Steering and suspension

9-1 Steering and suspension systems

Reasons for rejection

Mandatory equipment

1. A vehicle capable of exceeding a speed of 50km/h and equipped with a steering system (Note 1) with no direct mechanical connection between the driver’s means of control and the wheels, or other means of changing the vehicle’s direction, does not have at least one additional means of steering.

2. A LHD vehicle is operated in a transport service, rental service or otherwise for commercial purposes or for hire or reward (Note 2).

Condition

3. The steering wheel:

a) is insecurely attached to the steering shaft, or

b) shows excessive movement indicating unacceptable wear or looseness in the steering box or rack or steering column bearings, or

c) has a rim covering which is insecure so that the directional control of the vehicle is affected.

4. The power steering system, either hydraulic or electric:

a) has been disconnected, or

b) does not operate correctly, requiring unreasonable force to steer the vehicle, is unreasonably light, or

c) has a hose, pump drive, drive belt or pump mounting that is insecure, damaged or has significantly deteriorated, or

d) has a significant fluid leak

e) has a warning lamp or self-check system that indicates a defect in the power steering system.

5. Any steering component, including but not limited to linkages, joints, steering columns, arms, shafts, steering box or rack (Note 3)

a) is insecure, or

b) is damaged, significantly corroded, distorted or cracked, or

c) shows signs of welding or heating after original manufacture, or

d) has play beyond manufacturer’s specifications, or

e) does not operate smoothly without roughness or stiffness, or

f) has an excessive fluid leak, or

g) is fouling on the vehicle structure, wheel tyre or brake system component, or

h) shows signs of plastic injection.

6. A steering rack boot is missing, insecure or split.

7. A suspension component including shock absorbers, springs, upper or lower arms, sway bars, air suspension and kingpins (Note 4):

a) is insecure or missing, or

b) is damaged, significantly corroded, distorted or cracked, or

c) shows signs of welding or heating after original manufacture, or

d) has play beyond manufacturer’s specifications, or

e) does not operate smoothly without roughness or stiffness, or

f) has excessive leakage of damping fluid or air (Technical bulletin 9), or

g) shows excessive play, roughness or stiffness in a strut upper support bearing, or

h) has a replacement urethane suspension bush that is not voided or shaped to allow for similar movement to an OE bush, or

i) has a flexible bush that is significantly cracked, damaged or perished.

8. A lock stop is loose, damaged or missing.

9. Air bag bellows has obvious external damage – protruding or worn cords (Figure 9-1-2).

Note: Assessment to be conducted:

- At standard ride height (air bellows inflated)

- Normal air pressure

- Soap and water for leakage test is acceptable.

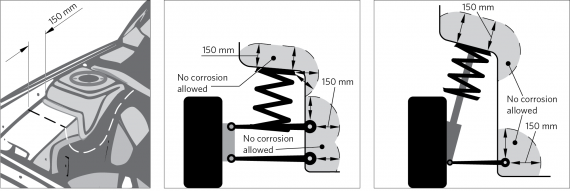

10. A steering or suspension component mounting point:

a) is insecure, or

b) has corrosion damage (Note 1), buckling or fractures within 150mm of a mounting point (Figure 9-1-1).

Performance

11. During operation:

a) the vehicle veers significantly to one side, or

b) the vehicle requires unreasonable force to steer, or

c) the steering is unreasonably stiff, rough or light, or

d) the vehicle does not handle safely under normal conditions of road use, eg the suspension is excessively hard or soft, or there is excessive body roll, or

e) the vehicle does not self-centre.

Modifications

12. A modification affects a steering or suspension component or system that directly or indirectly affects the directional control of the vehicle, and:

a) is not excluded from the requirements for LVV specialist certification (Table 9-1-1), and

b) is missing proof of LVV specialist certification, ie:

i. the vehicle is not fitted with a valid LVV certification plate, or

ii. the operator is not able to produce a valid modification declaration or authority card.

13. The LVV certified modified suspension ride height differs from the one listed on the LVV plate, when measured from the centre of the wheel to the underside of the wheel arch when the vehicle is unladen.

Note 1 Definitions

Modify means to change a vehicle from its original state by altering, substituting, adding or removing a structure, system, component or equipment, but does not include repair.

Repair means to restore a damaged or worn vehicle, its structure, systems, components or equipment to within safe tolerance of its condition when manufactured, including replacement with undamaged or new structures, systems, components or equipment.

Steering system means those components, parts and systems that connect the driver’s controls to a vehicle’s wheels or tracks by means of which the direction of motion of a vehicle is controlled.

Suspension system means a system that allows controlled and limited movement of an axle relative to the chassis or body of a vehicle; and includes a spring and damping system and any associated controls.

Note 2

The following LHD vehicles are not prohibited from operation in a transport service or otherwise for commercial purposes or for hire or reward:

a) a Category C1 - C5 specialist vehicle, or

b) a vehicle operated by a diplomat, or

c) a vehicle exempt from registration and licensing, or

d) a vehicle that was formerly owned by the Crown.

Note 3

A damaged boot on a steering joint is not a ground for rejection; however, the vehicle’s owner should be advised.

Note 4

A damaged boot on a suspension joint is not a ground for rejection; however, the vehicle’s owner should be advised.

Note 5

Corrosion damage is where the metal has been eaten away, which is evident by pitting. The outward signs of such corrosion damage is typically displayed by the lifting or bubbling of paint. In extreme cases, the area affected by the corrosion damage will fall out and leave a hole.

Note 6

Where a vehicle has LVV certified modified suspension, the ride height is provided on the LVV plate. The ride height is measured from the centre of the wheel to the underside of the wheel arch when the vehicle is unladen.

Table 9-1-1. Modifications that do not require LVV certification

Fitting of or modification to: | LVV certification is not required provided that: |

|---|---|

| Addition of anti-sway bar or uprated anti-sway bar |

Note: Removal or reduction/downrating of an antisway bar always requires certification. |

Blocks for leaf springs to adjust their ride height (up or down) |

|

Eccentric bolts/bushes for adjustability of wheel alignment (eg for camber correction in association with lowered suspensions) |

– designed as a means of correcting or improving wheel alignment; and – catalogued aftermarket items for that make and model of vehicle. |

Right-hand drive steering conversions |

|

Steering wheel spinner to assist in the operation of the steering wheel |

The operation of an airbag will not detach the spinner from the steering wheel. |

Steering wheels |

1 A vehicle that cannot comply with this clause cannot be LVV certified unless it has been issued with an LVV authority card or is at least 14 years old. 2 A vehicle fitted with a quick release steering wheel must always be referred for LVV certification and is only permitted within strict criteria. |

Springs and shock absorbers (including modification of ride height) |

|

Suspension braces (strut tower braces) |

the brace is attached to existing chassis/suspension points with the correct grade bolts and exposed thread is showing through the nut/fastener. |

Fitting of or modification to: | LVV certification is never required: |

|---|---|

Urethane suspension bushes |

|

Any modification for the purposes of law enforcement or the provision of emergency services |

Note 7

The following vehicles with a GVM of 2500 kg or less are required to comply with such a standard:

- class MA motor vehicles manufactured from 1 March 1999, and

- class MA motor vehicles that were less than 20 years old when they were first registered in New Zealand on or after 1 April 2002, and

- class MB or MC motor vehicles manufactured from 1 October 2003.

Note 8

Strut or spring spacers always require certification.

Note 9

The only other allowable methods of adjusting vehicle ride height without LVV certification are leaf spring blocks (as per below requirements) or adjustment of OE equipment (torsion bars or OE adjustable air suspension).

Note 10

When determining if there is sufficient travel remaining, consider a case where the vehicle is laden and in use

Note 11

Sufficient clearance must be maintained from the travel-limiting bump stop (not an O.E spring aid). The spring aid and/or bump stop must not be modified. A spring aid is a low-density conformable material that is fitted inside a coil spring or above a leaf spring by a vehicle manufacturer to assist the spring and acts as the bump stop only once it is fully compressed. The spring aid may be contacted at any loading condition to increase the vehicle’s spring rate, but the vehicle must retain sufficient wheel travel as per Note 10 above. A bump stop is a small high-density rubber bumper that is designed to stop vehicle suspension or driveline components from coming into contact with the vehicle structure at the extremes of its suspension travel and is not designed to carry the load of the vehicle for sustained periods of time.

Note 12

Rebound wheel travel should be measured as the difference between the distance from the top of the tyre and the wheel arch with the vehicle resting on the ground and the top of the tyre to the wheel arch with the vehicle lifted so that its tyres are clear of the ground (suspension hanging in full rebound). This difference must be greater than 40mm.

Note 13

Does not include such items as exhaust pipes and exterior body panels that do not contribute to the structural strength of the vehicle.

Figure 9-1-1. Corrosion limits around front or rear suspension anchorages

See also figures for corrosion limits to structure (section 3-1), hinge and latch anchorages (section 6-1), and seatbelt anchorages (section 7-5).

Figure 9-1-2. Sample air bag bellows images

Summary of legislation

Applicable legislation

- Land Transport Rule: Steering Systems 2001

- Traffic Regulations 1976, regulation 70

- New Zealand Gazette, 19 March 1998, issue 42, page 978, notice 1851 and amendment

- New Zealand Gazette, 25 February 1999, issue 23, page 575, notice 1478.

Mandatory equipment

1. The steering column of a motor vehicle shall be to the right of the longitudinal centreline of the body of the vehicle except as permitted below.

2. A motor vehicle capable of a speed of more than 50km/h and equipped with a steering system with no direct mechanical connection between the driver’s means of control and the wheels or other means of changing the vehicle’s direction must have at least one additional means of steering.

Permitted equipment

3. A registered vehicle may be in left-hand drive or dual-steer configuration. Such a vehicle is not required to carry a Left-Hand Drive Permit, as the LHD requirements are enforced at the time of first registration in New Zealand. Such a vehicle is not permitted to be operated in a transport service or otherwise for commercial purposes or for hire or reward.

Condition

4. The steering system and associated systems and components that directly or indirectly affect the directional control of the vehicle must be:

a) sound and in good condition, and

b) strong, durable and fit for their purpose, taking into account whether adverse effects have resulted from a loss of integrity of any protective system used by a relevant component.

Performance

5. The steering system and associated systems and components that directly or indirectly affect the directional control of the vehicle must provide the vehicle with safe, efficient, convenient and sensitive control.

Modifications

6. A modification that affects the steering system must be inspected and certified by an LVV Specialist Certifier, unless the vehicle:

a) is excluded from the requirement for LVV specialist certification (Table 9-1-1), and

b) has been inspected in accordance with the requirements in this manual, including those for equipment, condition and performance.

Page amended 1 October 2023 (see amendment details).