of applying the service brake of the trailer or trailers in a progressive manner, and

b) must automatically return to its original position when released, and

c) must not prevent the safe operation of the service brake of any of the vehicles in the combination vehicle.

34. A trailer may be fitted with a device that:

a) allows the release of its parking brake even when the brake of the trailer is not connected to the brake of the towing vehicle, and

b) ensures that the parking brake of the trailer is automatically applied when the trailer's brake is reconnected to the brake of the towing vehicle and the parking brake is reapplied.

Devices to keep a vehicle stationary for a limited time

35. A vehicle may be fitted with a device that can be operated by the driver from the driver's normal driving position to keep the vehicle stationary temporarily, provided that the device does not prevent the safe operation of the service brake or the parking brake of the vehicle.

36. A device in 35may utilise the service brake by:

a) applying the service brake, either partially or fully, on some or all of the vehicle's wheels, or

b) preventing the release of the service brake, when applied by the driver, on some or all of the vehicle's wheels.

37. A device in 35which can only be de-activated by the driver must have a label permanently attached displaying the words: “NOT FOR PARKING”.

38. A device in 34 which can be de-activated by the control system of the vehicle must either have:

a) a label permanently attached displaying the words: “NOT FOR PARKING”, or

b) an audible warning device that operates when the driver's door is open while the device is activated and the parking brake is not fully applied.

Additional requirements for vehicles not used in combination with other heavy motor vehicles

39. A vehicle of class MD3, MD4, ME, NB or NC manufactured or modified in New Zealand on or after 1 July 2008 in a way that affects the safety performance of a brake, and that does not have a towing connection to tow a vehicle of class TC or class TD must comply with 40.

40. For a vehicle in this section, compliance of the service brake with the requirements in 7(b) and 11(a) must be demonstrated by either:

a) certification for compliance with the requirements in Schedule 5, or

b) stopping tests:

i. under the conditions in 7, and

ii. with the vehicle in an unladen and in a heavily laden condition, and

iii. from a speed of at least 50km/h, and

iv. generating a peak deceleration of at least 0.45g without any wheel locking when the service brake is applied

41. An imported vehicle of class MD3, MD4, ME, NB or NC first registered in New Zealand on or after 1 July 2008 and that does not have a towing connection to tow a vehicle of class TC or class TD must comply with one or more of the approved vehicle standards in 23.

Additional requirements for towing vehicles

42. The brake of a heavy vehicle that has been fitted with a towing connection to tow a vehicle of class TC or class TD must comply with this section.

43. A vehicle in 42 certified for compliance with one of the codes or specifications in Schedules 1 to 4 before 1 March 2007 must continue to comply with that code or specification, if that vehicle:

a) has not been modified on or after 1/3/07, and

b) is being operated in a combination vehicle that has a gross mass exceeding 39,000kg but not exceeding 44,000kg.

44. A vehicle in 42 first registered in New Zealand after 1 March 2007 and before 1 July 2008 that is being operated in a combination vehicle that has a gross mass exceeding 39,000kg but not exceeding 44,000kg, must comply with:

a) the New Zealand Heavy Vehicle Brake Code, Second Edition (1997) in Schedule 4, or

b) the Interim Specification for Heavy Vehicle Braking in Schedule 1, or

c) the requirements with which a vehicle of the same class must comply if first registered in New Zealand or modified in New Zealand on or after 1 July 2008.

45. An imported vehicle of class NB or class NC to which 42applies that is first registered in New Zealand on or after 1 July 2008 must comply with:

a) at least one of the approved vehicle standards in 23 (a) or (b), and

b) clause 47, or

c) all of the following:

i. one or more of the approved vehicle standards in 23(c), (d), (e), (f) and (g), and

ii. be fitted with an anti-lock braking system except for a logging vehicle, provided that the standard with which it complies does not require an ABS function, and

iii. clause 46.

46. A vehicle of class NB or class NC in 7.1(1) that is manufactured in New Zealand and is first registered on or after 1 July 2008 and fitted with a towing connection to tow a trailer of class TC or TD, or a vehicle of class NB or class NC modified in New Zealand on or after that date, must comply with 61 to 66.

47. A vehicle in 44, 45 or 46 that is fitted with an air brake must, when the trailer becomes disconnected from the towing vehicle, have a means by which:

a) the air brake of the towing vehicle is protected from the loss of air pressure, and

b) the air brake of the trailer is activated.

48. A vehicle of class TC or class TD in 41 first registered or modified in New Zealand on or after 1 July 2008 must comply with the requirements in 63 to 67.

Additional requirements for trailers

49. The brake of a vehicle of class TC or class TD must comply with this section.

50. A vehicle in 49 certified for compliance with one of the codes or specifications in Schedules 1 to 4 before 1 March 2007 must continue to comply with that code or specification, if that vehicle:

a) has not been modified on or after 1 March 2007, and

b) is being operated in a combination vehicle that has a gross mass exceeding 39,000kg, but not exceeding 44,000kg.

51. A vehicle of class TC or TD, first registered in New Zealand or modified on or after 1 March 2007 and before 1 July 2008 that is being operated in a combination vehicle with a gross mass exceeding 39,000kg but not exceeding 44,000kg, must comply with either:

a) the New Zealand Heavy Vehicle Brake Code, Second Edition (1997) in Schedule 4, or

b) the Interim Specification for Heavy Vehicle Braking in Schedule 1, or

c) the requirements in 60 to 62.

52. A vehicle of class TC or class TD in 49 first registered in New Zealand on or after 1 July 2008, or modified on or after that date, must comply with the requirements in 61 to 63.

53. An air-braked vehicle in this section, except a vehicle that complies with the Interim Specification for Heavy Vehicle Braking in Schedule 1, or a vehicle that has an electronic control device which is capable of regulating and optimising vehicle deceleration according to an electric signal provided by the driver's brake control, must have a threshold pressure between 55 and 80 kPa (inclusive).

Requirements for anti-lock brake systems (ABS)

54. An anti-lock braking system of a vehicle of class NB, NC, TC or TD first registered in New Zealand on or after 1 July 2008, or that was fitted to a vehicle of those classes in New Zealand on or after that date, must be capable of continuously controlling and adjusting the braking effort on the wheels during braking to prevent:

a) the wheels from locking, and

b) the loss of directional control of the vehicle that could be caused by the application of the brake.

55. A control device in 54 must meet the technical requirements in

a) one or more of the approved vehicle standards in 23, if those standards specify requirements for that device, or

b) 56 to 59.

56. A control device to which 55(b) applies must act on each axle and must be capable of modulating the brake force separately for:

a) each axle set, and

b) each side of all axle sets except steering axles.

57. A control device to which 55(b) applies must have sensors to monitor the rotational speed of the wheels.

58. The sensors in 57 must be fitted to at least one wheel on each side of all axle sets.

59. If an axle set consists of more than one axle, the sensor in 57 must be fitted as follows:

a) if the axle set consists of two axles and they are designed to carry the same or a similar load, the sensors must be fitted to the axle on which the wheels are more likely to lock during braking

b) if the axle set consists of two axles and they are designed to carry significantly different loads, the sensors must be fitted to the axle that carries the greater load

c) if the axle set consists of more than two axles and they are designed to carry the same or a similar load, the sensors must be fitted to the axle on which the wheels are neither the most likely nor the least likely to lock during braking

d) if the axle set consists of more than two axles and one of them is designed to carry a significantly greater load than other axles in the set, the sensors must be fitted to the axle that carries the greatest load

e) if the axle set consists of more than two axles and two or more of them carry a greater load than the remaining axle or axles in the set, the sensors must be fitted to an axle:

i. that is one of the axles carrying a greater load, and

ii. the wheels of which are most likely to lock

f) if the axle set consists of more than two axles and two or more of them carry a greater load than the remaining axle or axles in the set and the likelihood that their wheels will lock is similar, the sensors may be fitted to any of the axles that carries the greater load

g) if the axle set consists of two or more axles that carry a similar load, and the likelihood that their wheels will lock is similar, the sensors may be fitted to any of the axles.

60. A control device in 54 that is fitted to a trailer of class TC or class TD must:

a) comply with the requirements in 54 to 61, without being connected to the control device of the towing vehicle, and

b) be capable of being supplied with power for its operation by means of an electric cable from the towing vehicle.

61. The power connection between vehicles that can be operated in a combination vehicle must comply with Parts 1 and 2 of ISO 7638: 1997, Road vehicles – Electrical connectors for braking systems.

Specific performance requirements for vehicles manufactured or modified in New Zealand

62. A vehicle to which 46, 48, 52(c) or 53 applies must, in addition to complying with the other applicable requirements in this Rule, comply with 63 and 64.

63. The brake force applied to a wheel of a vehicle in 62 during braking on a hard, dry, clean and level surface must:

a) for a vehicle without ABS other than one in 63(c), be approximately proportional to the load on the wheel, taking into account the dynamic load transfer that occurs during braking between the axles of a vehicle and that also may occur between the vehicles of a combination vehicle, at all conditions of loading up to the vehicle's gross vehicle mass

b) for a vehicle with ABS, be approximately proportional to the load on the wheel without relying on the operation of ABS, taking into account the dynamic load transfer that occurs during braking between the axles of a vehicle and that also may occur between the vehicles of a combination vehicle, when the vehicle is loaded to its gross vehicle mass

c) for a class TC vehicle, a logging vehicle, a heavy haulage trailer or a military trailer, be the brake force specified in 63(a) only when the vehicle is loaded to its gross vehicle mass, even if ABS is not fitted.

64. A vehicle complies with the requirements in 62 and 63, if it has been certified for compliance with the requirements in Schedule 5 and is within safe tolerance of its state when certified.

General requirements for modification

65. A modification to a vehicle's brake must not prevent the brake from complying with the Rule.

66. The modification of a brake, such as adding or removing a brake component or system, or altering the setting of a brake component or system, must not adversely affect the performance of the brake.

67. When a vehicle is modified in a way that may affect compliance with this Rule, such as altering a vehicle's wheelbase, the performance of the brake must be checked and modified if necessary to ensure continued compliance with this Rule.

68. A vehicle that is modified by fitting an additional axle, removing an axle, replacing an axle with one that is not of the same make and model, or replacing the brake of an axle with one that is not of the same make and model, must either:

a) be modified so as to continue to meet the technical and performance requirements of the approved standard in 23 with which the vehicle originally complied, or

b) comply with all other applicable requirements in this Rule.

Repair

69. A repair to a brake, or to a vehicle that affects its braking performance, must comply with this Rule and with Land Transport Rule: Vehicle Repair 1998

70. When a brake lining or a brake pad on an axle is replaced:

a) all the brake linings or brake pads on that axle must be replaced, and

b) all replacement brake linings and brake pads on that axle must be of the same make, type and grade.

Replacement components for vehicle repair

71. These clauses apply to any component that affects the braking performance of a vehicle and that is:

a) manufactured, stocked or offered for sale in New Zealand, and

b) supplied for fitting to a vehicle to be operated on a New Zealand road.

72. A component used in a repair must have equivalent performance characteristics to that of the original component and must not prevent a vehicle from complying with the Rule.

73. A brake lining assembly used as a replacement component, whether or not the brake to which it is fitted is required to comply with an approved vehicle standard, complies with this Rule if it complies with UN/ECE Regulation No. 90, Uniform Provisions concerning the approval of replacement brake lining assemblies and drum brake linings for power-driven vehicles and their trailers(E/ECE/324E/ECE/TRANS /505/Rev.1/Add.89).

Responsibilities

74. A person who repairs or adjusts a brake must ensure that the repair or adjustment:

a) does not prevent the vehicle from complying with this Rule, and

b) complies with Land Transport Rule: Vehicle Repair 1998.

75. A person who modifies a vehicle so as to affect the braking performance of the vehicle must:

a) ensure that the modification does not prevent the vehicle from complying with this Rule, and

b) notify the operator that the vehicle must be inspected and, if necessary, certified by a person or organisation appointed to carry out specialist inspection and certification of heavy vehicle brakes.

76. A vehicle inspector or inspecting organisation must not certify a motor vehicle under Land Transport Rule: Vehicle Standards Compliance 2002 if they have reason to believe that the vehicle does not comply with this Rule.

77. During the certification of a vehicle, compliance of a vehicle's brakes with the performance requirements in this Rule must be verified by means of appropriate tests, using approved testing devices and following correct test procedures.

78. For a vehicle to which 11 applies, if a vehicle inspector or inspecting organisation has reason to believe that there is an excessive delay between the time the driver starts to actuate the brake control and when effective braking starts, compliance with the stopping-distance requirements must be verified by measuring the stopping distance as specified in 13.

79. A person may manufacture, stock, or offer for sale a brake or its components, intended for fitting to a vehicle to be used on a New Zealand road, only if that brake or component:

a) complies with this Rule, and

b) does not prevent a repair to a vehicle, its structure, systems, components and equipment from complying with this Rule.

80. The Transport Agency may revoke, by giving written notice, a record of determination issued after specialist inspection and certification that a vehicle complies with this Rule, if the Transport Agency is satisfied on reasonable grounds that the applicable requirements have not been complied with.

Page amended 1 April 2023 (see amendment details)

Page updated 18 December 2023 (see update details)